Ultra-high performance concrete - ordinary concrete shield tunnel segment and its construction method

A shield tunnel segment and ordinary concrete technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve the problems of concrete damage, water leakage, and easy cracking of the outer surface, so as to achieve good waterproof performance and avoid structural damage , Improve the effect of interface shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

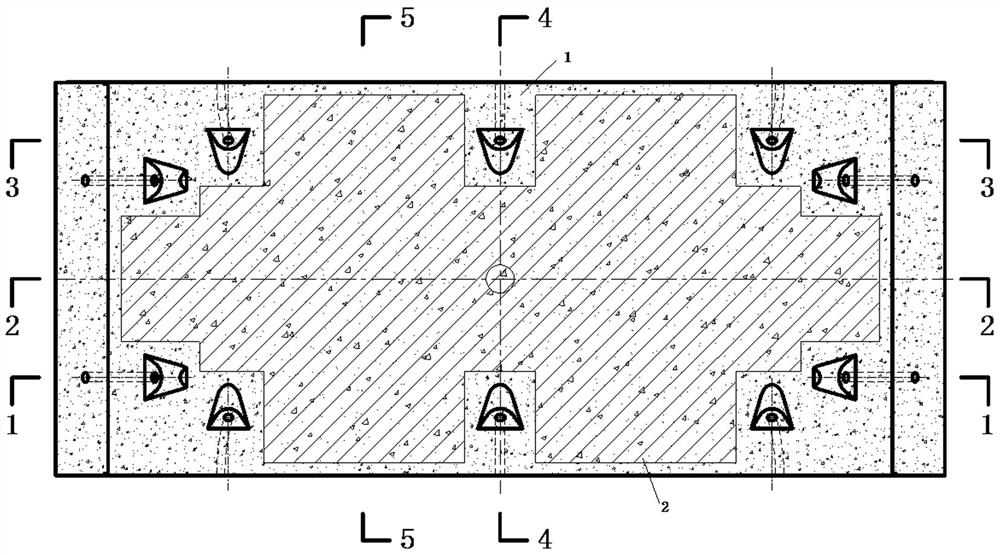

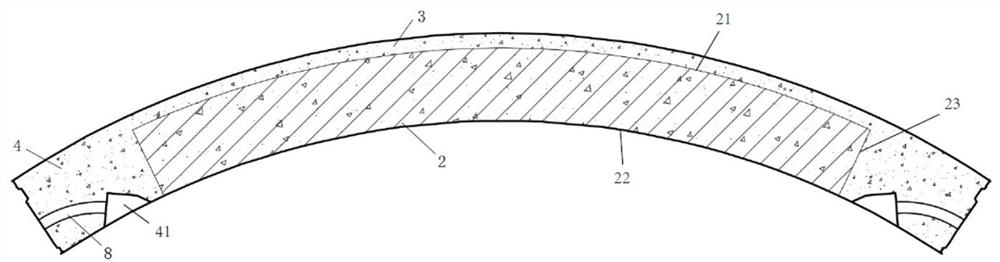

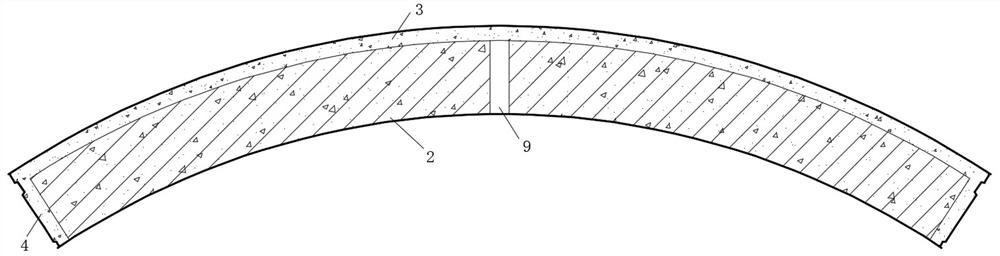

[0056] The invention provides an ultra-high performance concrete—ordinary concrete shield tunnel segment with an outer diameter of 6200mm, a wall thickness of 350mm, and a ring width of 1500mm. Among them, the ultra-high performance concrete layer is 50mm thick, the thinnest part of the flange of the ultra-high performance concrete layer is 50mm, and the thickest part is 410mm, and the thickness of the reinforced concrete layer is 300mm. The HRB400 steel bar, the stirrup adopts the HPB300 steel bar with a diameter of 10mm, the concrete grade is C50, and the compressive strength of ultra-high performance concrete is 150Mpa.

[0057] The present invention also provides a construction method of the ultra-high performance concrete-ordinary concrete shield tunnel segment, comprising the following steps:

[0058] Step 1. Welding steel mesh and steel cage respectively;

[0059] Step 2: Lift the reinforcement cage into the reinforced concrete layer mold, install the grouting hole res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com