Patents

Literature

56 results about "Three dimensional tomography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data acquisition system for nuclein and fluorescent dual module integral small animal molecules imaging

InactiveCN101057788ASmall doseEasy to implementSurgeryVaccination/ovulation diagnosticsQuantum yieldScintillation crystals

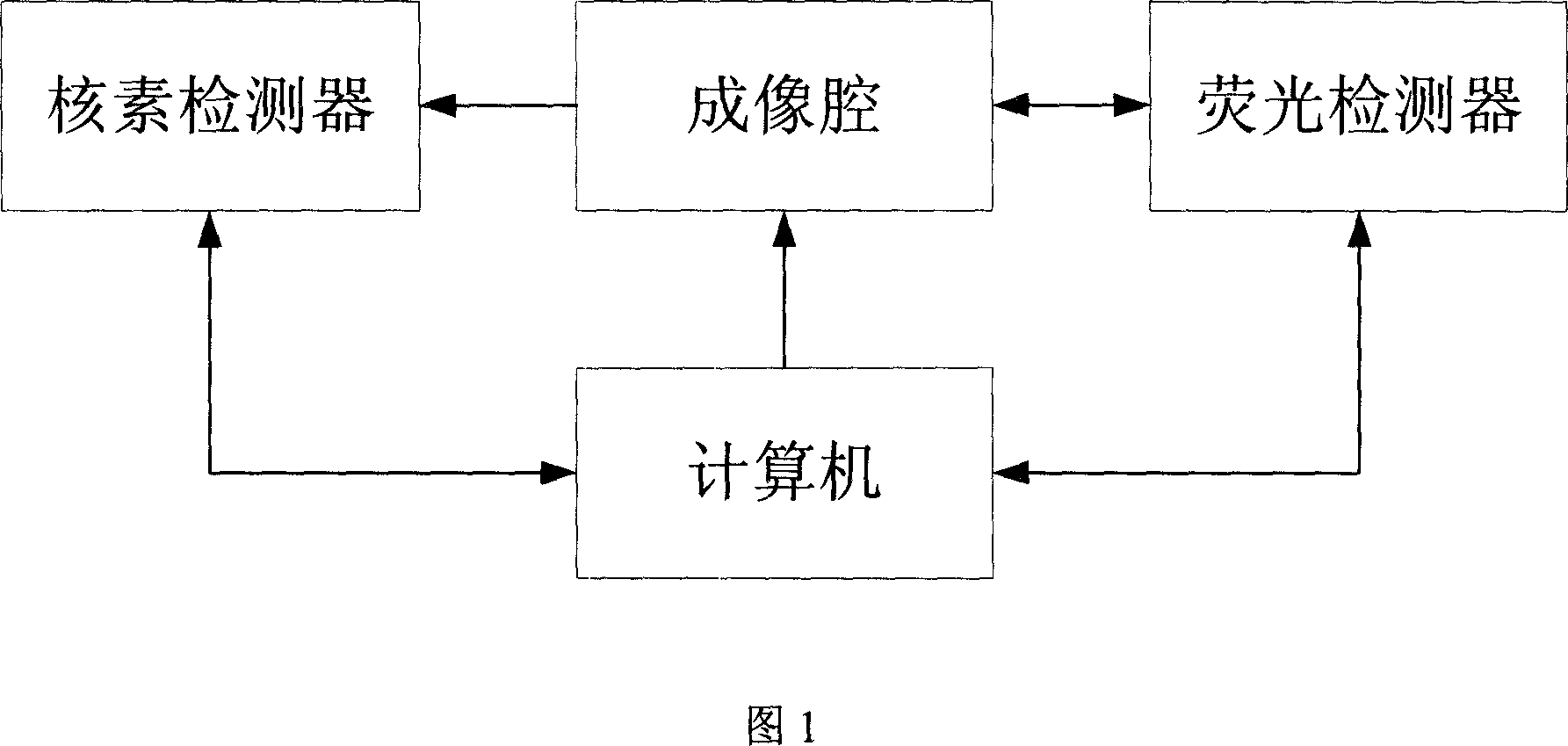

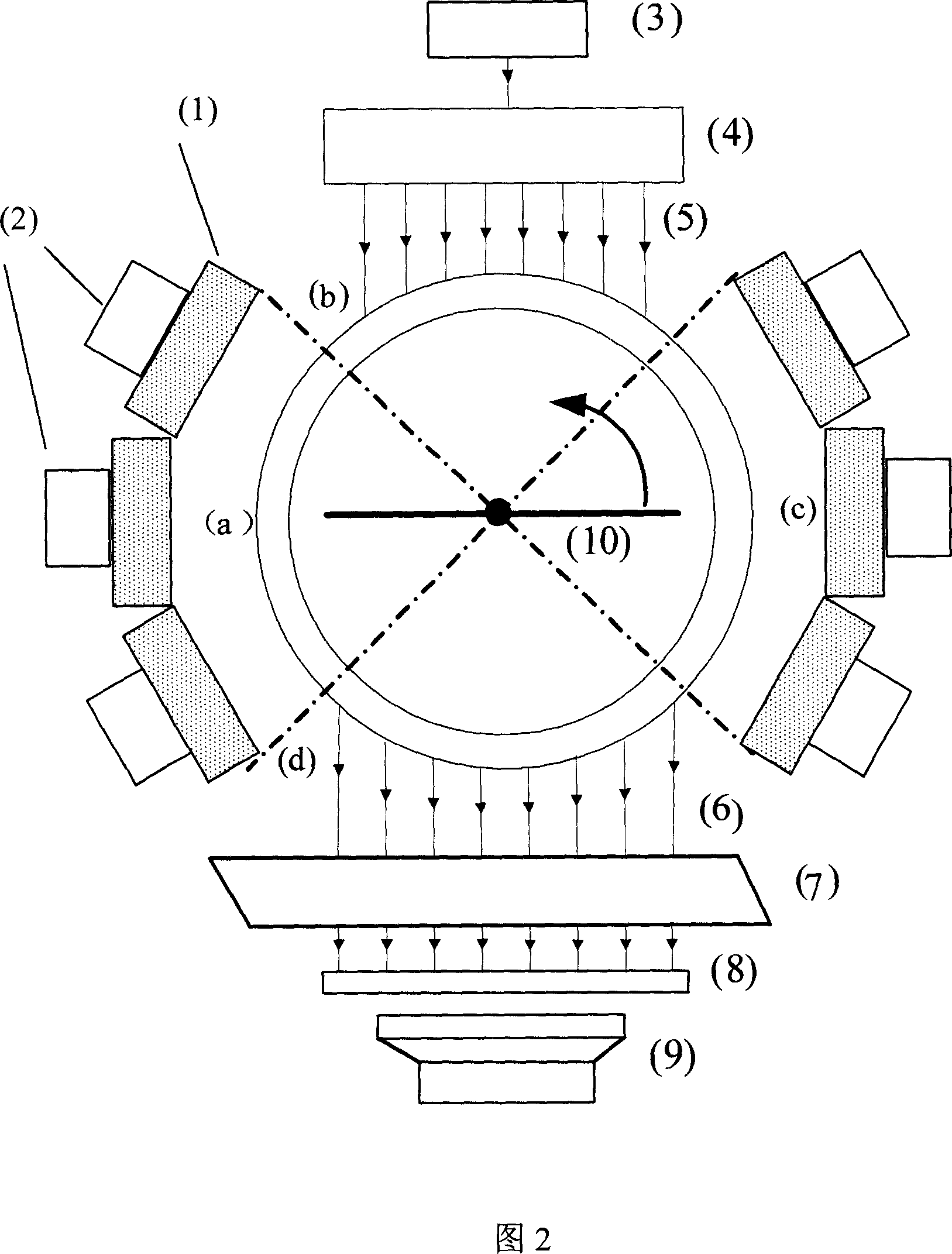

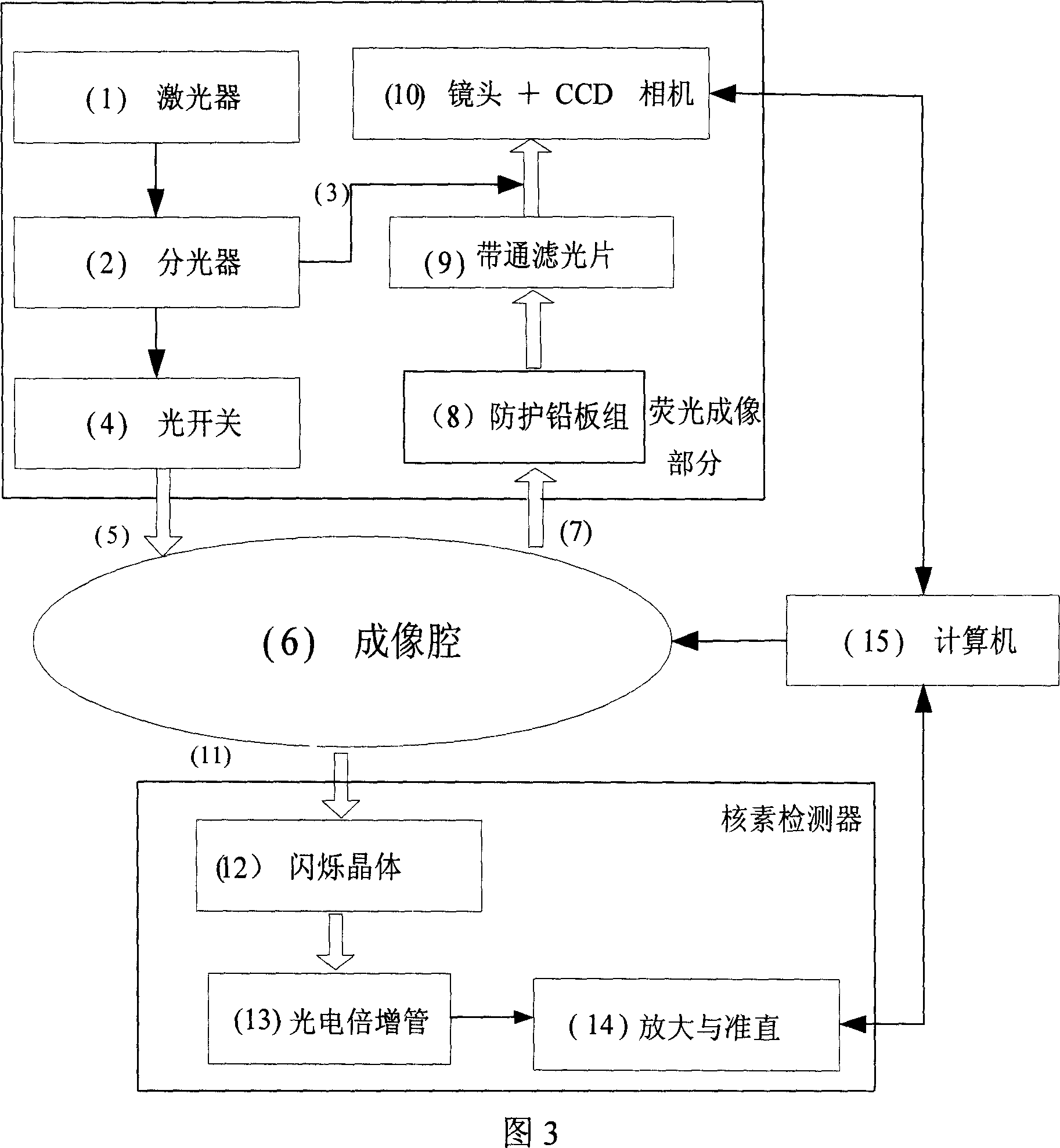

The invention belongs to the field of application of near-infrared laser, nuclear irradiation, electron and image rebuild in systematic biology and medicine. It is characterized in that high-specificity nuclear species and fluorescent probe are implanted in live animal to realize double mark of muscle deep layer or internal organ tumor cell. The emission signal of nuclear species is checked by sensitive electron-multiplier phototube in array copulation position of scintillation crystal; feeble fluorescent signal generated by visible light or infrared agitation is checked by high quantum yield CCD camera. The two checking systems are orthogonally arranged in the same surface, the live nuclear species and fluorescent signal can be checked simultaneously through rotary image cavity, and double module three dimensional tomography image of small animal can be rebuilt with software algorism. The invention is characterized by multi-image forming modules, abundant information and simple operation.

Owner:TSINGHUA UNIV

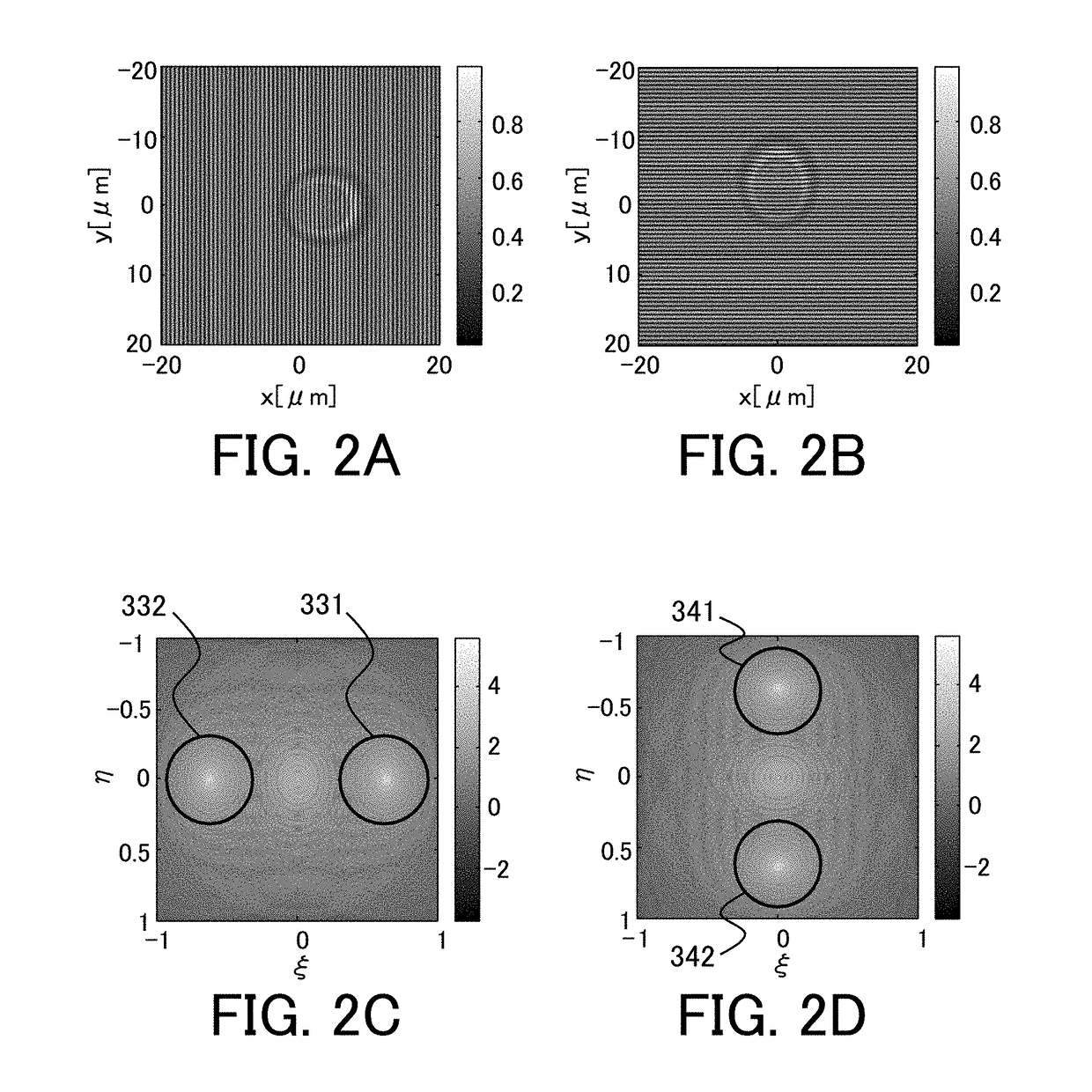

High-resolution digital holographic diffraction tomography

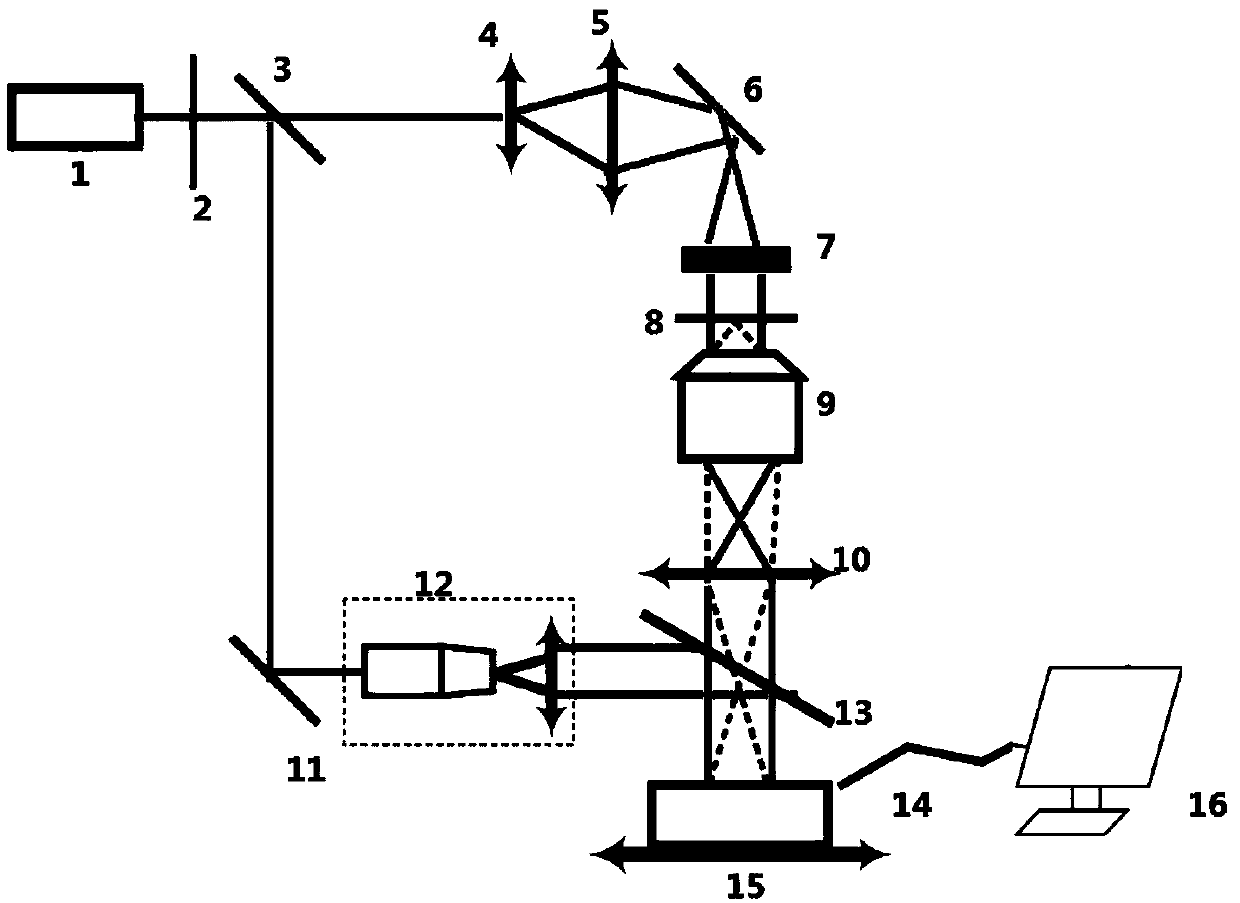

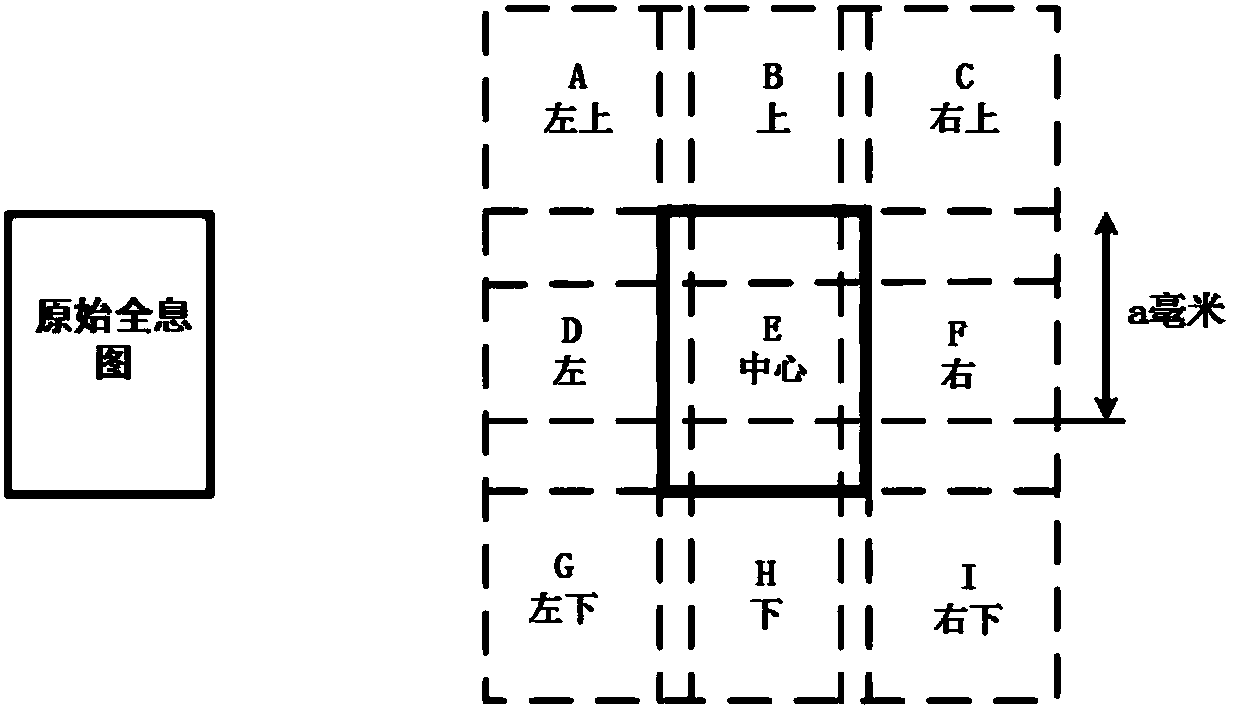

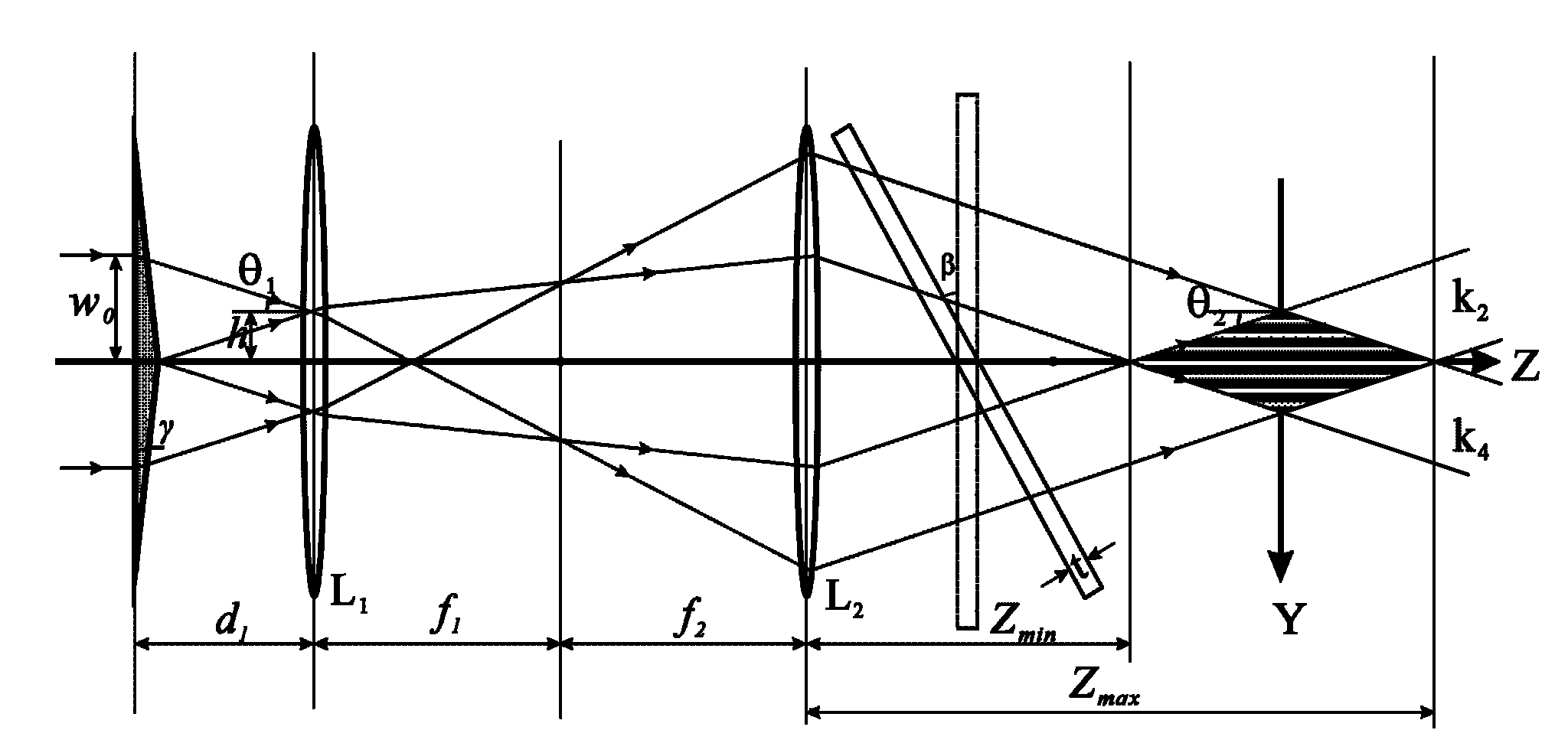

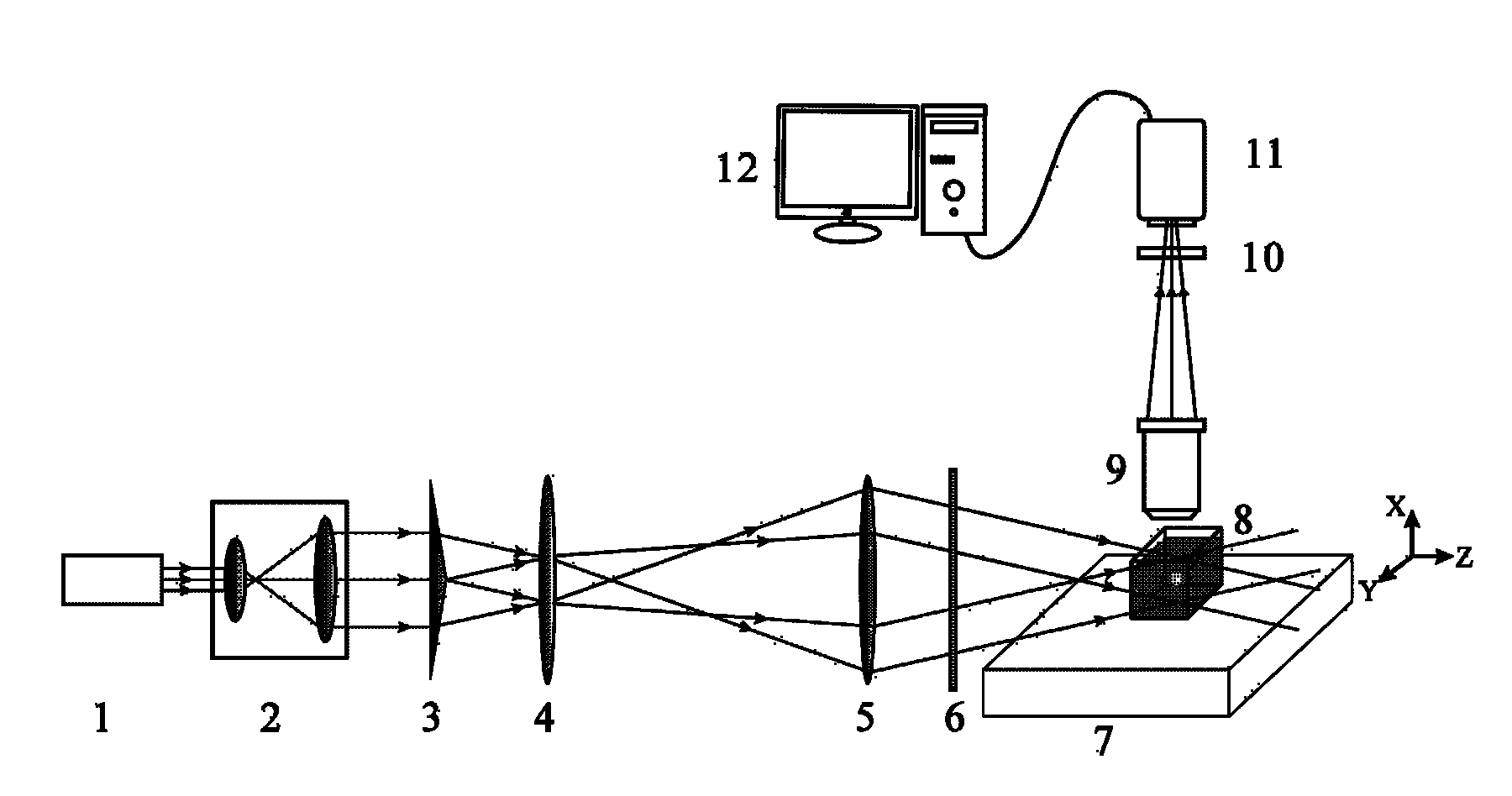

InactiveCN108519728AEnabling 3D tomography measurementsImprove imaging resolutionUsing optical meansImage resolutionDiffraction tomography

Provided is high-resolution digital holographic diffraction tomography, belonging to the field of digital holography and diffraction tomography. A digital holographic diffraction tomography device isused for obtaining N synthetic high-resolution holograms by utilizing a synthetic aperture method, and then the high-resolution three-dimensional refractive index reproduction of a tested sample is obtained. In order to improve the imaging resolution of the system, the synthetic aperture method is introduced into a digital holographic diffraction tomography system, a two-dimensional electric translation platform is used for moving the CCD, the high-frequency information around the original hologram is acquired, and m*m (m>=3) sub-holograms are recorded when the angle of a galvanometer is theta), the m*m sub-holograms are subjected to intensity registration and image dislocation sub-pixel micro-displacement, so that a synthetic high-resolution hologram is obtained. The high-resolution three-dimensional imaging is realized by combining a digital holographic diffraction tomography method and the synthetic aperture method. The digital holographic diffraction tomography system can realize non-contact, non-marking, lossless and three-dimensional tomography measurement.

Owner:BEIJING UNIV OF TECH

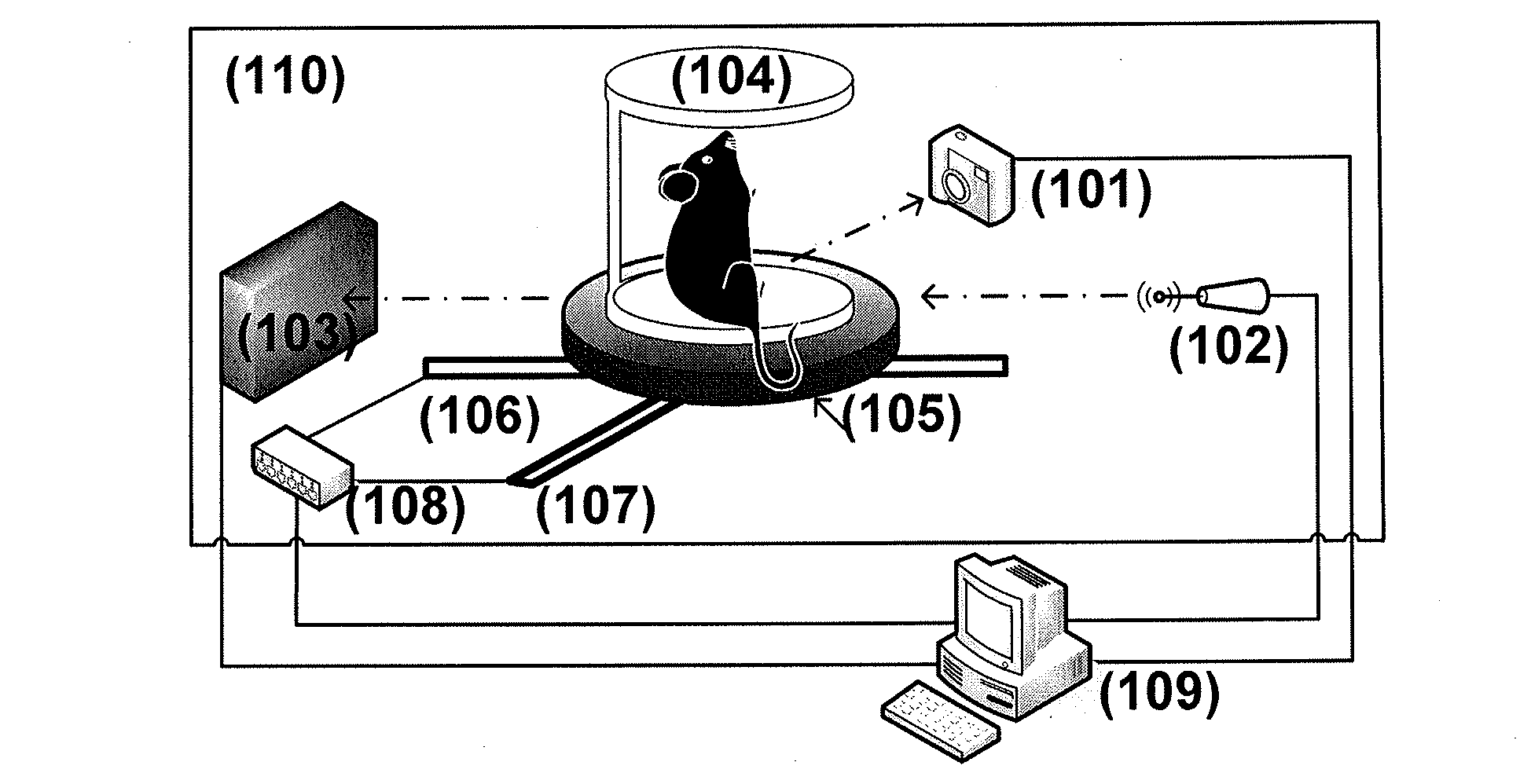

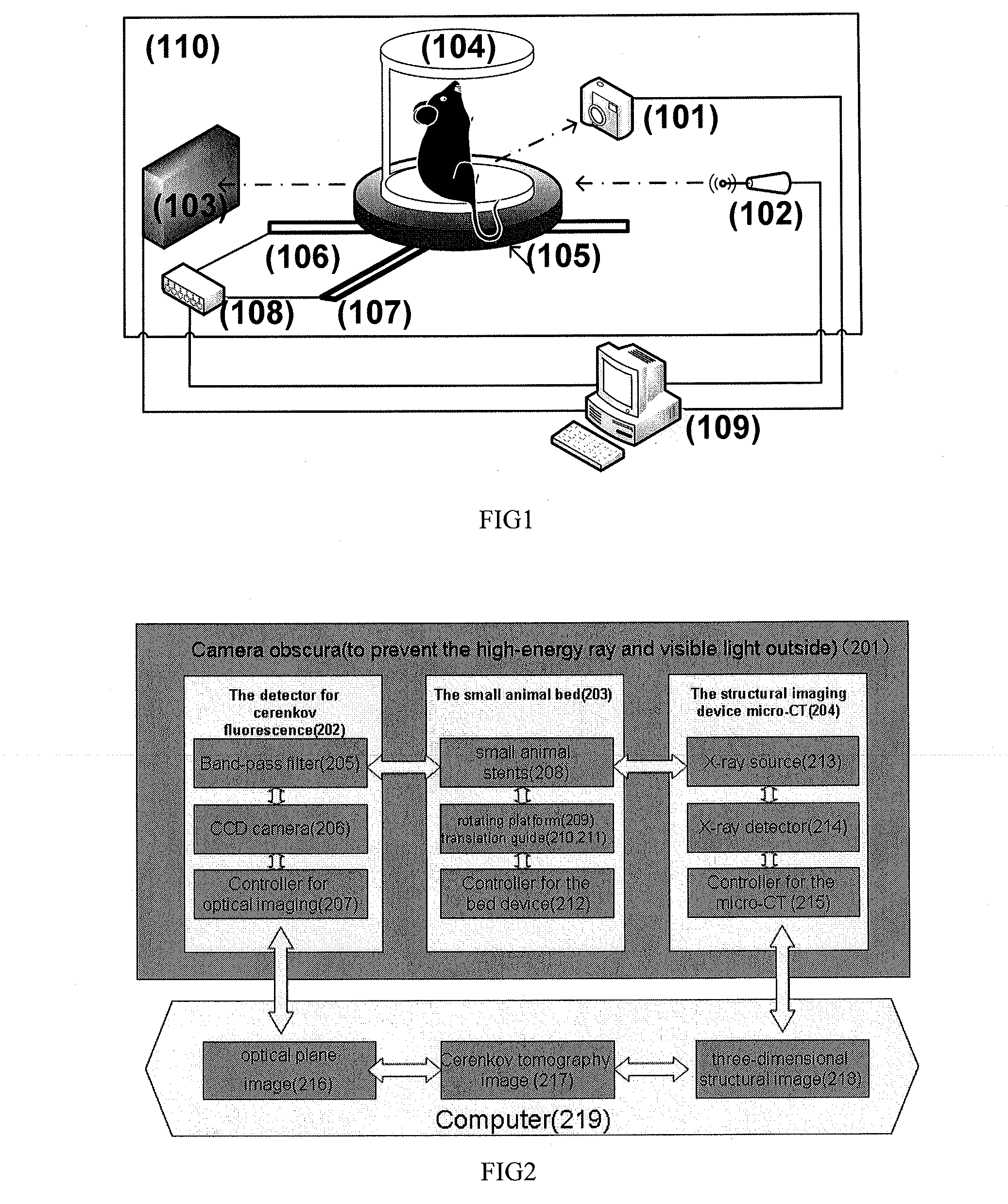

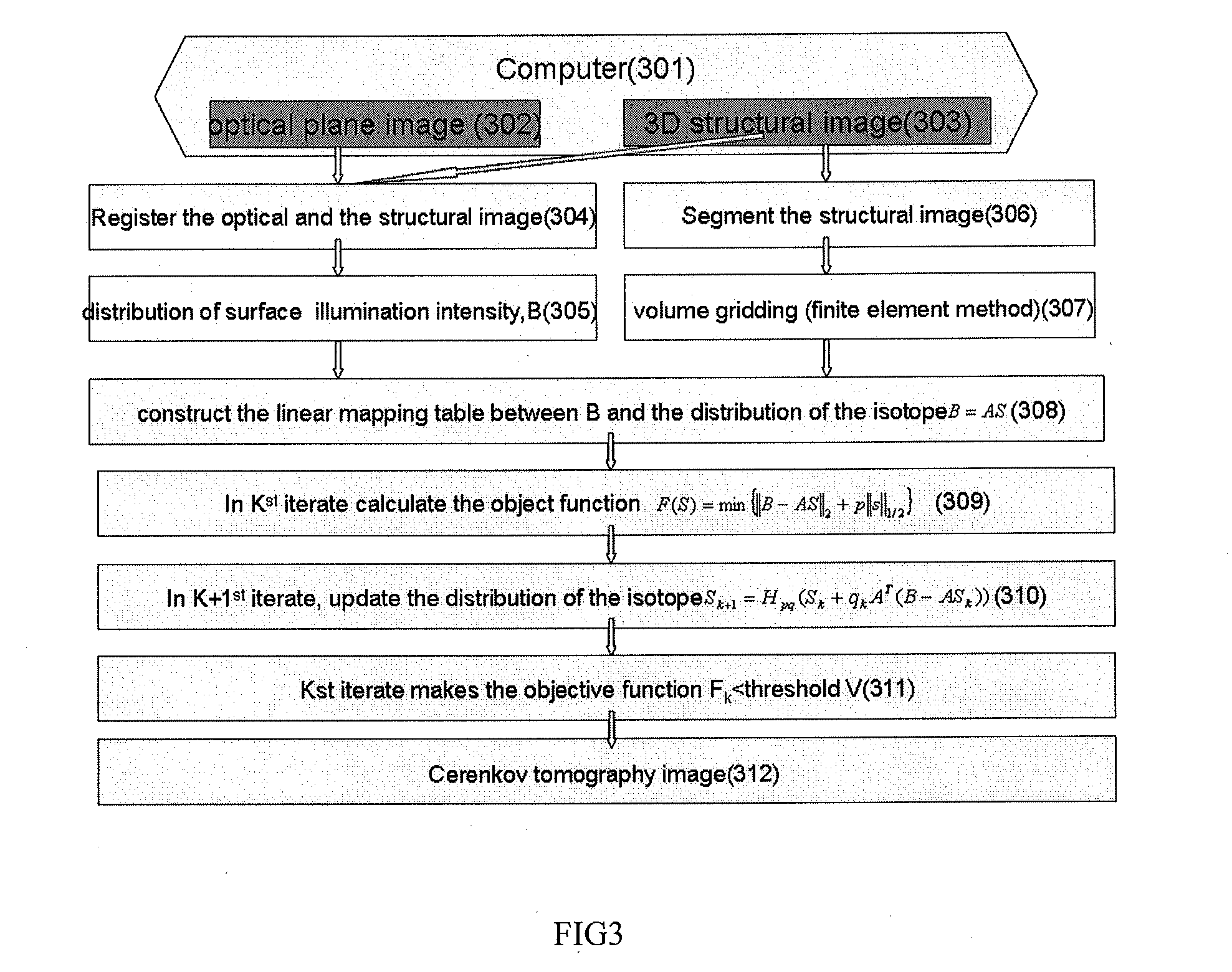

Tomography system based on cerenkov luminescence

ActiveUS20130259339A1Low costAdd optionsReconstruction from projectionMaterial analysis using wave/particle radiationFluorescenceIterator

A tomography system based on Cerenkov tomography, comprising: a detector of Cerenkov fluorescence for acquiring optical plane images; a structural imaging system for acquiring three-dimensional structural images;a bed device for supporting an object to be imaged; a computer for forming an optical image, a structural image and a CLT image. The invention adopts the SP3 model and the semi threshold iterator to implement the global reconstruction of the CLT, and obtains the three-dimensional tomography to image of the distribution of the radiopharmaceutical and the molecular probe in vivo within a short time. Since ordinary CCD camera is used, the cost of the imaging system has been sharply reduced for the equipment's construct and maintenance compared with PET / SPECT or γ camera. Therefore the present invention expands the options of the molecular probe, and application of the is medicine Imaging.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

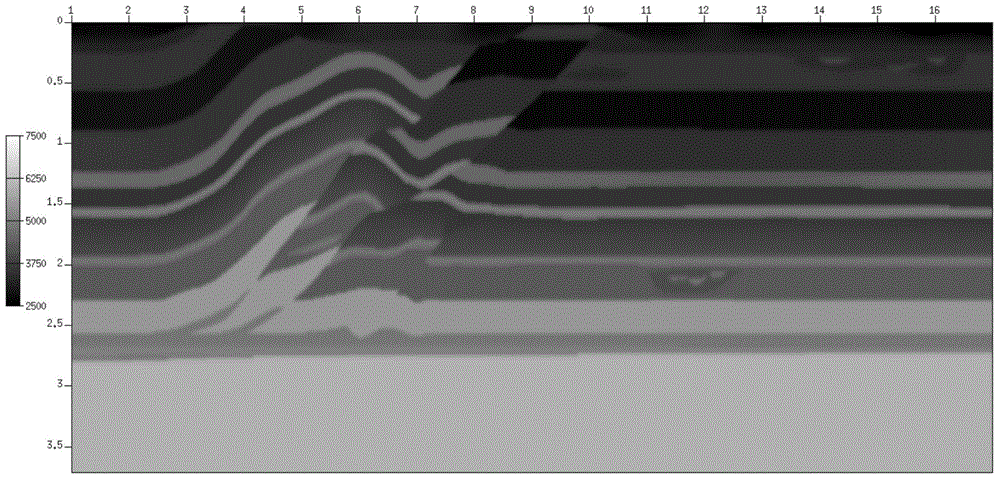

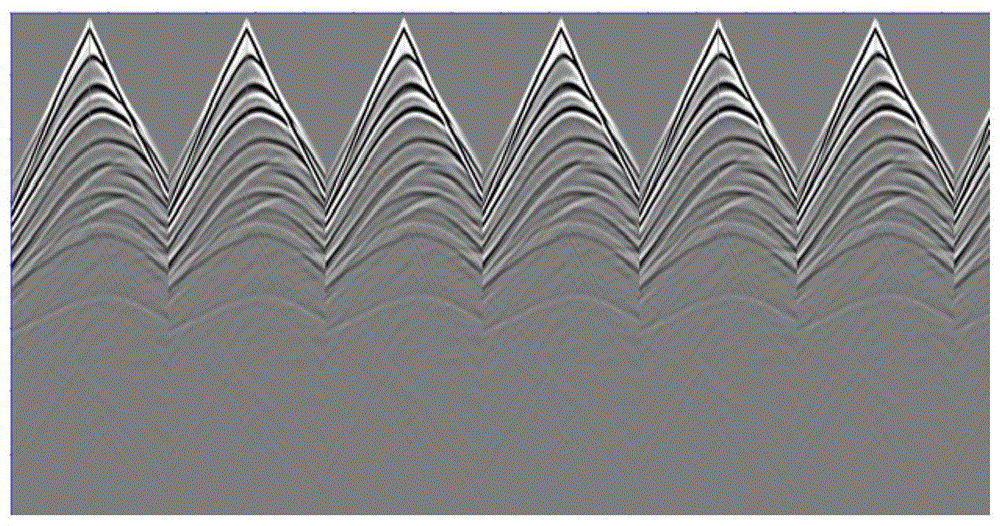

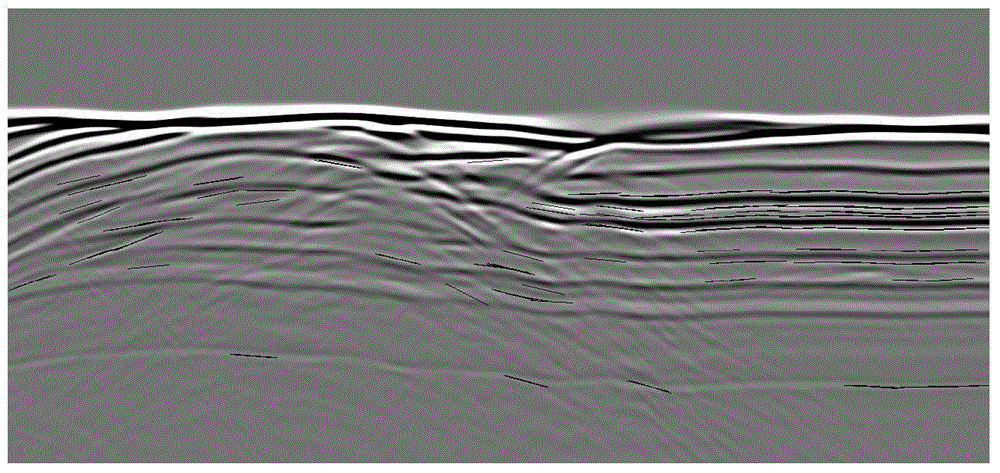

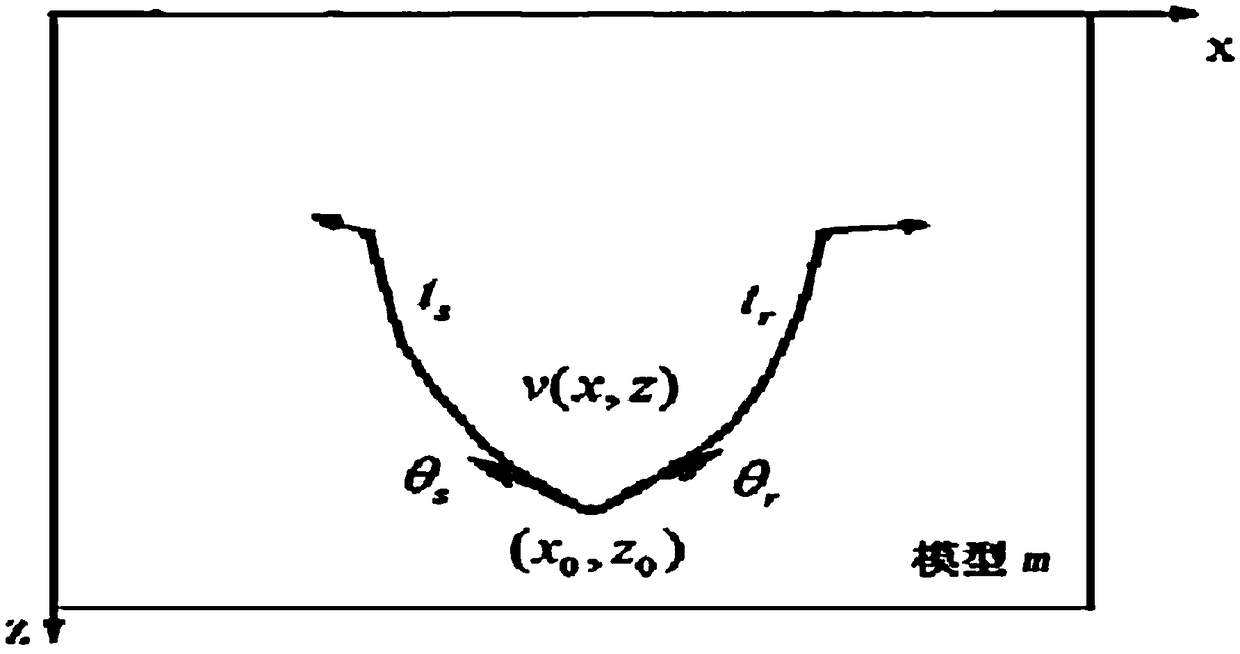

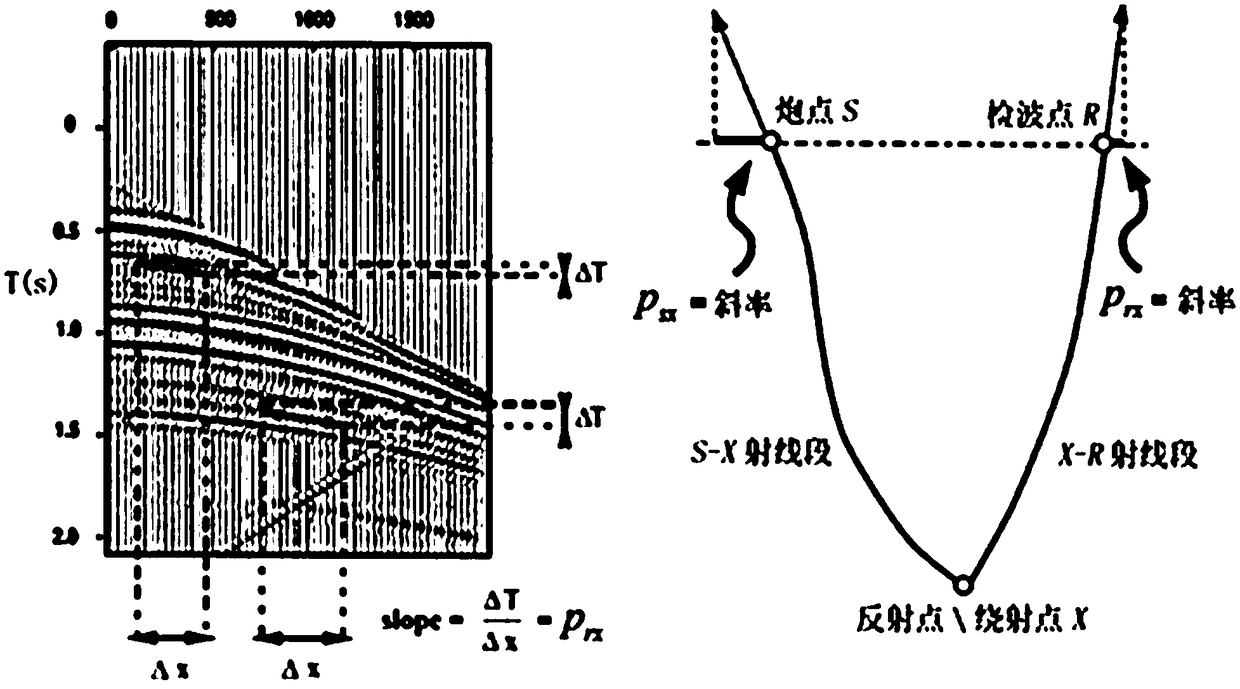

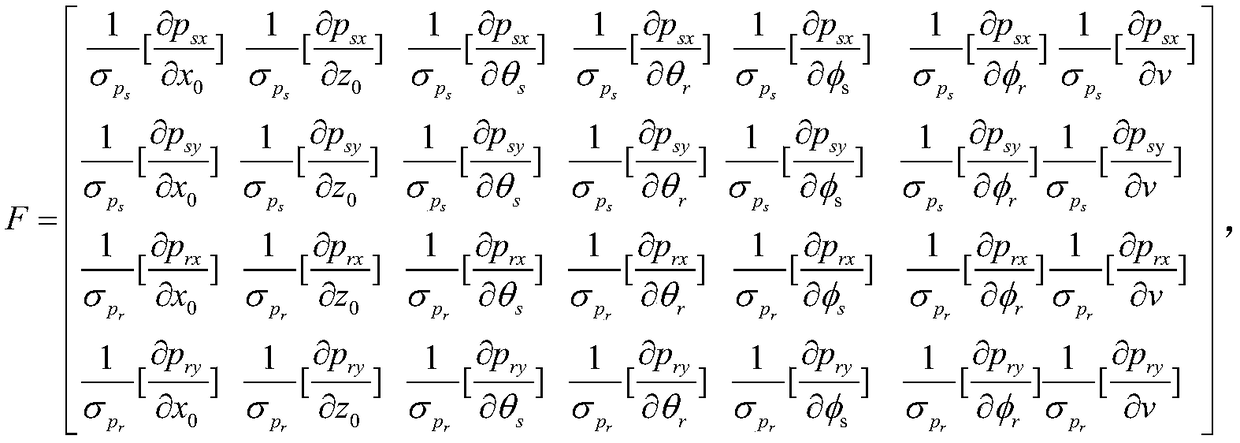

Full-automatic three-dimensional tomography inversion method using a local event slope

ActiveCN105319589AImprove the efficiency of the velocity estimation processReduce manual workloadSeismic signal processingSpecial data processing applicationsThree dimensional tomographyInversion methods

The invention provides a full-automatic three-dimensional tomography inversion method using a local event slope and belongs to the seismic imaging and inversion field in oil and gas exploration and development. The method includes the following steps that: (1) an event slope is picked up in an automated manner; (2) an event slope coordinate transformation identical equation is utilized to perform quality monitoring, data points (S, R, PS, PR, t) pick are picked up in a filtering manner; and (3), a regularized three-dimensional tomography equation is established and solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

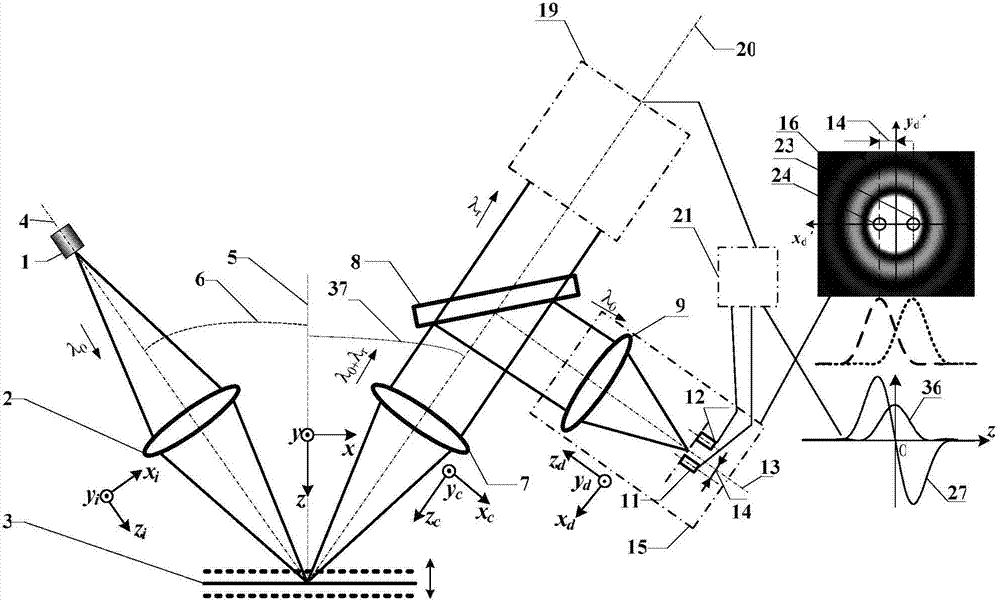

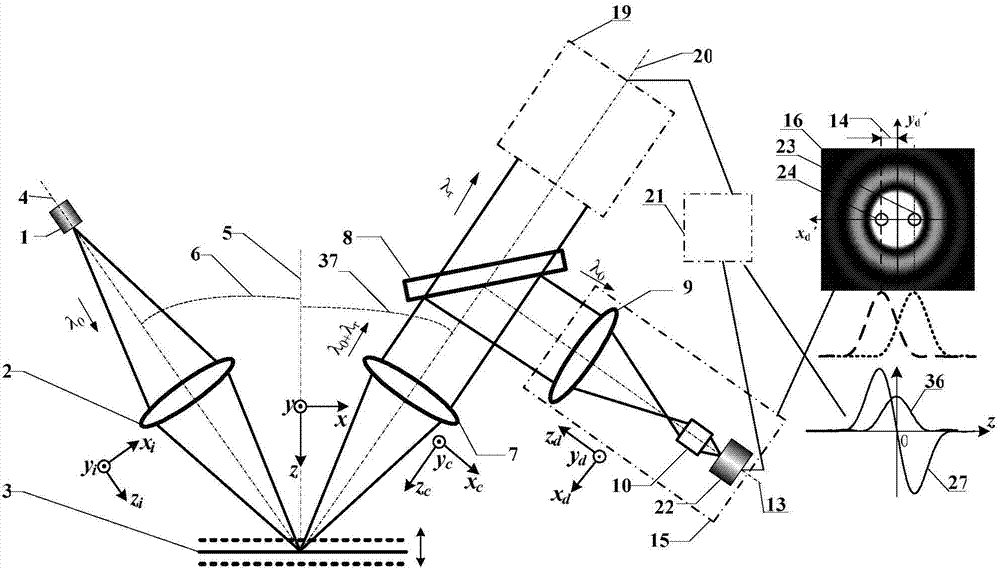

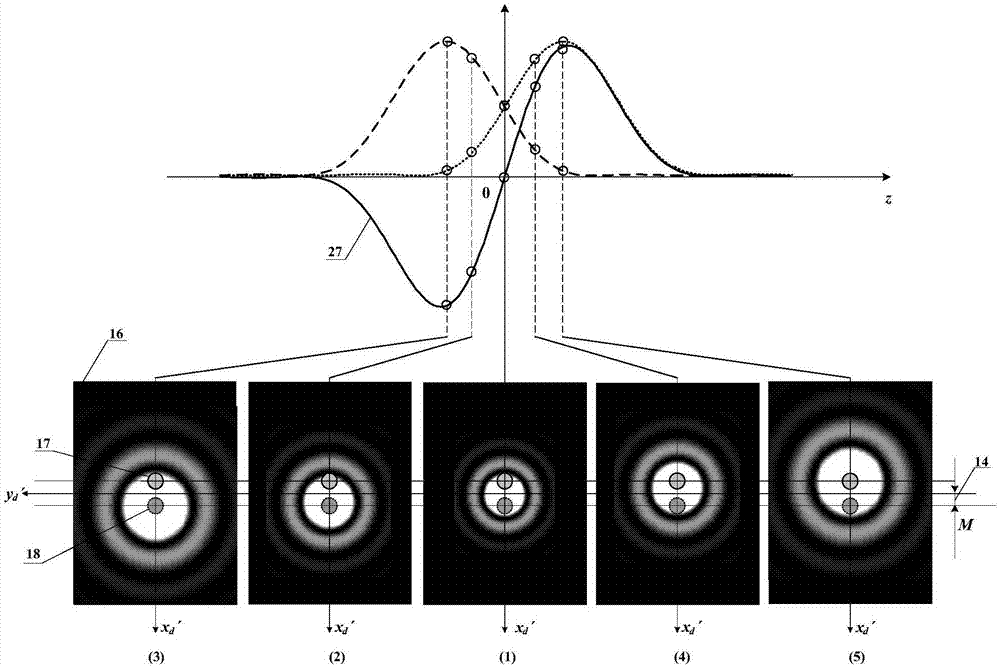

High spatial resolution biaxial differential confocal spectrum microscopic imaging method and apparatus

ActiveCN103926197AImprove horizontal resolutionReduce intensityRaman scatteringMicroscopesVisual field lossHigh spatial resolution

The invention belongs to the technical field of spectrum measurement, and relates to a high spatial resolution biaxial differential confocal spectrum imaging method and an apparatus. According to the present invention, the biaxial differential confocal microscopy technology and the spectrum detection technology are fused, focal spot cutting differential detection is adopted so as to achieve precise imaging of the geometry position, simplify the optical path structure of the traditional differential confocal microscopy system, inherit the advantages of large visual field and large work distance of the biaxial microscopy technology, and achieve high spatial resolution spectrum integrated detection of the system; and high spatial resolution is provided, three modes such as three-dimensional tomography geometry imaging, spectrum detection and micro-region spectrum tomography imaging are provided, a new solving approach is provided for micro-region spectrum detection, and broad application prospects are provided in the fields of biomedicine, physical material science and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

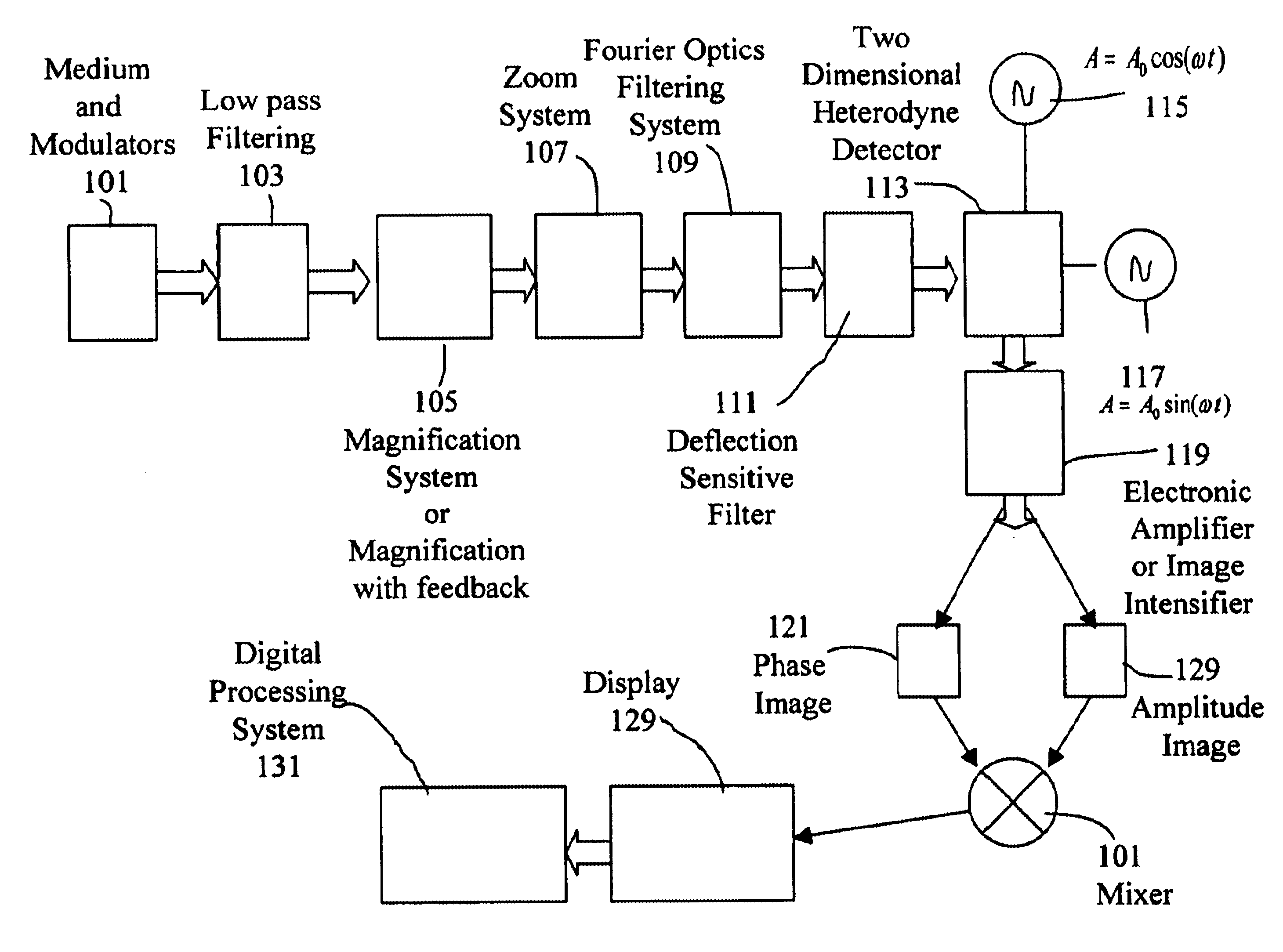

2-D microscopic tomographic systems utilizing 2-D deflection sensors

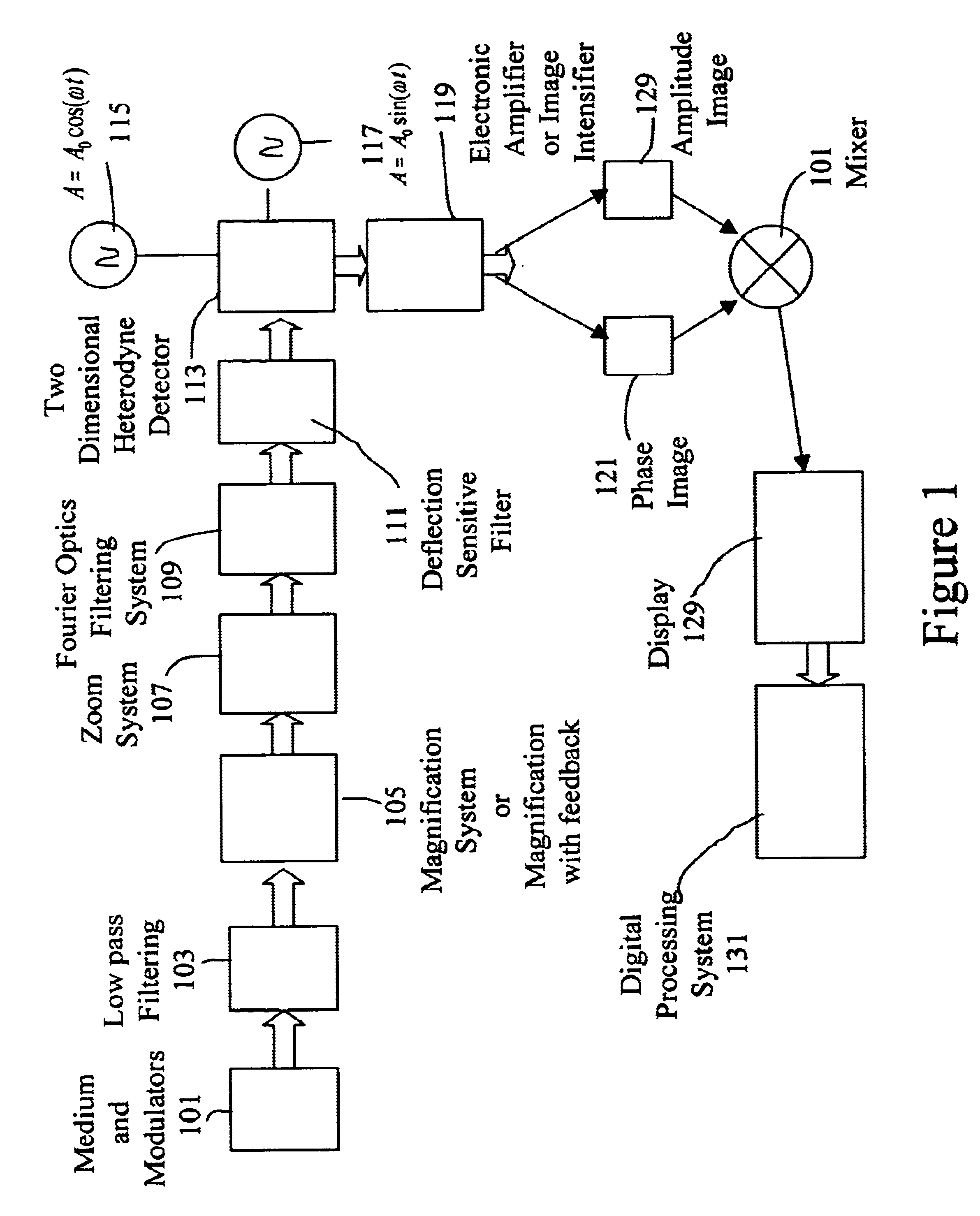

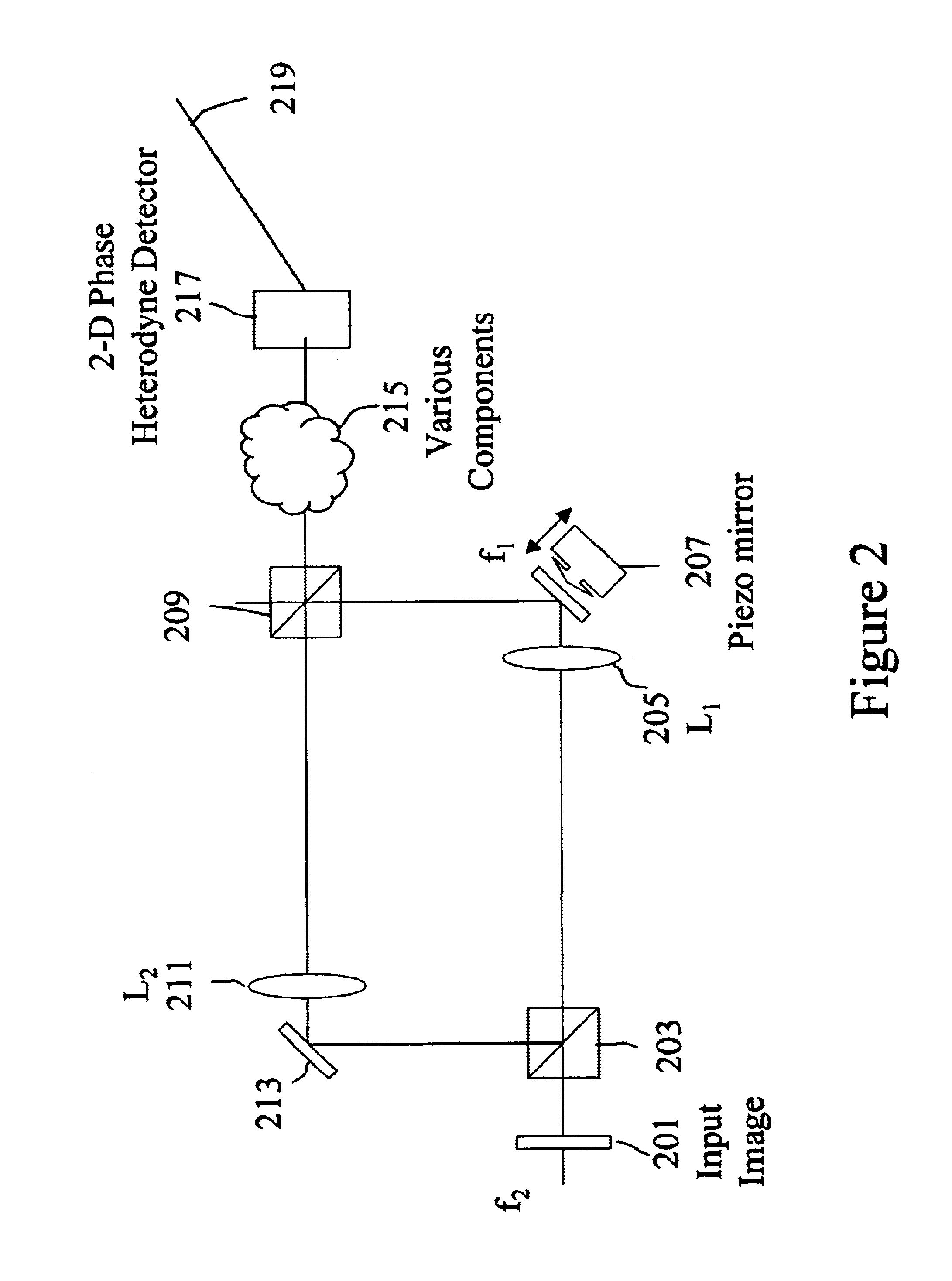

InactiveUS6849844B2Image enhancementMaterial analysis using wave/particle radiationGratingDisplay device

A high resolution, non-scanning system for microscopy and / or tomography whereby a broad non-focused input image transmitted through a medium such the human body is processed, in contrast with a focused scanning beam. A high pass filter provides high sensitivity, and a high magnification feedback loop magnifier having reduced lens aberrations is also provided. A zoom lens focuses the input image such as a tumor at different planes within the medium. Image processing systems for correction via a back-propagation algorithms followed by a two-dimensional (2-D) deflection sensor and a 2-D Demultiplexer is employed to produce separate phase and amplitude image signals that are then mixed and applied to a display yielding three dimensional tomographic images. Novel two demultiplexers for calculation amplitude and phase images are disclosed based on a smart pixelated array, a tunable grating, and a two-probe beam hologram, each beam having two different wavelengths or two different modulations.

Owner:KHOURY JED

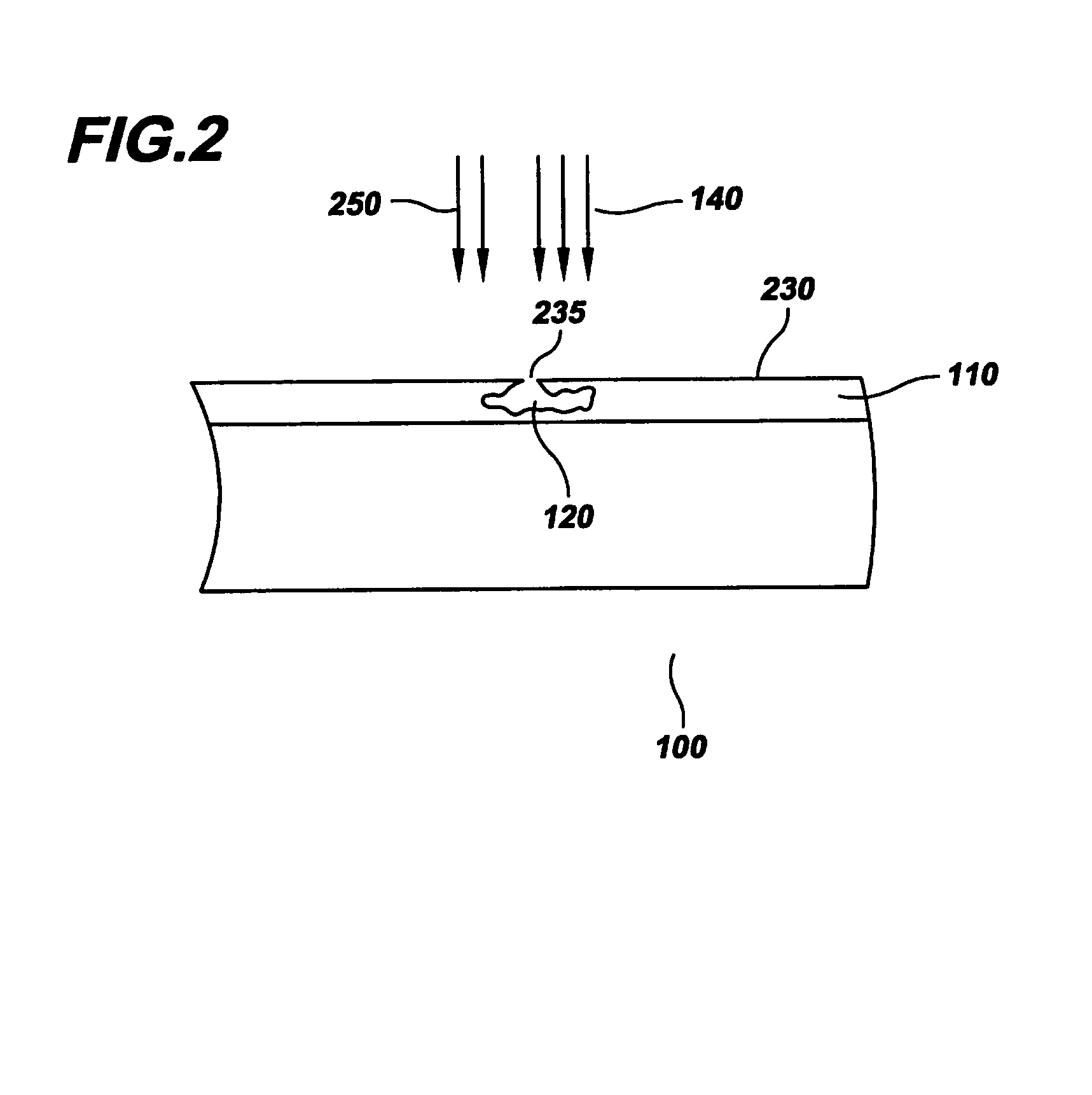

Three-dimensional tomography

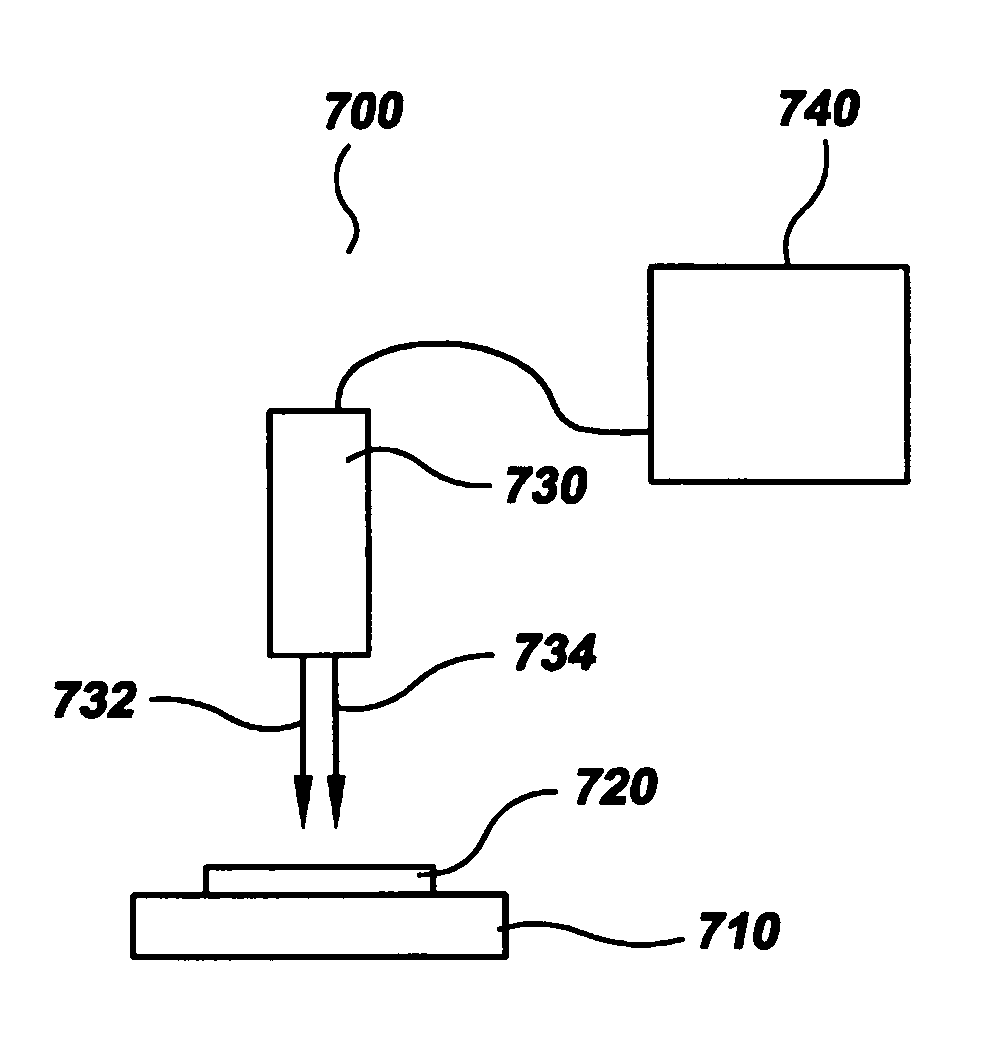

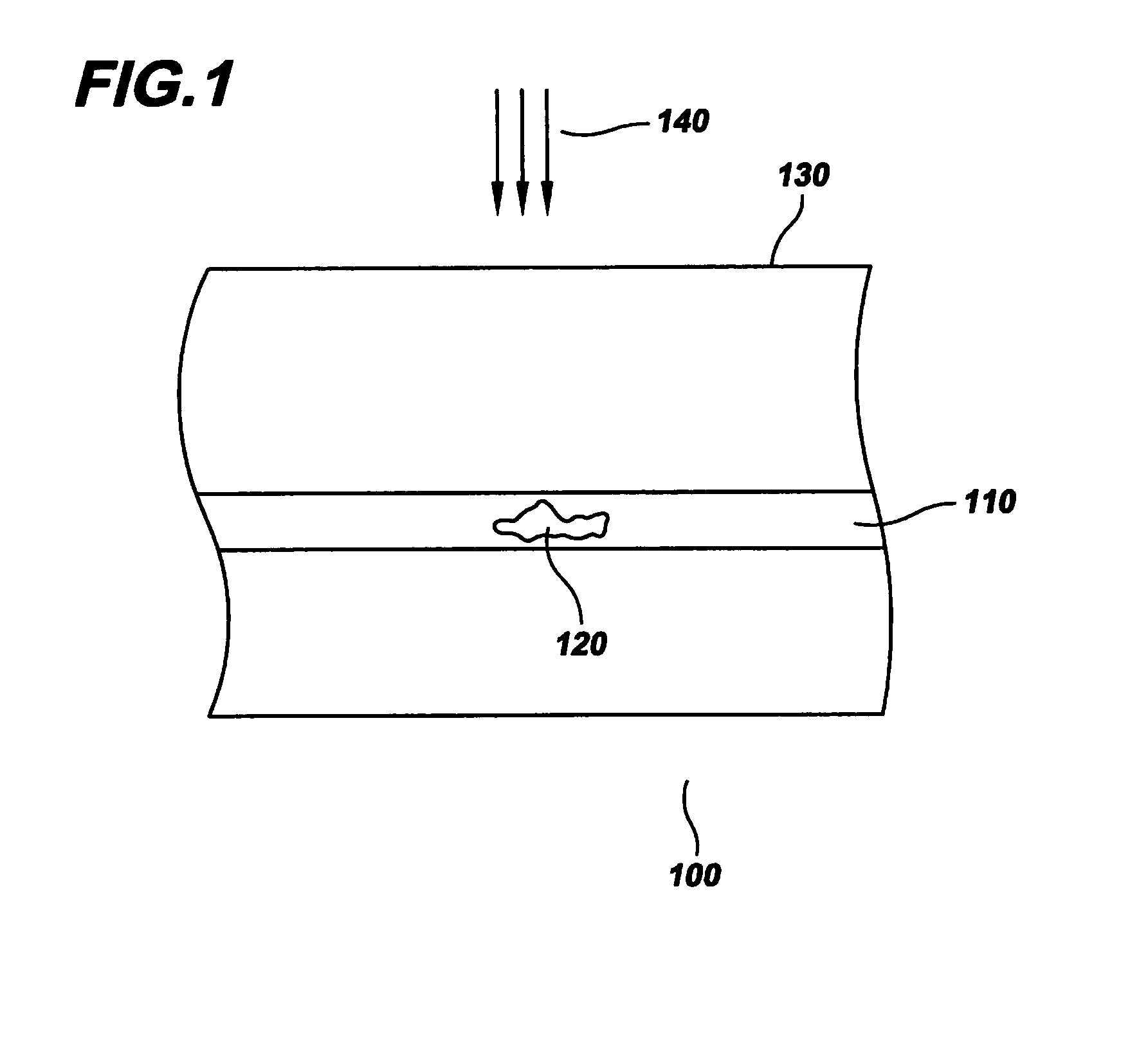

InactiveUS7088852B1Improve abilitiesMaterial analysis using wave/particle radiationSemiconductor/solid-state device manufacturingThree dimensional tomographySemiconductor

Defect analysis of a semiconductor die is enhanced in a manner that makes possible the viewing of spatial manifestations of the defect from virtually any angle. According to an example embodiment of the present invention, substrate is removed from a semiconductor die while simultaneously obtaining images of the portions of the die from which substrate is being removed. The images are taken at various points in the substrate removal process, recorded and combined together to form a three-dimensional image of selected portions of the die. The image is then used to view the selected portions, and the nature of one or more defects therein are analyzed.

Owner:GLOBALFOUNDRIES INC

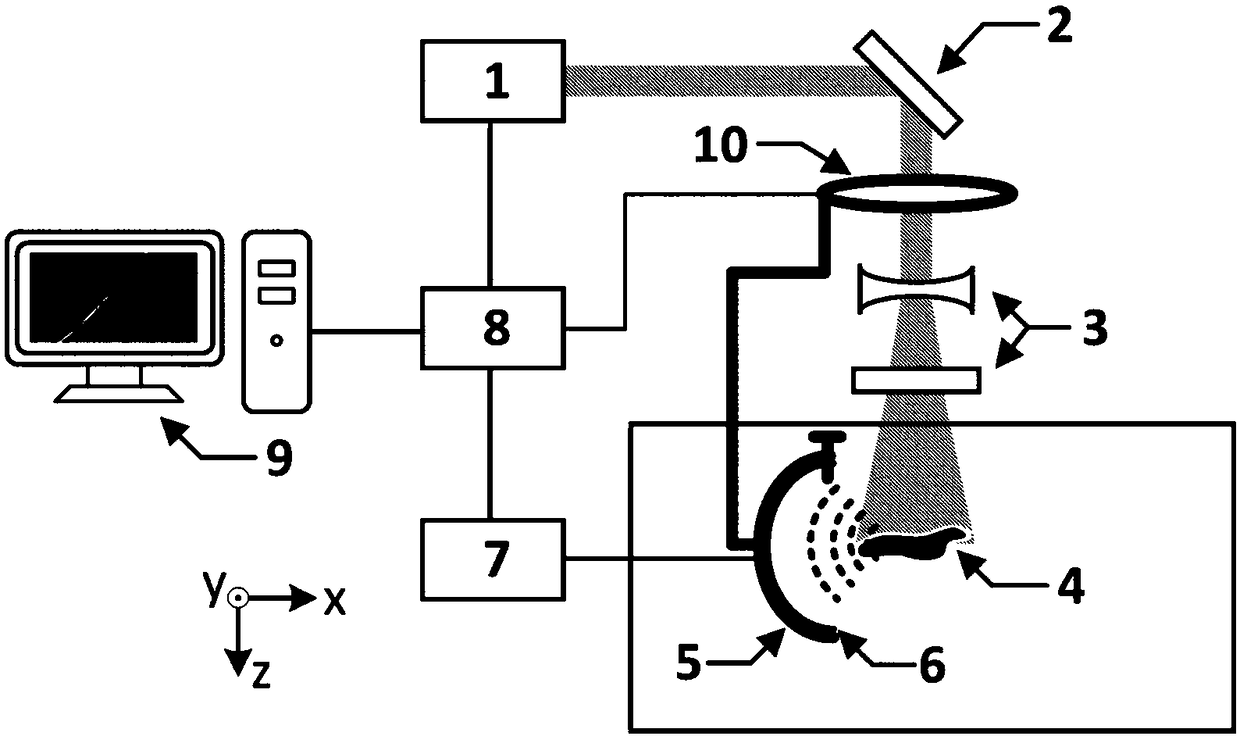

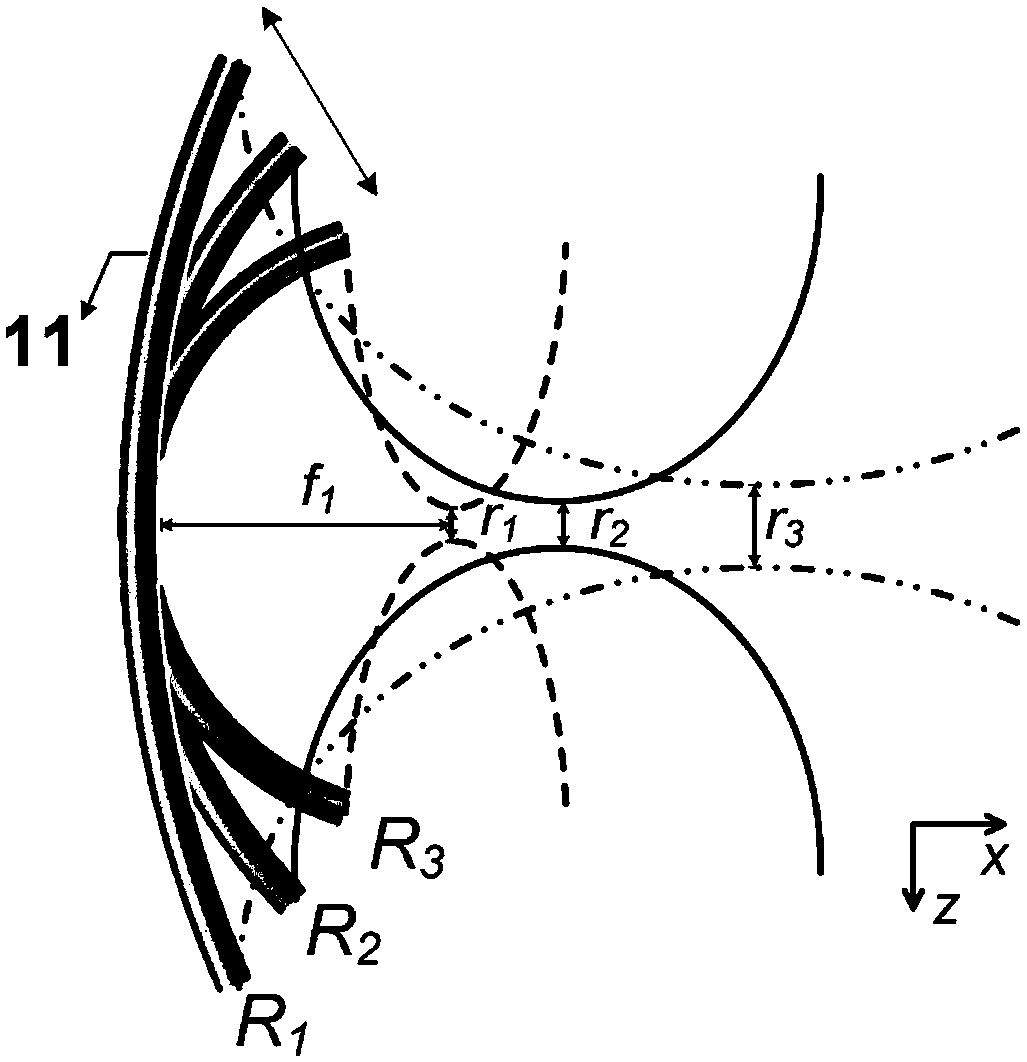

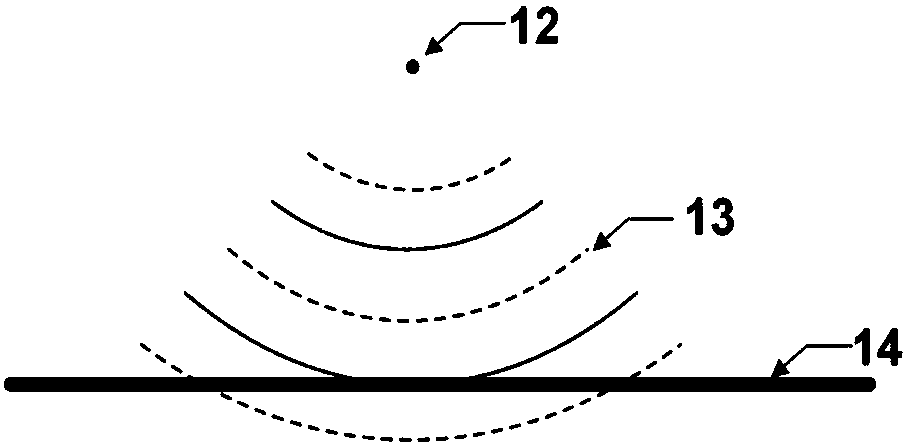

Photoacoustic computed tomography system based on adjustable focusing type optical fiber sensor

ActiveCN108606777ACompact structureEasy to adjustMaterial analysis by optical meansDiagnostic recording/measuringPhotoelectric effectPhotoacoustic effect

The invention discloses a photoacoustic computed tomography system based on an adjustable focusing type optical fiber sensor. The photoacoustic computed tomography system comprises a short-pulse laserdevice, a reflector, a beam expander, a water tank, a to-be-measured object, an optical fiber clamp, the adjustable focusing type optical fiber sensor, a rotary stepping motor, a photoelectric detector, a data collecting card and a computer and is characterized in that the short-pulse laser device emits short-pulse laser which irradiates the to-be-measured object, the to-be-measured object generates an ultrasonic wave due to a photoacoustic effect, the optical fiber sensor receives the ultrasonic wave and converts the same into an optical signal, the optical signal is processed by the photoelectric detector and the data collecting card and transmitted to the computer for reconstruction to obtain a two-dimensional tomography image, and a linear translation platform controls the to-be-measured object to move axially to obtain a three-dimensional tomography image. The adjustable focusing type optical fiber sensor is simple in structure, adjustable in curvature, high in sensitivity and suitable for being used in the photoacoustic computed tomography system.

Owner:JINAN UNIVERSITY

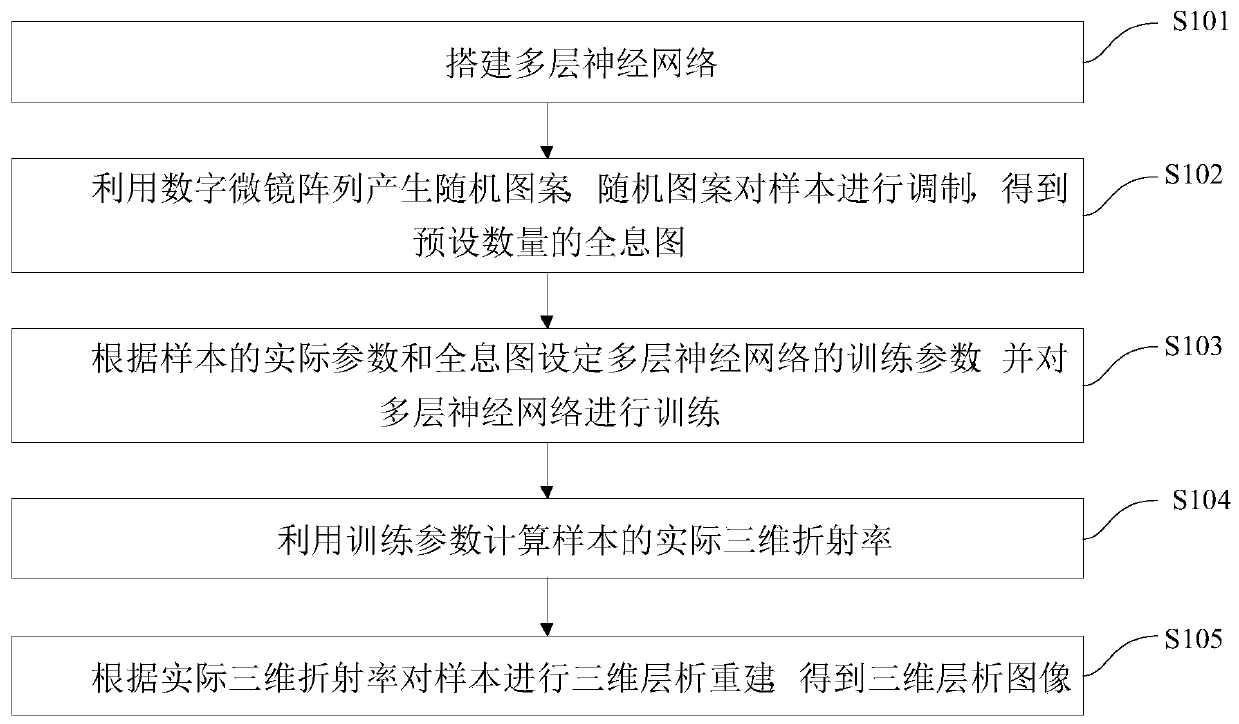

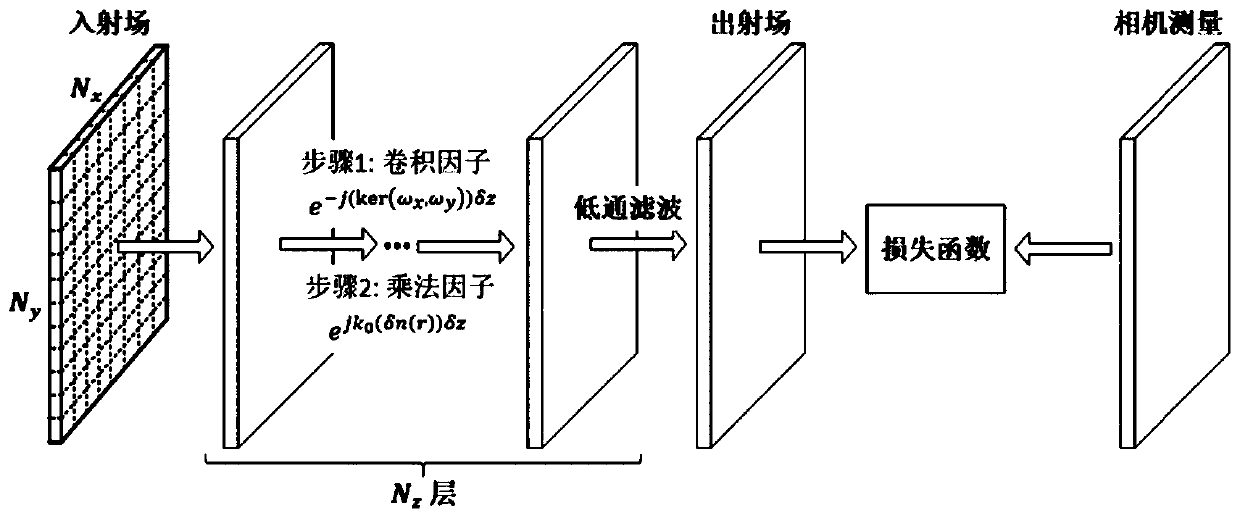

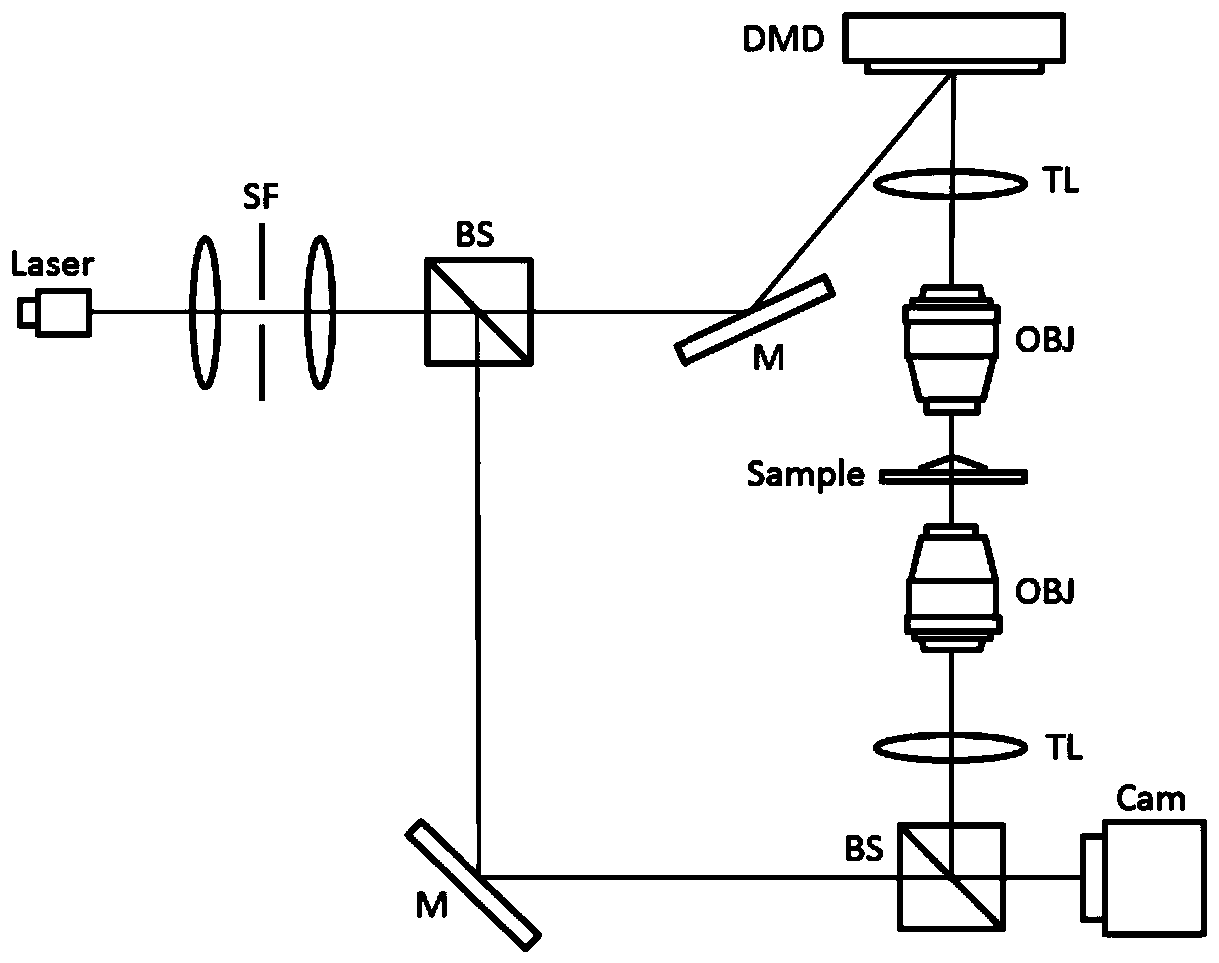

Phase chromatography method and device based on deep learning and random patterns

The invention discloses a phase chromatography method and a phase chromatography device based on deep learning and random patterns. The method comprises the following steps: establishing a multi-layerneural network; generating a random pattern by using the digital micromirror array, and modulating the sample by using the random pattern to obtain a preset number of holograms; setting training parameters of the multi-layer neural network according to the actual parameters of the sample and the hologram, and training the multi-layer neural network; calculating the actual three-dimensional refractive index of the sample according to the training parameters; and performing three-dimensional tomography reconstruction on the sample according to the actual three-dimensional refractive index to obtain a three-dimensional tomography image. According to the method, an inclined illumination light beam is not required to be designed and generated. The high-precision phase chromatography reconstruction of a sample can be realized only by using a digital micro-mirror array to project random patterns and using a small amount of random patterns.The functions of high-speed acquisition and precise chromatography are realized by designing a calculation scheme and utilizing a deep learning neural network to be matched with an intensity random modulation plane wave illumination acquisition system.

Owner:TSINGHUA UNIV

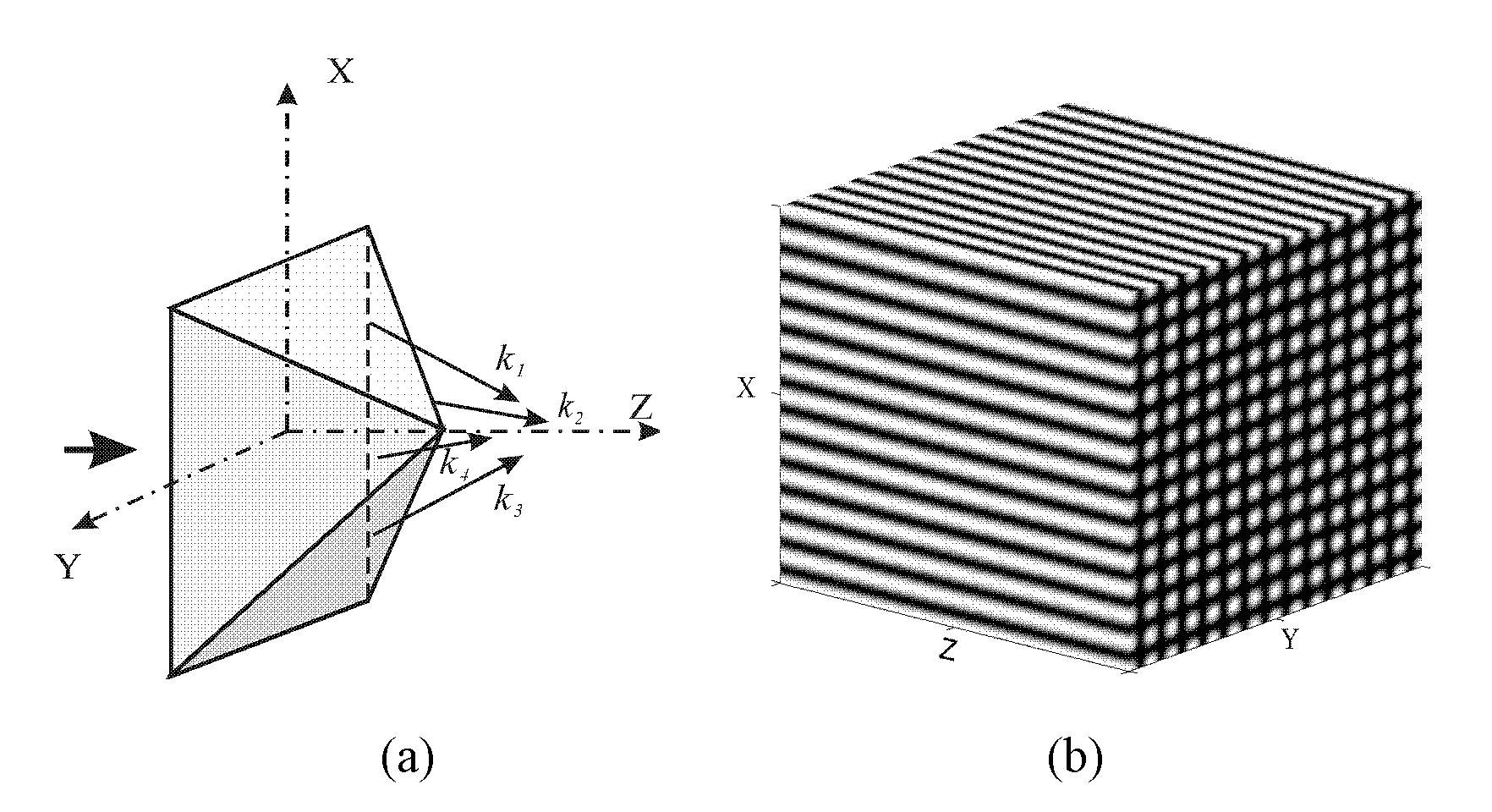

Method and device of fluorescence microscopy by using pyramid lens to generate structured lighting

The invention provides a method and a device of fluorescence microscopy by using a pyramid lens to generate structured lighting. The device comprises parallel beams, a structured lighting system, a sample cell and an image acquisition system, wherein the structured lighting system comprises a pyramid lens, a telescope system and a phase-shifting glass sheet; and the sample cell is arranged at the rear part of the phase-shifting glass sheet. The parallel beams are refracted after passing through the pyramid lens, thus generating a four-beam interference field with two-dimensional space structure distribution and exciting a sample by the four-beam interference field. The three-dimensional tomography can be realized through image processing algorithm by translating the interference optical field acted on the sample Compared with the existing microscopy for structured lighting, the invention can achieve higher axial resolution but lower photo-bleaching effect. Therefore, the invention is suitable for the research on the imaging of living creatures.

Owner:BEIJING LUSTER LIGHTTECH

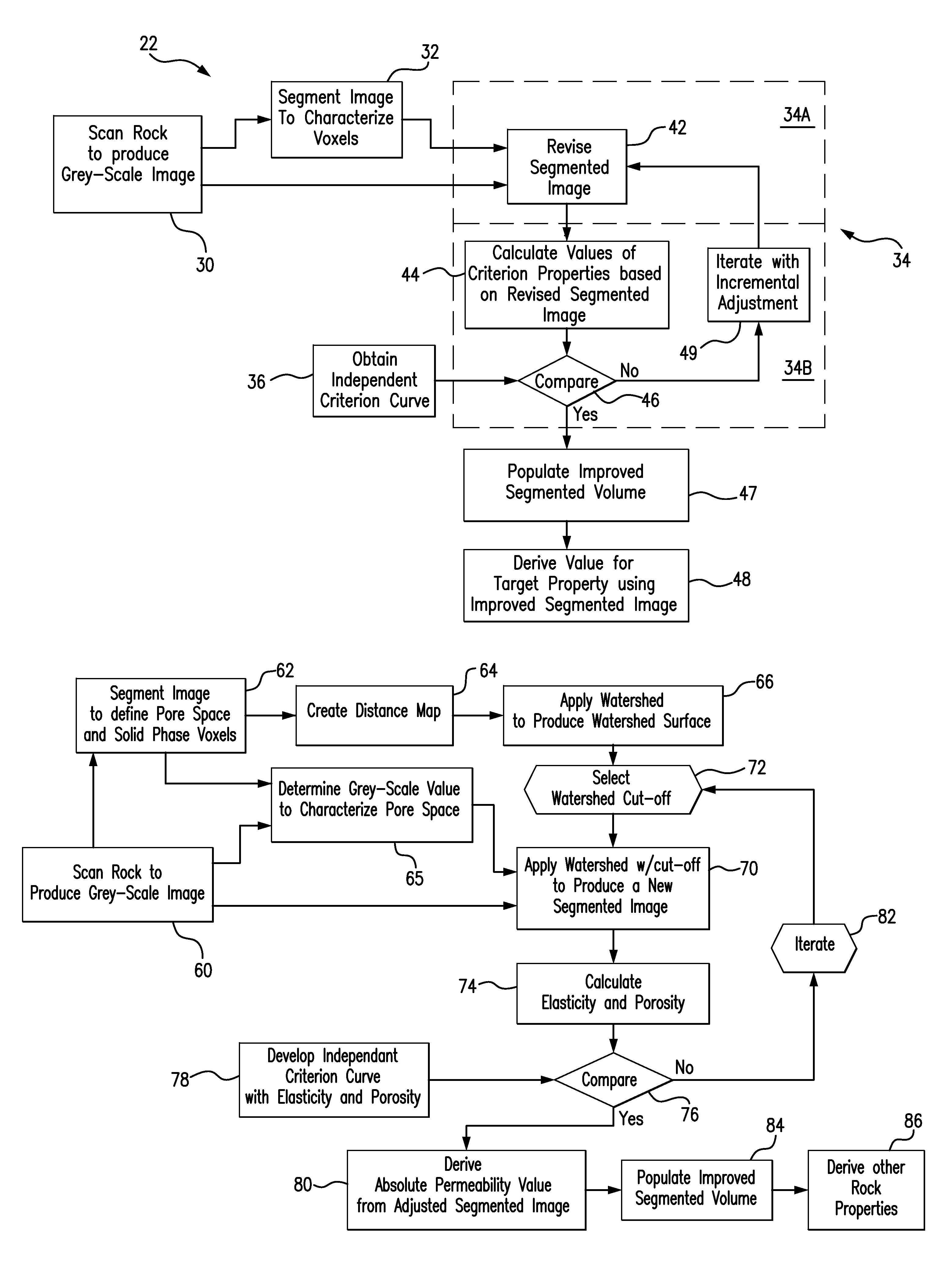

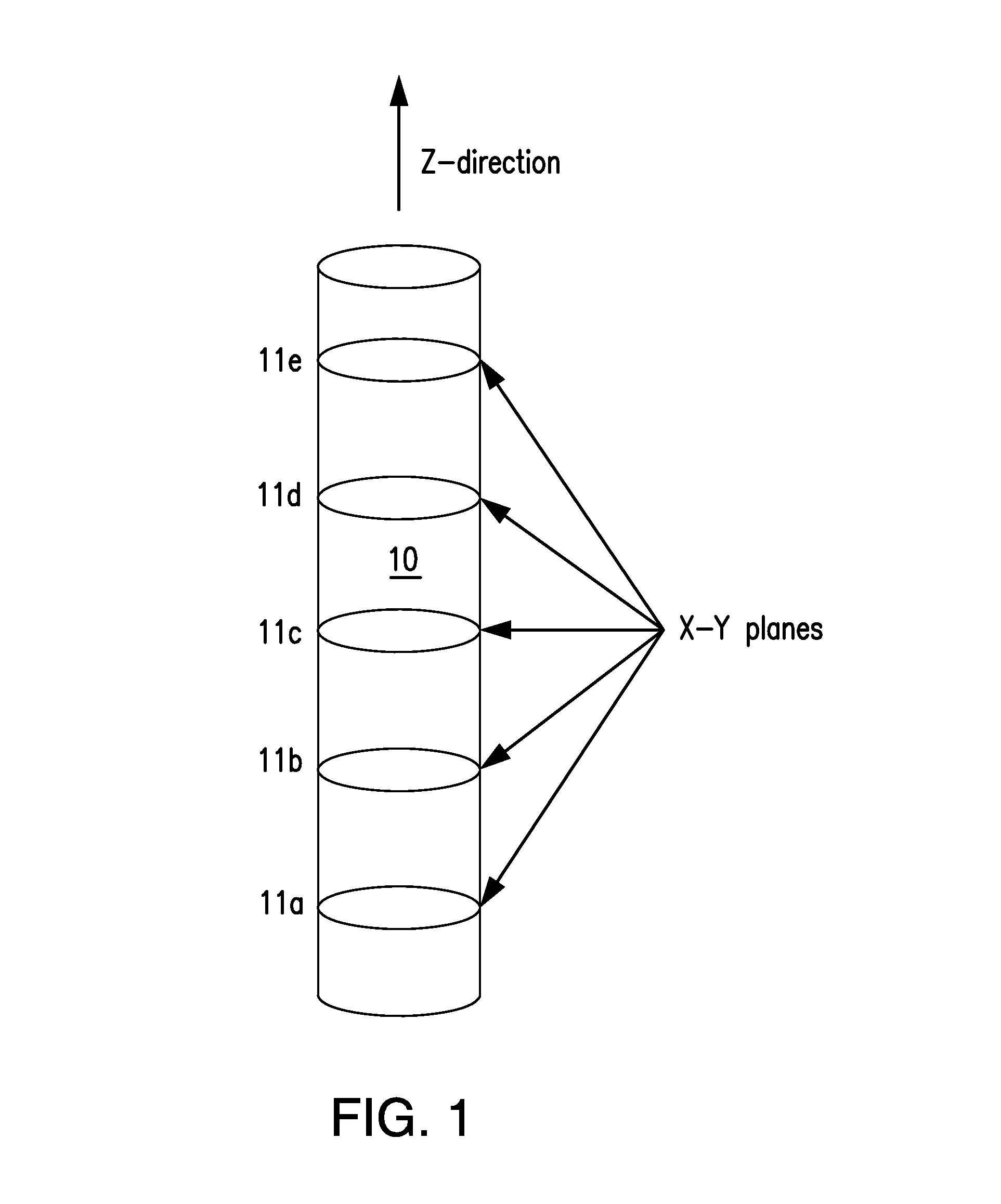

Method for improving the accuracy of rock property values derived from digital images

ActiveUS9047513B2High target accuracyAccurate representationImage enhancementImage analysisComputer graphics (images)Porous medium

A method for increasing the accuracy of a target property value derived from a rock sample is described in which the sample is scanned to obtain a three-dimensional tomographic digital image which can be processed to pore space and solid material phases through a segmentation process. A process is used which revises the segmented volume, e.g., by increasing pore space connectivity, in a manner affecting the target property value that would be derived. Another described method increases the accuracy with which a segmented volume represents a material sample having structure not adequately resolved in an original three-dimensional tomographic digital image. Further, a system for performing the processes, and a segmented digital volume which more accurately represents a sample of a porous media, are described.

Owner:HALLIBURTON ENERGY SERVICES INC

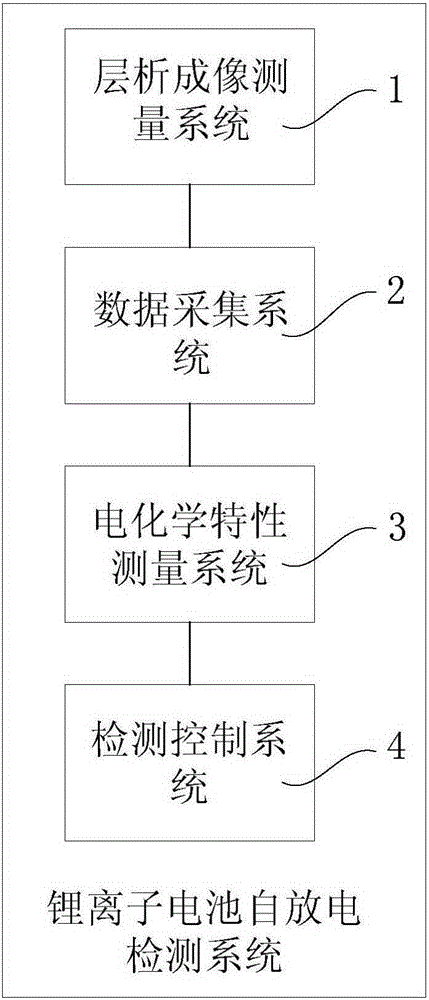

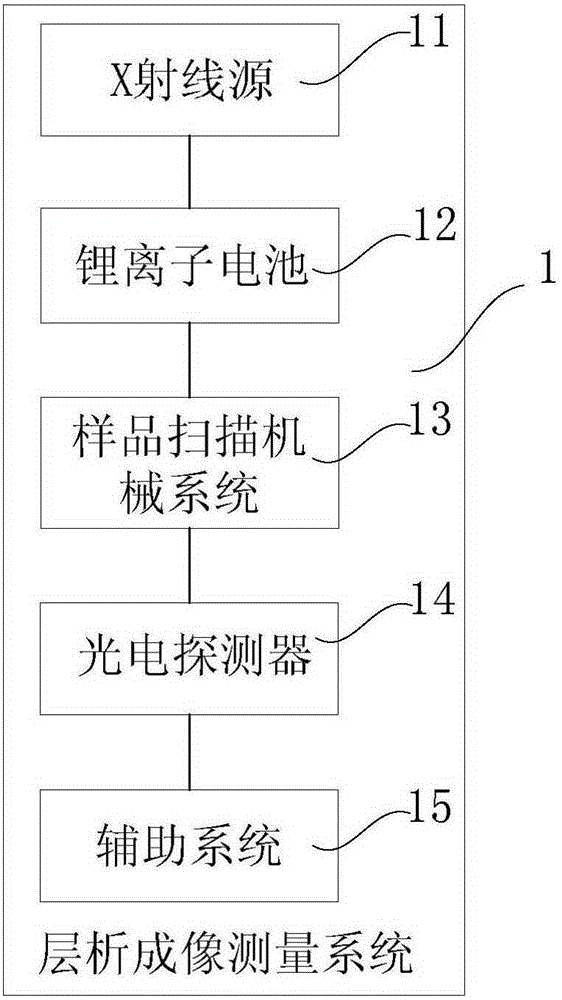

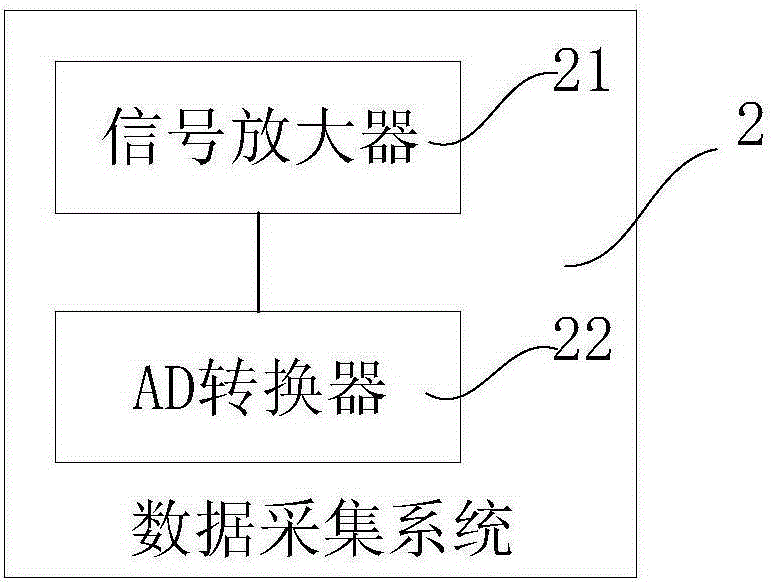

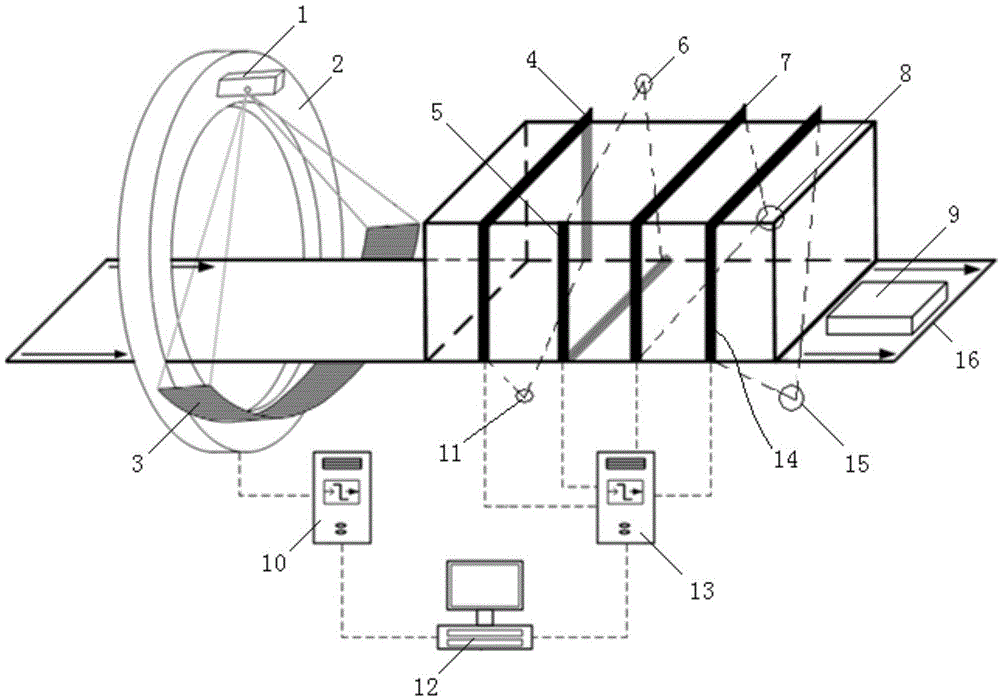

Self-discharging detection system for lithium ion battery

The invention discloses a self-discharging detection system for a lithium ion battery. The system includes a tomography measurement system, a data collecting system, an electrochemical characteristic measuring system and a detection control system. The tomography measurement system is used for obtaining complete data required for reconstructing a three-dimensional tomography image of the lithium ion battery; the data collecting system is used for performing treatment such as amplification, A / D conversion and the like on output signals of the tomography measurement system. The electrochemical characteristic measuring system is used for acquiring basic parameters such as voltage, current, capacity and the like of the lithium ion battery. The detection control system is used for scanning control during the data collection process, obtaining the self-discharging rate of the lithium ion battery and performing treatment such as display, storage and the like. The system provided by the invention realizes real time, lossless and accurate detection of the self-discharging rate of the lithium ion battery and is used for self-discharging rate detection during the lithium ion battery production process and lithium ion battery automatic sorting based on the self-discharging rate, and has important realistic meaning in improving the technique level in battery self-discharging detection of China.

Owner:SOUTH CHINA UNIV OF TECH

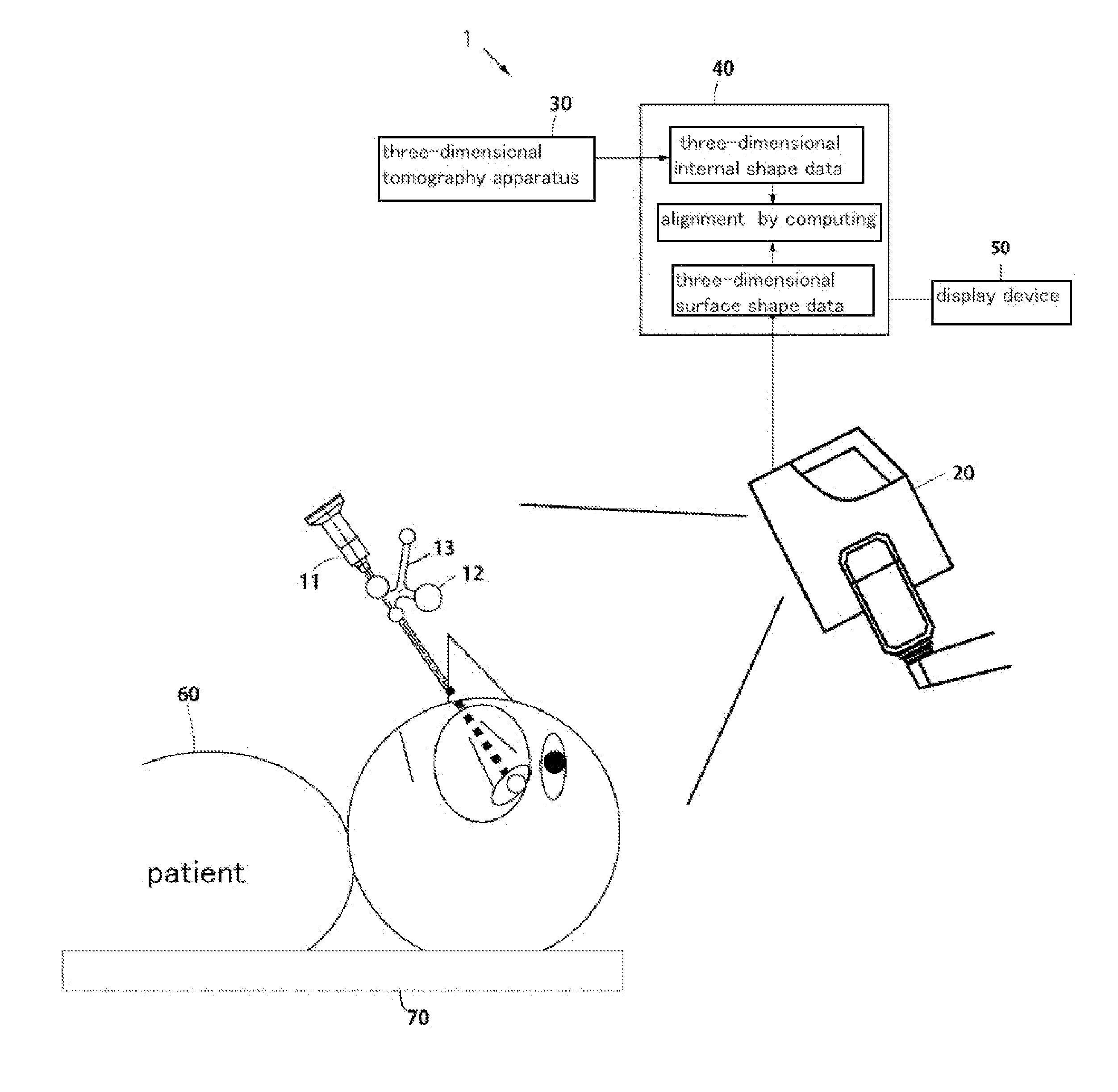

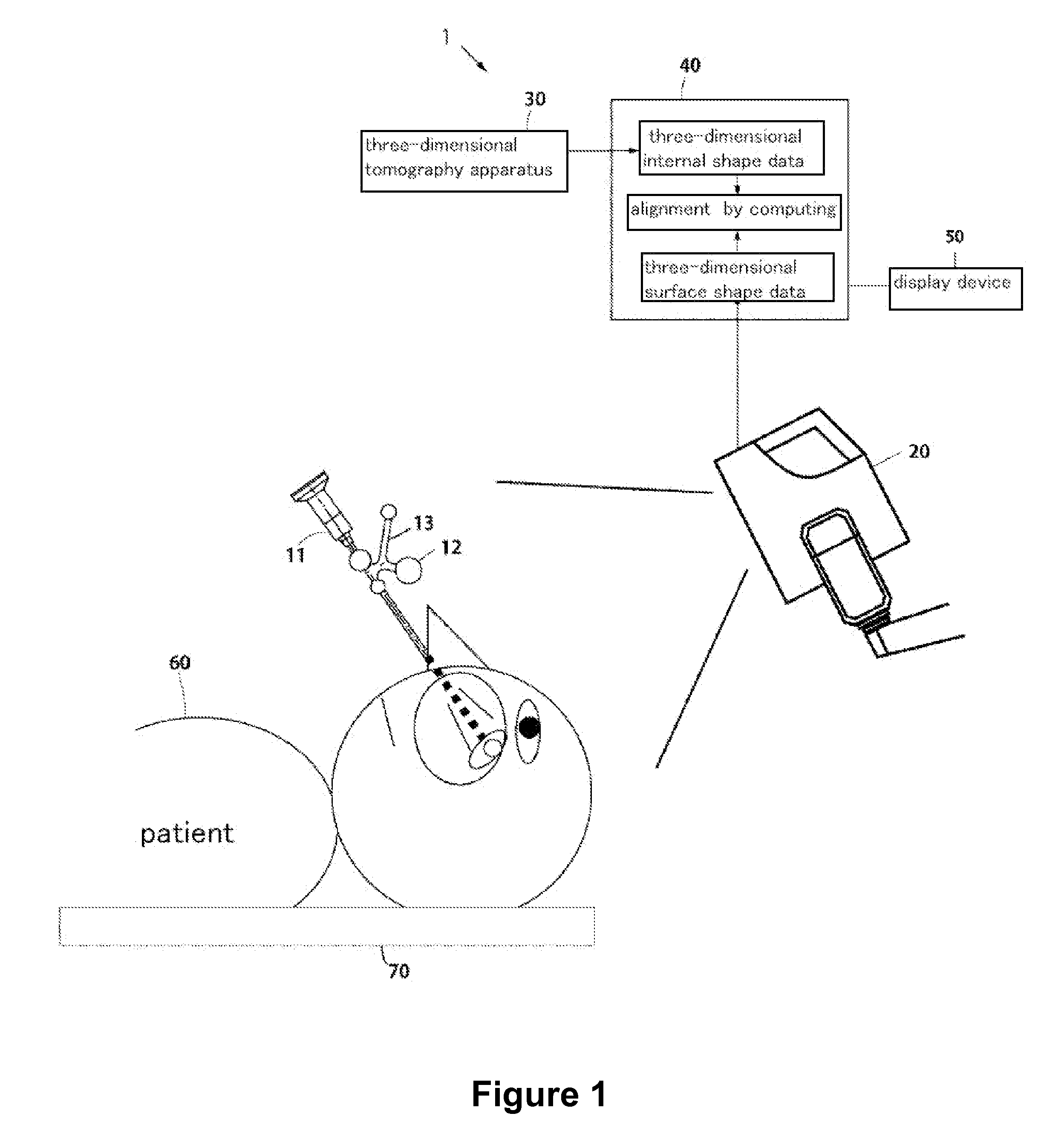

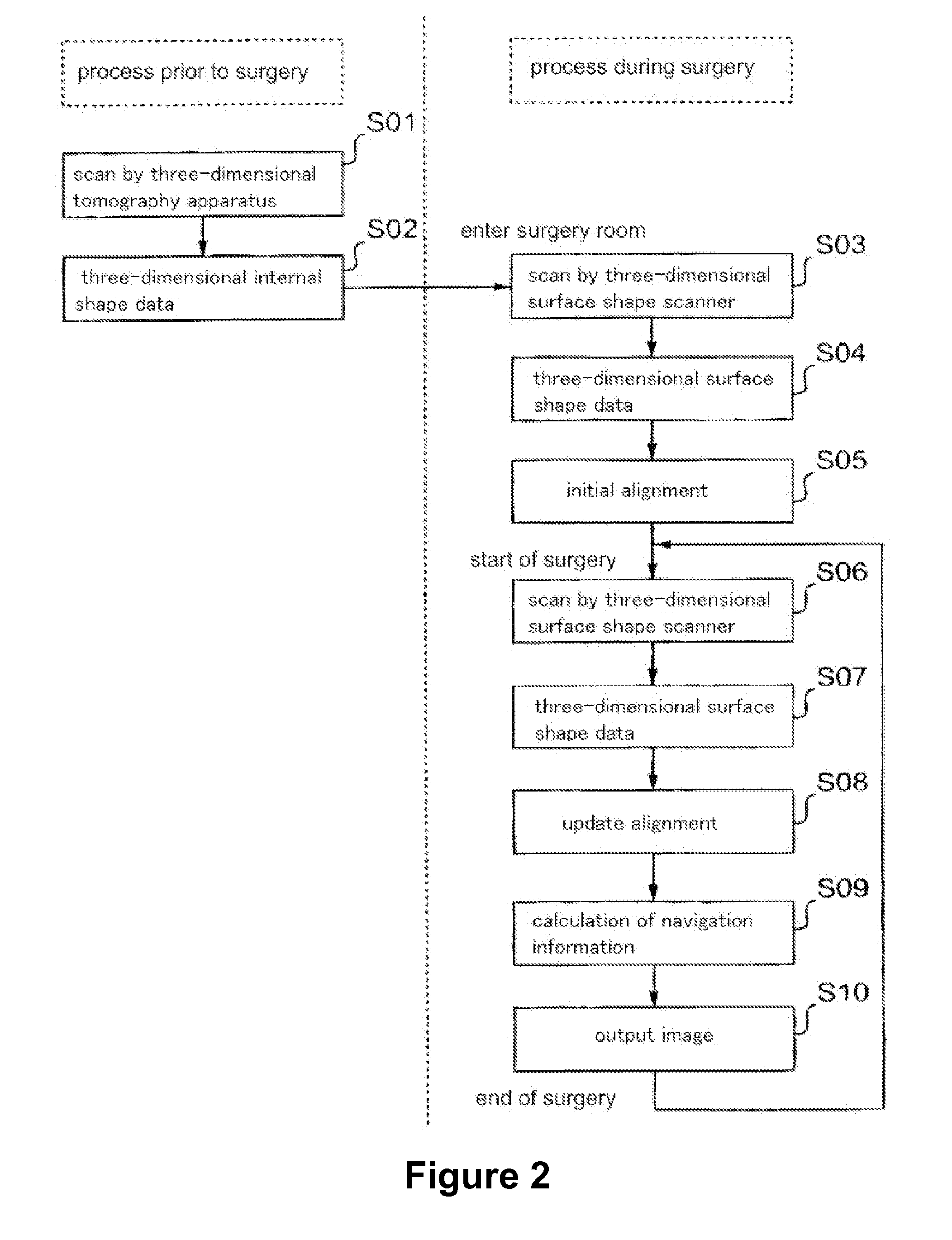

Surgery assistance system

InactiveUS20120004541A1Perform fast and accurateSurgical navigation systemsComputerised tomographsSkin surfaceMedicine

Provided is a surgery assistance system to perform relatively fast and accurate alignment between three-dimensional surface shape data acquired by measurement using a three-dimensional surface shape scanner and three-dimensional internal shape data acquired in advance, even when the position of the patient and the surface shape of the skin of the patient change during the surgery. A surgery assistance system (1) includes a three-dimensional surface shape scanner (20) for acquiring three-dimensional surface shape data by measuring a three-dimensional surface shape of a patient (60) and a computing device (40) for processing the data from the three-dimensional surface shape scanner. The computing device stores therein three-dimensional internal shape data of the patient that is acquired in advance by measurement using a three-dimensional tomography scanner (30). The computing device has a unit that aligns the three-dimensional internal shape data and the three-dimensional surface shape data with each other by using data of a portion where a distance between a skeleton and a skin surface is small in the three-dimensional internal shape data and three-dimensional surface shape data corresponding to this portion.

Owner:HAMAMATSU UNIV SCHOOL OF MEDICINE

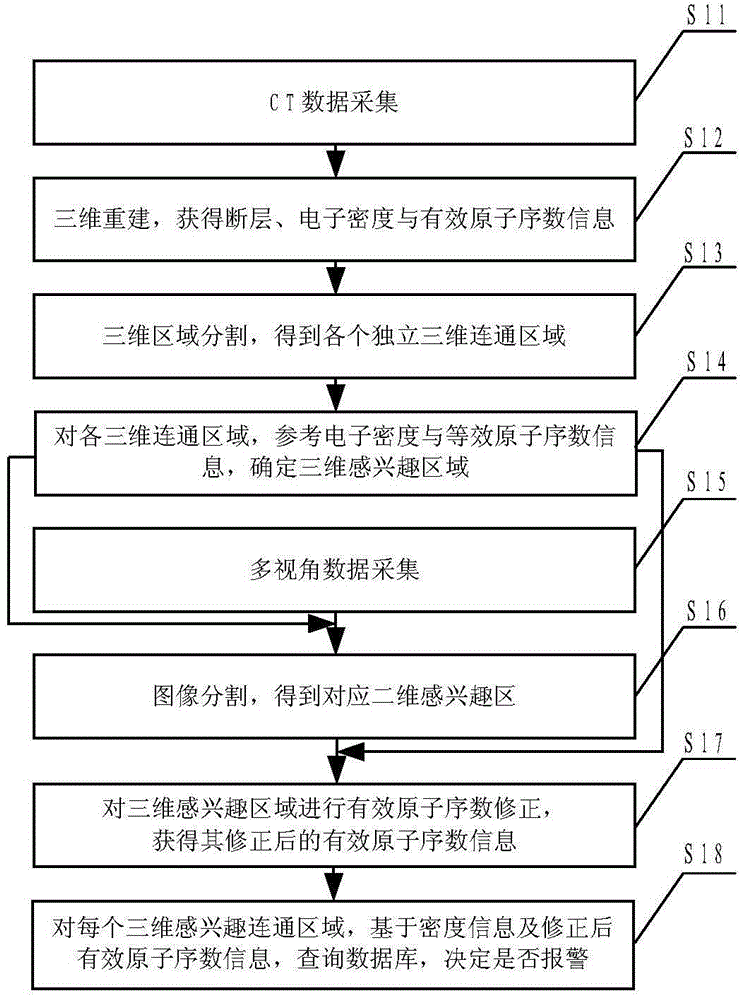

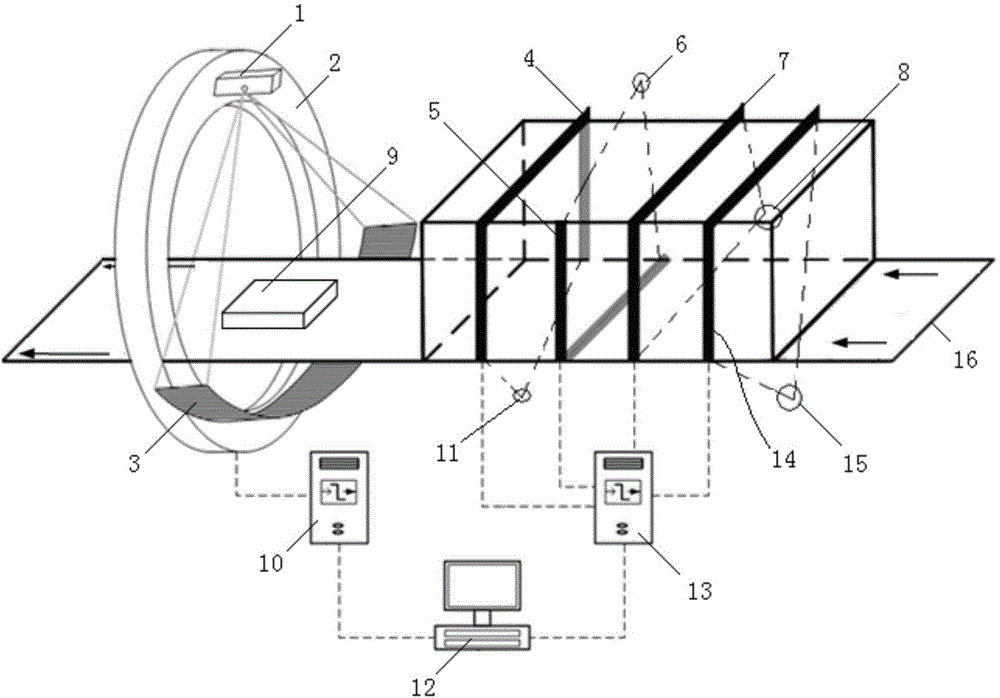

Safety detection apparatus and detection method thereof

ActiveCN105759318AHigh precisionImprove detection accuracyMaterial analysis by transmitting radiationNuclear radiation detectionHigh densityThree dimensional tomography

The invention relates to a safety detection apparatus and a detection method thereof. The safety detection apparatus comprises a CT detection apparatus and a multi-view detection apparatus, wherein the CT detection apparatus and the multi-view detection apparatus share one detection channel. The safety detection apparatus further comprises a transmission apparatus which passes through the detection channel of the CT detection apparatus and the detection channel of the multi-view detection apparatus. The safety detection method comprises a detected object passing through the CT detection apparatus and the multi-view detection apparatus, or the detected object passing through the multi-view detection apparatus and the CT detection apparatus. The advantages are as follows: the multi-view detection apparatus and the CT detection apparatus are combined for application, three-dimensional tomography structure information of the detected object is obtained by use of the CT detection apparatus, and thus the detection precision of the detected object is improved; and at the same time, the multi-view detection apparatus makes up for the disadvantage of lowered atomic number detection precision of the CT detection apparatus in a high-density metal object environment, and the precision of the whole detection apparatus is improved while the equipment cost is decreased.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

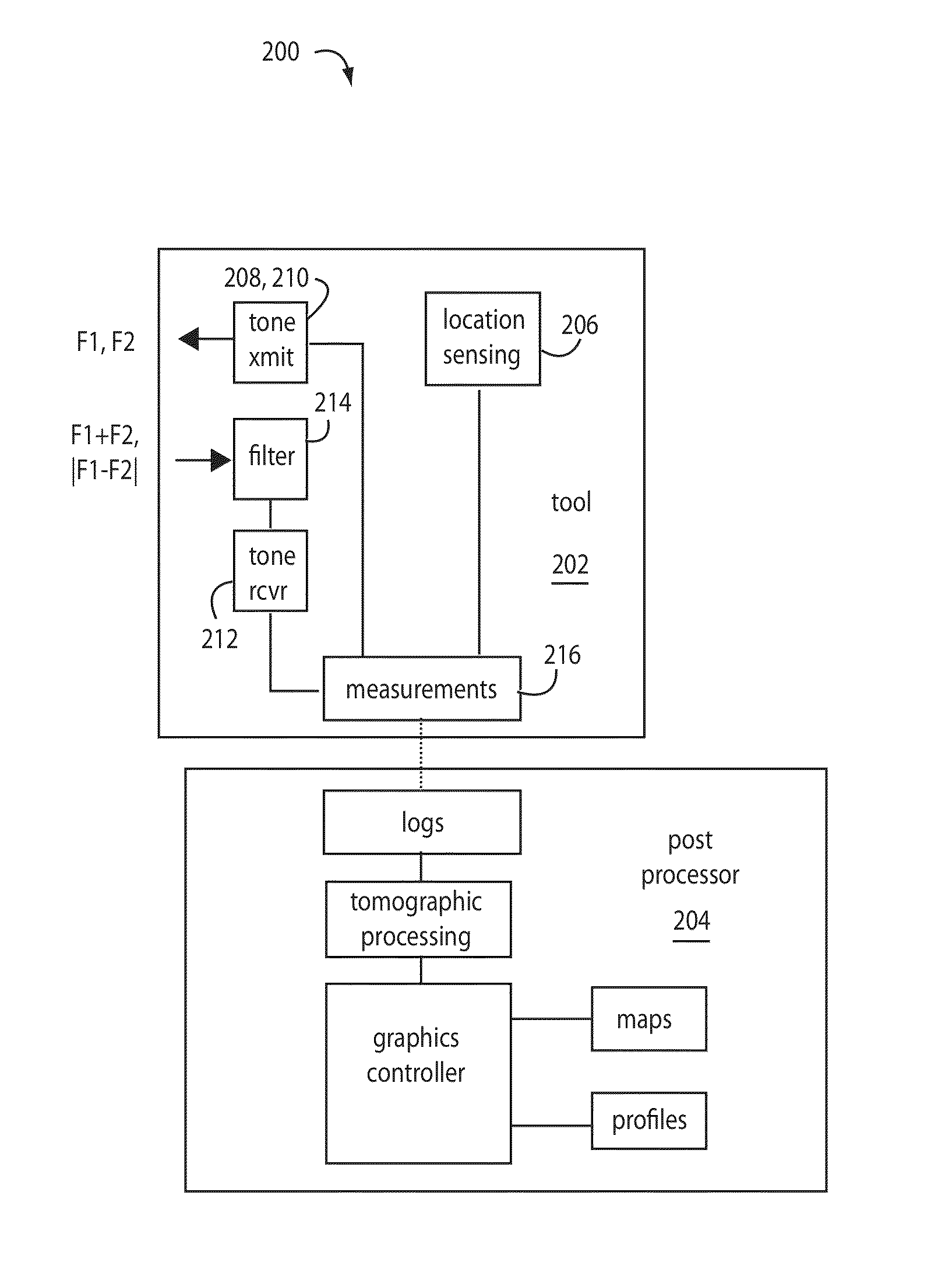

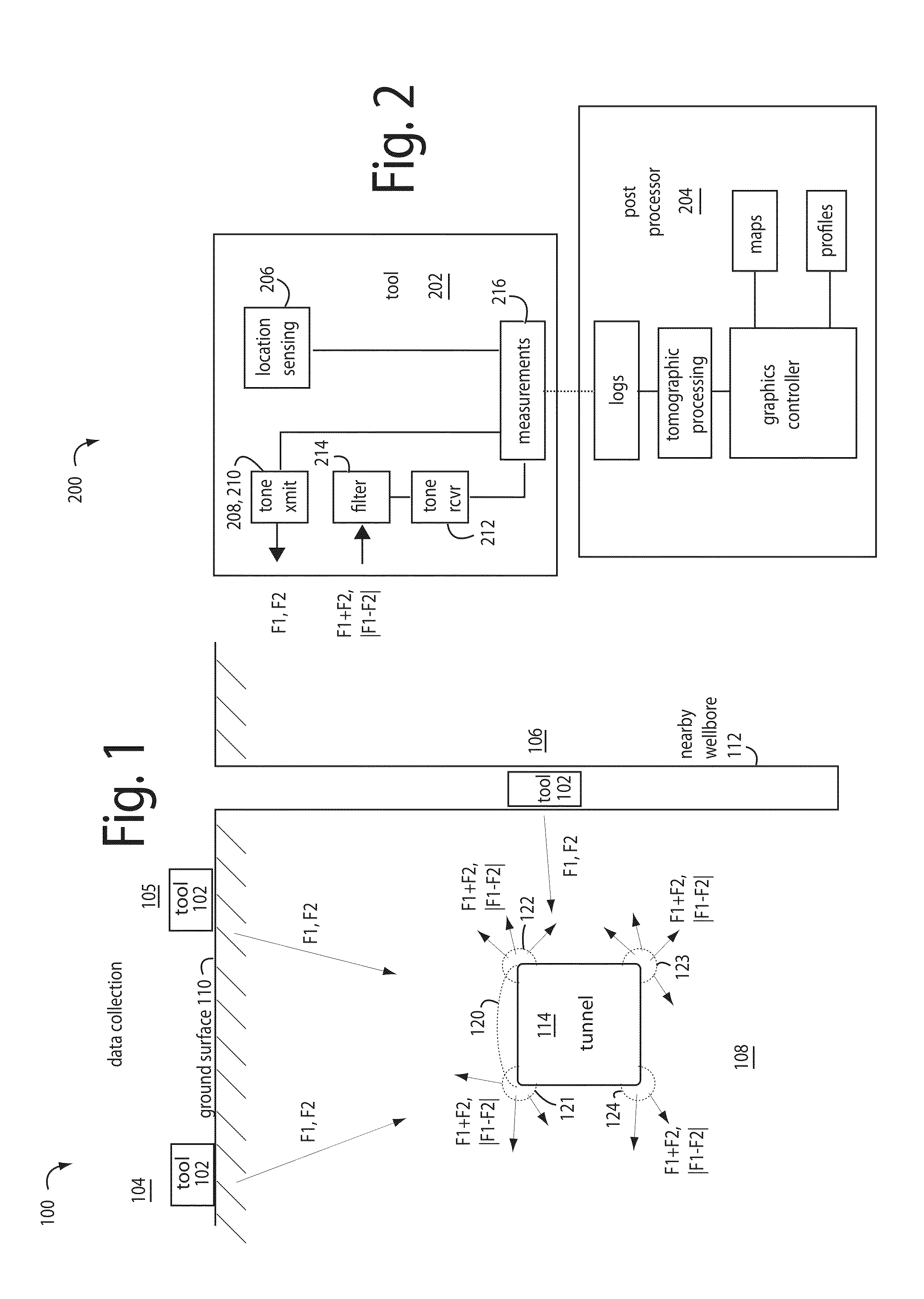

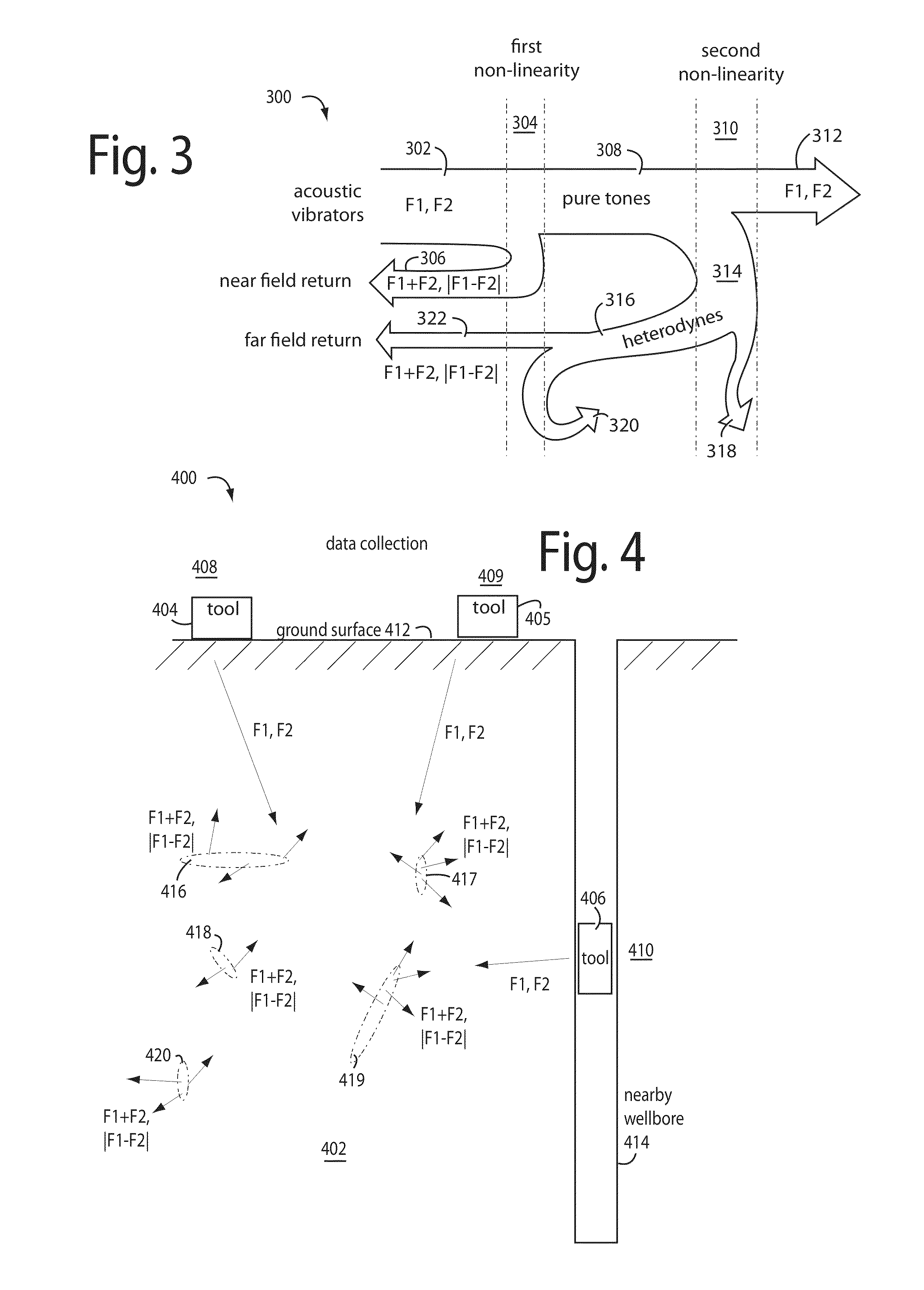

Acoustic heterodyne radar

InactiveUS20140043183A1Earthquake measurementRadio wave reradiation/reflectionGraphicsRelative attenuation

Acoustic heterodyne radars use accurately surveyed or otherwise known locations to repetitively launch at least two, intense acoustic tone soundwaves (F1, F2) into an underground area of search. An acoustic receiver is tuned to receive either the sum (F1+F2) or difference (|F1−F2|) heterodynes and is configured to measure and log the overall relative attenuation and roundtrip travel times of the soundwaves, like a typical radar. Any acoustic heterodynes received are assumed to be the work of non-linearities and stresses in the search area. A full-waveform three dimensional tomography algorithm is applied by a graphics processor to the collected and logged data to generate maps and profiles of objects beneath the ground which are interpreted to have produced the acoustic heterodynes.

Owner:STOLAR

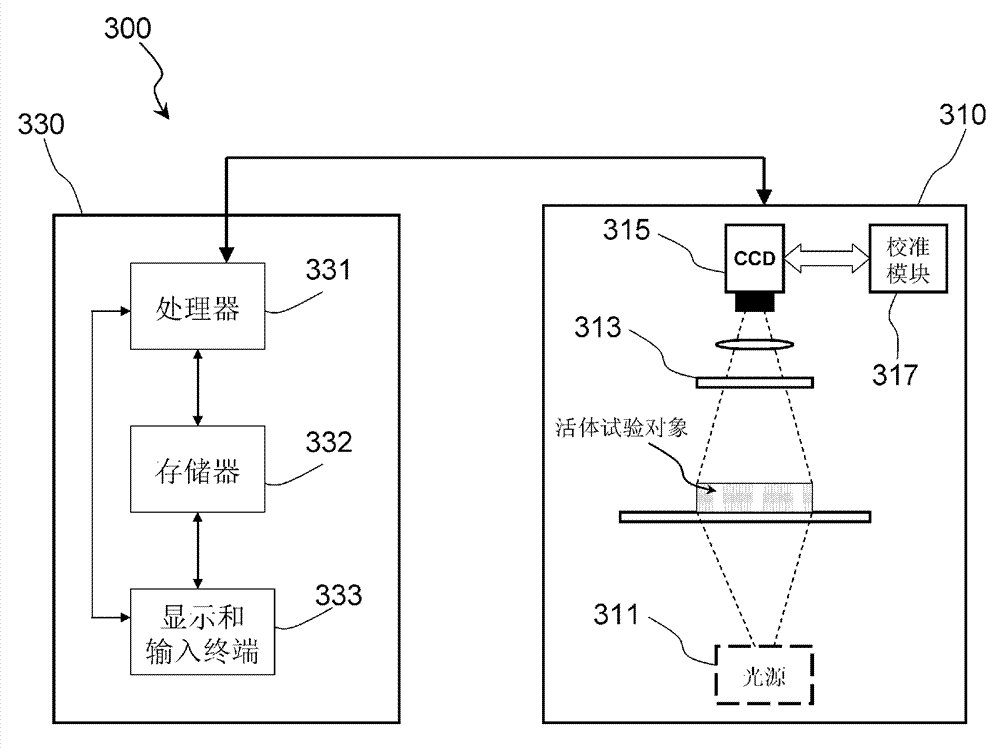

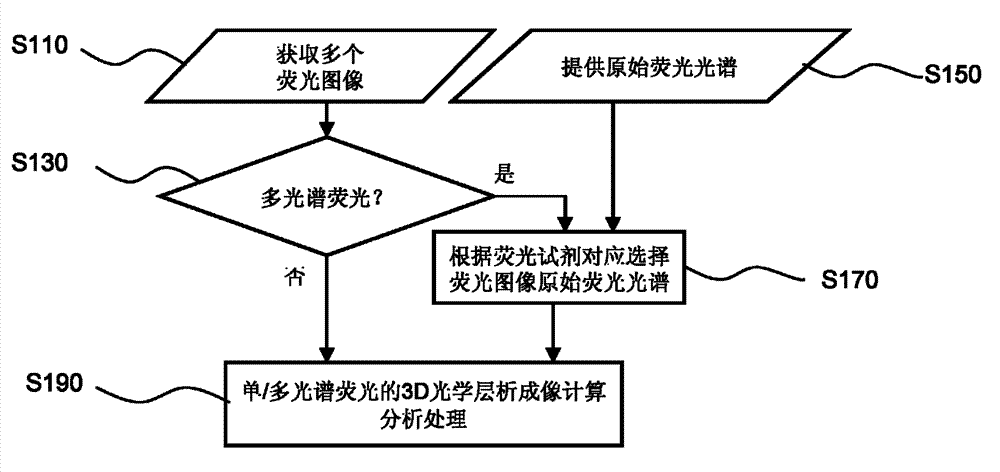

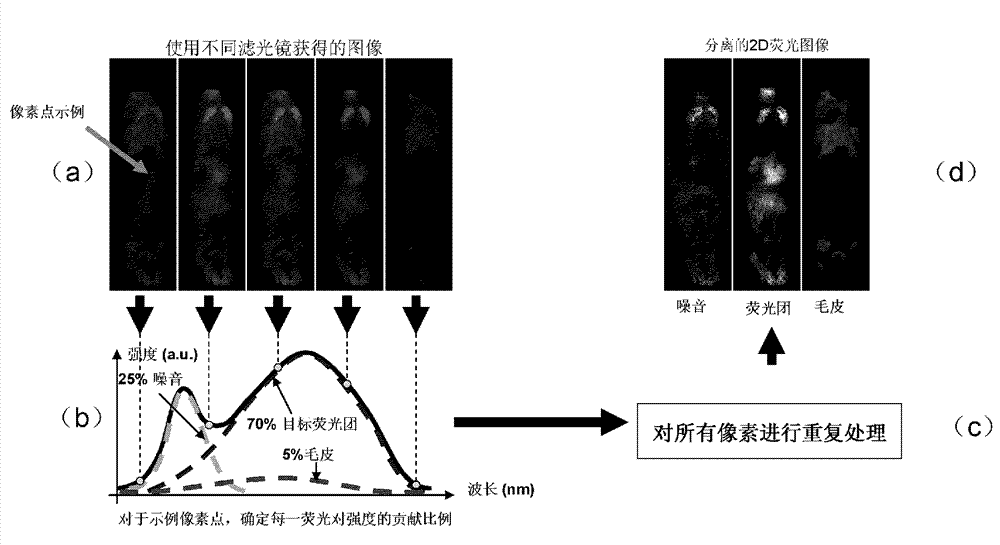

Multispectral fluorescence three-dimensional tomography method and device

InactiveCN103356165AEasy to operateImprove accuracyDiagnostic recording/measuringSensorsOptical tomographyMolecular imaging

The invention provides multispectral fluorescence three-dimensional tomography method and device and belongs to the technical field of molecular imaging. The method includes: acquiring a multispectral fluorescence image from a target living body, subjecting the data of the multispectral fluorescence image to multispectral fluorescence three-dimensional optical tomography calculation and analysis in order to reconstruct a three-dimensional fluorescence image on the basis of original fluorescence spectra of multiple fluorescent reagents used in the target living body. The device allows for 3D imaging by the multispectral fluorescence three-dimensional tomography method, is fine in accuracy and reality of 3D fluorescence images and is simple for users to operate during the process of 3D tomography.

Owner:RAYCO SHANGHAI MEDICAL PROD

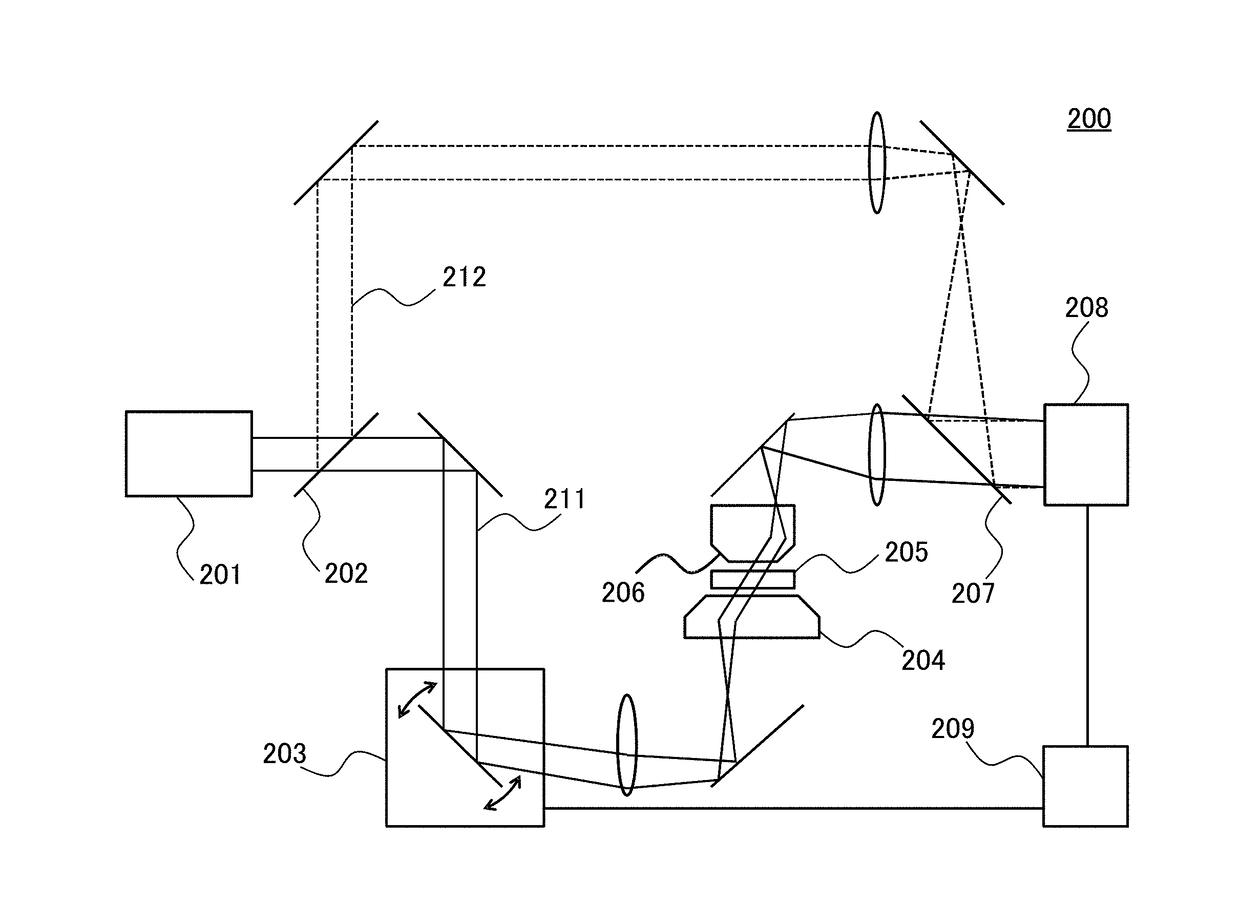

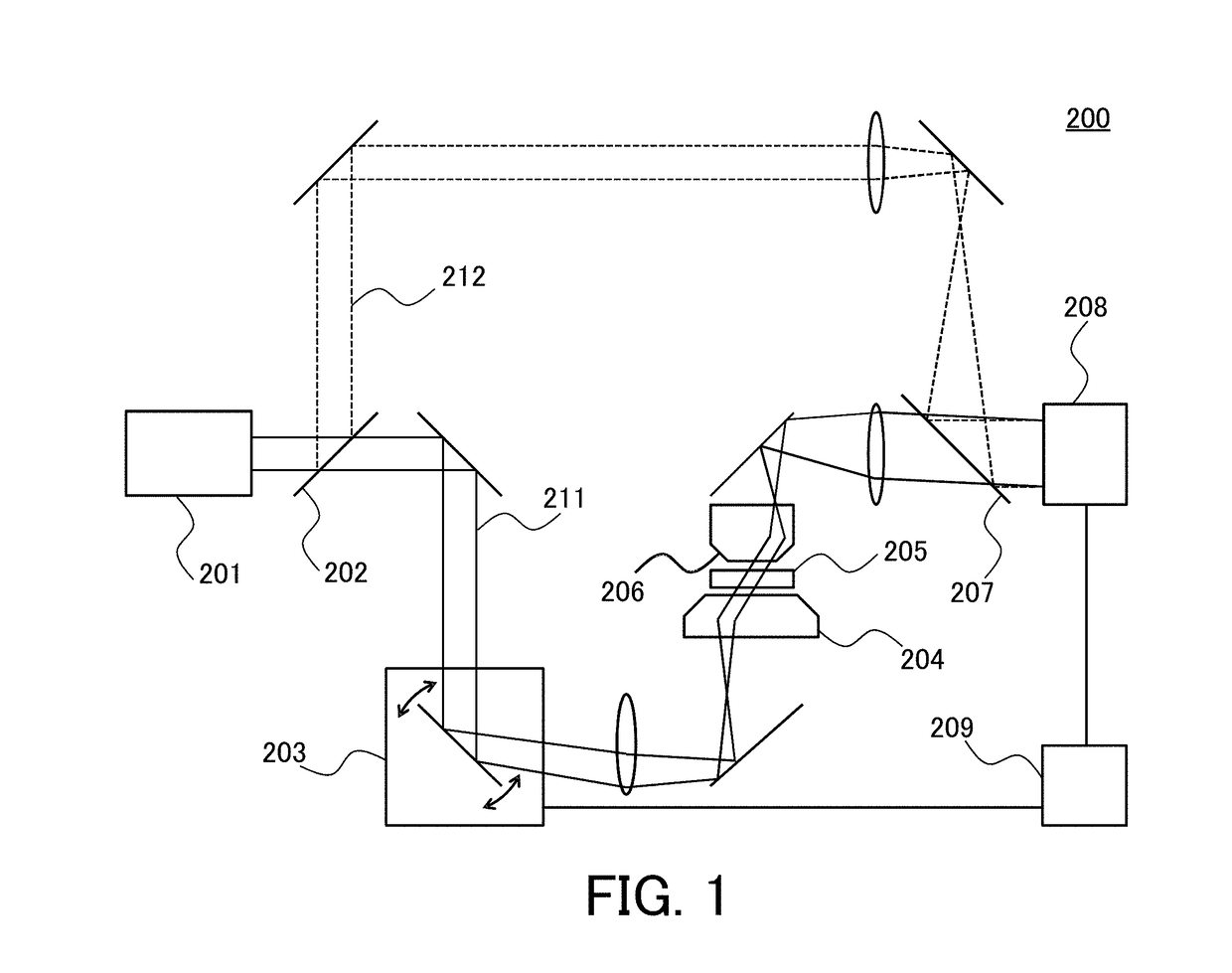

Three-dimensional image capturing apparatus and image capturing method using digital holography

InactiveUS20170199495A1Improve accuracySimple configurationHolographic light sources/light beam propertiesHolographic optical componentsThree dimensional tomographyLight beam

An image capturing apparatus (500) capable of performing three-dimensional tomography of an object by digital holography, includes a splitting element (502) which splits a light beam emitted from a light source into an object light beam and a reference light beam, an illumination system (503) which controls a plurality of object light beams that are generated from the object light beam and that move in directions different from each other to be incident on the object simultaneously, a composite element (507) which causes the plurality of object light beams to interfere with the reference light beam, an image sensor (508) which acquires hologram generated by interference of each of the plurality of light beams with the reference light beam, and a controller (509) which controls the illumination system so that the plurality of object light beams interfere with each other on the image sensor.

Owner:CANON KK

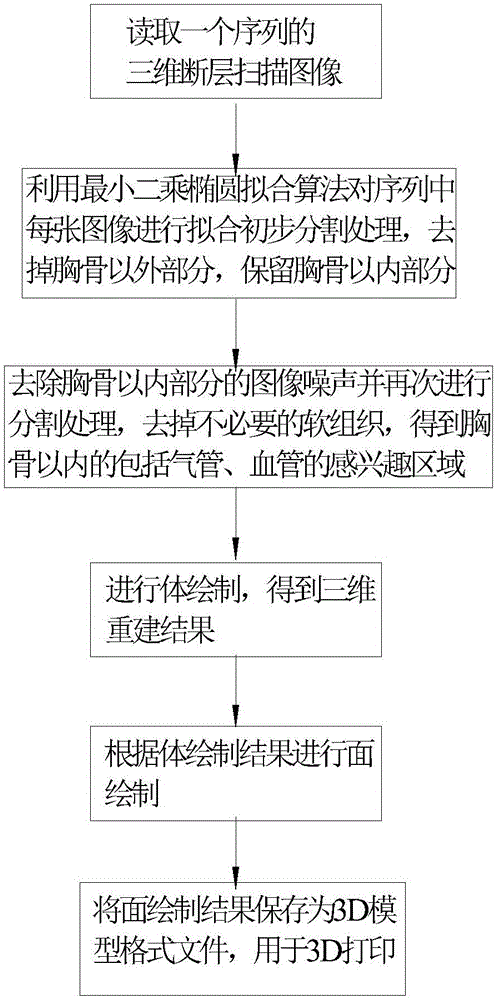

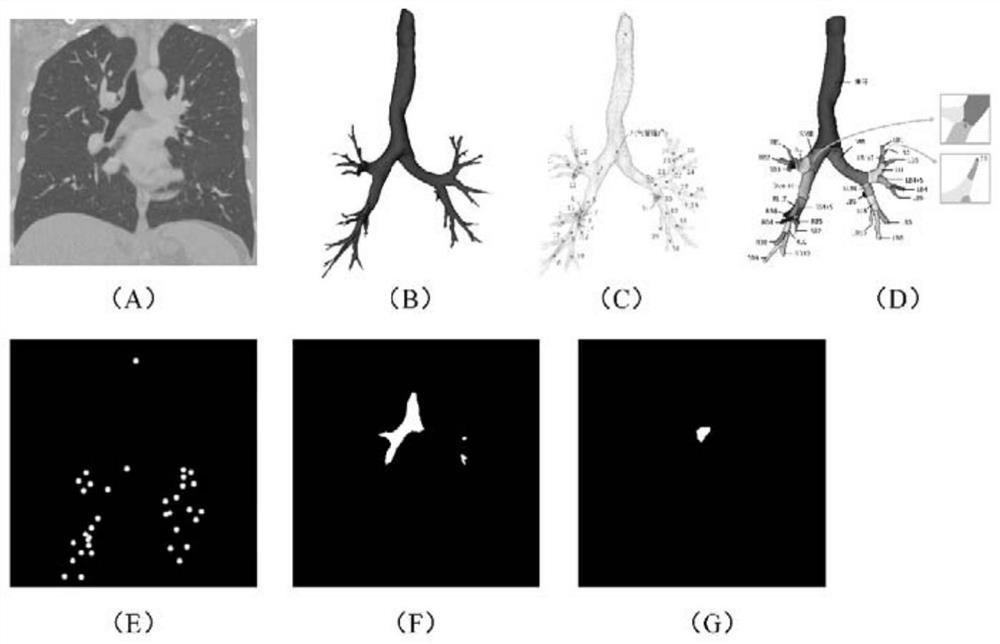

Automatic extraction method of human chest organ tissue

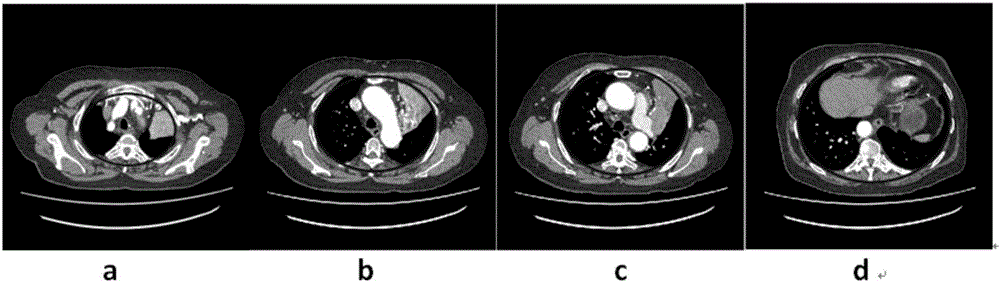

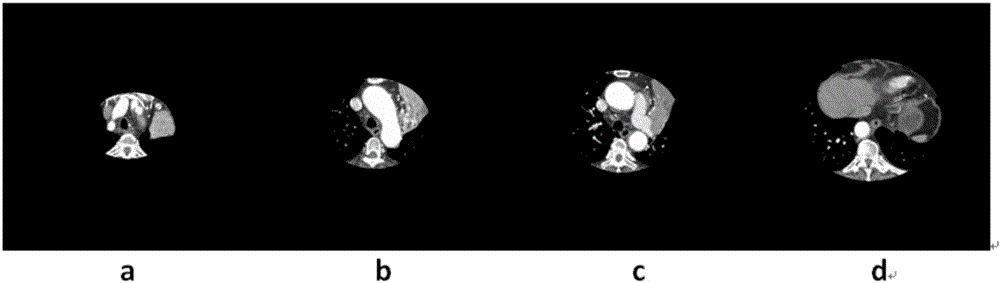

ActiveCN106355586AAchieve rotationSolve the problem that the image segmentation is not clear enoughImage enhancementImage analysisHuman bodyBreast bone

The invention discloses an automatic extraction method of human chest organ tissue, belongs to the technical field of medical image processing, and aims to solve the problems that boundaries of organ tissue are unsmooth and observation by researchers and clinicians is affected due to the fact that an existing image segmentation technology is not clear enough. The automatic extraction method is characterized by comprising steps as follows: reading three-dimensional tomography images; performing fitting and primary segmentation processing on each image in a sequence with a least square ellipse fitting algorithm, parts outside sternums are removed, and parts inside the sternums are reserved; image noise of the parts inside the sternums is removed, segmentation processing is performed again to remove unnecessary soft tissue, and regions of interest, including trachea and blood vessels, inside the sternums are obtained; volume rendering and surface rendering are performed. Medical image segmentation has great significance in three-dimensional visualization, three-dimensional positioning, operation planning formulation and computer assisted diagnosis. With the adoption of the automatic segmentation method, the effect of subjective factors of an observer is completely avoided, the data processing speed is increased, and the repeatability is good.

Owner:HEILONGJIANG TUOMENG TECH CO LTD

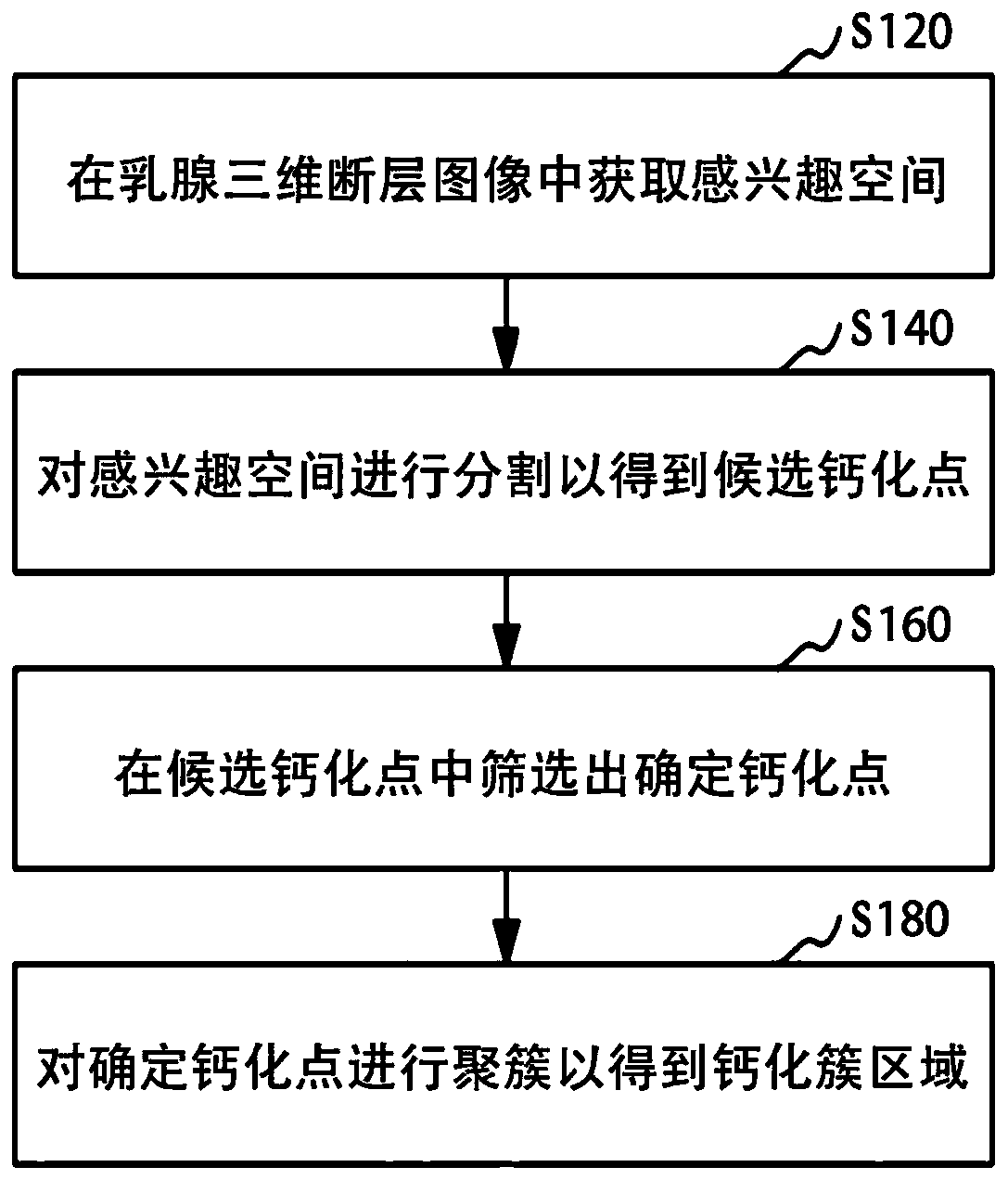

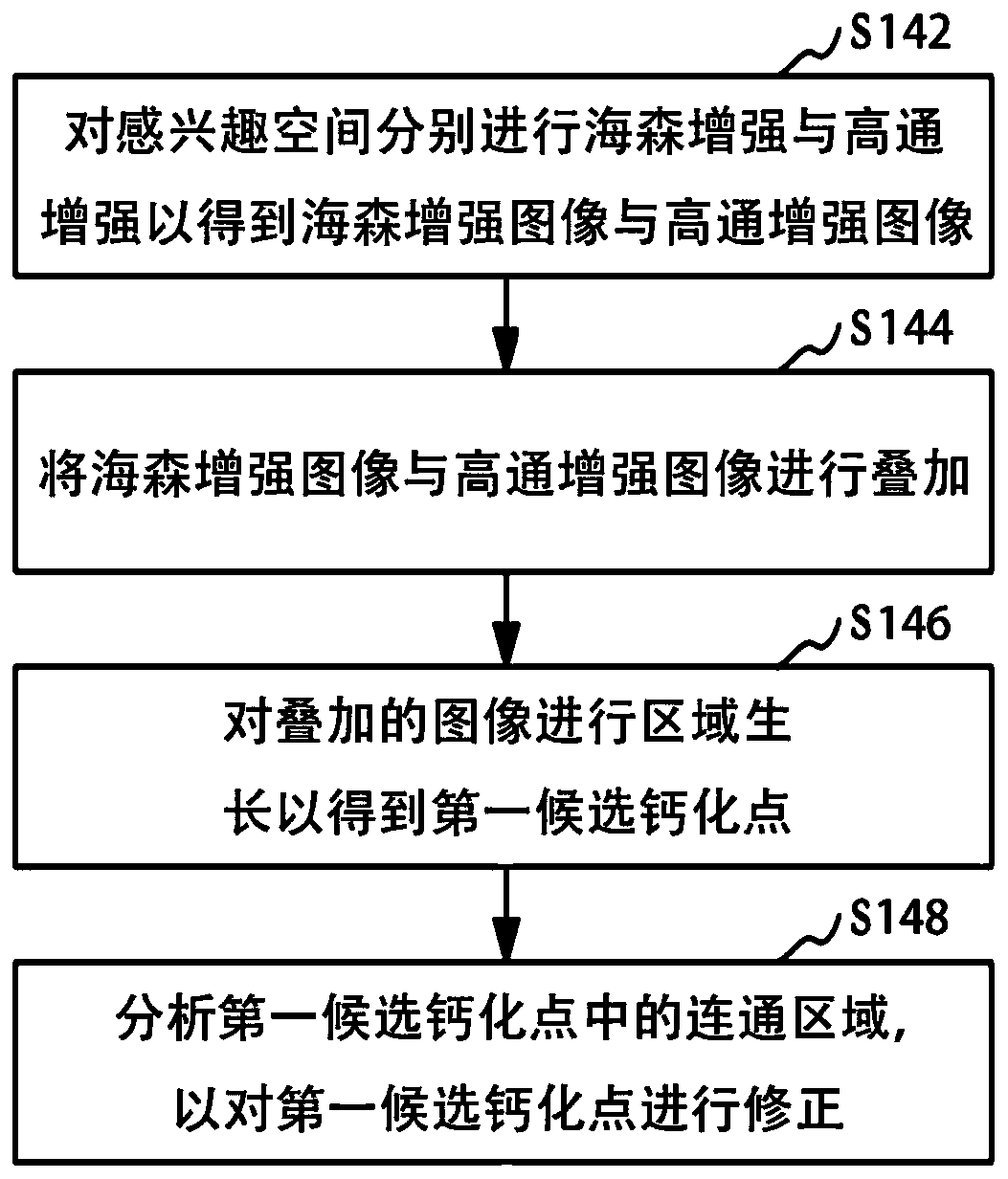

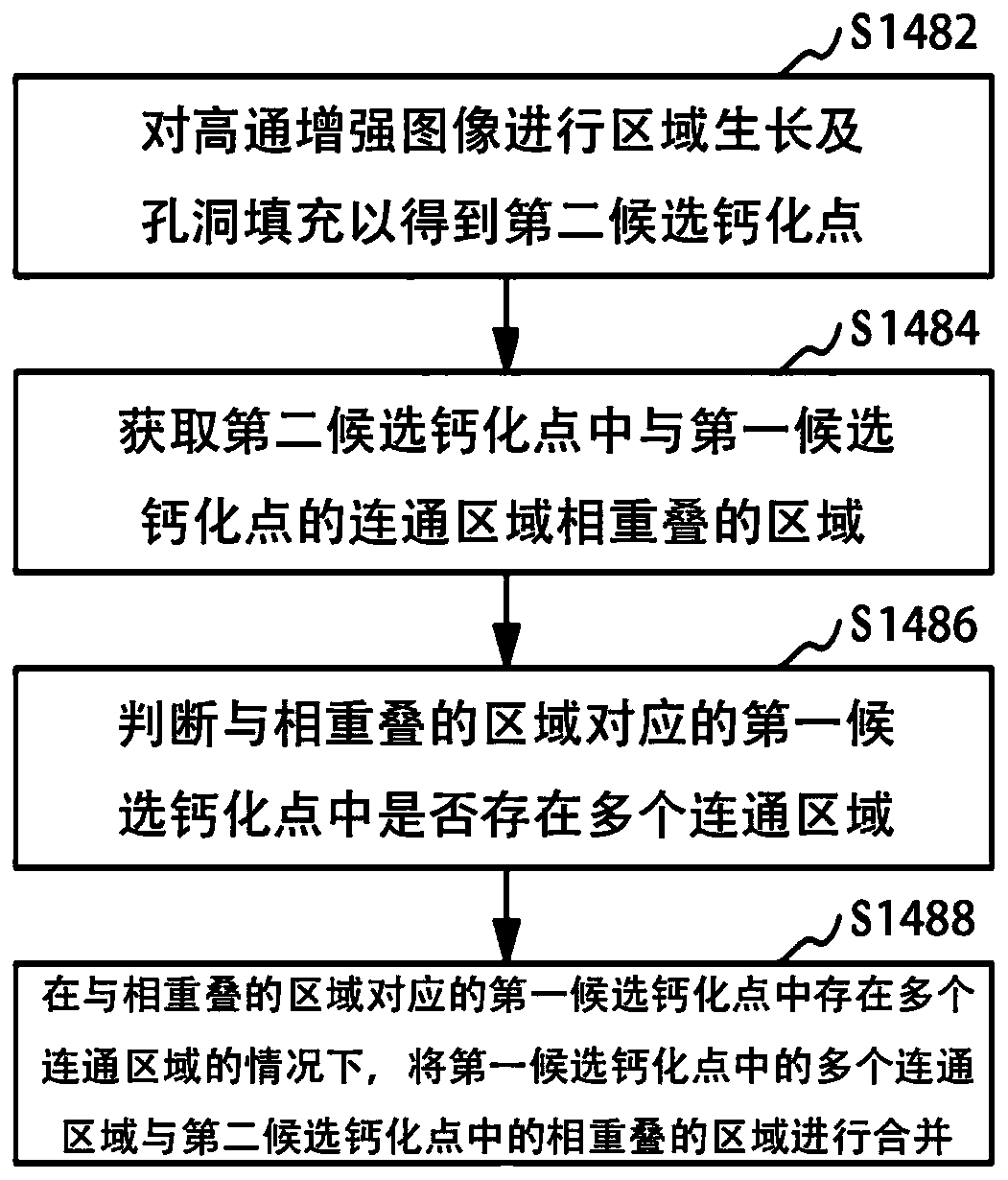

Calcified cluster positioning method and device, computer equipment and storage medium

The invention relates to a calcified cluster positioning method and device, computer equipment and a storage medium, and the calcified cluster positioning method is applied to a mammary gland three-dimensional tomographic image, and comprises the steps: obtaining an interested space in the mammary gland three-dimensional tomographic image; segmenting the space of interest to obtain candidate calcification points; screening out and determining a calcification point from the candidate calcification points; and clustering the determined calcification points to obtain a calcification cluster region. According to the positioning method of the calcified cluster, the interested space is selected from the mammary gland three-dimensional tomographic image; According to the method, the interested space can be segmented and screened, the calcification points are clustered after being obtained, so that positioning of the calcification clusters is achieved, only reconstructed mammary gland three-dimensional tomography image data are needed in the positioning process, scanned original data are not needed, the processed data size is reduced, and positioning of the calcification clusters is rapidand accurate.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

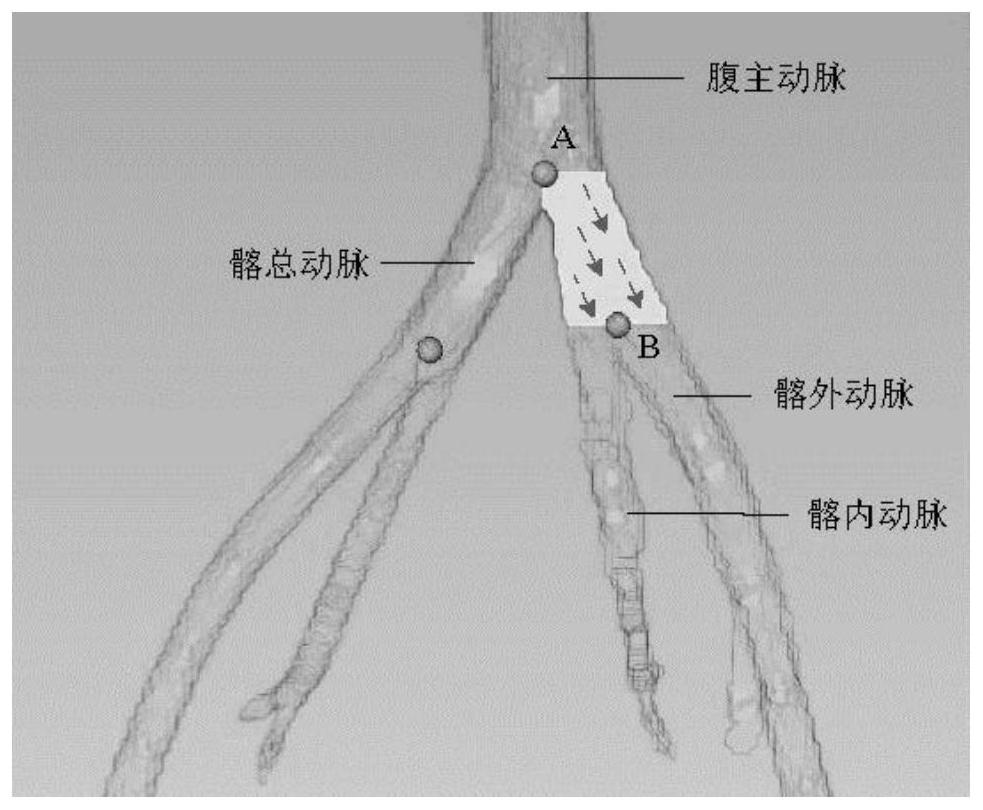

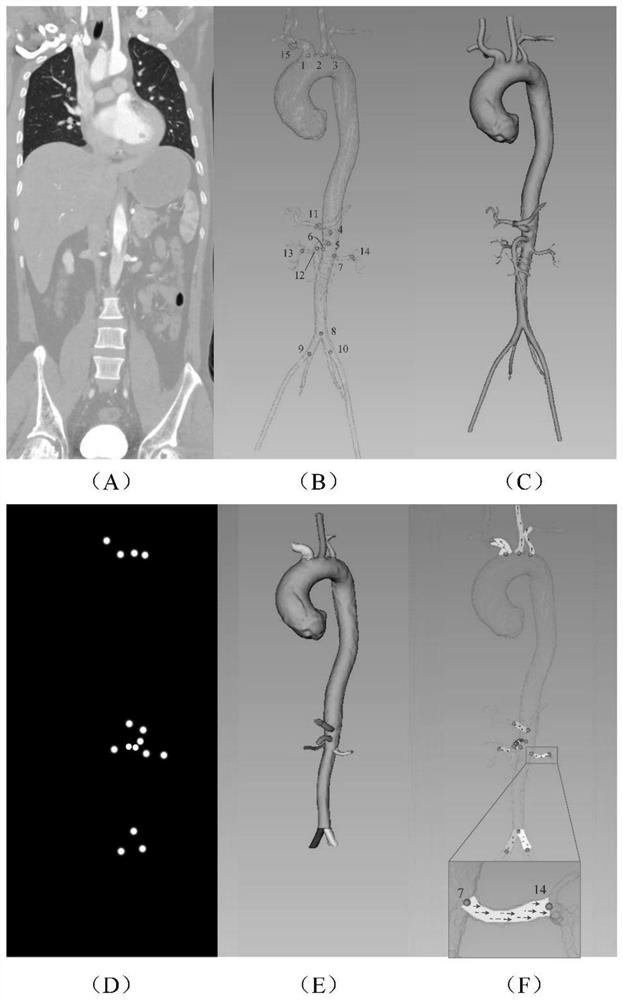

Method for detecting tree-shaped structure bifurcation key point in three-dimensional tomography image

Owner:TSINGHUA UNIV

Three-dimensional tomography method based on seismic wave in-phase axis slope information

InactiveCN109387868ASolve for stabilityAvoid distractionsSeismic signal receiversSeismic signal processingThree dimensional tomographyClassical mechanics

The invention relates to a three-dimensional tomography method based on seismic wave in-phase axis slope information. The method comprises the steps that 1) effective data picking is carried out on athree-dimensional common shot point gather and a common detection wave point gather to acquire horizontal component information of ray parameters at shot points and detection wave points; 2) a three-dimensional slope tomographic matrix is established according to the acquired horizontal component information of the ray parameters at the shot points and detection wave points; 3) a regularization term is added into the linear equations of the established three-dimensional slope tomographic matrix to acquire large-scale sparse linear equations; and 4) the large-scale sparse linear equations are solved to acquire a macroscopic velocity model of slope tomographic inversion, and the model is used for three-dimensional migration imaging or as an initial model of three-dimensional full waveform inversion. The method provided by the invention can be widely applied in the field of exploration seismology.

Owner:CHINA NAT OFFSHORE OIL CORP +1

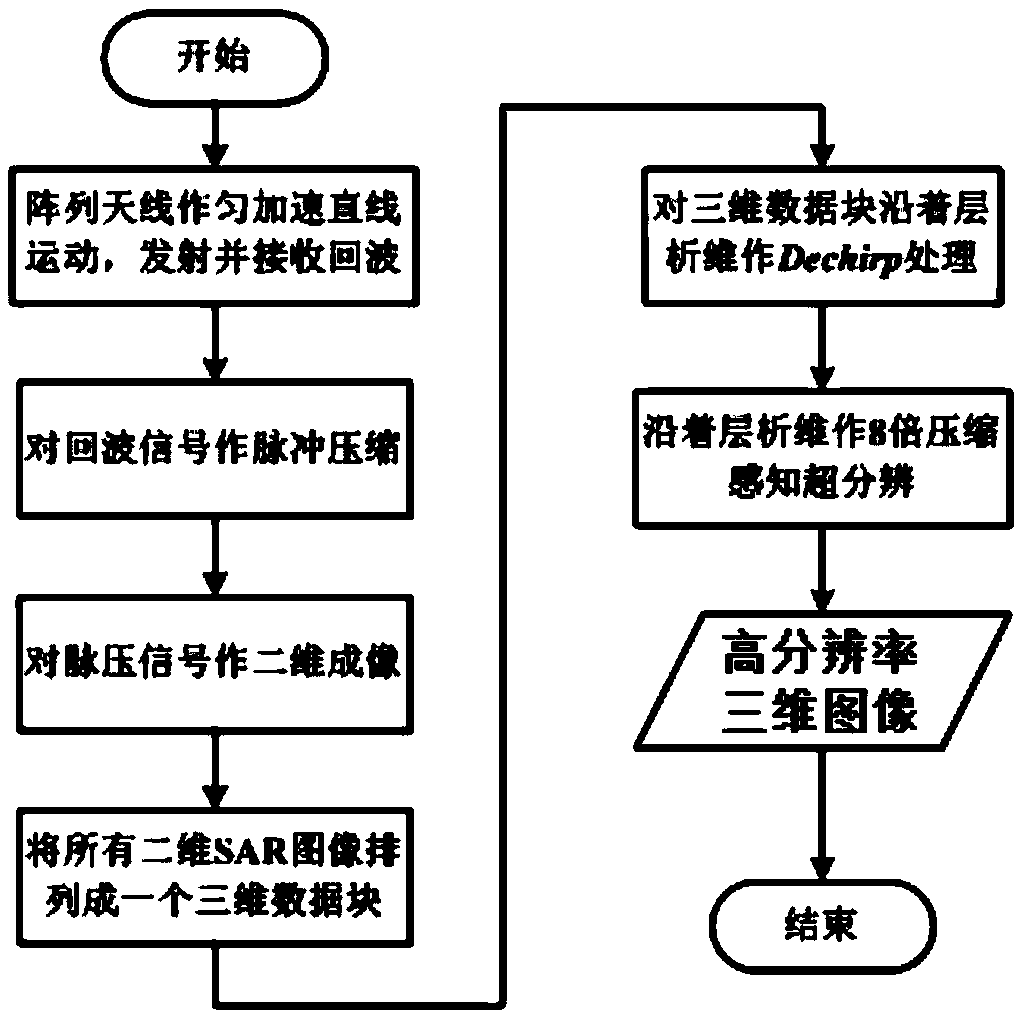

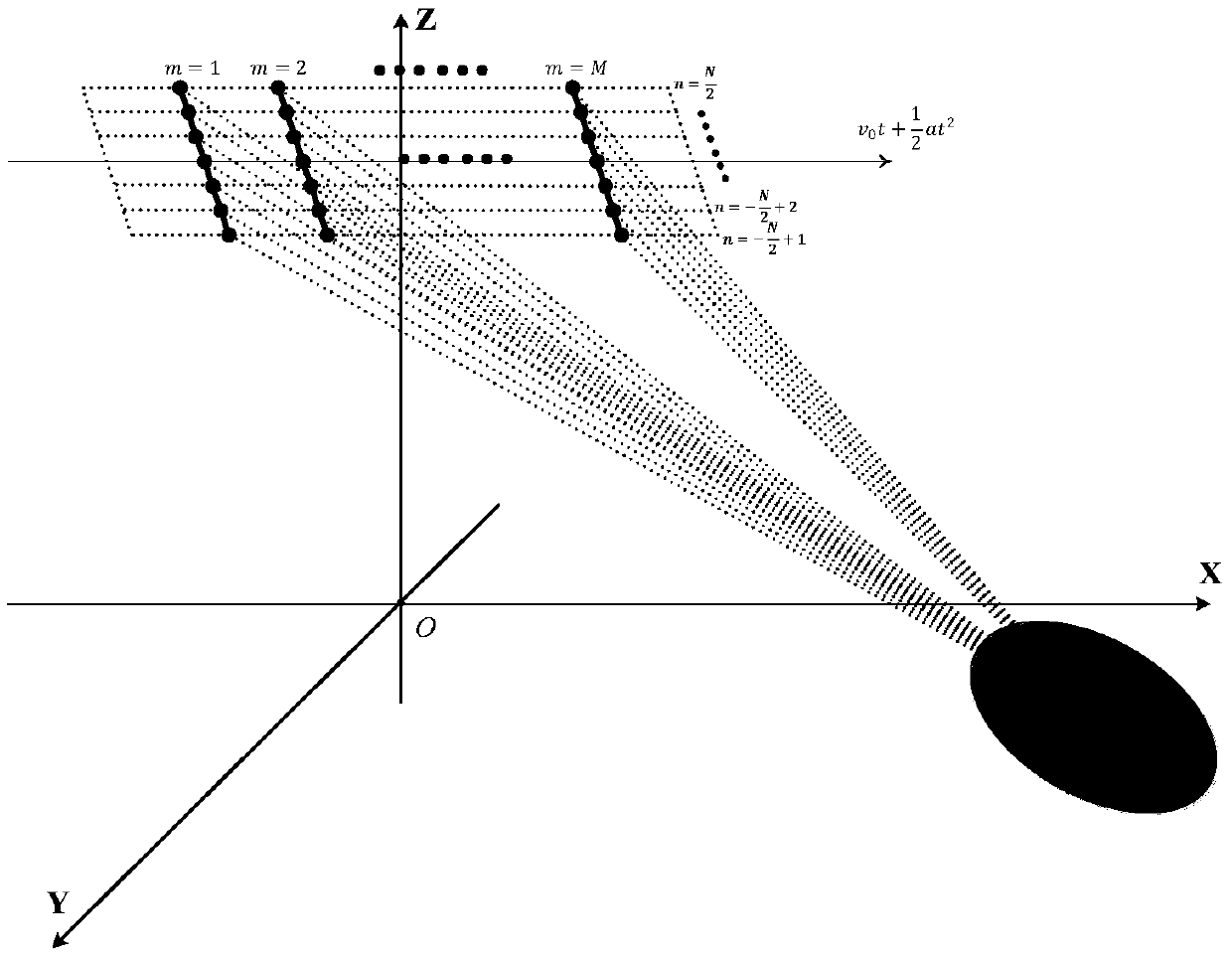

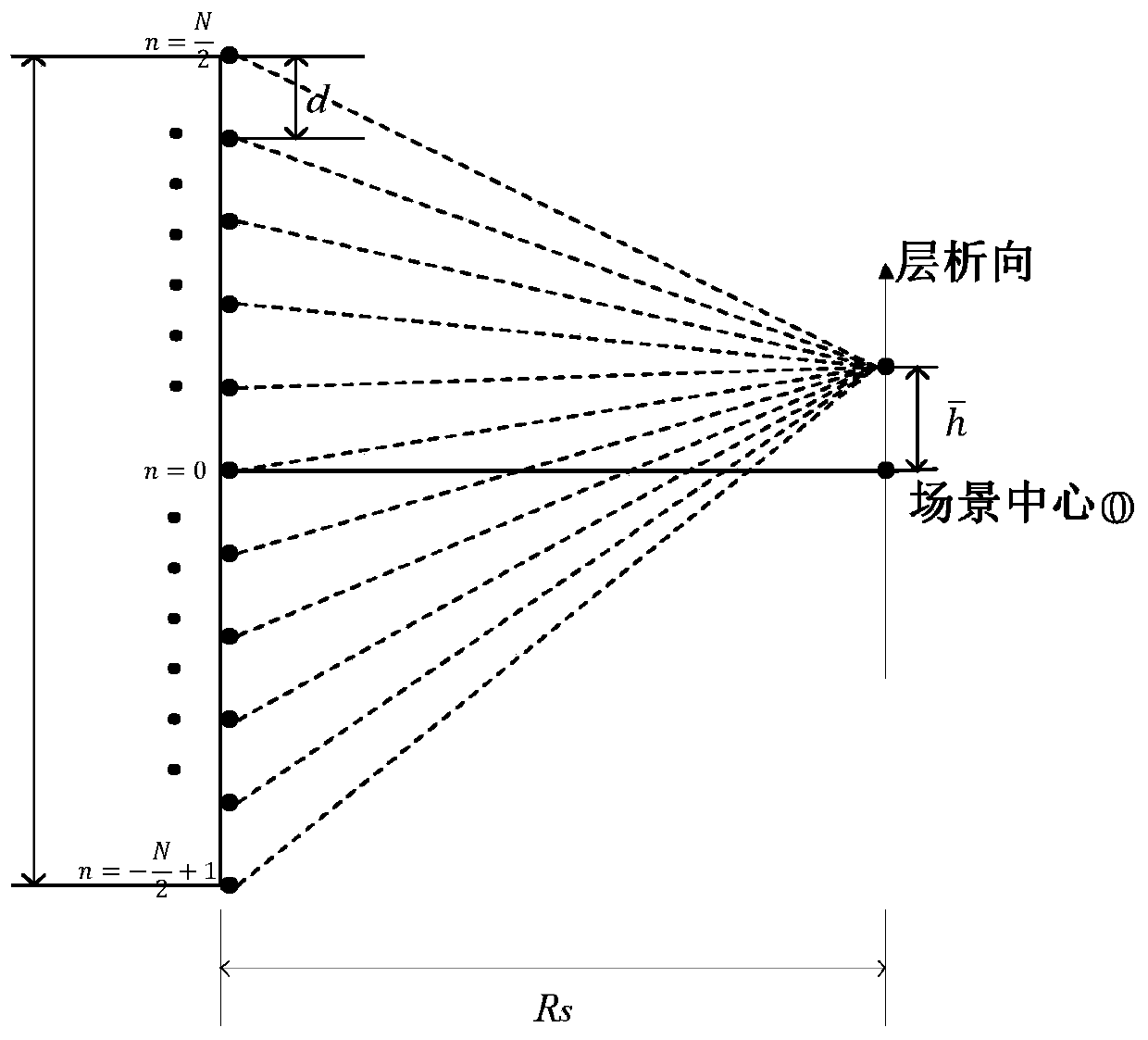

Maneuvering track front side view synthetic aperture radar tomography method

ActiveCN110146884AHigh-resolutionAvoid the defect of oversampling in the angle domainRadio wave reradiation/reflectionRadarThree dimensional tomography

The invention discloses a maneuvering track front side view synthetic aperture radar tomography method. The method comprises the following steps of in a maneuvering track front side view three-dimensional tomography process, uniformly dividing a route along an azimuth direction to obtain sub-apertures with a same length, and establishing a corresponding polar coordinate grid for each sub-aperture,wherein an angular domain division interval of each polar coordinate grid is determined by the sub-aperture length; then, projecting each sub-aperture data to the corresponding polar coordinate gridto form a sub-aperture image and acquiring a distance-azimuth two-dimensional imaging result through interpolation fusion; and finally, carrying out super-resolution sparse reconstruction on the datain each distance-azimuth unit along a chromatography direction through using a compressed sensing method to obtain a high-resolution three-dimensional tomography result. In the method of the invention, the lengths of the sub-apertures are the same, a problem of excessive sampling of an angular domain of the shorter sub-aperture and a large number of redundant projection operations during an entireimaging process when the lengths of the sub-apertures are not uniform are avoided, and imaging efficiency is increased.

Owner:XIDIAN UNIV

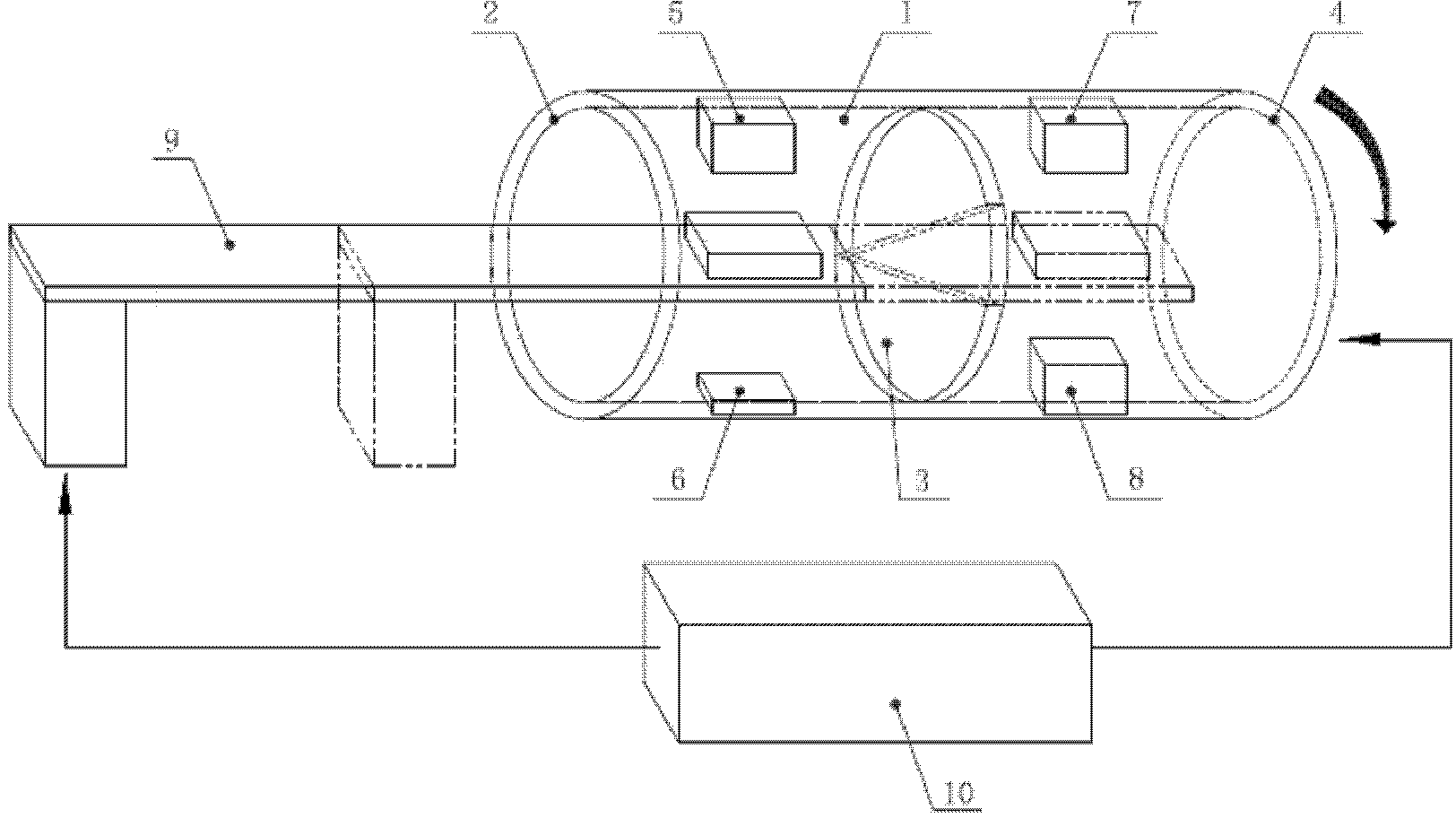

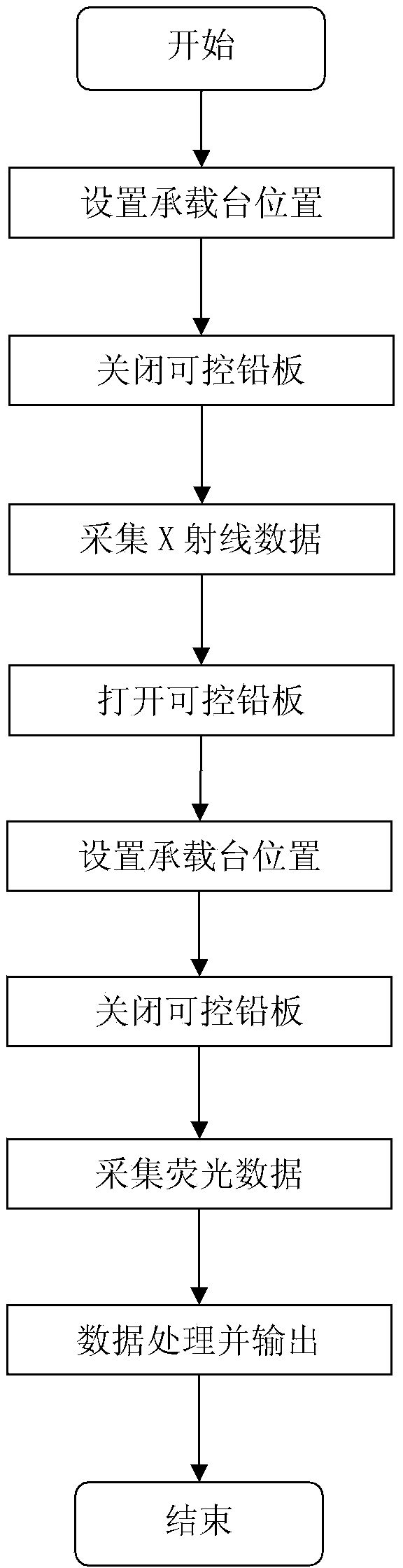

Separate multimode fusion three-dimensional tomography system and method

ActiveCN103431912AGet quicklyEliminate interactionSurgeryComputerised tomographsDiagnostic Radiology ModalityData acquisition

The invention discloses a separate multimode fusion three-dimensional tomography system and a separate multimode fusion three-dimensional tomography method. The system comprises a data source transmission module, a data acquisition module, a system control and data transmission module and a data processing module, wherein the data source transmission module is used for transmitting X rays and an exciting light source to irradiate a sample respectively; the data acquisition module is used for detecting the dose of the X rays passing through the sample, and receiving fluorescent information excited from the sample; the system control and data transmission module is used for controlling the ordered operation of each module in the system; the data processing module is used for processing the acquired imaging data of the sample, and three-dimensionally reconstructing the structure information of the sample and light source distribution information. The system and the method can be used for realizing the real-time and nondestructive multimode image acquisition of in vivo fluorescence molecular imaging and X-ray tomography, the biological information of an imaging sample can be rapidly obtained, influence between modes is overcome in terms of physical position, and meanwhile, different mode data of the imaging sample can be well fused in terms of physical position.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

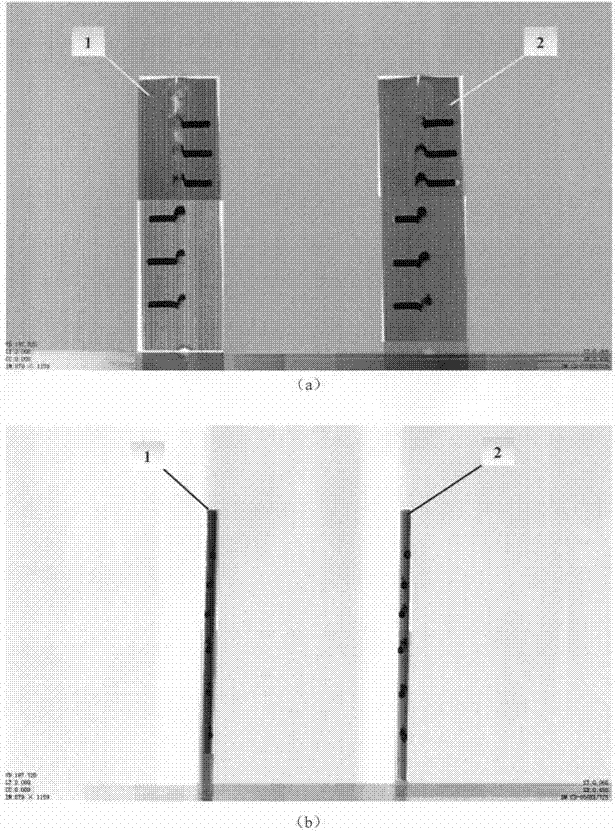

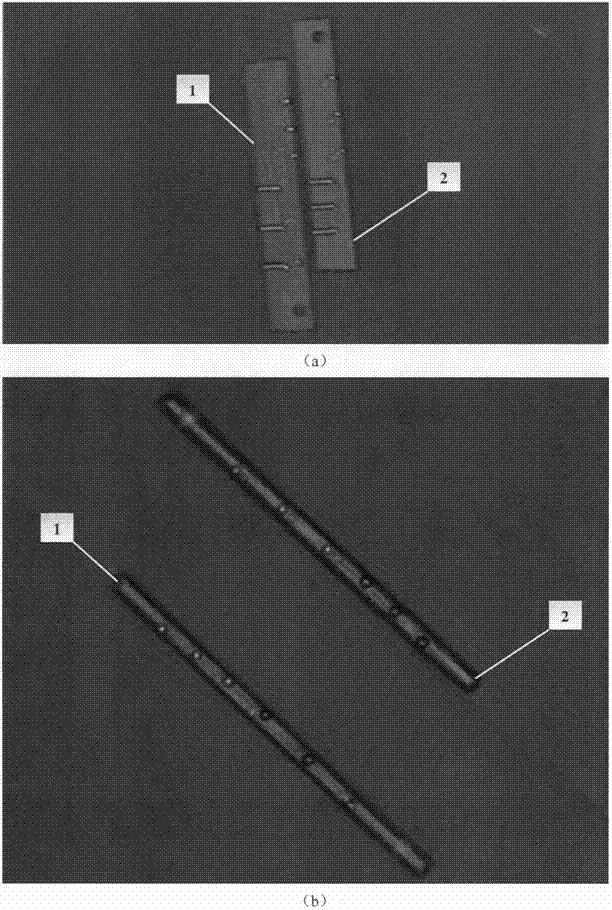

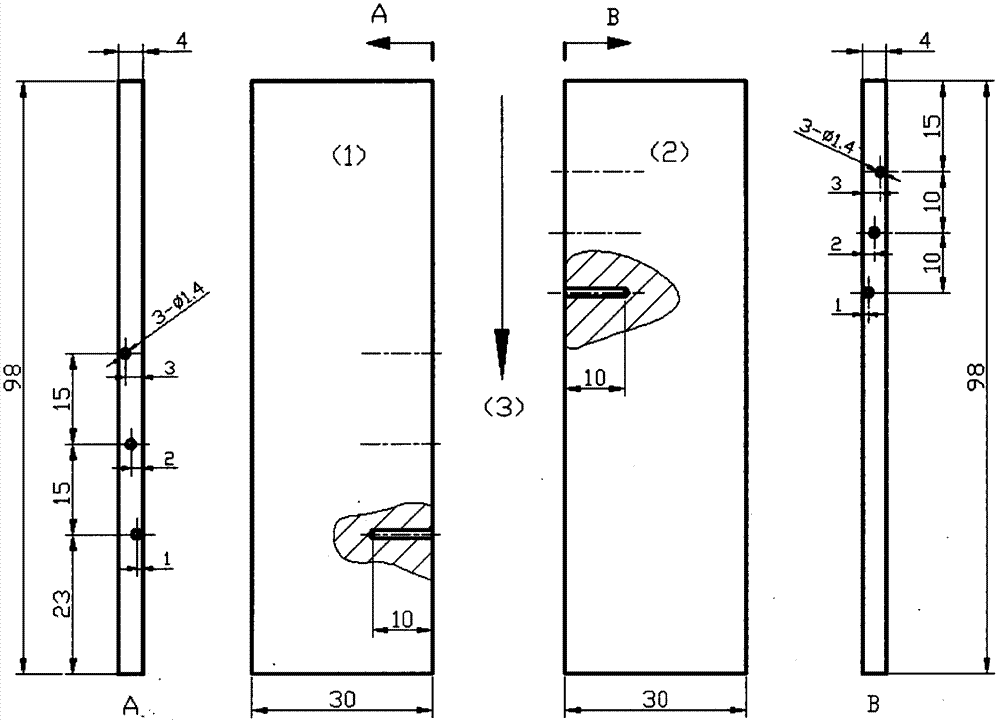

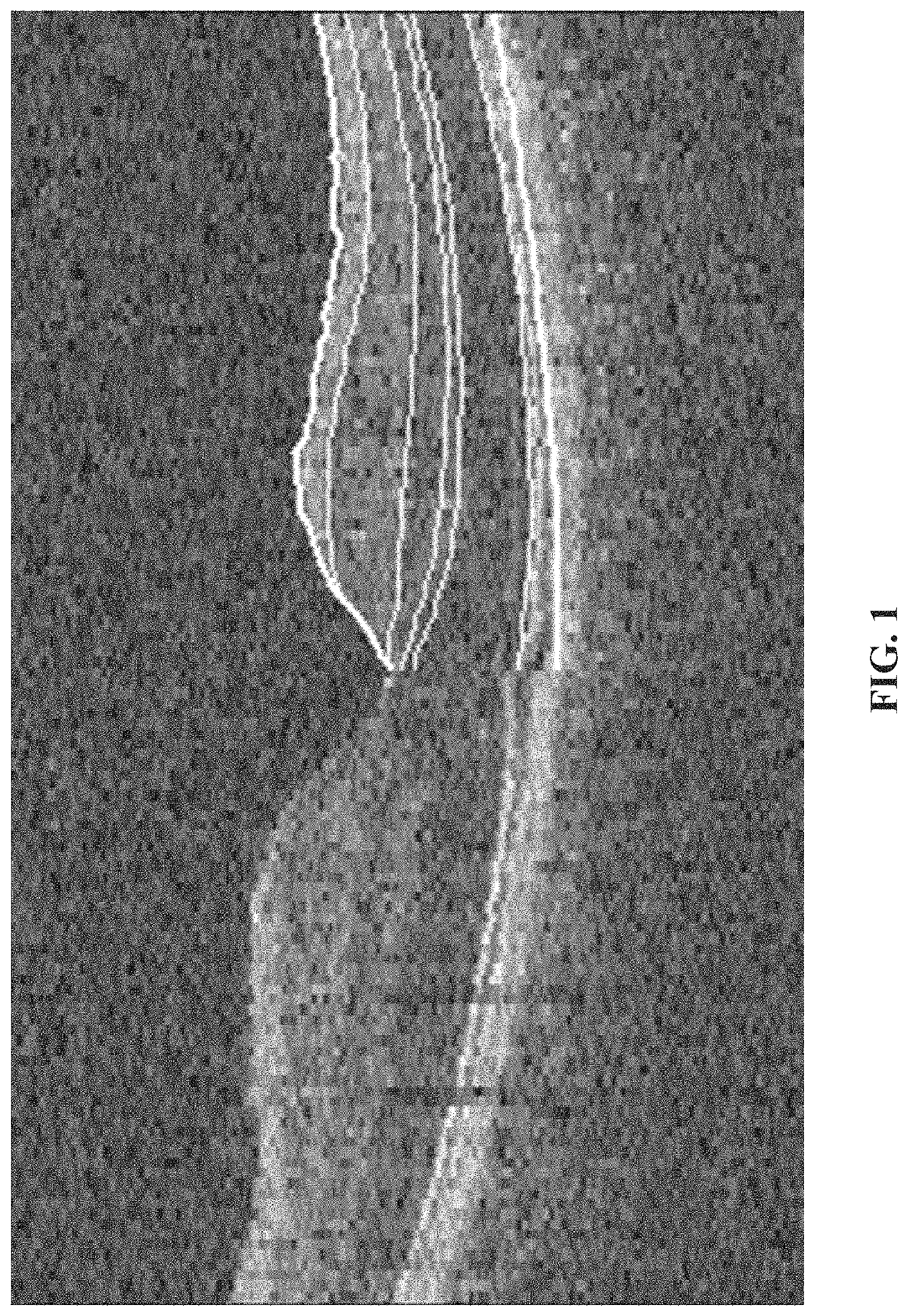

Detection and characterization method for plastic flow characteristic of weld metal in friction stir welding process

PendingCN107570861ASmall plastic flow effectsEasy to detectNon-electric welding apparatusButt weldingCopper wire

The invention provides a detection and characterization method for the plastic flow characteristic of weld metal in the friction stir welding process. The detection and characterization method can overcome the defects of existing characterization methods and can achieve non-destructive, convenient and rapid detection and characterization of the plastic flow characteristic of the weld metal in theFSW process. The detection and characterization method specifically comprises the steps that before butt welding in the stir friction welding process, at least three pure copper wires are embedded into the to-be-welded side of base metal on the advancing side and the retracting side to serve as marking materials, wherein the diameter of each copper wire is 1.0-1.5 mm, the length of each copper wire is greater than the radius of the shaft shoulder of a stirring head; the copper wires are perpendicular to the stirring head and the welding direction and are spaced from one another by at least 10mm in the welding direction and evenly distributed in the thickness direction; and three-dimensional computed tomography scanning is conducted on a weld joint through the industrial computed tomography (ICT) after friction stir welding, and the three-dimensional topography is obtained after the copper wires deform and used for characterizing the plastic flow characteristic of the weld material ofthe base metal in the friction stir welding process. The detection and characterization method for the plastic flow characteristic of the weld metal in the friction stir welding process has the advantages that a welded sample is not damaged, operation is safe, the practicability is high, and the plastic flow characteristic of the material in the friction stir welding process can be characterized rapidly and accurately.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG +1

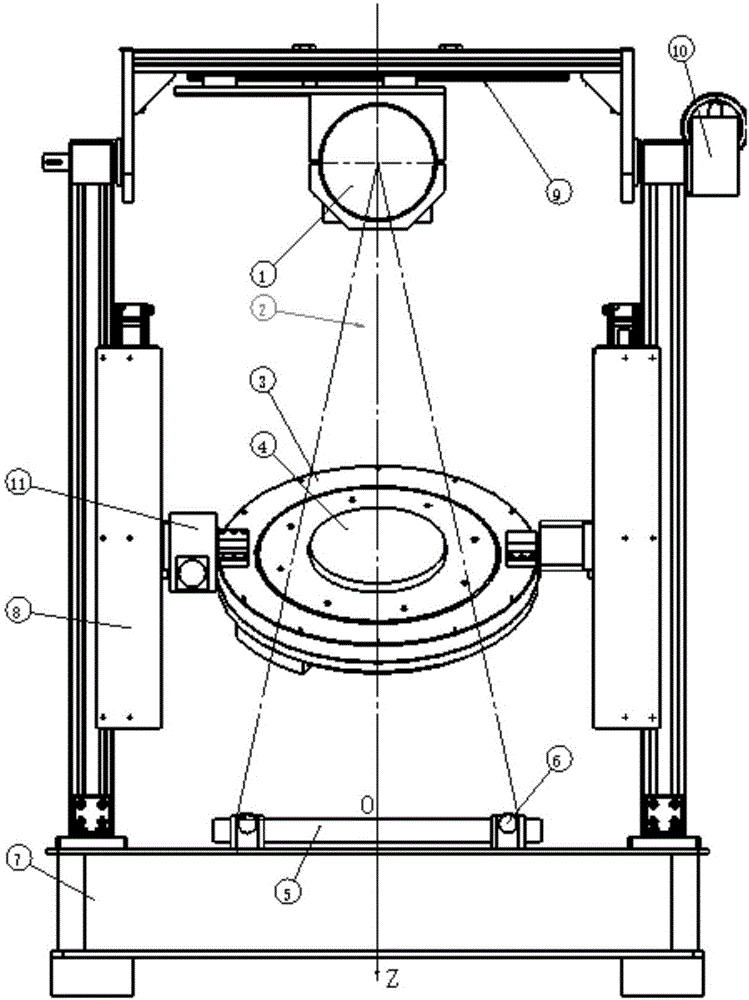

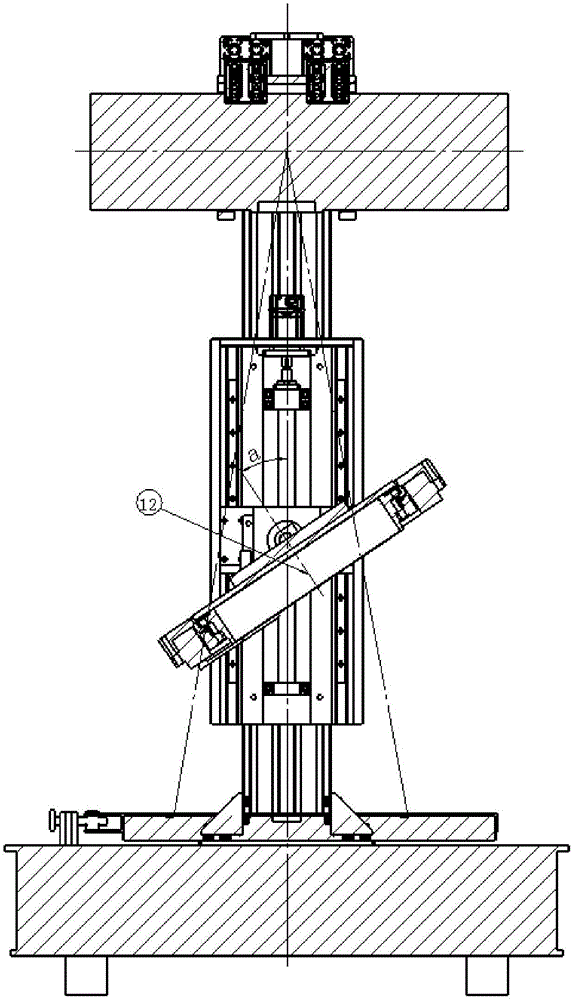

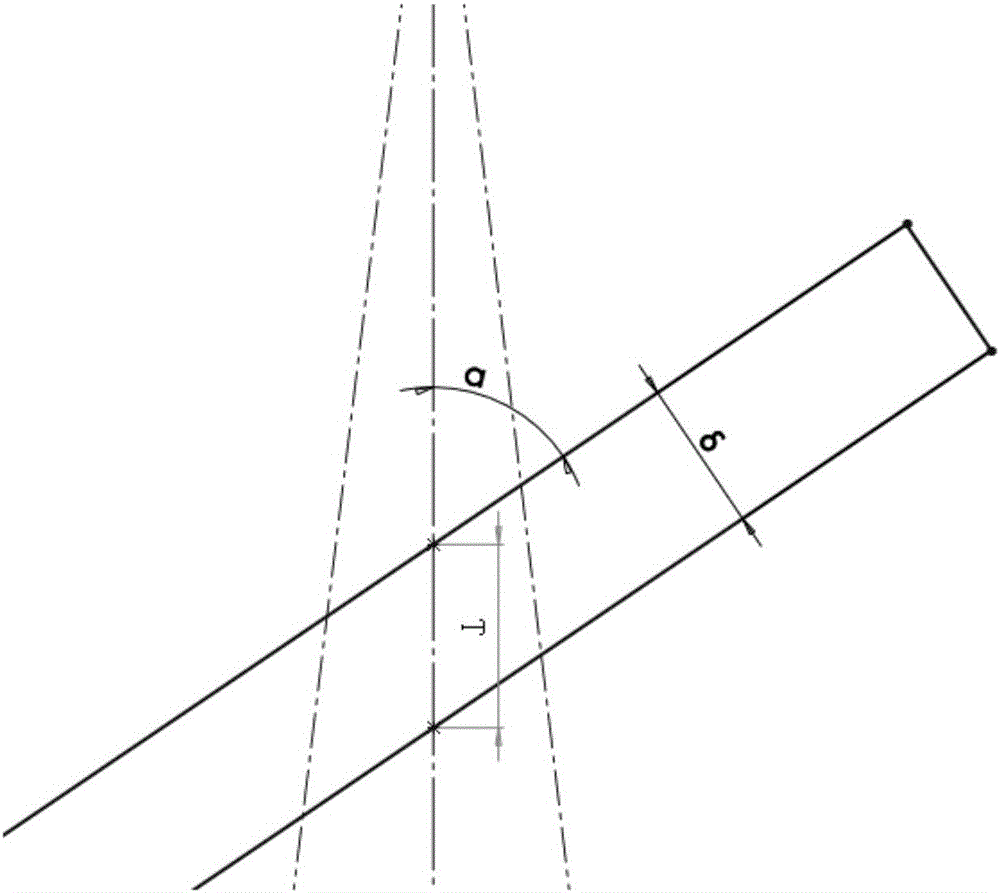

CT tomographic scanning device of plate-shaped workpiece

PendingCN107436308AMaterial analysis by transmitting radiationVertical planeThree dimensional tomography

The invention discloses a CT tomographic scanning device of a plate-shaped workpiece and relates to the technical field of three-dimensional tomography of workpieces. The CT tomographic scanning device comprises a rotating platform, a lifting mechanism and a turnover mechanism. The rotating platform can vertically moved up and down under the action of the lifting mechanism and is turned over on the vertical plane under the action of the turnover mechanism so that the axis of the rotating platform and the vertical line form a fixed included angle. After the position of the rotating platform is adjusted under the action of the lifting mechanism and the turnover mechanism, the rotating platform can rotate on the plane where the rotating platform exists. The included angle alpha of the rotation axis and vertical line (ray beam centerline) of the plate-shaped workpiece on the rotating platform is fixed so that the thickness delta of the plate-shaped workpiece is constant and thus in motion of the plate-shaped workpiece along with the rotating platform, transmission thickness T=delta*arccos alpha of the same ray in different rotation positions of the plate-shaped workpiece is constant and the precise plate-shaped workpiece scanning is realized.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

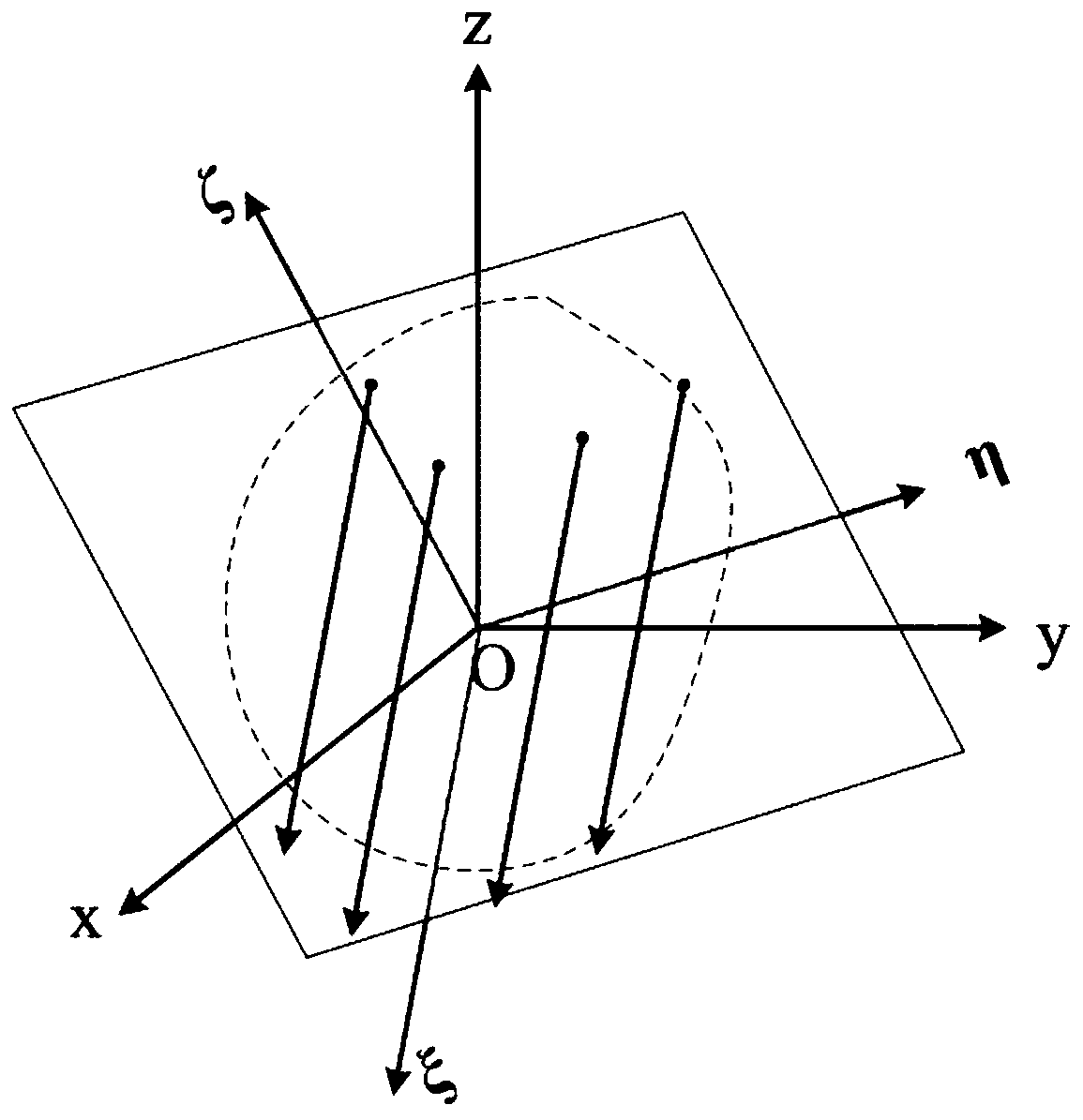

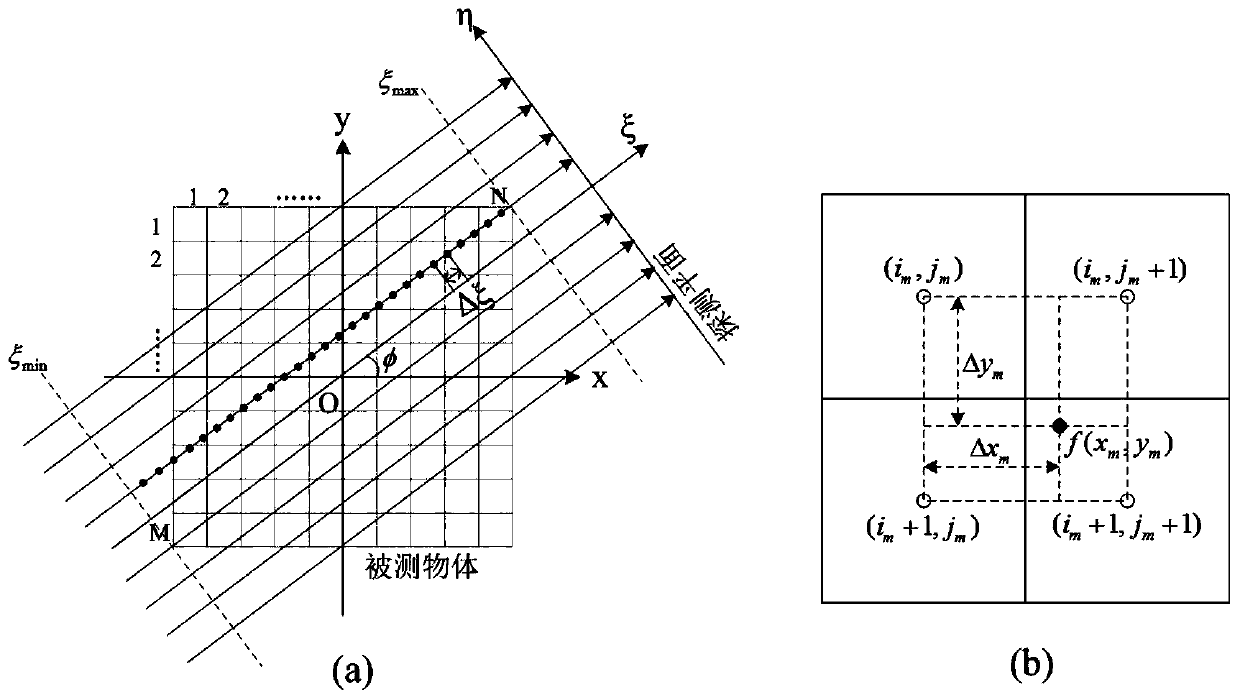

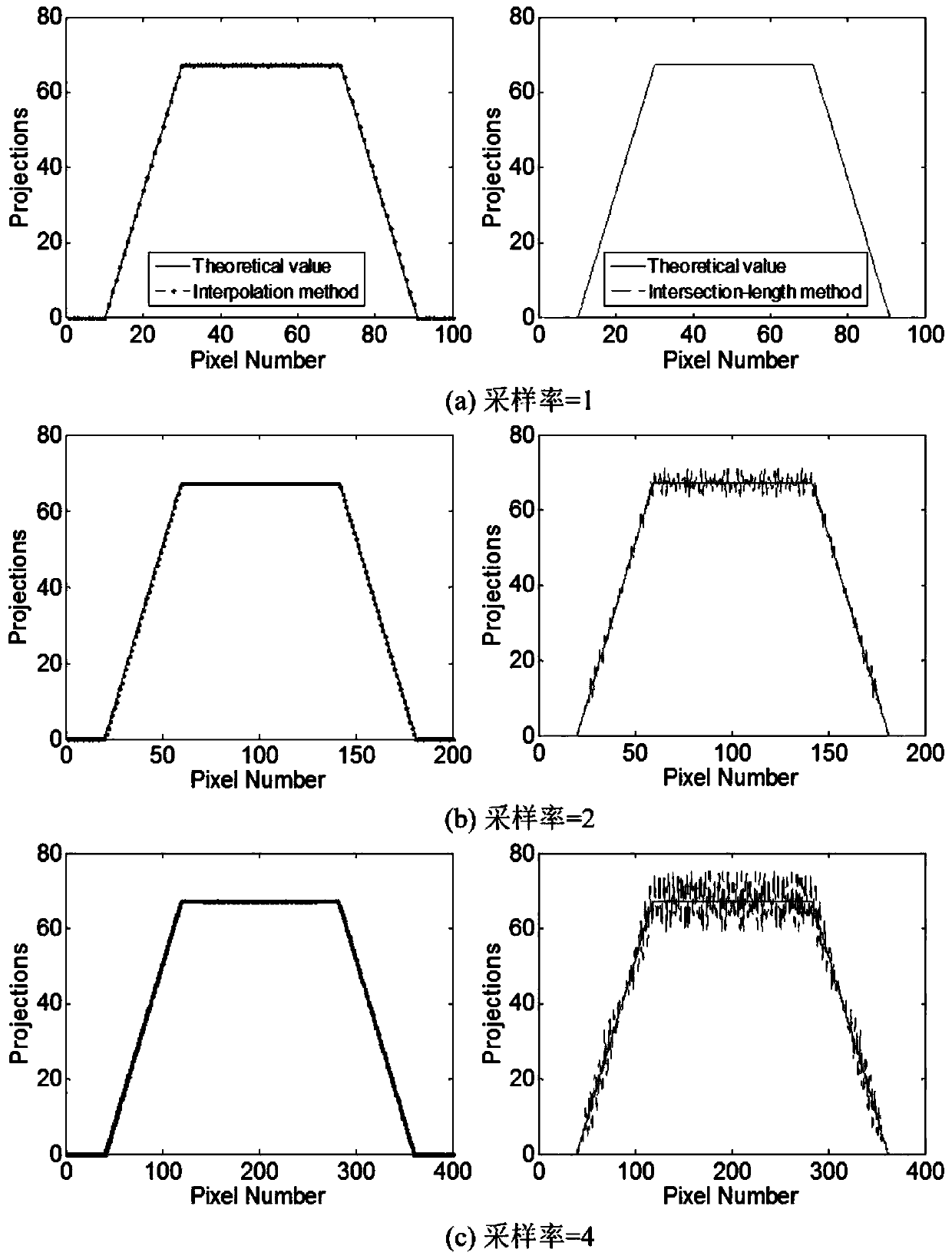

Method for determining emission tomography weight matrix based on bilinear interpolation principle

ActiveCN110400253AHigh precisionImprove computing efficiencyGeometric image transformationThree-dimensional spaceThree dimensional tomography

The invention relates to a method for determining an emission tomography weight matrix based on a bilinear interpolation principle. The method comprises the following steps: firstly, obtaining a three-dimensional projection model of emission tomography; discretizing and expressing projection integrals; and finally, determining a weight matrix of the chromatography system by utilizing a bilinear interpolation principle. According to the method, a three-dimensional space two-dimensional Radon transformation model used for accurately describing emission tomography projection is obtained, and a theoretical basis is provided for three-dimensional tomography reconstruction; the principle of determining the weight matrix based on the bilinear interpolation principle is simple, the calculation efficiency is high, and the weight matrix numerical value can be quickly obtained; the calculation result is high in accuracy, interference caused by discretization in the calculation process can be reduced, and the accuracy of the calculation result is greatly improved; and the method not only can be used for two-dimensional Radon transformation in a three-dimensional space, but also is suitable forweight matrix calculation in a traditional two-dimensional chromatography technology.

Owner:XIAN TECHNOLOGICAL UNIV

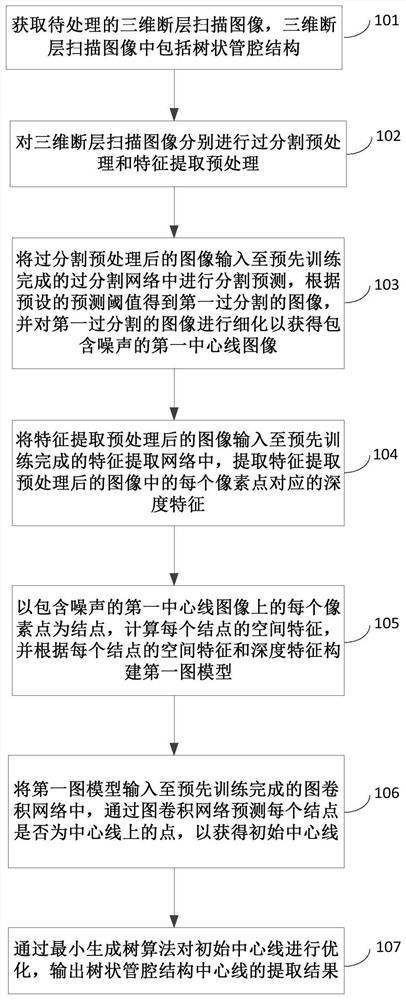

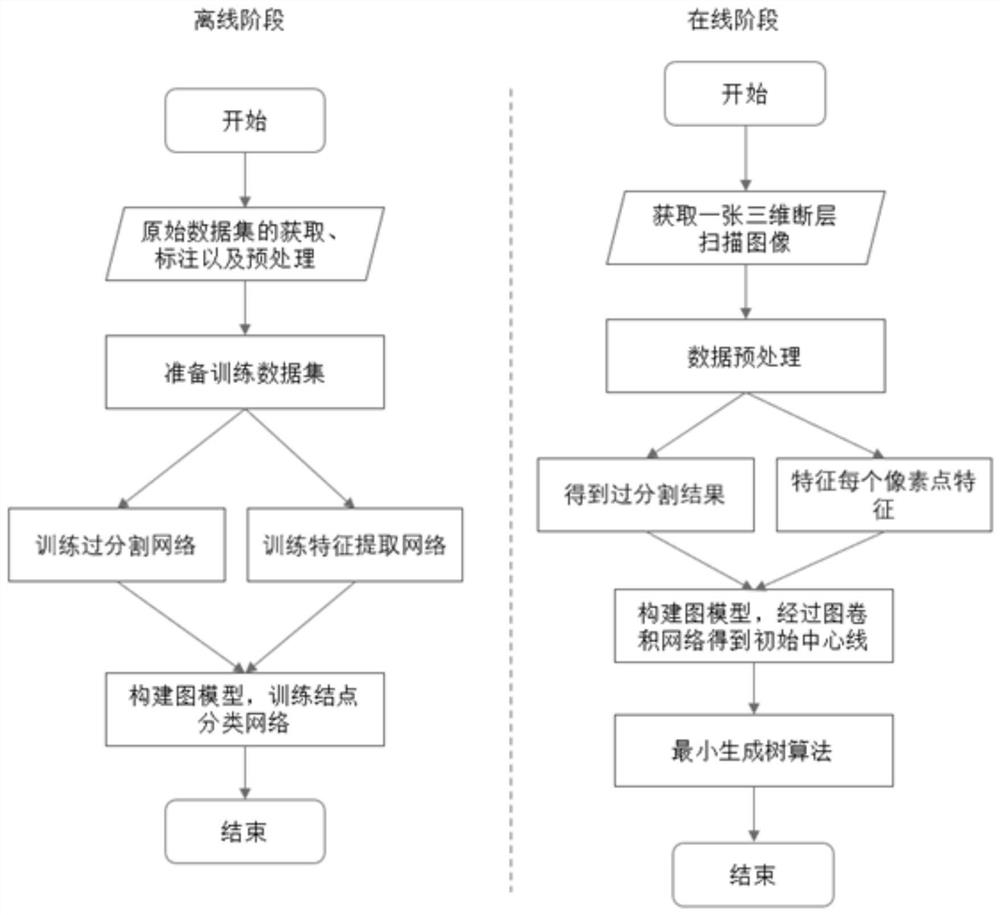

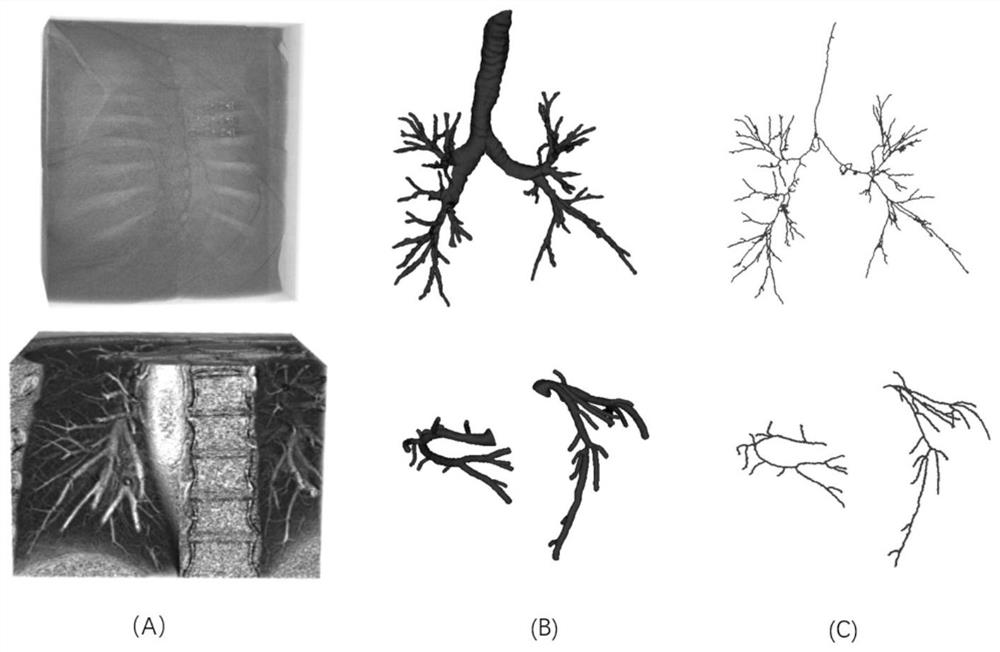

Method and device for extracting centerline of tree-shaped lumen structure in three-dimensional tomography image

PendingCN113744215AIntegrity guaranteedGuaranteed stabilityImage enhancementImage analysisImaging processingFeature extraction

The invention provides a method and device for extracting a centerline of a tree-shaped lumen structure in a three-dimensional tomography image, and relates to the field of image processing.The method comprises the steps of obtaining the three-dimensional tomography image to be processed, carrying out over-segmentation preprocessing and feature extraction preprocessing respectively, processing the image subjected to over-segmentation preprocessing through an over-segmentation network to obtain a first over-segmented image, and refining the first over-segmented image to obtain a first center line image; extracting a depth feature corresponding to each pixel point in the image after feature extraction preprocessing through a feature extraction network; and taking each pixel point on the first center line image as a node, constructing a first graph model according to the spatial feature and the depth feature of each node, obtaining an initial center line through a graph convolutional network, performing optimization through a minimum spanning tree algorithm, and outputting an extraction result of the center line of the tree-shaped lumen structure. According to the invention, the center line can be accurately extracted, and the stability and robustness of center line extraction are improved.

Owner:TSINGHUA UNIV +1

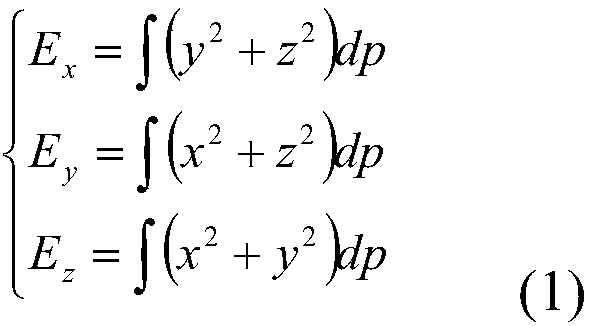

Method for reconstructing arch structure by means of arch fossil

ActiveCN107945263AAchieve completenessDetails involving processing stepsImage generationPoint cloudThree dimensional tomography

The invention discloses a method for reconstructing an arch structure by means of an arch fossil. The method comprises the steps of: selecting a modern human, performing three-dimensional tomography and reconstruction on a right side arch of the modern human; saving a reconstructed arch bone in a point cloud form; defining Euler quantities including Euler, Euler moments, Euler products and Euler main axis, rotating the arch bone of the modern human according to specific sequences based on the quantities till all the Euler products are zero, and recording the rotating sequences and angle displacements of the arch bone of the modern human; and rotating an arch bone fossil according to specific sequences till all the Euler products are zero, then inversely rotating the arch bone fossil in thereverse direction according to the sequences and angle displacements of the arch bone of the modern human, and completing the reconstruction of the arch structure. The method disclosed by the invention provides a new approach for the human body structure reconstruction of a human fossil, and provides new evidence for interpretation of the evolution process of human.

Owner:FUJIAN NORMAL UNIV

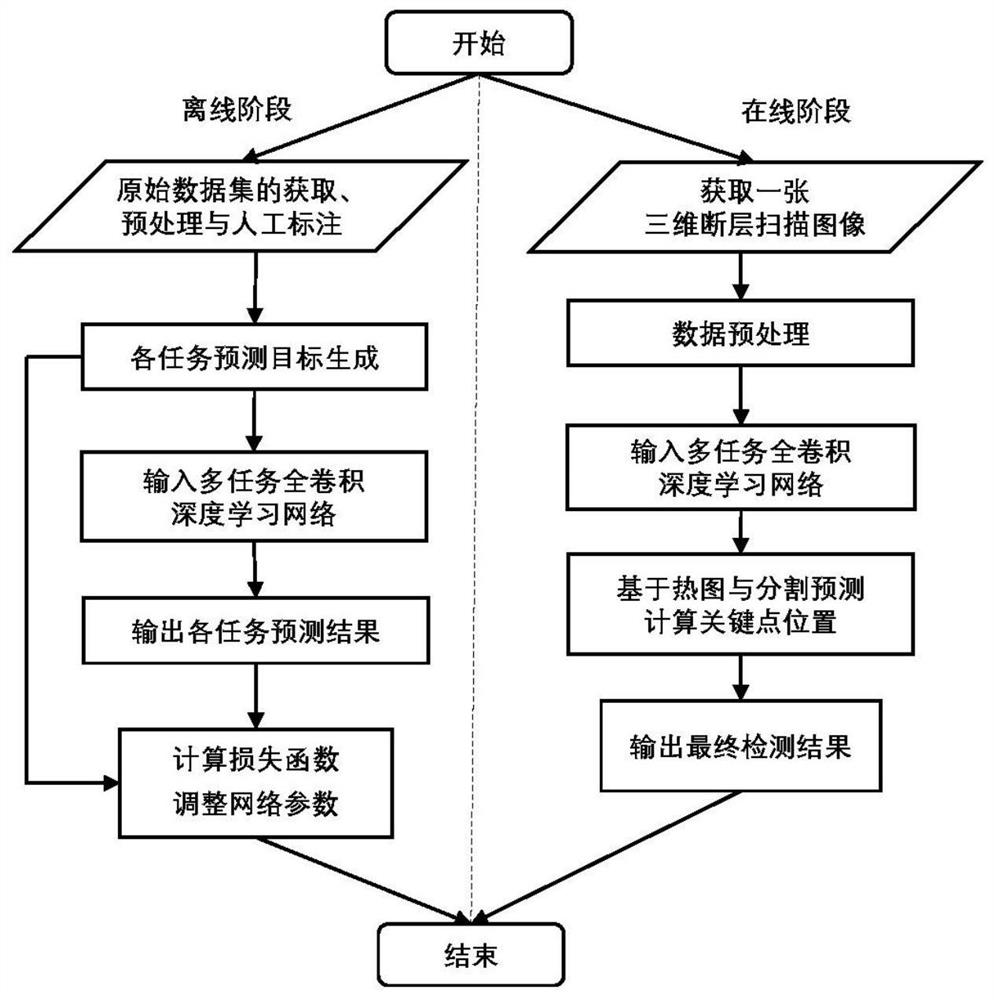

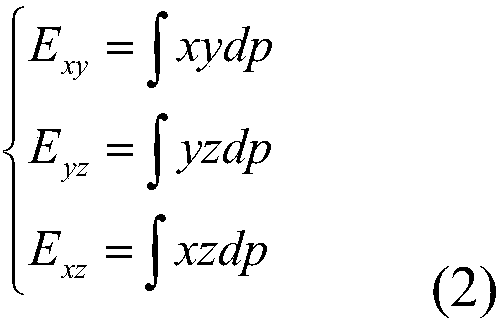

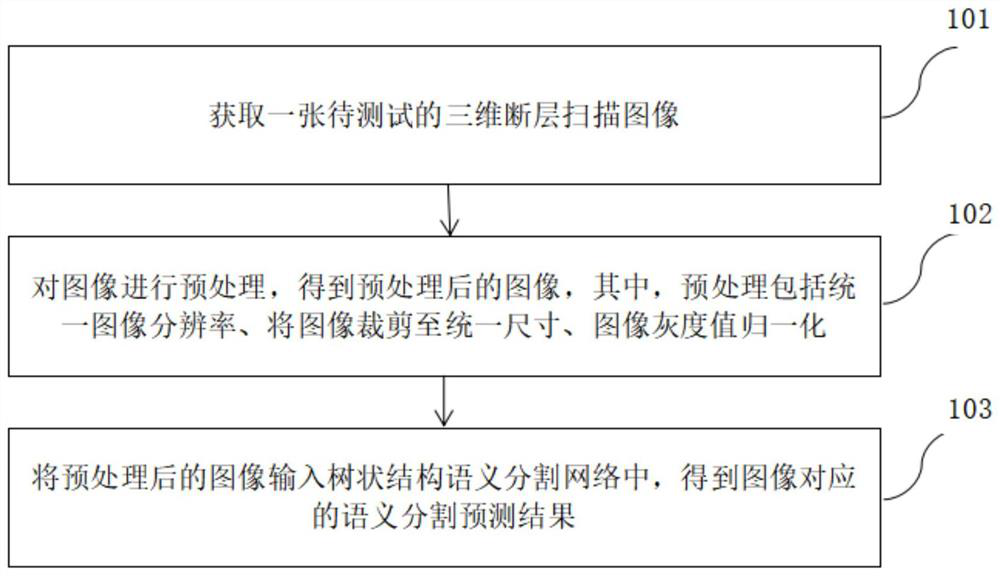

Semantic segmentation method and device for tree structure in three-dimensional tomography image

PendingCN113192069AImprove segmentation performanceImage enhancementImage analysisImaging processingFeature extraction

The invention provides a semantic segmentation method for a tree structure in a three-dimensional tomography image, and relates to the technical field of medical image processing, and the method comprises the steps: obtaining a to-be-tested three-dimensional tomography image; preprocessing the image, obtaining a preprocessed image, and preprocessing comprises the steps of unifying the image resolution, cutting the image to be in a unified size and normalizing the gray value of the image; and inputting the preprocessed image into the tree-structure semantic segmentation network to obtain a semantic segmentation prediction result corresponding to the image. According to the method, the multi-task full convolutional network and the graph convolutional network are used for completing feature extraction together, then a semantic segmentation result of a tree structure is obtained, spatial context information is modeled, structural priori knowledge is explicitly introduced, and good segmentation performance can be achieved.

Owner:TSINGHUA UNIV

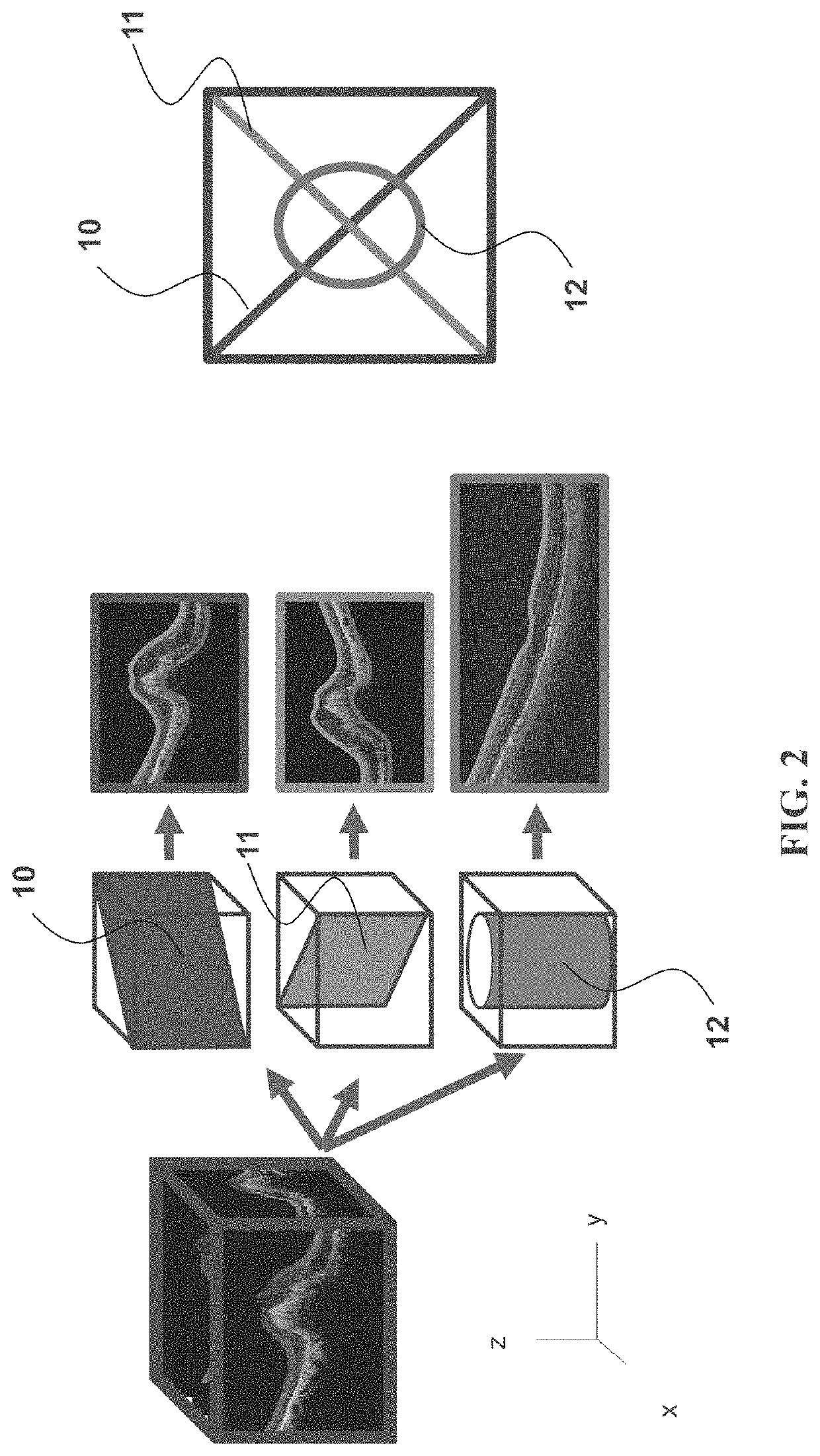

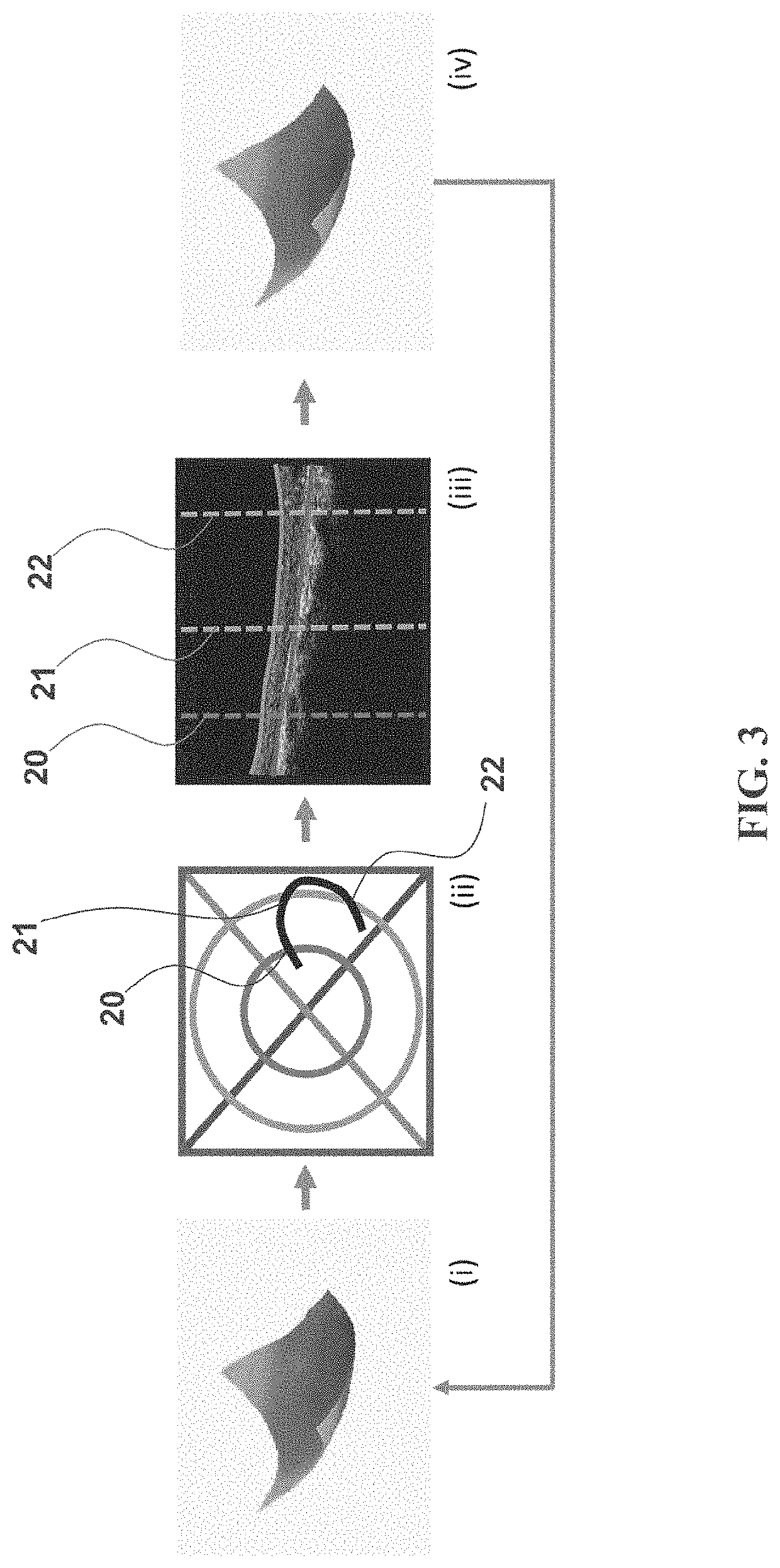

Method and apparatus for generation or editing of layer delineations

Methods are disclosed for the generation and editing of layer delineations within three-dimensional tomography scans. Cross sections of a subject are generated and presented to an operator, who has the ability to edit layer delineations within the cross section, or determine parameters used to generate new cross sections. By guiding an operator through a set of displayed cross sections, the methods can allow for a more rapid, efficient, and error-free segmentation of the subject. The cross sections can be nonplanar in shape or planar and non-axis-aligned. The cross sections can be restricted to exclude one or more user-defined regions of the subject, or to include only one or more user-defined regions of the subject. The cross sections can be localized to a point-of-interest. Iterative implementations of the methods can be used to arrive at a segmentation deemed satisfactory by the user.

Owner:VOXELERON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com