Double-layer lifting workbench

A technology for raising and lowering workbenches and workbenches, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

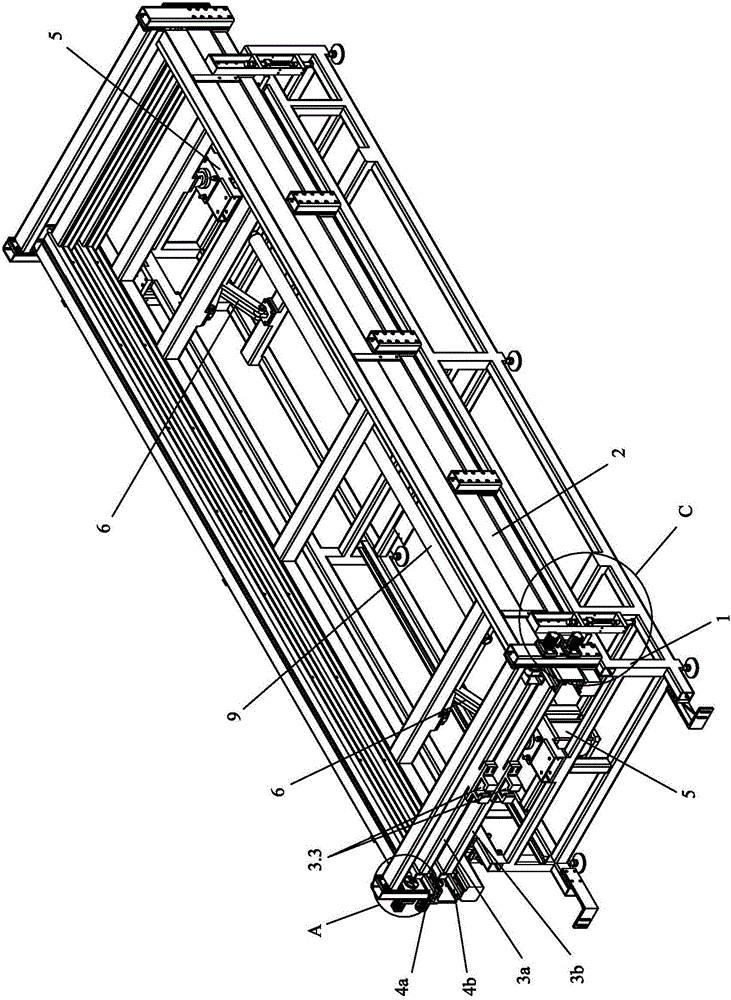

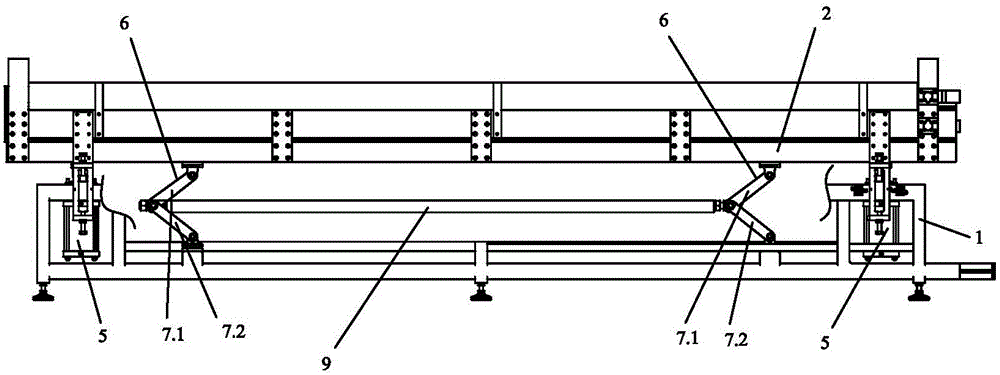

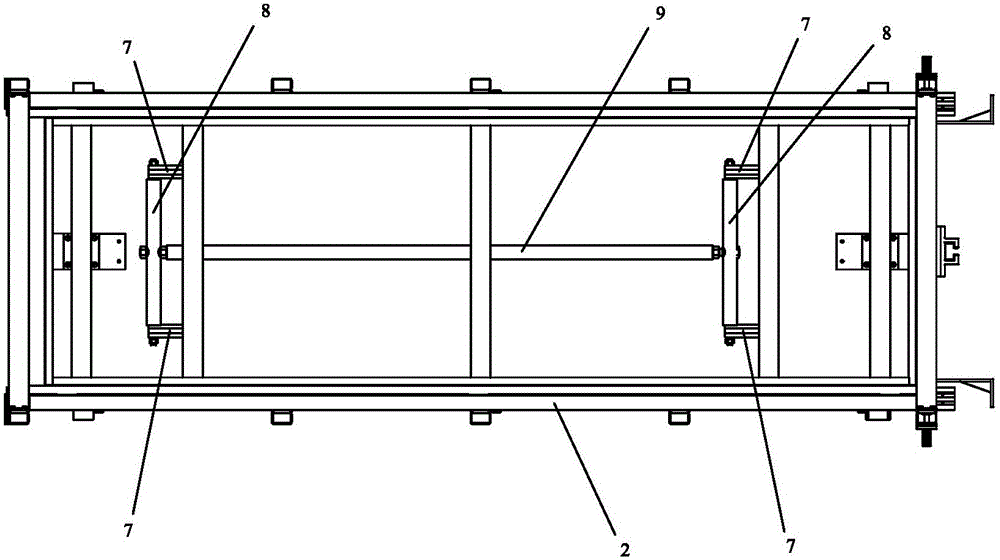

[0028] See attached figure 1 to attach Figure 9 As shown, a double-layer lifting workbench includes a support 1, a bed 2, two workbenches that are both slidably connected to the bed 2, and is installed on the support 1 and connected with the bed 2 to drive the bed 2 The driving device 5 that lifts together with the workbench; the bed 2 is provided with a guide rail group, and pulleys 3.2 are installed on the two long edges of the workbench; the workbench can slide on the bed 2 through the cooperation of the pulleys and the guide rails, and The table can be slid into the bed 2 or out of the bed 2 . The workbench includes a first workbench 3a and a second workbench 3b arranged in parallel up and down; the first workbench 3a is located above the second workbench 3b; correspondingly, the bed is provided with a first guide rail group 4a and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com