Lifting carrier vehicle

A carrier vehicle and lifting technology, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of time-consuming and labor-intensive handling, large space occupation, and bulky volume, etc., to reduce labor intensity, occupy small space, and The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

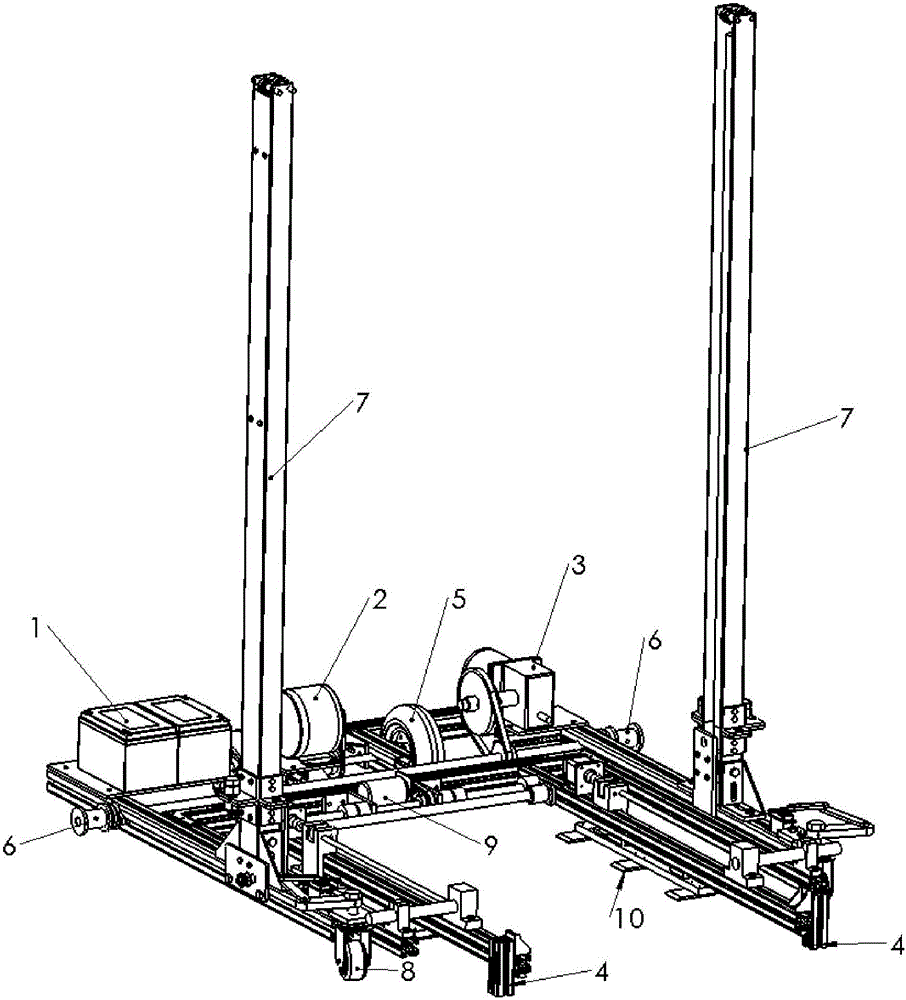

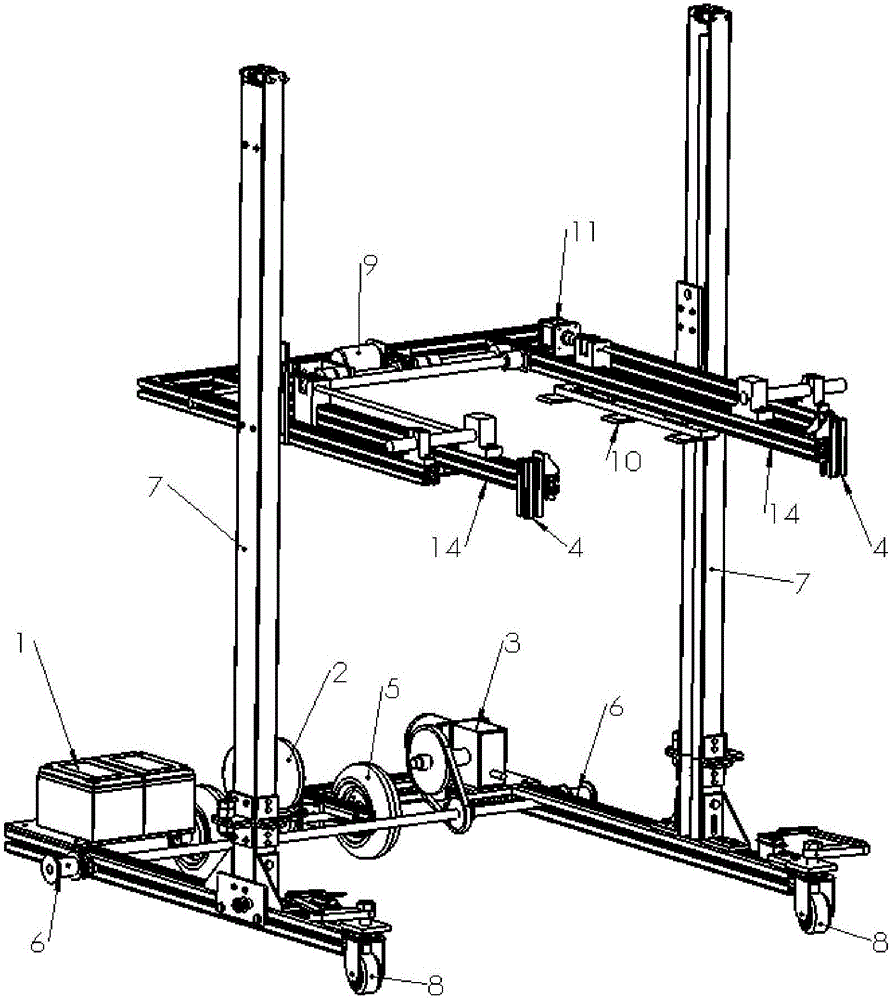

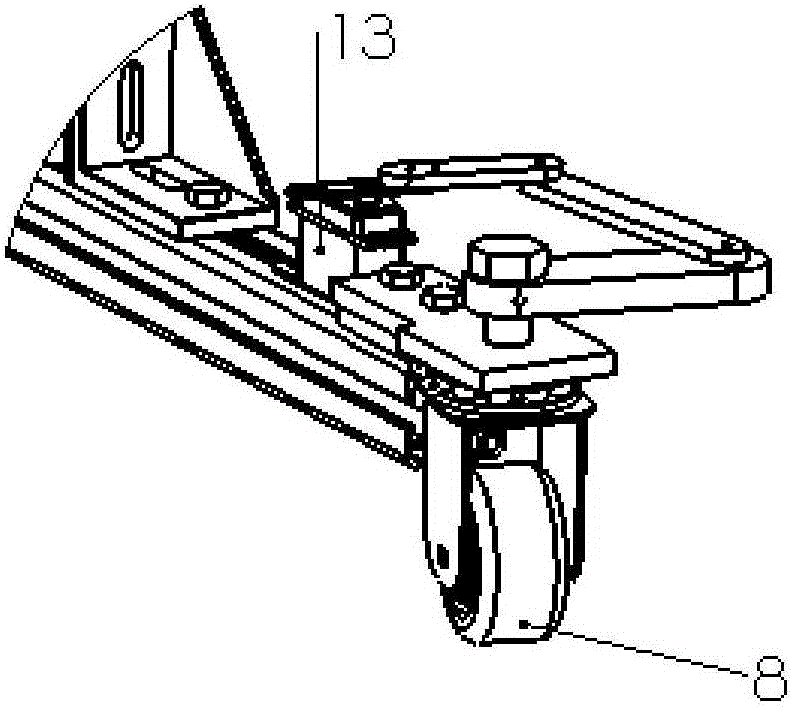

[0030] An elevating carrier vehicle in this embodiment comprises a vehicle chassis, a driving device for driving the vehicle chassis to move and turn, a movable clamping device for carrying heavy objects, and a lifting device for driving the movable clamping device to move in the vertical direction. device, and a lifting support rod mechanism; the driving device is installed on the undercarriage, the lifting device is movably arranged on the lifting support rod mechanism, and the lifting support mechanism is fixedly arranged on the base.

[0031] when working, such as figure 1 As shown, the goods are placed on the ground without pallets underneath. The lifting carrier is controlled by the remote control device to travel to the appropriate position of the goods. At this time, the fork claw 10 is facing the goods. Two movable aluminum rods 14, a DC motor 9 and two left-handed screw rods 15 and right-handed The screw rod 16 forms a movable clamping structure, and the DC motor 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com