Bipolar plate for liquid flow energy storage battery and preparation method thereof

A bipolar plate and composite plate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of reducing contact resistance, unable to ensure that the porous electrode and bipolar plate form a conductive path, and the improvement of voltage efficiency and energy efficiency is limited. and other problems, to achieve the effects of reducing contact resistance, easy batch preparation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 5 kg of polypropylene and 5 kg of graphite powder respectively, and add them to a high-speed stirrer at a stirring speed of 3000 rpm, for 10 minutes, and twice. Then it was sent into a twin-screw extruder for mixing and granulation to obtain a conductive masterbatch. The mixing temperature was 220° C. and the mixing time was 20 minutes. Then, the conductive masterbatch was fed into the extruder, and the temperature of the head of the extruder was 220°C, and the sheet was extruded and calendered to obtain a 1mm thick carbon-plastic composite board.

[0036] Weigh 100g of graphite powder, add it to 1L of ethanol, stir and mix evenly, use a spatula to scrape it on the surface of the carbon-plastic composite board with a thickness of 100μm, then dry to remove the ethanol; then put it into a mold and heat press it. The hot-pressing temperature is 200° C., the hot-pressing pressure is 20 MPa, and the hot-pressing time is 5 minutes. The thickness of the conductive layer...

Embodiment 2

[0043]Weigh 50 g of polypropylene and 50 g of graphite powder respectively, and add them into a high-speed stirrer at a stirring speed of 3000 rpm, for 10 minutes, and twice. Then put the uniformly mixed powder into the mold, raise the temperature to 220°C and keep it for 15 minutes, apply a pressure of 20MPa and keep it for 30 minutes, then cool and demould to obtain a 1mm thick carbon-plastic composite board.

[0044] Weigh 2g of graphite powder and 0.2g of polyvinylidene fluoride, add it to 20ml of N-methylpyrrolidone, stir and mix evenly, scrape it on the surface of the carbon-plastic composite board with a 100μm scraper, and then dry to remove ethanol; then put it into In the mold, thermoforming. The hot-pressing temperature is 200° C., the hot-pressing pressure is 20 MPa, and the hot-pressing time is 5 minutes. The thickness of the conductive layer after hot pressing is 40 μm.

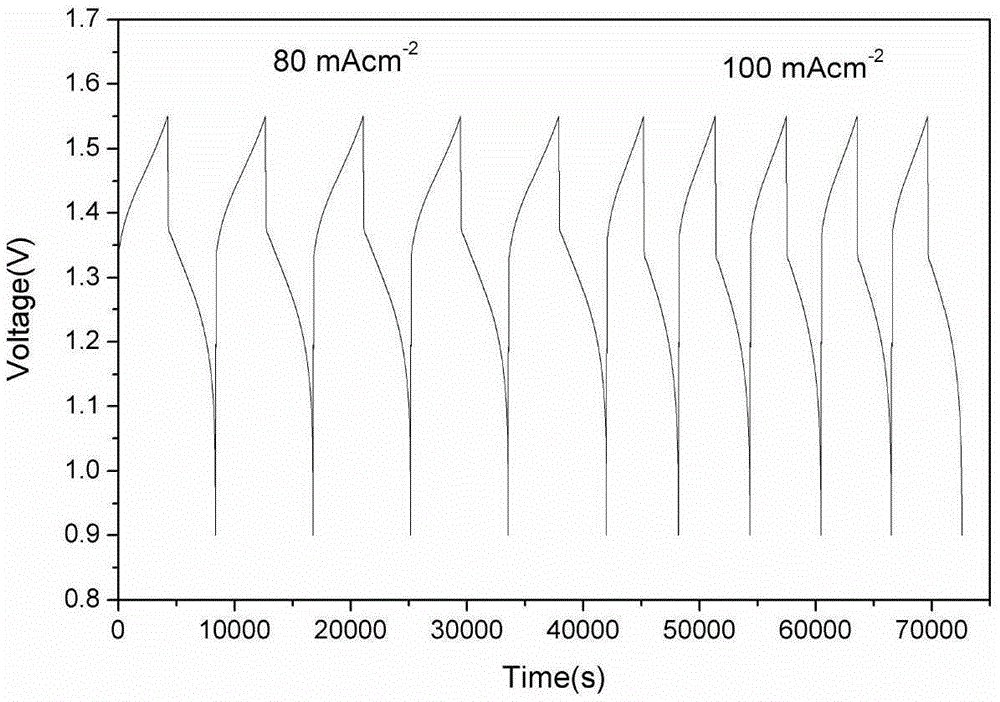

[0045] Use the bipolar plate of this embodiment to assemble into an all-vanadium flow cell,...

Embodiment 3

[0047] Weigh 5 kg of polyvinyl chloride resin and 5 kg of carbon black, respectively, and add them to a high-speed stirrer at a stirring speed of 2500 rpm for 10 minutes and twice. Then, it is sent into a twin-screw extruder for mixing and granulation to obtain a conductive masterbatch. The mixing temperature is 180° C. and the mixing time is 10 minutes. Then the conductive masterbatch is sent into the extruder, the temperature of the head of the extruder is 200°C, the sheet is extruded and calendered to form a carbon-plastic composite board.

[0048] Weigh 100g of graphite powder, add it to 1L of ethanol, stir and mix evenly, scrape it on the surface of the carbon-plastic composite board with a 100μm scraper, then dry to remove the ethanol; then put it into a mold and heat press it. The hot-pressing temperature is 200° C., the hot-pressing pressure is 20 MPa, and the hot-pressing time is 5 minutes. The thickness of the conductive layer after hot pressing is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com