Maintenance method and special maintenance device for ship rudder blade and rudder arm

A special device and rudder arm technology, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of increased maintenance workload, great influence on the normal operation of the ship, and low efficiency, so as to improve maintenance safety performance and avoid slipping damage , The effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

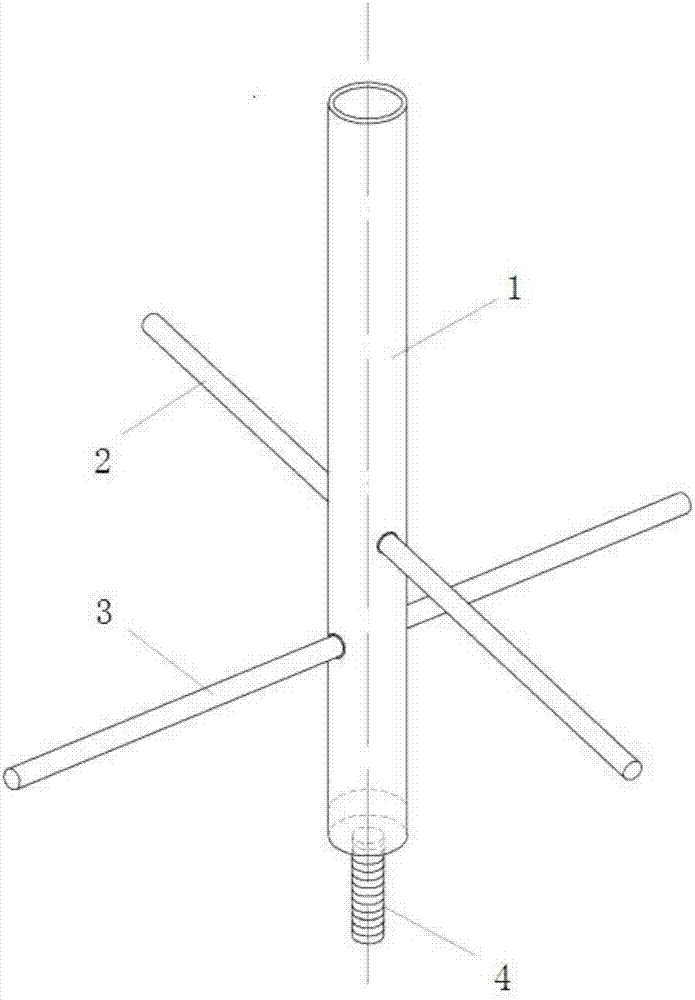

[0015] See figure 1 , The special device for repairing rudder blades and rudder arms of the present invention includes a main body 1 , a first cross bar 2 , a second cross bar 3 and a threaded part 4 . The main part 1 is elongated cylindrical, and its outer diameter is slightly smaller than the diameter of the rudder blade shaft. Through holes are respectively arranged at 2 / 3 and 1 / 3 of the main part 1 from bottom to top, and the two through holes are along the The main parts 1 extend radially and are perpendicular to each other. The first crossbar 2 and the second crossbar 3 are elongated cylinders with the same radius and the same length, and are respectively inserted into the two through holes, so the first crossbar 2 and the second crossbar 3 are perpendicular to each other. The threaded part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com