A slope reinforcement device and reinforcement method

A reinforcement device and slope technology, which is applied in the fields of tracks, roads and bridges, to achieve the effect of prolonging service life, simple construction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

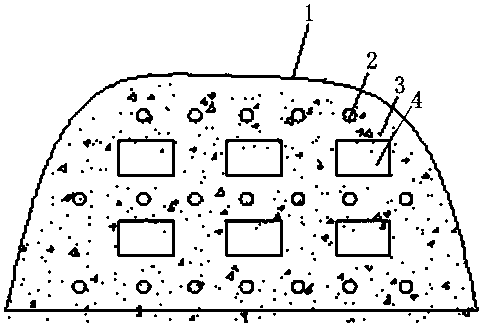

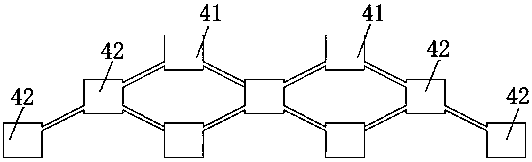

[0027] Such as figure 1 As shown, a side slope reinforcement device includes a side slope 1, a mortar layer 3 is sprayed on the surface of the side slope 1 and a number of greening pits 2 are left, and a liquid supply system consisting of a number of water collection wells 41 and a number of water diversion wells 42 is also included. 4. Each water diversion well 42 is evenly arranged in the soil body of the slope 1 and communicates with each other, and each water collection well 41 is arranged on the mortar layer 3 and communicates directly or indirectly with each water diversion well 42, such as figure 2 shown.

[0028] The water diversion wells 42 are distributed in steps, with a horizontal spacing of 2-3m and a vertical spacing of 1.5-2m.

[0029] Each green pit 2 is spaced 1-1.5m apart.

[0030] The thickness of the mortar layer 3 is 120-200mm, and the strength is not lower than C20.

Embodiment 2

[0032] A slope reinforcement method, comprising the following steps:

[0033] The first step is to level the slope of side slope 1.

[0034] The second step is to excavate some greening pits 2, water collection wells 41 and water diversion wells 42 and the grooves connecting each water collection wells 41 and water diversion wells 42 respectively on the slope surface, and establish molds for each groove, water collection wells 41 and water diversion wells. 42. Greening pit 2 cast-in-place mortar or concrete molding, such as figure 1 shown.

[0035] In the second step, each water-distributing well 42 is distributed in a ladder shape, and the horizontal spacing is 2-3m, and the vertical spacing is 1.5-2m. figure 2 shown.

[0036] In the second step, each greening pit 2 is spaced 1-1.5m apart.

[0037] The third step is to spray mortar or concrete on the slope as a whole to cover all the other parts except the greening pit 2 and the water collection well 41 .

[0038] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com