Hyper-heuristic algorithm based ZDT flow shop job scheduling method

A zero-idle pipeline and heuristic algorithm technology, applied in computing, instruments, data processing applications, etc., can solve problems such as low quality scheduling solutions, difficulty in obtaining optimal solutions, and inability to guarantee a single meta-heuristic algorithm. The effect of avoiding uncertainty and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical solutions and features of the present invention, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

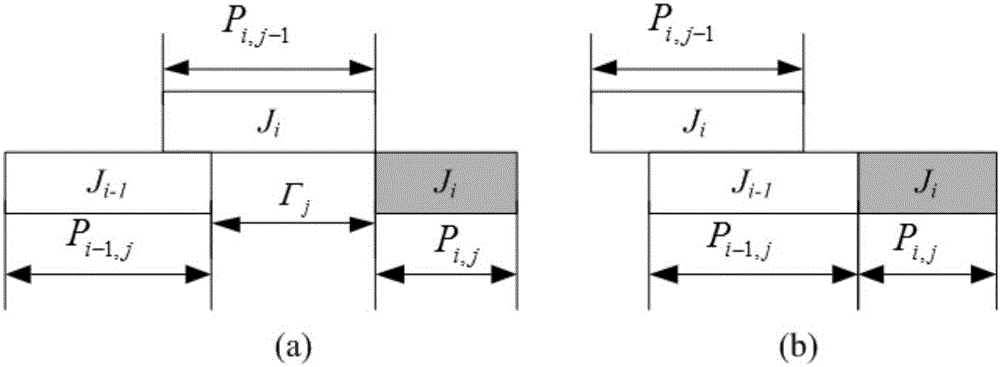

[0037] First, it is necessary to set the objective function fit( ) of the job scheduling optimization problem in a zero-idle flow shop. Since the optimization objectives under different scheduling indicators are different, this embodiment takes the common minimum completion time (Makespan) as an example to illustrate . Given scheduling solution π={J 1 ,J 2 ,...,J n}, where J 1 ,J 2 ,...,J n For n workpieces to be operated, they need to pass through m machines in the zero-idle assembly line in sequence, that is, no idle time is allowed between adjacent workpieces processed on the machine. Set workpiece J i (i=1,2,…,n) on machine j (j=1,2,…,m) the processing time, start time and completion time are respectively P i,j , S i,j and C i,j . figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com