Well pattern spacing method of triangular horizontal well

A horizontal well, triangular technology, applied in wellbore/well components, earthwork drilling, production of fluids, etc., can solve the problems of fractured water flooding and large initial decline, reduce initial decline, improve single well production, reduce Effects of Fracture Flood Risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

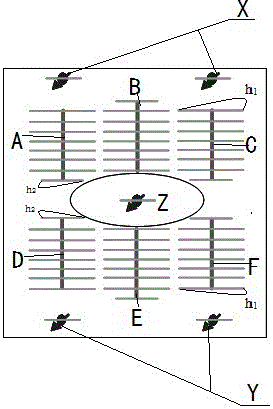

[0030] Such as figure 1 As shown, the triangular horizontal well pattern well layout method includes the following steps,

[0031] Step 1, select six parallel first horizontal well A, second horizontal well B, third horizontal well C, fourth horizontal well D, fifth horizontal well E, sixth horizontal well F, fourth horizontal well D The first horizontal well A is located in the same column and coaxial, the fifth horizontal well E and the second horizontal well B are located in the same column and coaxial, the sixth horizontal well F and the third horizontal well C are located in the same column and coaxial,

[0032] The third water injection well Z is located between the second horizontal well B and the fifth horizontal well E, and is perpendicular to the second horizontal well B, and the two first water injection wells X are respectively on the same side of the first horizontal well A and the third horizontal well C and perpendicular to the first horizontal well A or the th...

Embodiment 2

[0041] On the basis of Example 1, the spacing between two adjacent wells of the six horizontal wells described in Step 1 is 500m. The row spacing between the first water injection well X at the end of the first horizontal well A and the first horizontal well A, and the row spacing between the first water injection well X at the end of the third horizontal well C and the third horizontal well C , the row spacing between the second water injection well Y at the end of the fourth horizontal well D and the fourth horizontal well D, and the row spacing between the second water injection well Y at the end of the sixth horizontal well F and the sixth horizontal well F are 180-220m. The row spacing between the first water injection well X at the end of the first horizontal well A or the third horizontal well C and the second horizontal well B, the second injection well at the end of the fourth horizontal well D or the sixth horizontal well F The row spacing of the water injection wel...

Embodiment 3

[0062] On the basis of Example 2, the row spacing between the first water injection well X at the end of the first horizontal well A and the first horizontal well A, the distance between the first water injection well X at the end of the third horizontal well C and The row spacing of the third horizontal well C, the row spacing between the second water injection well Y at the end of the fourth horizontal well D and the fourth horizontal well D, the second water injection well Y at the end of the sixth horizontal well F and the sixth horizontal well Y The row spacing of horizontal well F is 200m. The row spacing between the first water injection well X at the end of the first horizontal well A or the third horizontal well C and the second horizontal well B, the second injection well at the end of the fourth horizontal well D or the sixth horizontal well F The row spacing of water injection well Y and the fifth horizontal well E are both 130m.

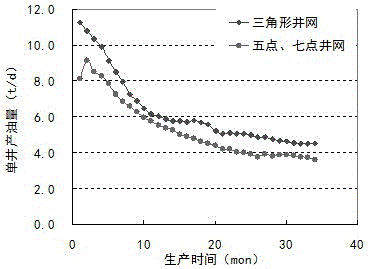

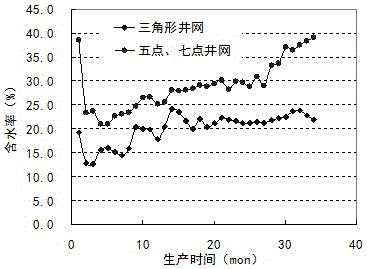

[0063] According to the main lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com