Ultra-thin glass density testing device and testing method

An ultra-thin glass and testing device technology, which is applied in measuring devices, specific gravity measurement, instruments, etc., can solve problems such as large error range, weighing error, density test result error, etc., to improve measurement accuracy, reduce test errors, Fast test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

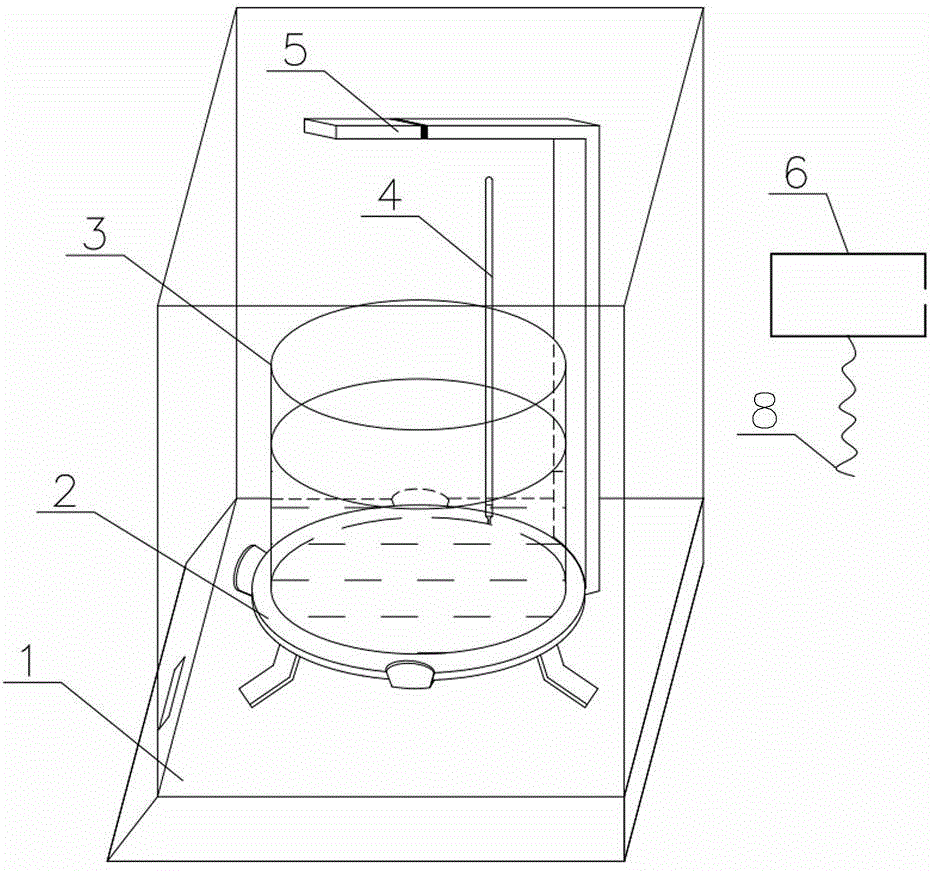

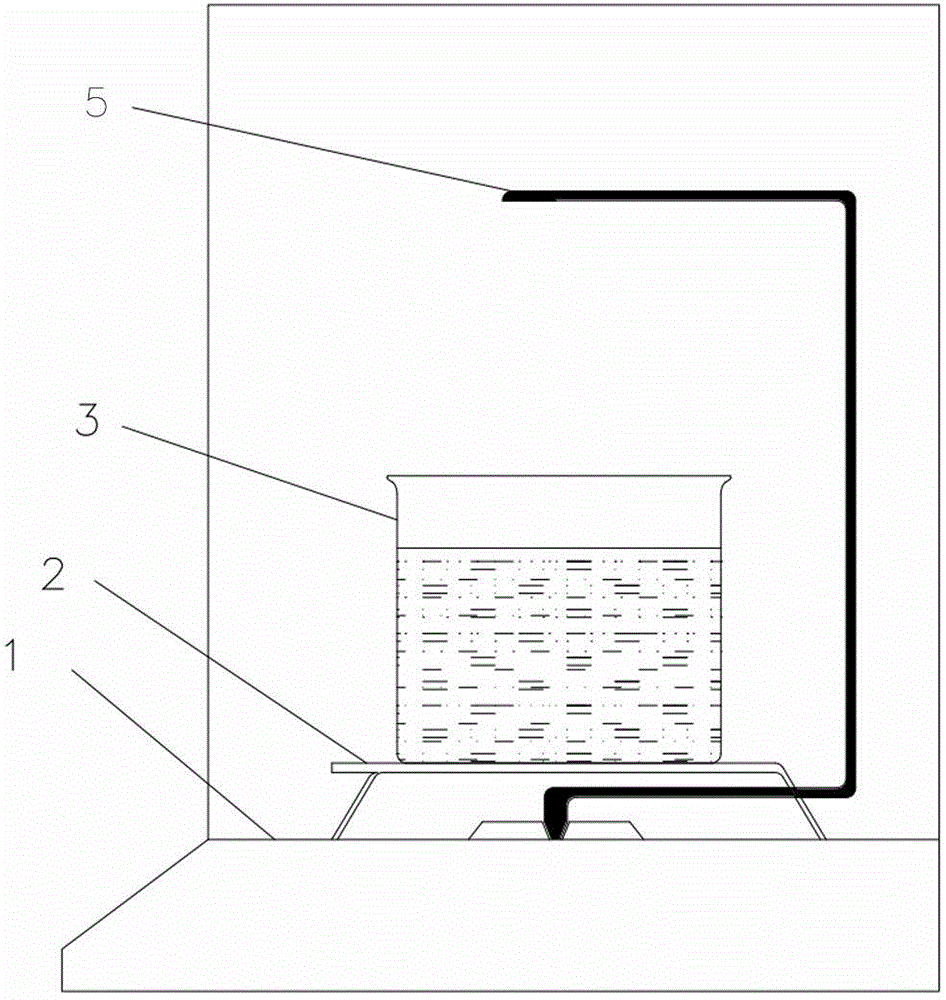

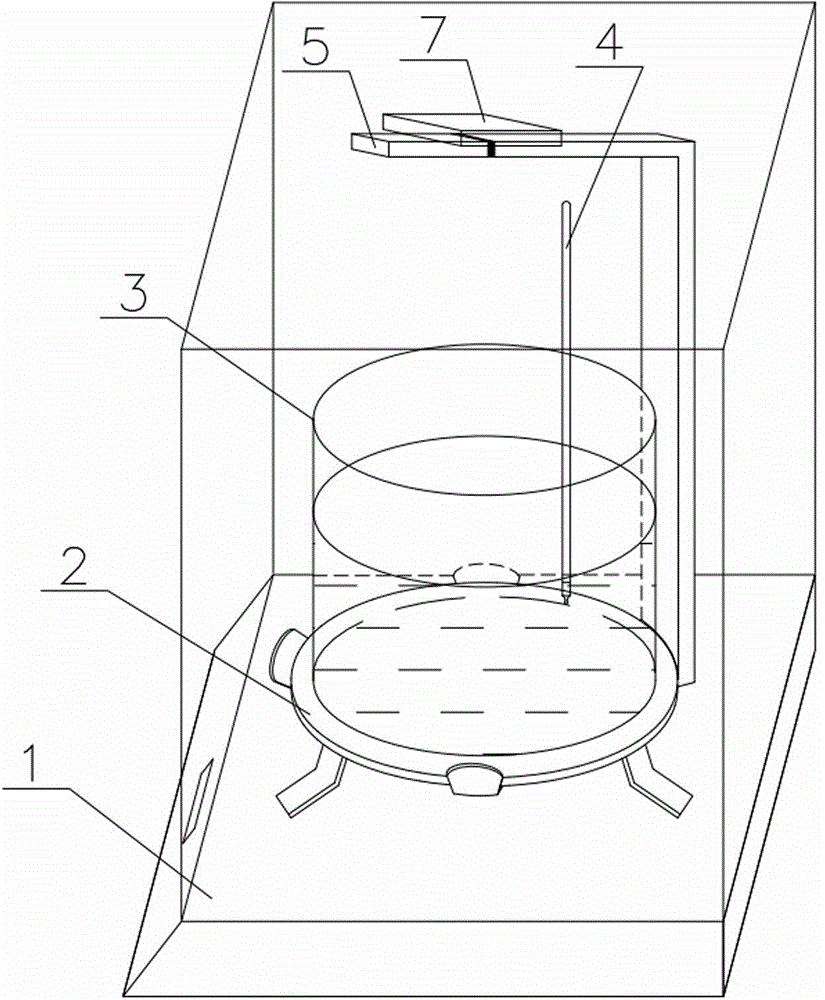

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] see figure 1 and figure 2 . The invention provides a device for testing the density of ultra-thin glass, comprising an electronic balance 1, on which a beaker support 2 and a weighing pan bracket 5 for placing a glass sample 7 are arranged, a beaker 3 is arranged on the beaker support 2, and the weighing pan The upper end of bracket 5 is positioned at the top of beaker 3; Thermometer 4 is set on beaker 3 inwalls; Described testing device also comprises pendant 6 and sling 8; Described pendant 6 is hung on the upper end of weighing pan carriage 5, and One end of the sling 8 is tied to the pendant 6, and the other end is provided with a slipknot for fixing the glass sample 7.

[0024] The pendant 6 should be selected from lightweight non-deformable materials, preferably metal wires and plastics.

[0025] In order to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com