Display mother board, manufacturing method of display mother board, display panel and display device

A technology for display substrates and display panels, which is used in identification devices, nonlinear optics, instruments, etc., can solve the problems of the sealant 11 being enlarged, affecting mass production, blank bubbles, etc., so as to improve the cutting yield and reduce the ratio of light leakage at four corners. , the effect of increasing the possibility of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

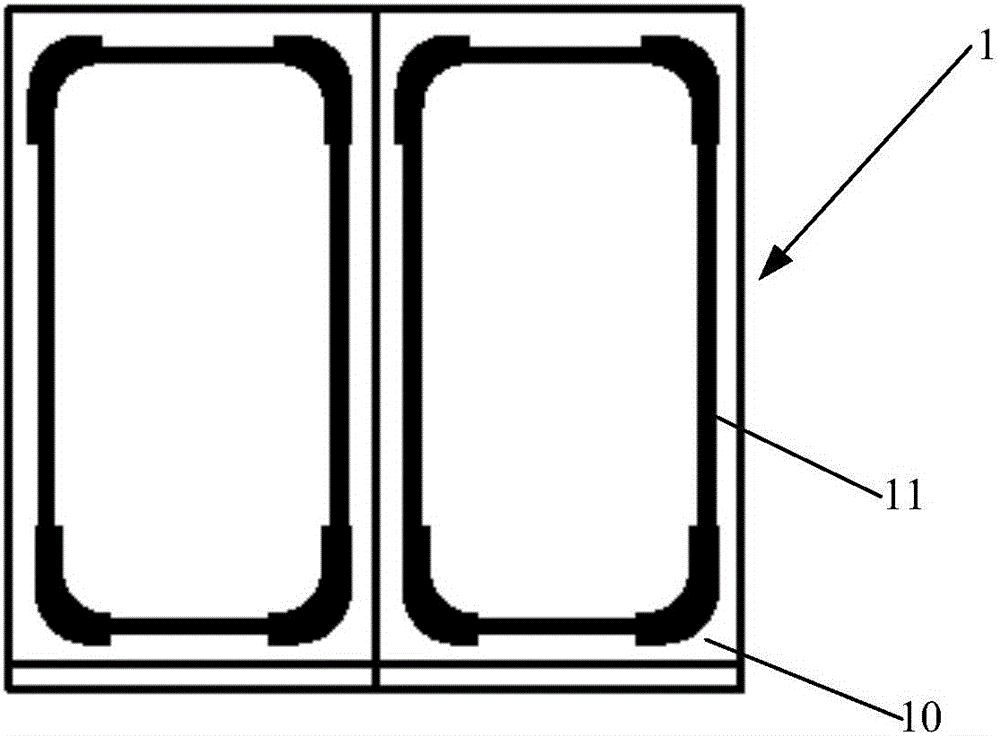

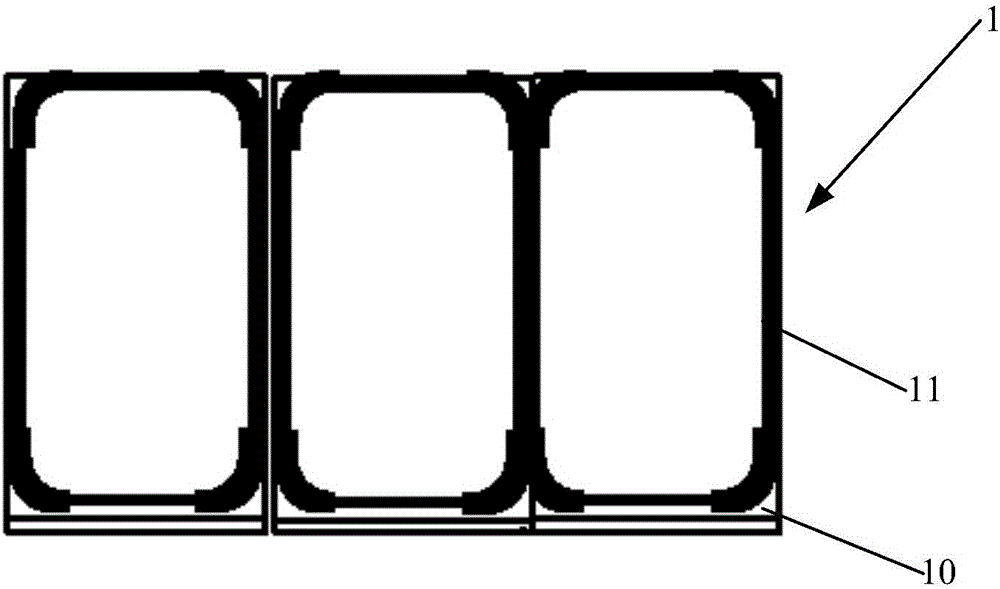

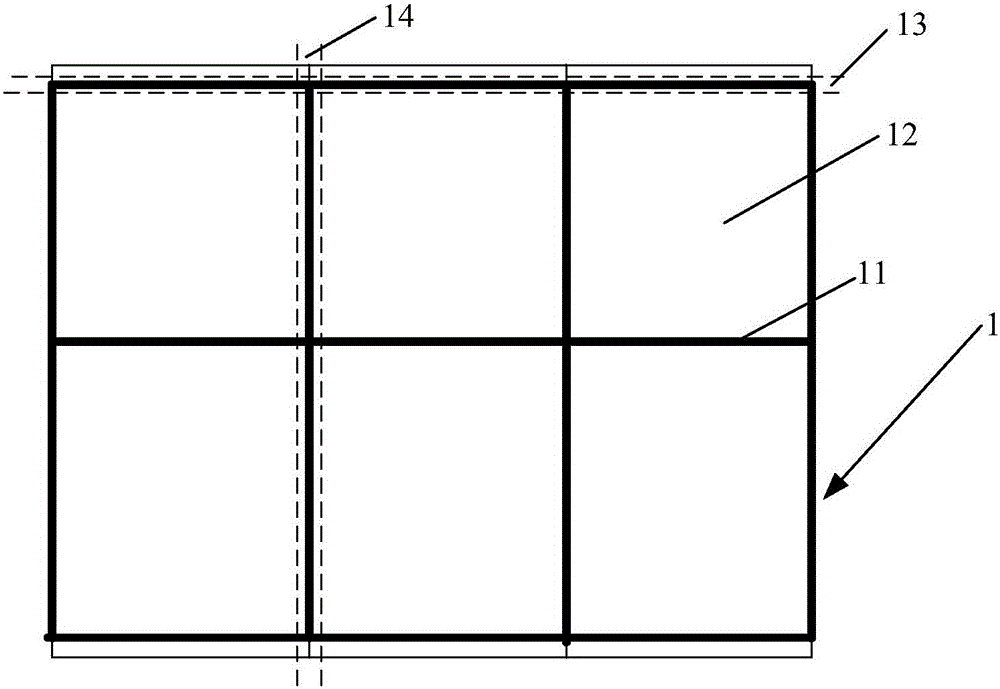

[0023] Such as image 3 As shown, this embodiment provides a method for preparing a display motherboard, wherein the display motherboard 1 includes multiple rows of first sealing regions 13 and multiple columns of second sealing regions 14, and the first sealing regions 13 and the second sealing regions The intersecting positions of the sealing areas 14 define a display area 12; the preparation method includes: applying the sealant 11 to the first sealing area 13 and the second sealing area 14 in a linear coating manner.

[0024] It should be noted that the coating sequence of the first sealing area 13 and the second sealing area 14 is not limited in this embodiment, that is, the first sealing area 13 can be coated sequentially and then the second sealing area 13 can be coated sequentially The second sealing area 14 may also be coated sequentially with the second sealing area 14 and then the first sealing area 13 , of course, the coating of the first sealing area 13 and the se...

Embodiment 2

[0033] This embodiment provides a display device, which includes the display panel in Embodiment 1. So its performance is better.

[0034] Of course, the display device in this embodiment can be any product or component with a display function, such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0035] Of course, the display device in this embodiment also has structures such as the outer frame of a conventional display device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com