Alpha-beta scanning method for confocal microscopic system

A technology of confocal microscopy and scanning method, applied in the field of α-β scanning, can solve the problems of low measurement efficiency, inability to make full use of the effective field of view of the optical system, and difficulty in reliability, so as to improve measurement efficiency, prolong service life, and improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in conjunction with accompanying drawing, a kind of α-β scanning method that is used for confocal microscope system of the present invention, such as Figure 4 shown, including the following steps:

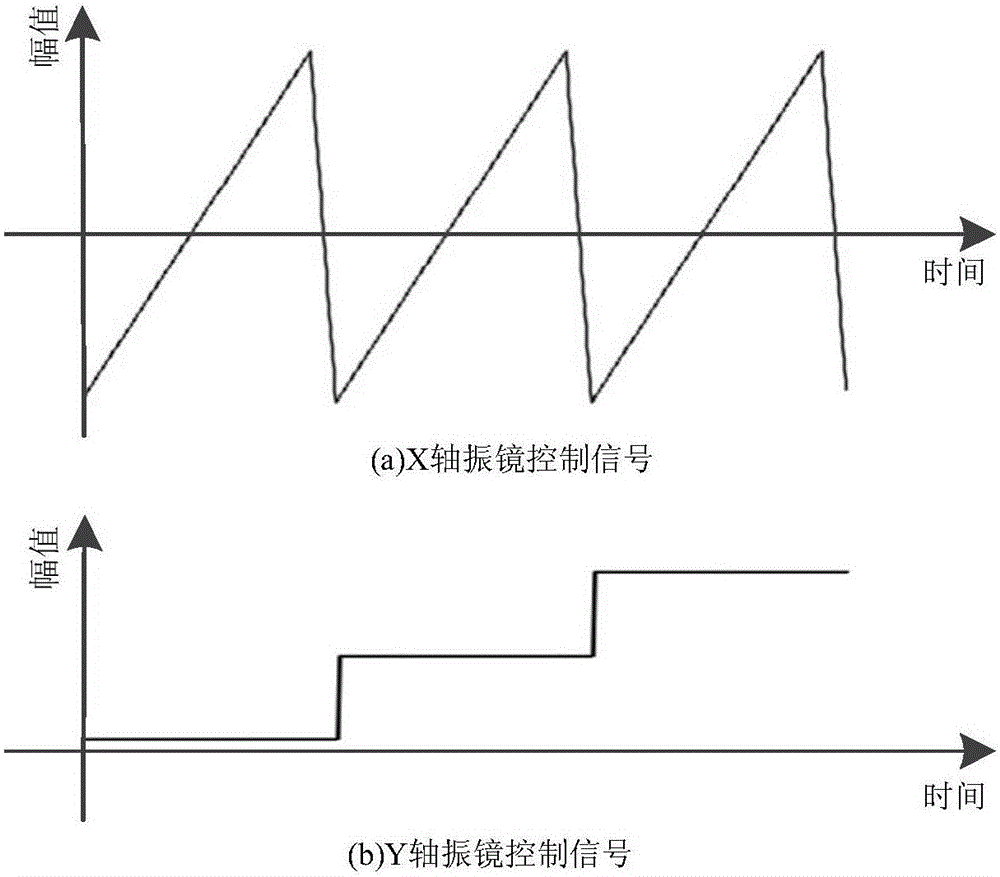

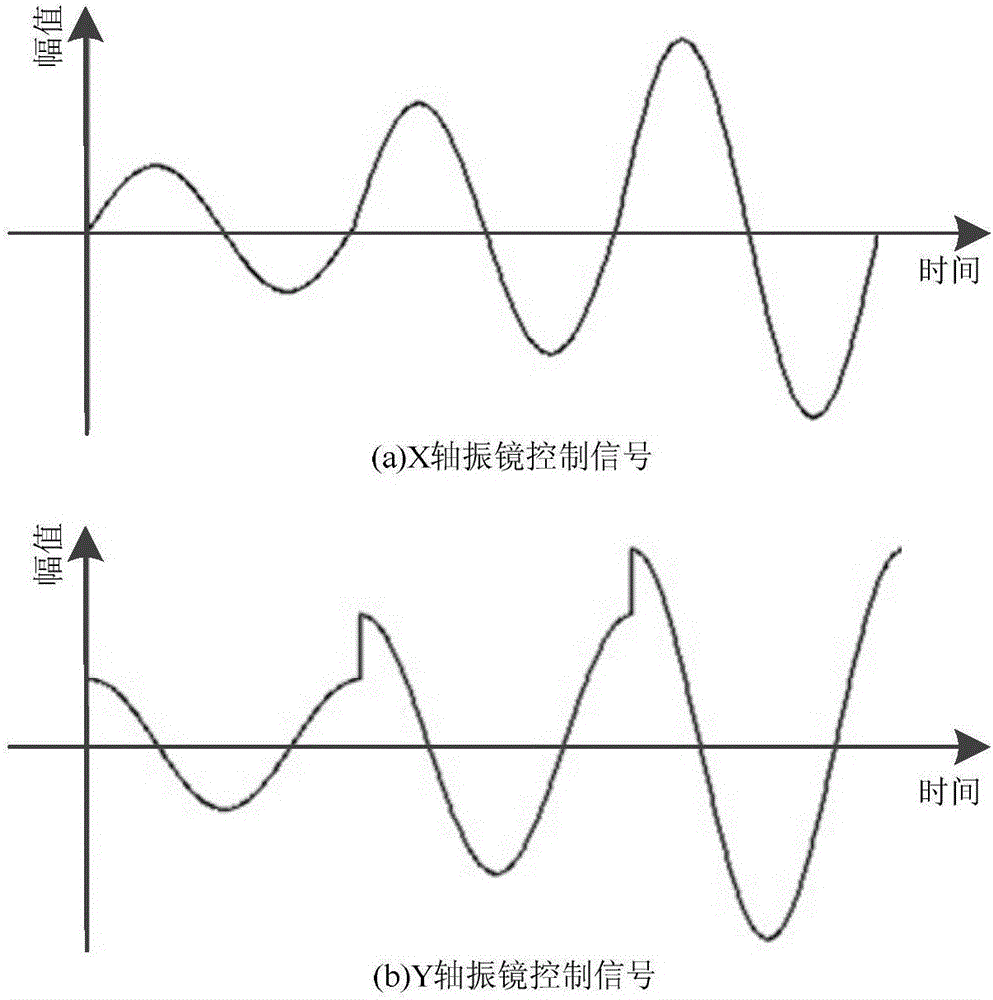

[0021] (a) Use the host computer software to construct two sinusoidal signals: α signal and β signal, such as figure 2 As shown, it is used as the control signal of the galvanometer system;

[0022] (b) communicate with the data acquisition card through the host computer software, and output the α signal and the β signal constructed in the step (a) through the two channels of the data acquisition card respectively, so as to control the scanning motion of the galvanometer system;

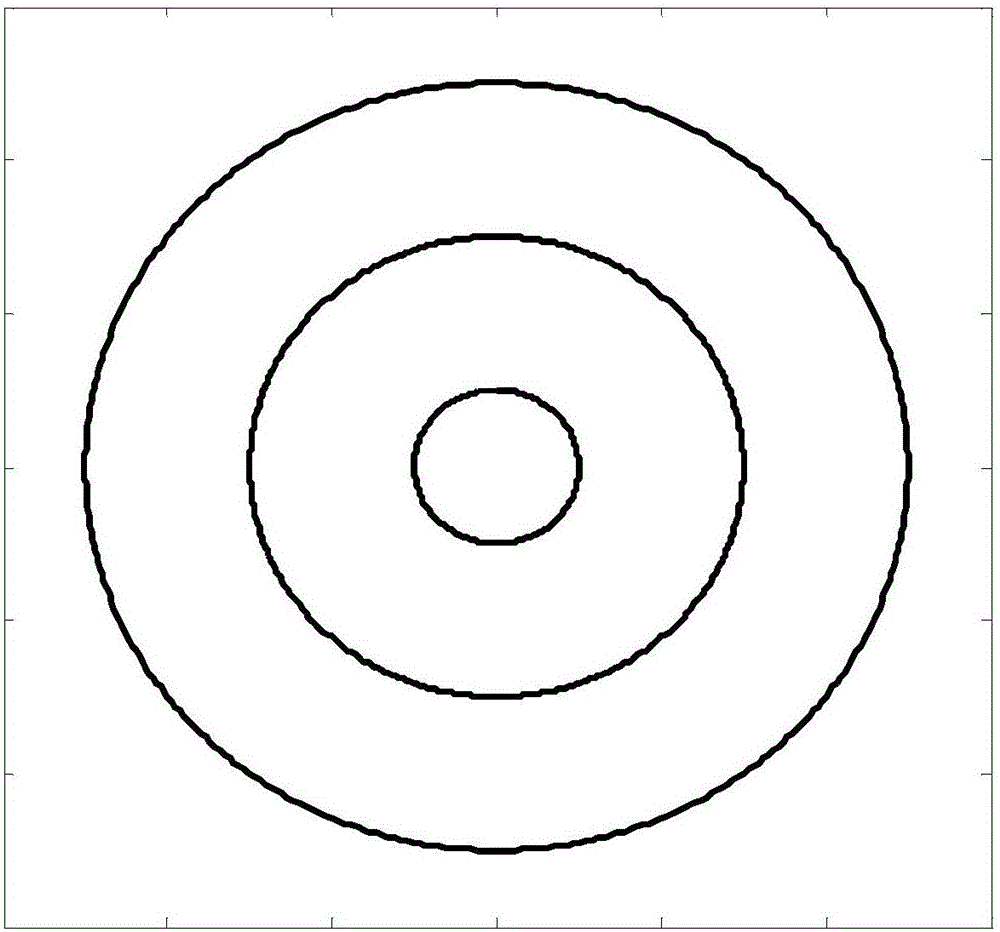

[0023] (c) The galvanometric galvanometer system performs scanning motion according to the α signal and the β signal, and realizes the two-dimensional scanning of the scanning spot with concentric circle tracks. The scanning spot trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com