Fluid control device

A technology for controlling equipment and fluids, which is applied in the direction of mechanical equipment, engine control, fuel air intake, etc., can solve the problem of small working range, achieve the effect of ensuring reliability and optimizing combustion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the figures, the same reference numerals denote similar elements. The drawings are merely schematic diagrams, not intended to portray specific parameters of the invention. Moreover, the drawings are intended to depict only typical embodiments of the invention and therefore should not be considered as limiting the scope of the invention.

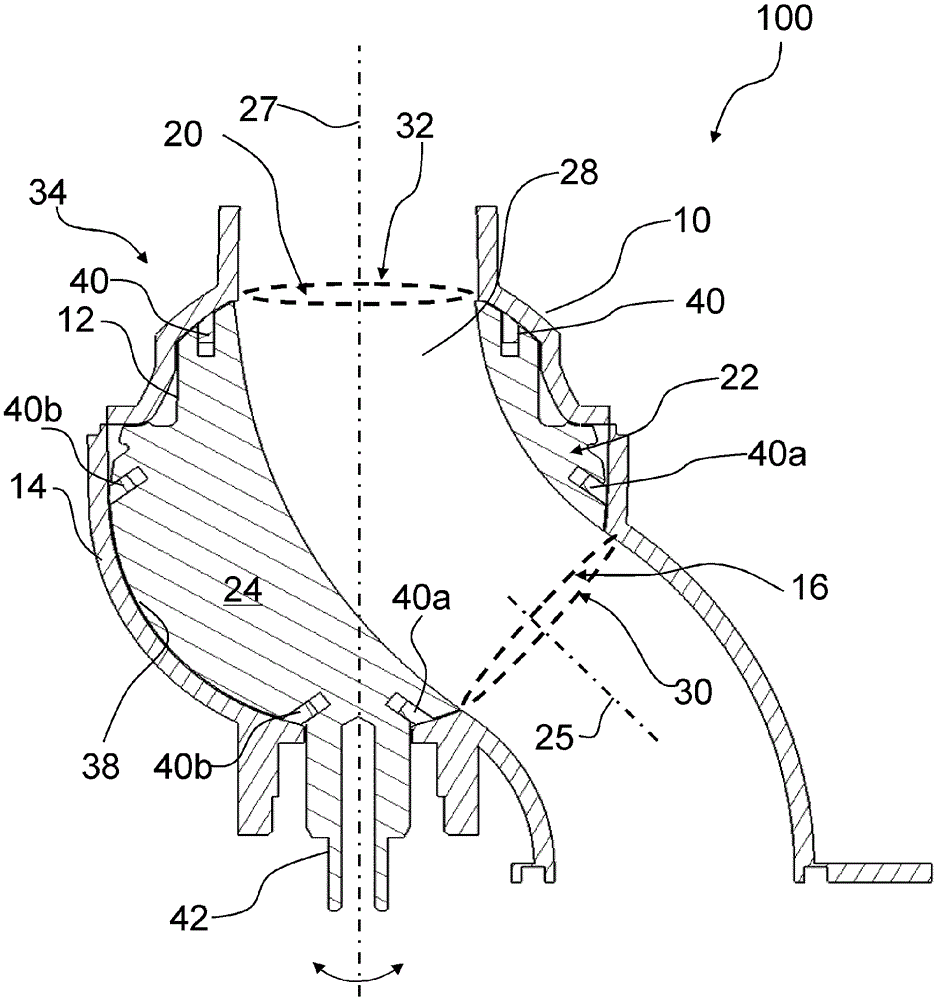

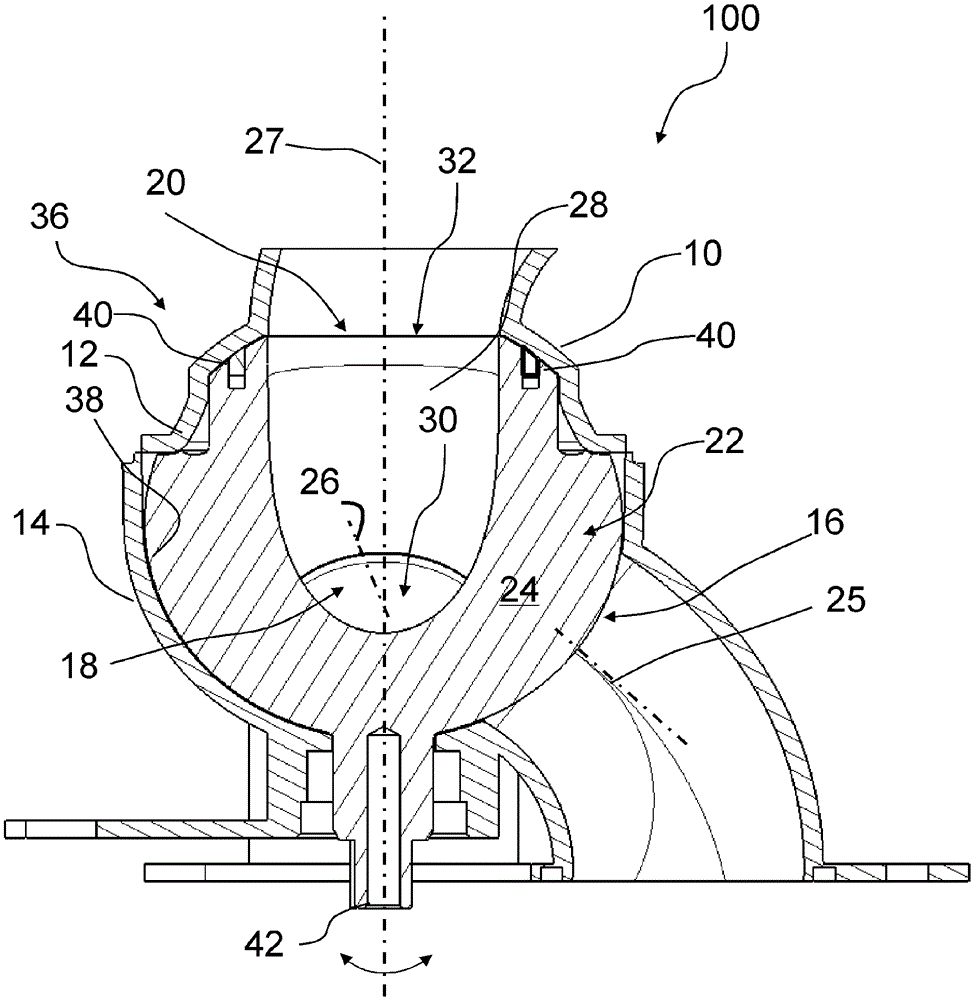

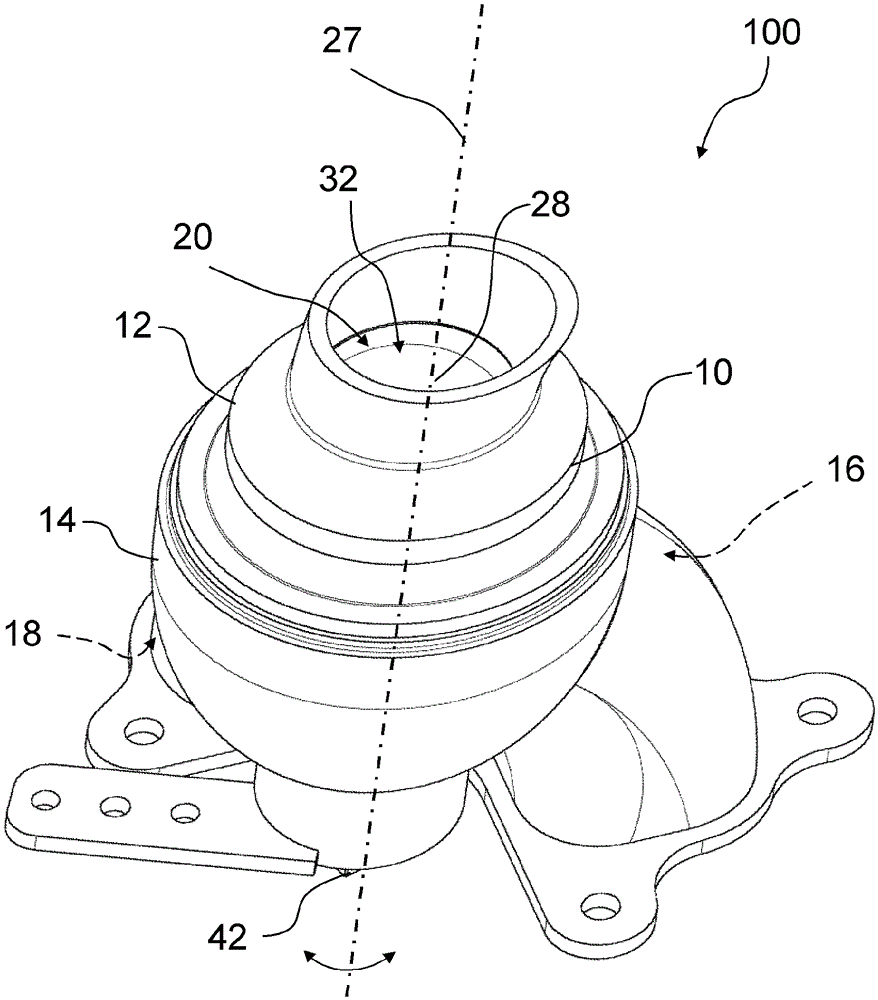

[0038] figure 1 A first example embodiment of a fluid control device 100 according to the present invention is depicted in a cross-sectional view in a first position of the valve body 24 of the control device 22, in which position the opening from the first port 20 to the second port 20 is open. The fluid path 28 of the second port 16 . figure 1 A fluid control device 100 (such as an air intake converter) in a fluid control device includes a housing 10 having a first port 20 and having a second port 16, the first port 20 having a first main axis perpendicular to the cross-section of the first port 20 27 , the second port 16 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com