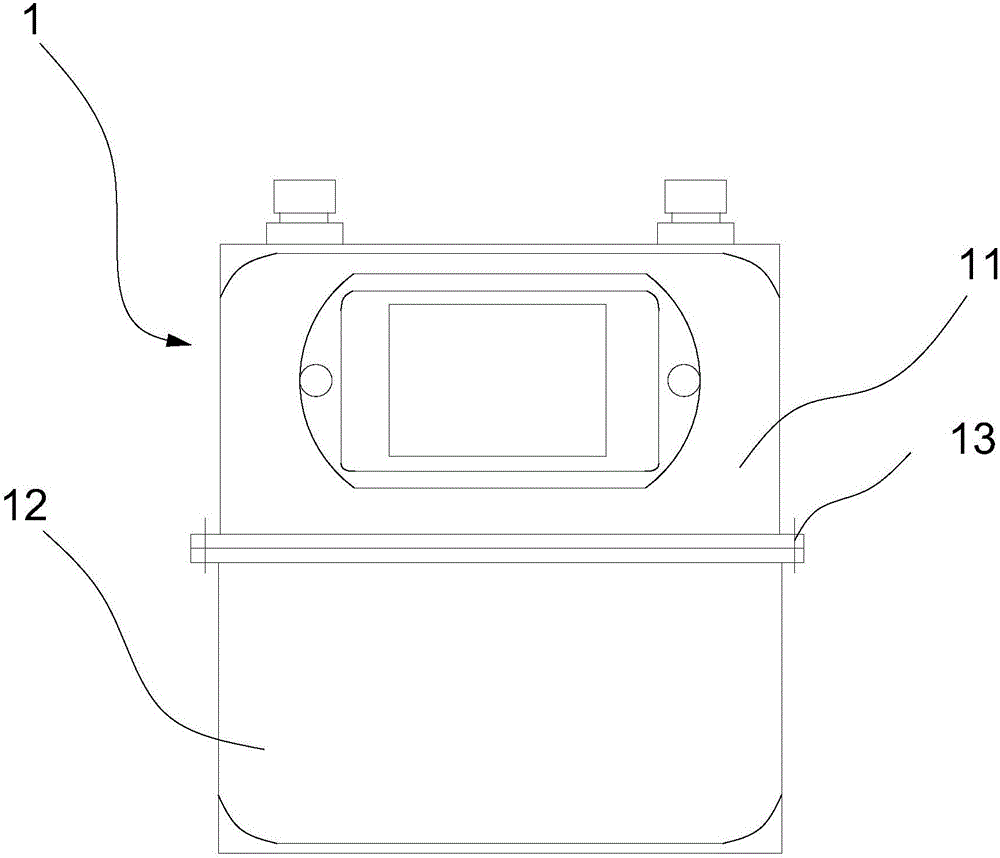

Automatic feeding and locking assembly line for locking screw of diaphragm gas mater

A membrane gas meter, automatic feeding technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency and large assembly workload, so as to improve assembly efficiency, reduce assembly workload, shorten the The effect of assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

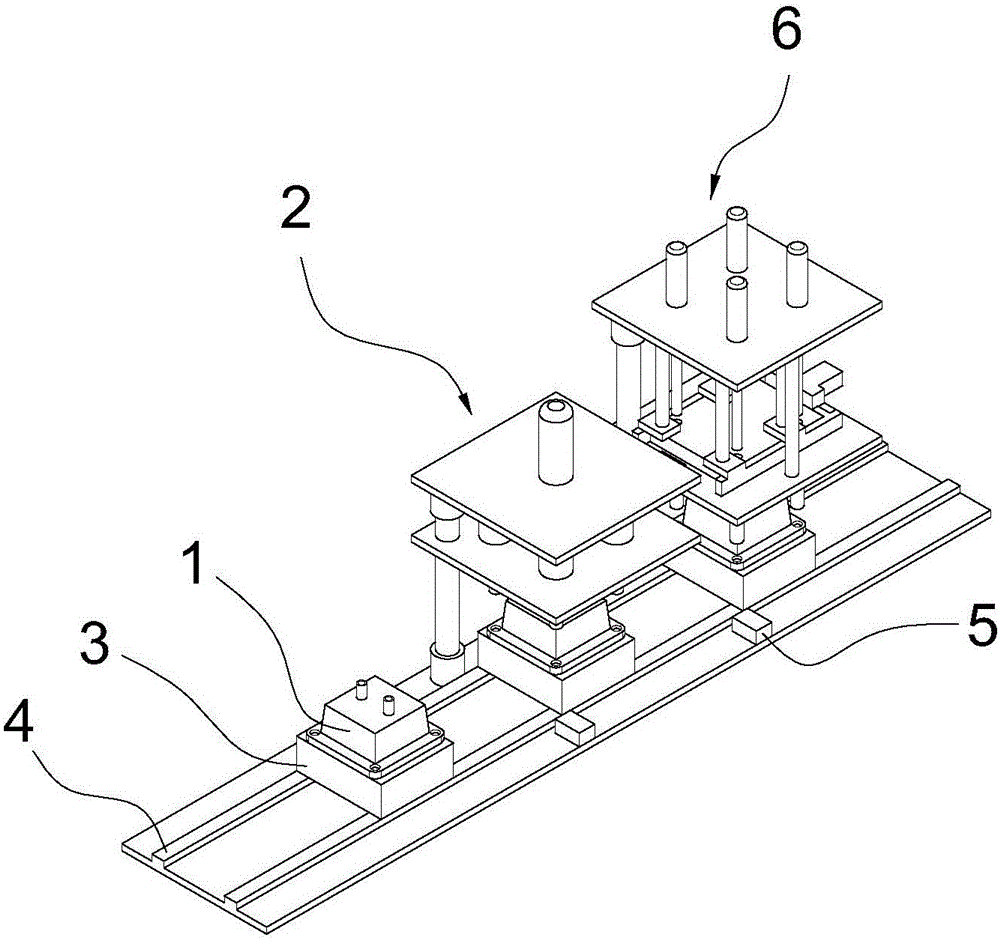

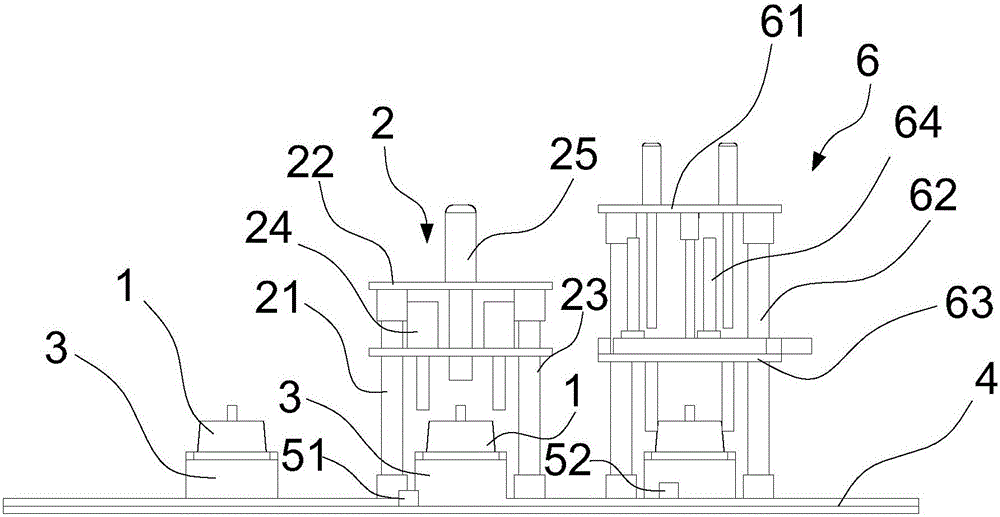

[0027] Such as Figure 1 to Figure 3 As shown, the membrane gas meter locking screw automatic feeding and locking assembly line of the present invention includes a locking device 2, a transport trolley 3, a guide rail 4, and a feeding device 6; the locking device 2 includes a top plate 21, a guide post 22. Slide plate 23; said guide post 22 has at least two, said top plate 21 is arranged on the top of guide post 22, and is fixedly connected with guide post 22, and said slide plate 23 is arranged under top plate 21; The column 22 passes through the sliding plate 23 and is slidably connected with the sliding plate 23;

[0028] A lifting device 25 is arranged between the sliding plate 23 and the top plate 21; the telescopic end of the lifting device 25 is fixedly connected with the sliding plate 23, and the other end is fixedly connected with the top plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com