Movable and turnover automatic burdening mechanism

A technology of automatic batching and turning mechanism, which is applied in the direction of measuring devices, instruments, weighing, etc., to achieve the effects of light weight, small weighing error, and reduced power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0026] In the description of the present invention, the terms "left end, right end, front end, rear end, left side, right side, inward, outward" etc. are only for convenience of description and definition, and should not be construed as limiting the present invention.

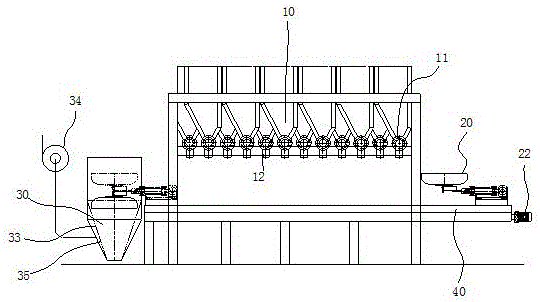

[0027] see figure 1 , The mobile reversible automatic batching mechanism mainly includes a number of feed bins 10, weighing instruments 20, and storage bins 30.

[0028] A control valve 11 is provided at the outlet of each silo, and the outlets 12 of the silo are located on the same straight line.

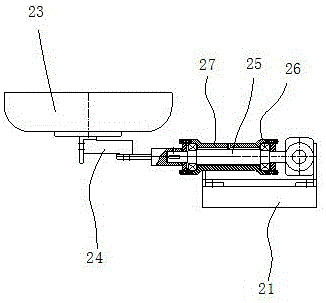

[0029] The weighing instrument 20 is arranged on a linear guide rail 40 and can move along the linear guide rail, and the moving track of the weighing instrument 20 enters below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com