Lightweight and high-strength thermal insulation material and preparation method thereof

A thermal insulation material and high-strength technology, applied in the field of building materials, can solve the problems of endangering human and animal safety in runoff areas, polluting groundwater and soil, low utilization rate of ferrochromium slag, etc., achieving significant economic and social benefits, simple preparation method, reducing The effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

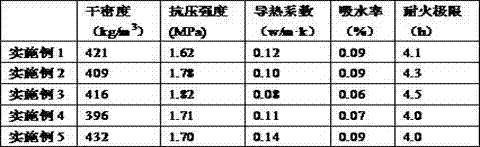

Examples

Embodiment 1

[0027] A light-weight and high-strength thermal insulation material, which is composed of the following raw materials in parts by weight: 100 parts of cement, 10 parts of vermiculite, 25 parts of fly ash, 50 parts of granulated ferrochrome slag, 0.25 parts of activator, and 10 parts of admixture parts, 180 parts of water;

[0028] The activator is obtained by mixing ethylenediaminetetraacetic acid and tetramethylammonium iodide in a weight ratio of 1:0.3;

[0029] The admixture is obtained by mixing polycarboxylic acid superplasticizer, sodium lauryl sulfate, triethanolamine, calcium carbonate and silane coupling agent according to the weight ratio of 3:3.5:1.5:5:1.0.

[0030] The particle size of the granulated ferrochrome slag is 1mm.

[0031] As mentioned, the particle size of the vermiculite is 4.75mm.

[0032] As mentioned, the fly ash is commercially available grade I fly ash.

[0033] A method for preparing a lightweight and high-strength thermal insulation material,...

Embodiment 2

[0039] A light-weight and high-strength thermal insulation material, which is composed of the following raw materials in parts by weight: 100 parts of cement, 13 parts of vermiculite, 28 parts of fly ash, 32 parts of granulated ferrochrome slag, 0.5 parts of activator, and 13 parts of admixture parts, 160 parts of water;

[0040] The activator is obtained by mixing ethylenediaminetetraacetic acid and tetramethylammonium iodide in a weight ratio of 1:0.4;

[0041] The admixture is obtained by mixing polycarboxylate superplasticizer, sodium lauryl sulfate, triethanolamine, calcium carbonate and silane coupling agent according to the weight ratio of 4:2.5:1.4:6:0.9.

[0042] The particle size of the granulated ferrochrome slag is 5mm.

[0043] As mentioned, the particle size of the vermiculite is 4.05mm.

[0044] As mentioned, the fly ash is commercially available grade II fly ash.

[0045] All the other are with embodiment 1.

Embodiment 3

[0047] A light-weight and high-strength thermal insulation material, which is composed of the following raw materials in parts by weight: 100 parts of cement, 15 parts of vermiculite, 30 parts of fly ash, 30 parts of granulated ferrochrome slag, 0.8 parts of activator, and 16 parts of admixture parts, 150 parts of water;

[0048] The activator is obtained by mixing ethylenediaminetetraacetic acid and tetramethylammonium iodide in a weight ratio of 1:0.4;

[0049] The admixture is obtained by mixing polycarboxylic acid superplasticizer, sodium lauryl sulfate, triethanolamine, calcium carbonate and silane coupling agent according to the weight ratio of 5:2:1.3:7:0.8.

[0050] The particle size of the granulated ferrochrome slag is 10mm.

[0051] As mentioned, the particle size of the vermiculite is 3.10mm.

[0052] As mentioned, the fly ash is commercially available grade I fly ash.

[0053] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com