A bipolar plate for a flow battery and its preparation and application

A flow battery and bipolar plate technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor toughness of composite plates, damage to battery life, and unsuitable stack assembly, etc., to achieve easy production process, high durability Corrosive, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.5kg of high-density polyethylene (melt index is 1), 0.8kg of graphite powder, 0.7kg of carbon black, 10g of polyethylene wax, and 10g of zinc stearate, and add them to the internal mixer, and the internal mixing temperature is 220°C , the rotor speed is 50r / min, and the banburying time is 20 minutes. Then, the evenly mixed banbury material is pulverized by a pulverizer and sent into a single-screw extruder. The temperature of the barrel of the extruder is 220°C, the speed of the main engine is 10rpm, and the temperature of the die is 190°C. The sheet is extruded and calendered. A carbon-plastic composite bipolar plate with a thickness of 1mm was formed.

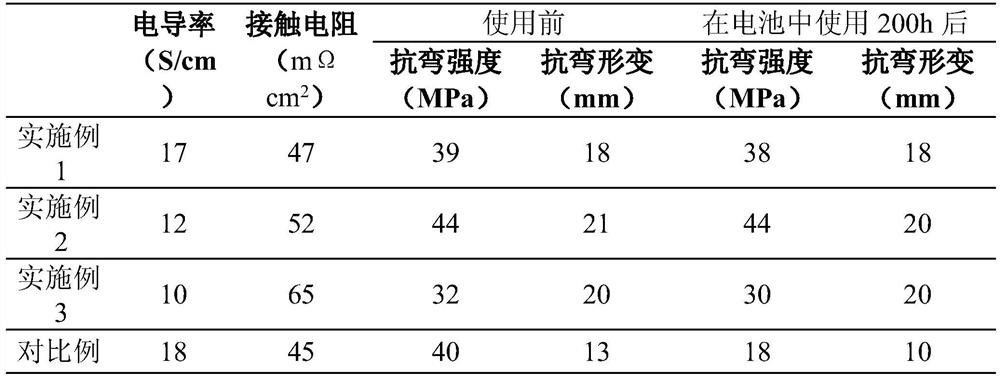

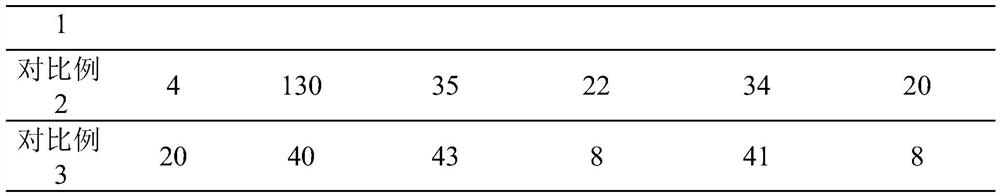

[0026] The electrical conductivity, contact resistance and mechanical properties of the bipolar plate of this embodiment and the carbon-plastic composite plate in each comparative example were tested respectively, and the results are listed in Table 1. Compared with Comparative Example 1, the bipolar plate of t...

Embodiment 2

[0029] Weigh respectively 0.6kg of high-density polyethylene (melt index is 0.5), graphite powder 1.0kg, carbon black 0.4kg, paraffin wax 15g, stearic acid 5g, join in the banbury mixer, banbury temperature is 230 ℃, rotor speed 50r / min, banburying time 20 minutes. Then, the evenly mixed banbury material is pulverized by a pulverizer and then sent to a single-screw extruder. The barrel temperature of the extruder is 220°C, the speed of the main engine is 8rpm, and the die temperature is 200°C. The sheet is extruded and calendered. A carbon-plastic composite bipolar plate with a thickness of 1mm was formed.

Embodiment 3

[0031] Weigh respectively high-density polyethylene (melt index is 5) 0.7kg, graphite powder 0.9kg, carbon nanotube 0.4kg, polyethylene wax 10g, calcium stearate 10g, join in the banbury mixer, banbury temperature is 220 ℃, the rotor speed is 50r / min, and the banburying time is 20 minutes. Then, the evenly mixed banbury material is pulverized by a pulverizer and then sent to a single-screw extruder. The temperature of the barrel of the extruder is 210°C, the speed of the main engine is 8rpm, and the temperature of the die is 190°C. Extrude the sheet and calender A carbon-plastic composite bipolar plate with a thickness of 1mm was formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com