Self-discharging detection system for lithium ion battery

A technology of lithium-ion battery and detection system, applied in the field of lithium-ion battery self-discharge detection system, can solve the problems of narrow observation range, long measurement period, poor data reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A lithium-ion battery self-discharge detection system proposed in this patent is described as follows in conjunction with the accompanying drawings:

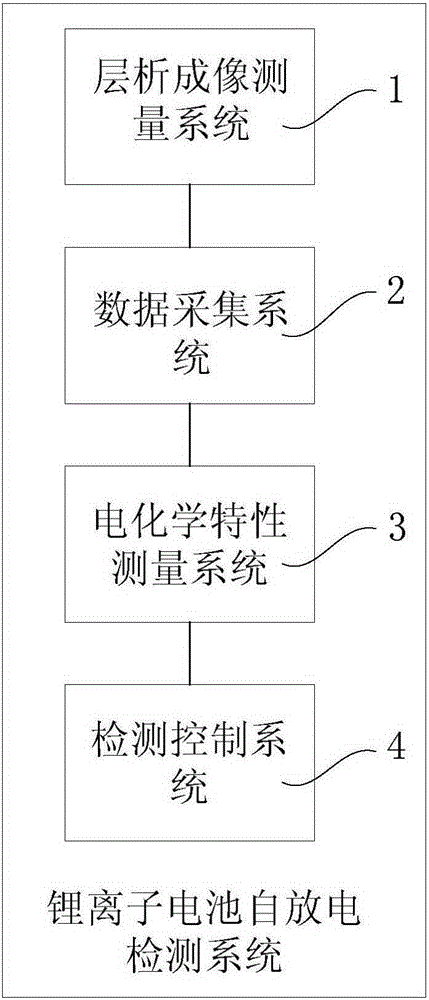

[0036] see figure 1 , A lithium-ion battery self-discharge detection system, including a tomography measurement system 1, a data acquisition system 2, an electrochemical characteristic measurement system 3, and a detection control system 4.

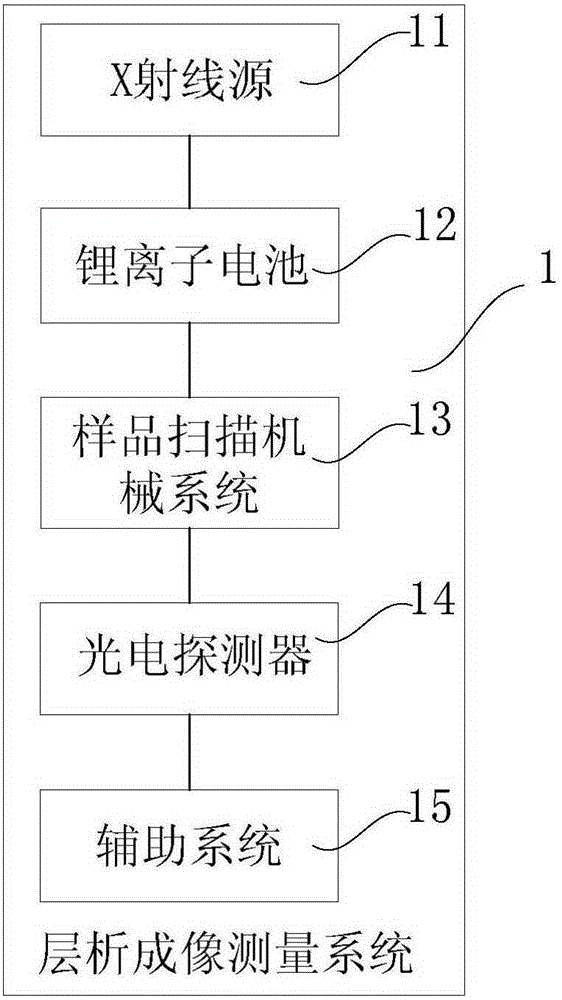

[0037] Such as figure 2 , the tomography measurement system 1 includes an X-ray source 11, a lithium-ion battery 12, a photodetector 13, a sample scanning mechanical system 14, and an auxiliary system 15 (such as an auxiliary power supply and a radiation safety system, etc.), for obtaining and rebuilding lithium Complete data required for 3D tomographic imaging of ion batteries.

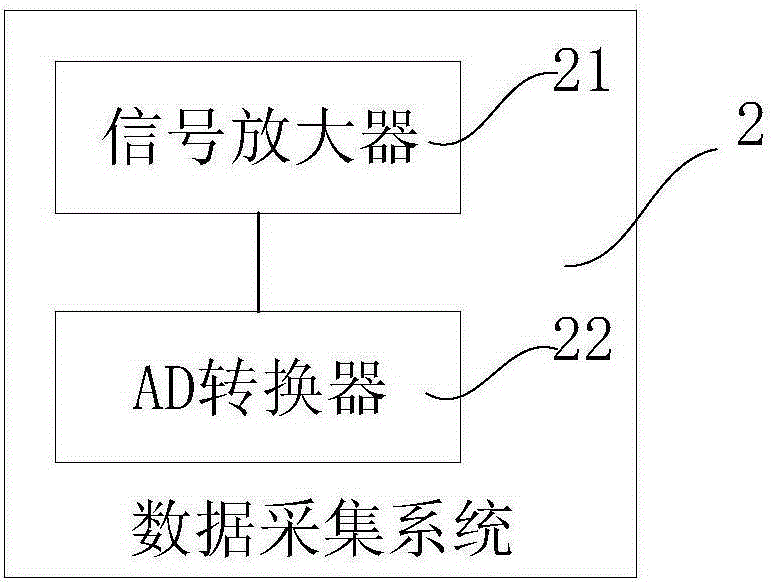

[0038] Such as image 3 , the data acquisition system 2 includes a signal amplifier 21 and an AD converter 22, which are used to amplify and AD convert the signal output from the photodetector 13.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com