Fuel pump layout and EFI vehicle

A layout structure and fuel pump technology, applied in the direction of gasoline barrels, bicycle accessories, liquid fuel feeders, etc., can solve the problem of large increase in residual oil in fuel tanks, high requirements for manufacturing quality control, and small effective capacity of fuel tanks, etc. problems, to improve reliability and service life, make full use of space, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

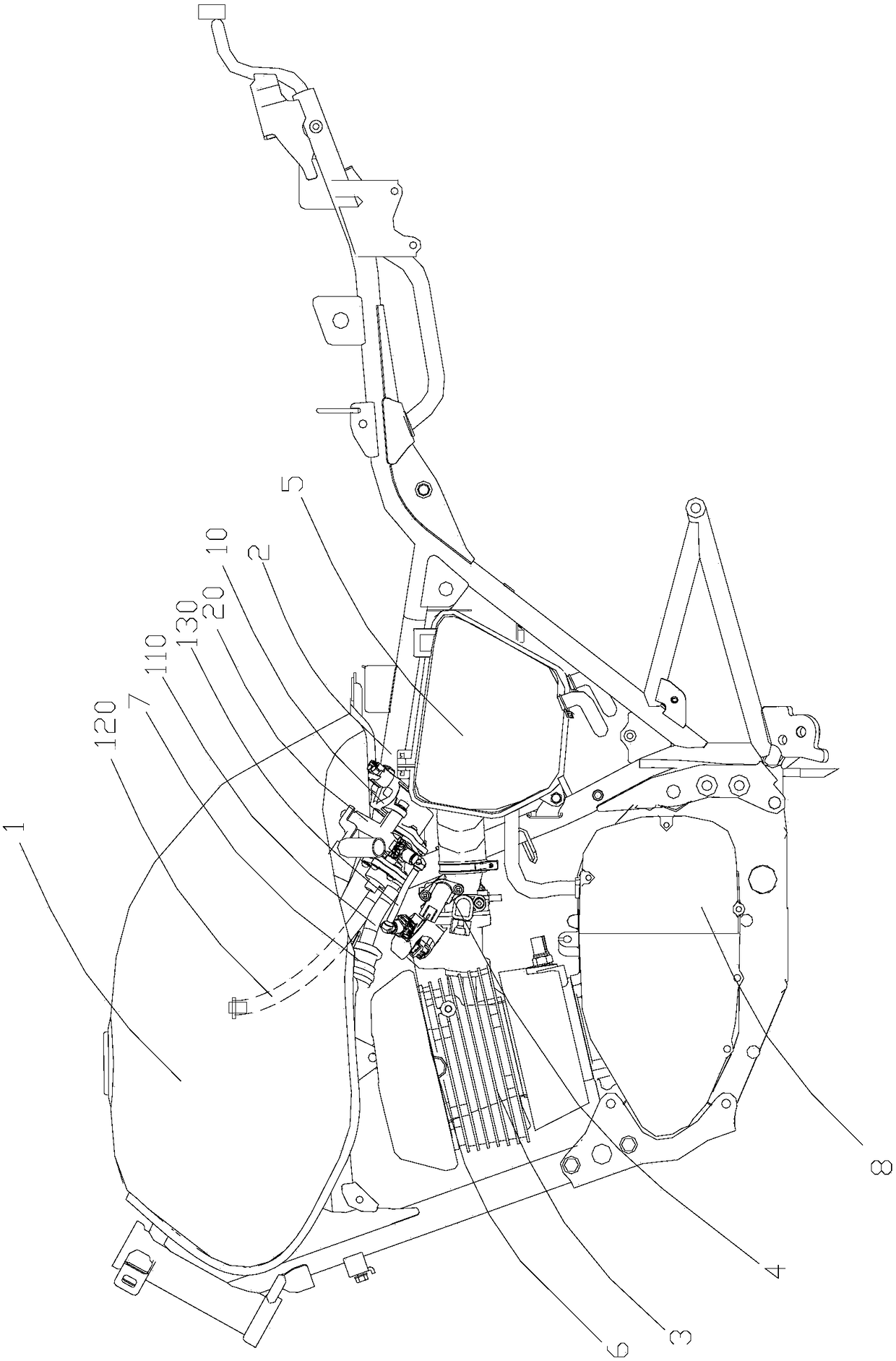

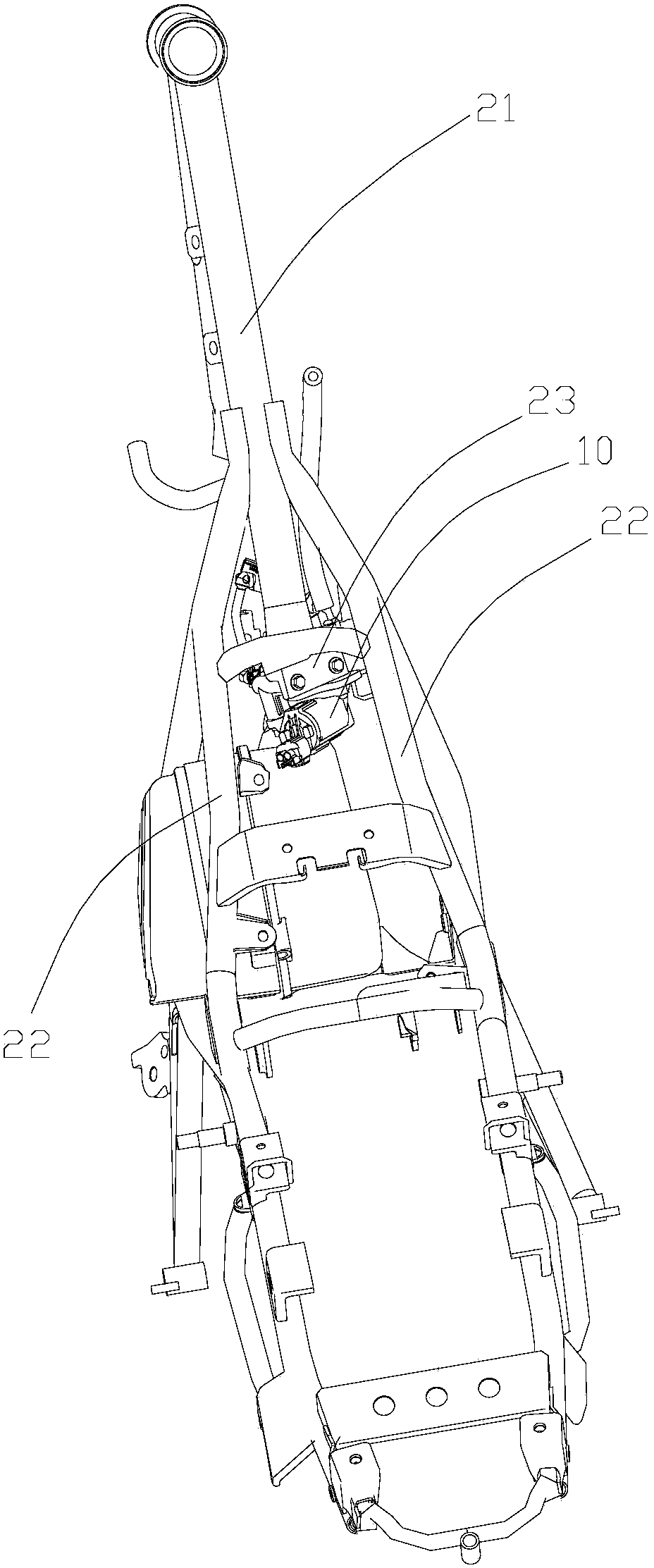

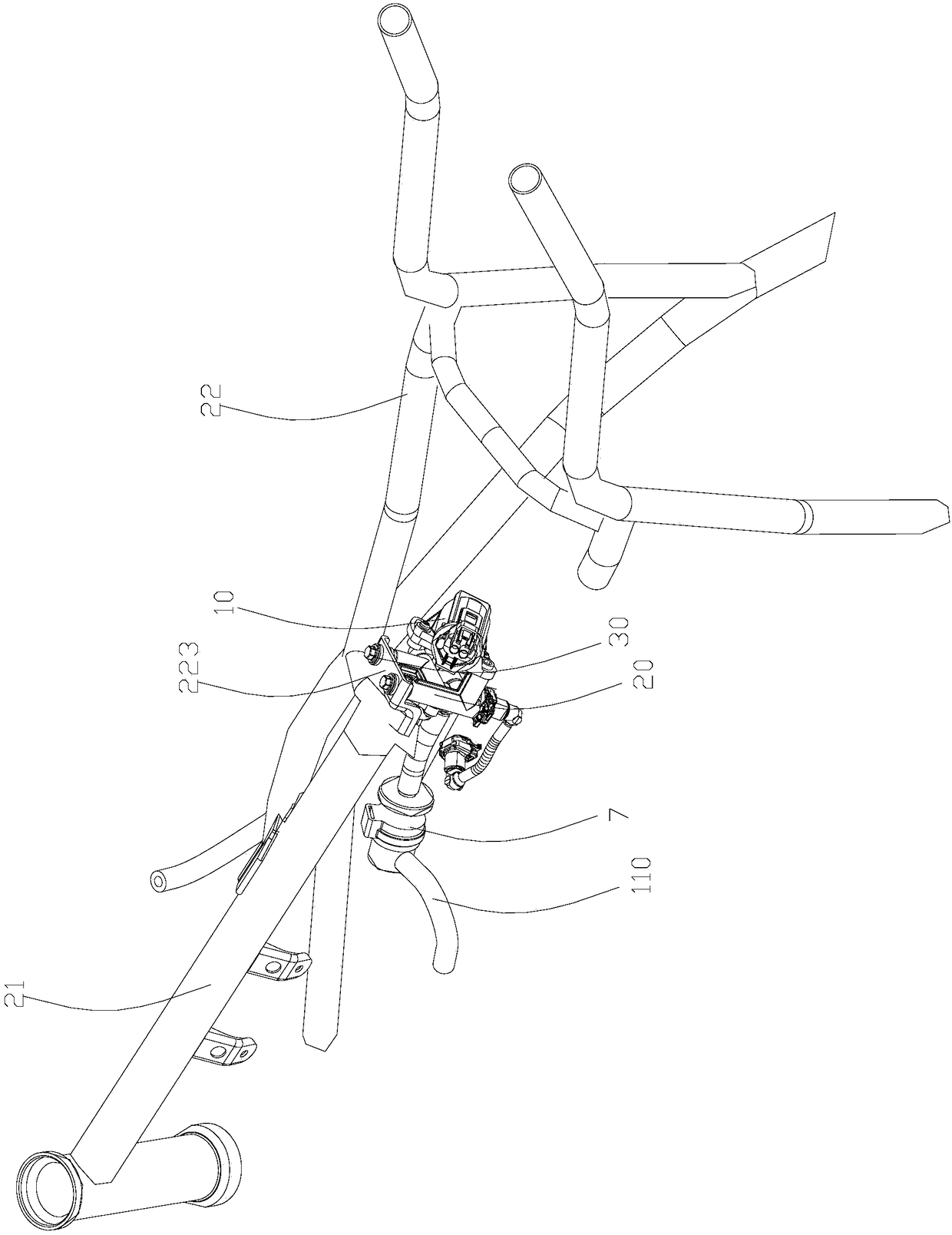

[0023] Such as Figures 1 to 4 As shown, a fuel pump arrangement structure includes a fuel pump 10 located outside the fuel tank 1, the fuel pump 10 is fixed on the vehicle frame 2, and the fuel pump 10 is located at the upper rear of the throttle body 4, the fuel pump 10 The fuel pump 10 is connected to the fuel tank 1 through the fuel inlet pipe 110 and the fuel return pipe 120 respectively, and the fuel pump 10 is connected to the fuel tank 1 through the oil supply pipe 110 and the fuel return pipe 120. The pipe 130 is connected to the fuel injector 6 of the engine 3 . In this embodiment, the fuel inlet pipe 110 is provided with a fuel filter 7 for filtering the fuel entering the fuel pump 10 from the fuel tank 1 . The front and rear are referred to the car with the fuel pump layout structure, the front is near the front of the vehicle, and the rear is the rear. The vehicle frame 2 has a frame main pipe 21 and a vehicle frame main pipe 22, forming the body of the vehicle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com