Electric driving system

A technology of electric drive and drive seat, which is applied in the direction of electric power devices, motor vehicles, transmission devices, etc., can solve the problems of poor safety and stability, large drive volume, and inconvenient maintenance, and achieve convenient maintenance and repair, accurate reduction ratio, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

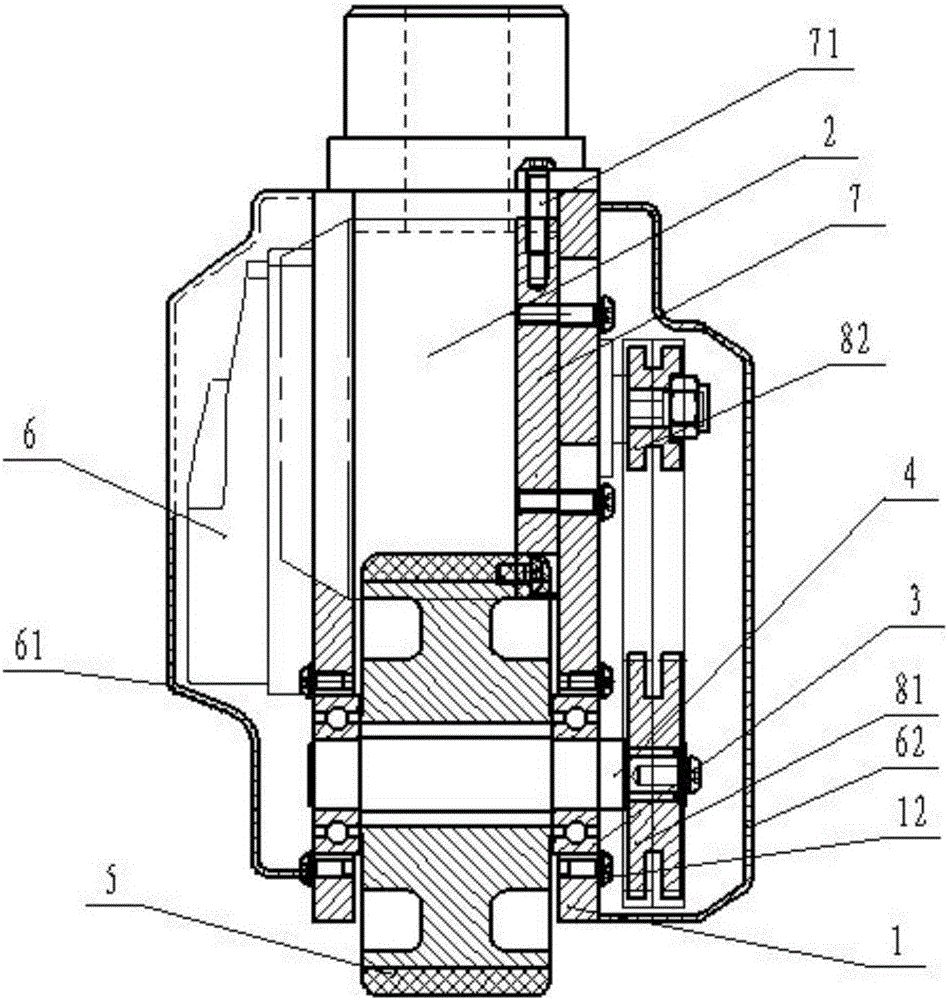

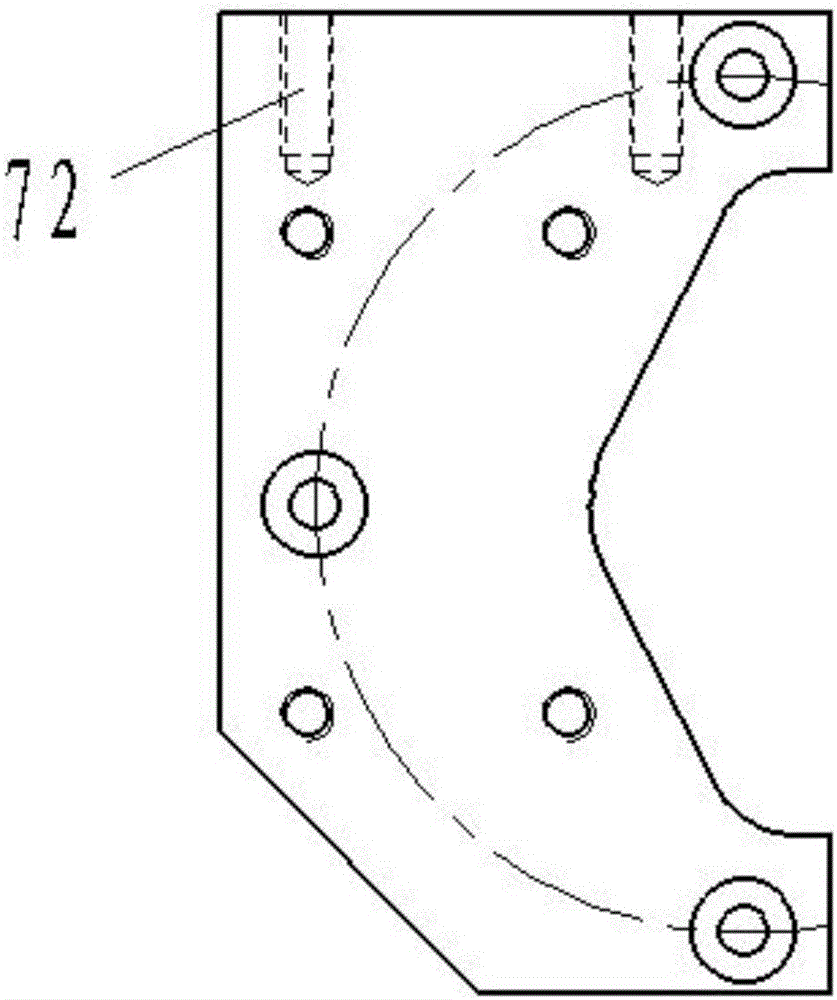

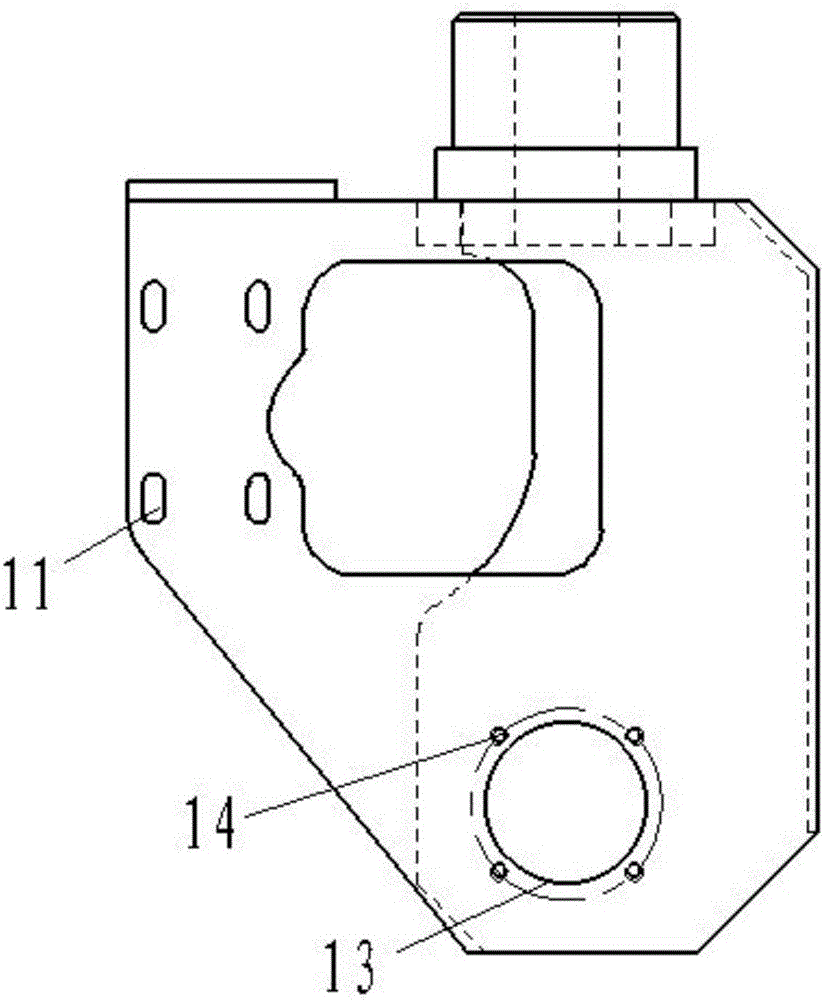

[0025] An electric drive system such as Figure 1-Figure 6 As shown, the drive base 1 is included, the drive base 1 is fixed with a motor mounting plate 7 by bolts, and the motor mounting plate 7 is provided with threaded mounting holes on the front, which can be installed on the drive base 1 by bolts; the motor mounting plate 7 is fixedly installed with Drive motor 2. The driving seat 1 is provided with a waist hole 11 for the bolt to move up and down, and the bolt passes through the waist hole 11 and is fixed in the threaded mounting hole to realize the fixing of the motor mounting plate 7. The waist hole 11 is arranged along the height direction, and the screw of the bolt The diameter of the cap part is greater than the width of the waist hole 11, and the height of the motor mounting plate 7 is changed by changing the position of the bolt in the waist hole 11. In this embodiment, the top of the motor mounting plate 7 is provided with a longitudinally arranged threaded moun...

Embodiment 2

[0031] The same as embodiment 1, the difference is that the drive shaft 4 in this embodiment is provided with a keyway, and the torque is transmitted between the middle part of the drive wheel and the drive shaft through a flat key, so that the drive wheel 5 rotates with the drive shaft 4, avoiding the drive shaft. The situation that the driving wheel cannot effectively and continuously output the driving force due to mutual rotation with the driving wheel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com