Corrosion inhibition method and coating device for converter valve aluminum radiating base

A heat sink, converter valve technology, applied in the direction of coating, solid-state chemical plating, metal material coating process, etc., can solve the problems of heavy workload, treatment effect is greatly affected by human factors, etc., to solve the scaling problem , Solve the scaling problem of equalizing electrodes and slow down the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example

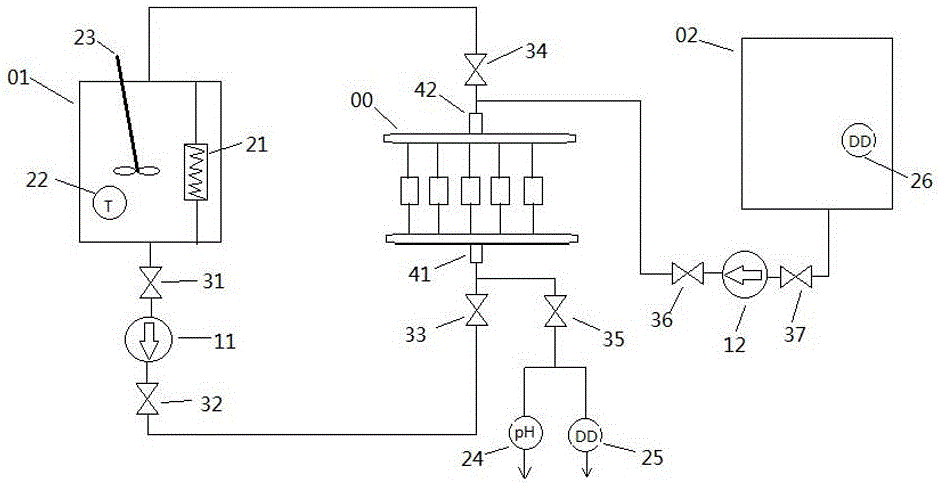

[0035] A coating device for the aluminum heat sink of the converter valve of the present invention, such as figure 1 As shown, the coating device includes a coating solution volume tank 01, the coating solution volume tank 01 is provided with a liquid outlet pipeline and a liquid return pipeline, and the liquid outlet pipeline is communicated with the manifold inlet 41 of the valve assembly 00, The liquid return line is communicated with the manifold outlet 42 of the valve assembly 00, and the valve assembly 00 is provided with a converter valve aluminum heat sink (due to the existing structure of the valve assembly 00, in the figure 1 The drawing is omitted in the figure); there is a coating liquid injection pump 11 on the liquid outlet pipeline. The inlet of the coating liquid injection pump 11 is connected to the bottom of the coating liquid volume tank 01, and a coating liquid injection pump inlet door 31 is installed therebetween, and the outlet of the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com