Manufacture of sliding unloading device controlled by hydraulic displacement and method for unloading components

A technology of displacement control and unloading device, which is applied in building construction, processing of building materials, construction, etc., can solve problems such as unstable unloading, achieve the effects of avoiding welding process, convenient operation, and ensuring precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

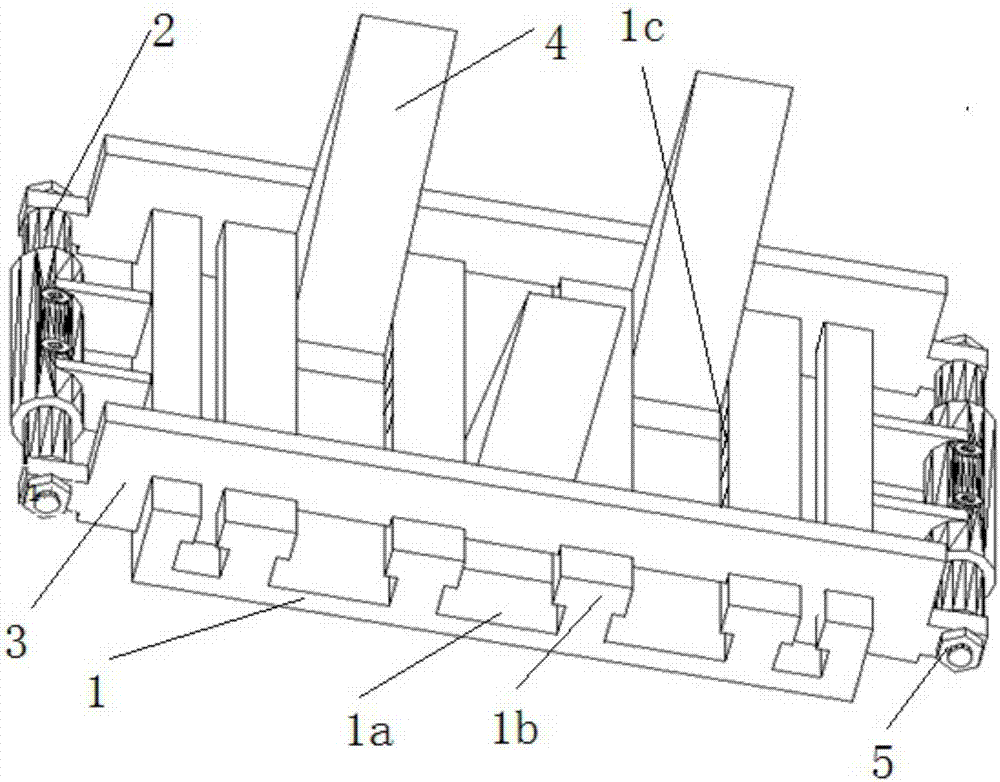

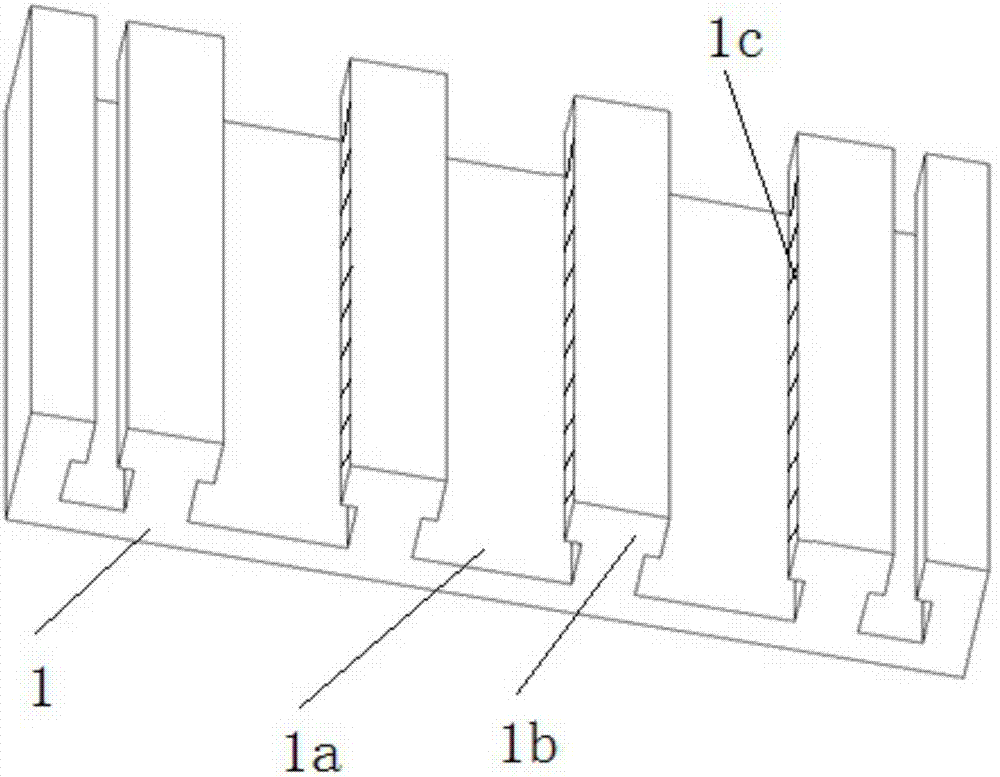

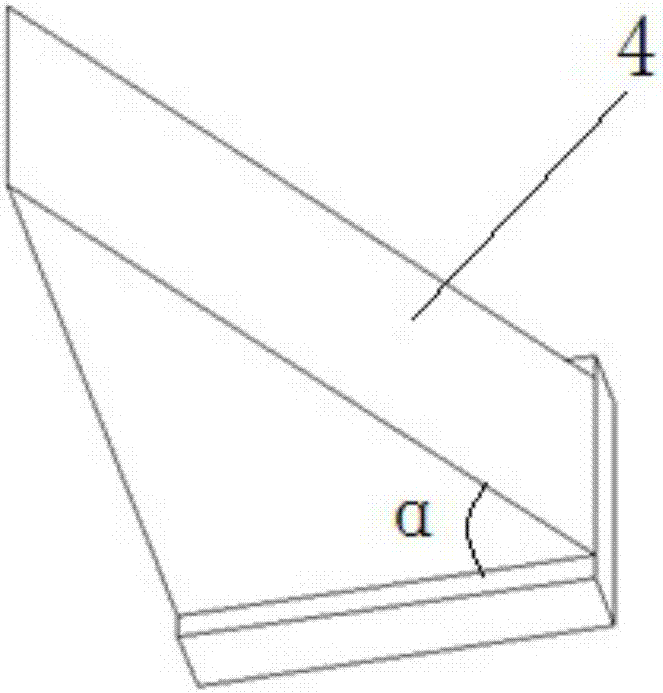

[0019] Such as Figure 1 to Figure 5 The sliding unloading device with hydraulic rod displacement control shown includes a rectangular support base 1 with a set of parallel chute 1a on the top surface, and two limiting hydraulic rods that are symmetrically installed on both sides of the support base and are parallel to the chute. 2. Two parallel baffles that are symmetrically installed on the other two sides of the support base and can slide along the chute 3. Right-angled triangular plates that are installed on the support base and are located in the two baffles and can slide along the chute 4; baffles The two ends of 3 are respectively set on the limit hydraulic rods 2 on both sides; a raised guide rail 1b is formed between the chutes; there are at least three right-angled triangles, of which two right-angled triangles are installed symmetrically at least one chute apart,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com