Detection and characterization method for plastic flow characteristic of weld metal in friction stir welding process

A technology of friction stir welding and plastic flow, which is applied in metal processing equipment, welding equipment, non-electric welding equipment, etc. It can solve the problems of difficult to observe the whole picture of marking materials, X-ray leakage, and damage samples, and achieves convenient and fast characterization methods , little effect of plastic flow and small deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

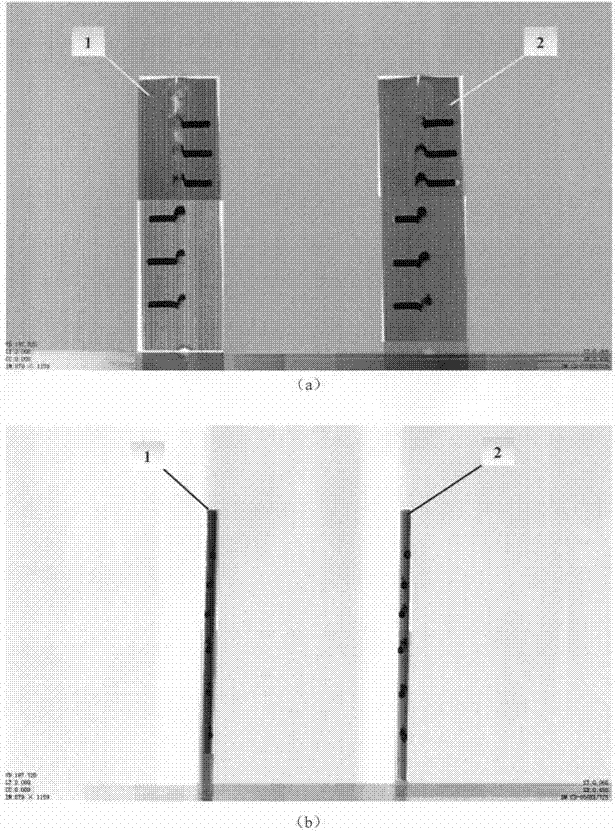

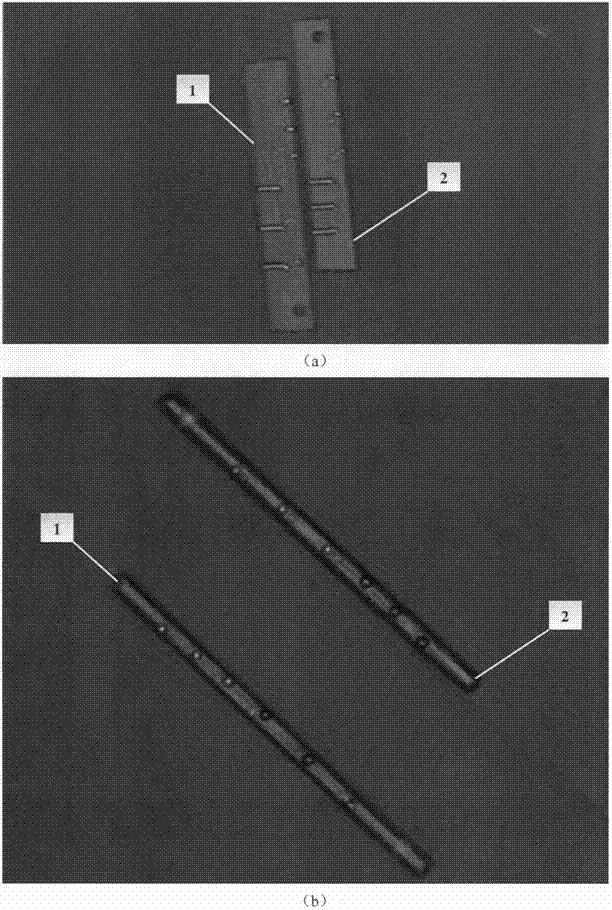

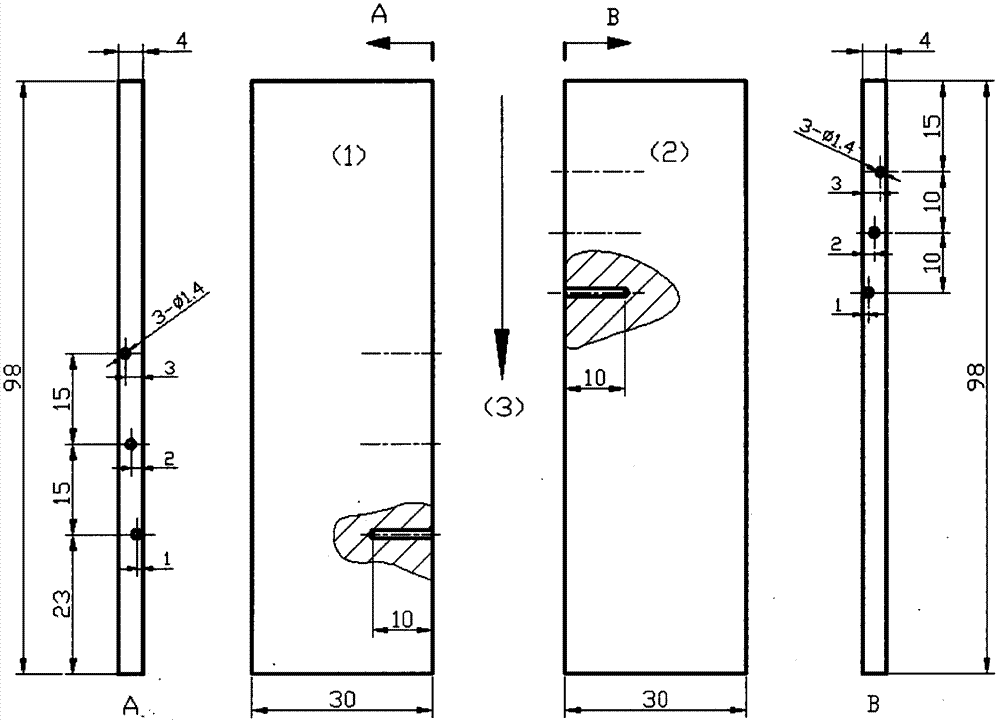

[0026] Welding material: The welding base material is ADC12 aluminum alloy, 4mm thick; before welding, drill a hole on the cross section of the welding base metal to be welded, the diameter of the hole is 1.4mm, the depth is 10mm, and the hole is perpendicular to the stirring head and the welding direction; The positions of the holes are respectively taken at the bottom, middle and upper part of the cross-section to observe the plastic flow characteristics of the metal along the thickness direction of the weld; conventional physical and chemical treatment methods are used to clean the base metal and copper wire before welding to remove the surface oxide film , oil and water.

[0027] Welding equipment and process parameters: The friction stir welding is produced by Beijing Saifuster Co., Ltd., the model is FSW-3LM-4012 welding machine; the welding form is butt welding, the welding speed is 100mm / min, and the rotation speed is 1300r / min, stirring needle length 4mm, shaft shoul...

Embodiment 2

[0030] Welding material: the welding base material is AZ91D magnesium alloy, 4mm thick; before welding, drill a hole on the cross section of the welding base metal to be welded, the diameter of the hole is 1.4mm, the depth is 10mm, and the hole is perpendicular to the stirring head and the welding direction; The positions of the holes are respectively taken at the bottom, middle and upper part of the cross-section to observe the plastic flow characteristics of the metal along the thickness direction of the weld; conventional physical and chemical treatment methods are used to clean the base metal and copper wire before welding to remove the surface oxide film , oil and water.

[0031] Welding equipment and process parameters: Friction stir welding uses a welding machine produced by Beijing Saifuster Co., Ltd., model FSW-3LM-4012; the welding form is butt welding, the welding speed is 120mm / min, and the rotation speed is 1500r / min, stirring needle length 4mm, shaft shoulder di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com