Mounting bracket of LED display screens and hoisting structure

A technology of LED display screen and mounting bracket, applied in the field of display screen, can solve the problems of low installation accuracy, troublesome operation, inability to install, etc., and achieve the effects of high flatness, improved accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

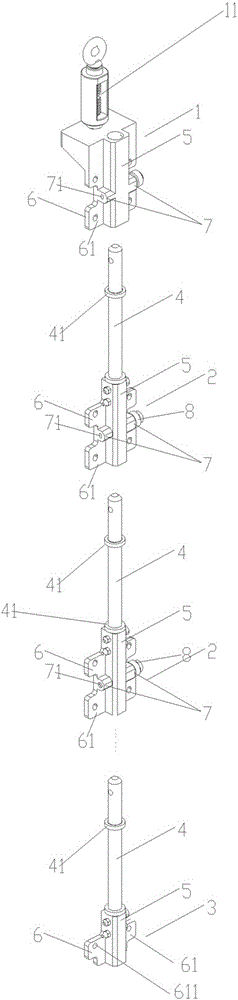

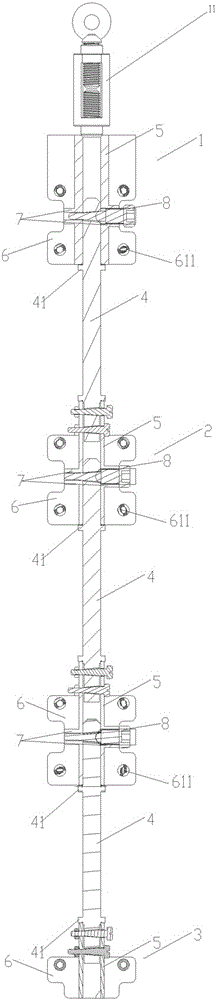

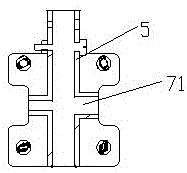

[0026] refer to Figures 1 to 2 As shown, the bracket of the present invention is composed of an upper mounting base 1 , more than one intermediate extension base 2 , a lower lifting base 3 and more than two connecting columns 4 . The connecting column 4 can be installed between the upper installation base 1 and the middle extension base 2 , or between the middle extension base 2 and the middle extension base 2 , or between the middle extension base 2 and the lower suspension base 3 . During specific implementation, the numbers of the middle extension base 2 and the connecting columns 4 are determined according to the height of the display screen. , when hoisting different display cabinets, the length of the connecting column 4 is also different, which should match the height of the display cabinet. Wherein, as shown in the figure, the upper mounting base 1 , the middle extension base 2 , and the lower lifting base 3 are all provided with a casing 5 and a box mounting plate 6...

Embodiment 2

[0029] refer to Figure 5 , The hoisting structure of the LED display screen of the present invention is formed by combining two LED display screen mounting brackets on the basis of the first embodiment. As shown in the figure, the upper mounting seat 1 of the mounting bracket is installed on the suspension beam 91 through the suspension ring assembly 11. In addition, there are several beams 92, and the two ends of the beam 92 are respectively installed on the upper mounting bases 1 of two adjacent mounting brackets. to prevent the stand from swinging from side to side. The LED display cabinets are arranged in sequence and installed on the cabinet mounting plates 6 on two adjacent mounting brackets. In the preferred solution, the frame of the LED display box can be installed on the hoisting structure first, and then the frame of the LED module is installed on the body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com