Vacuum self-sucking pump with suction aid mechanism

A self-priming pump, vacuum pump technology, applied in the direction of the pump, the components of the pumping device for elastic fluid, the driving pump, etc., can solve the problems of burning out the motor or diesel engine, idling of the pump, low suction lift, etc., to achieve protection Safe operation and improved suction lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

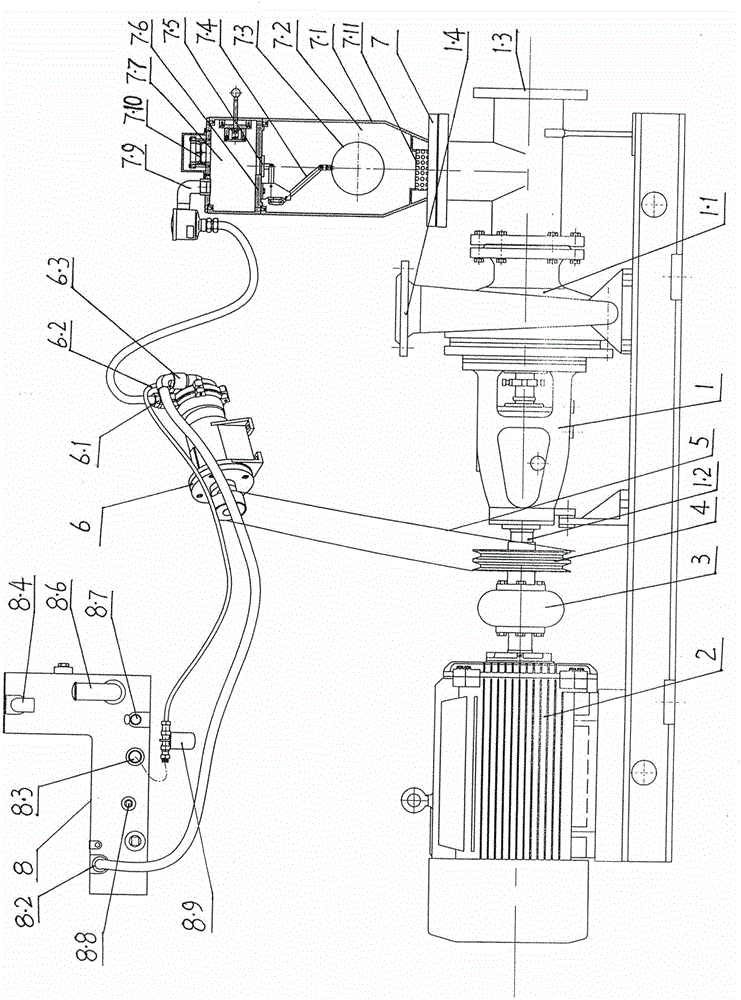

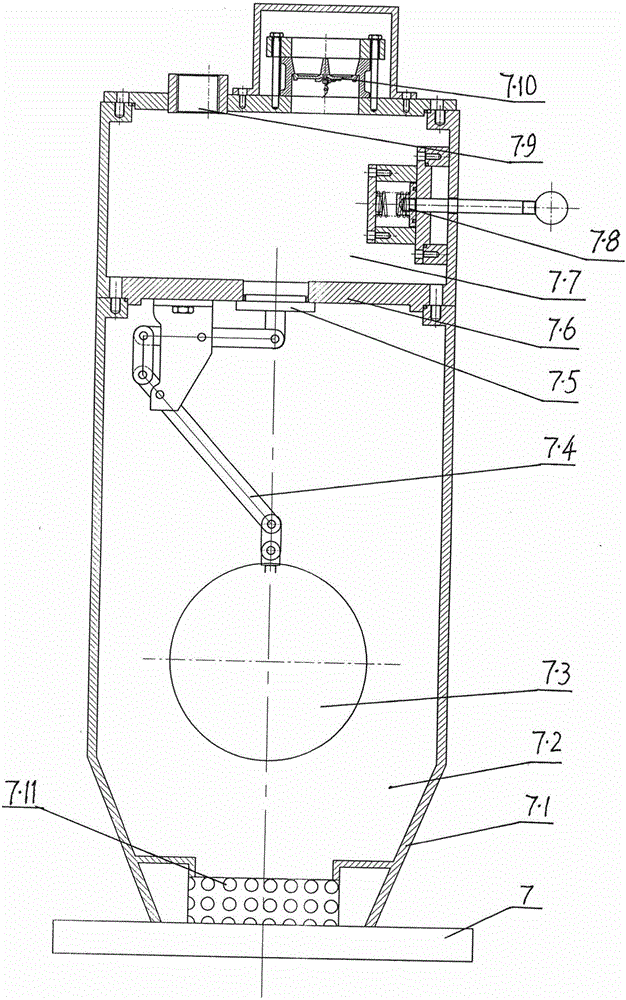

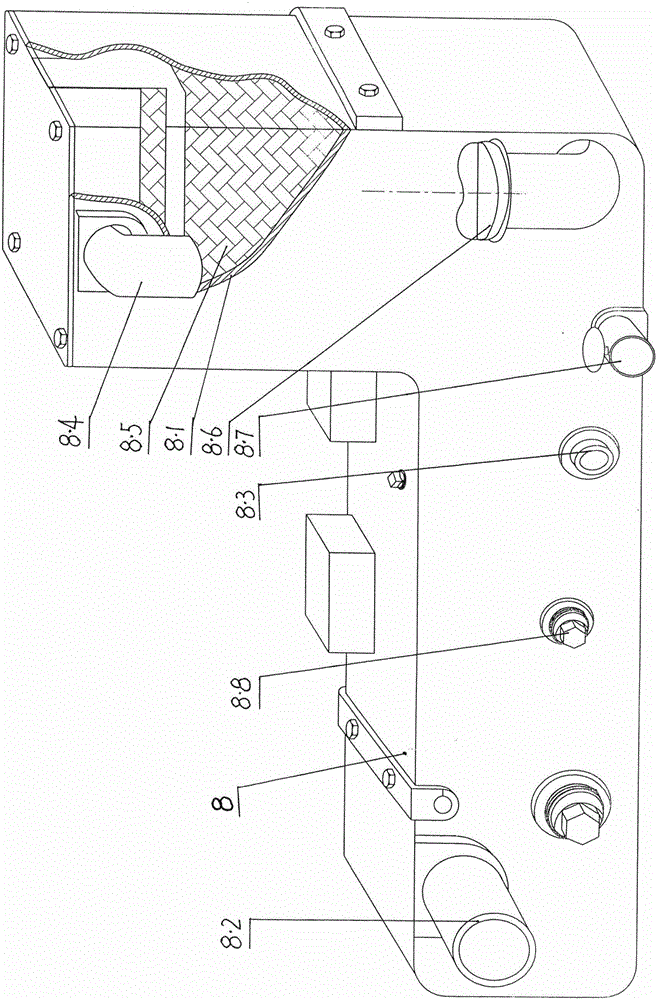

[0013] Such as figure 1 The vacuum self-priming pump with a suction-assisted mechanism shown includes a pump 1 and a power part. The pump 1 includes a pump body 1.1, a pump shaft 1.2, and an impeller. The pump body 1.1 has an inlet channel 1.3 and an outlet channel 1.4. One end of the pump shaft 1.2 is connected to the The impeller is fixedly connected, and the other end of the pump shaft 1.2 is connected to the output shaft of the power part through a coupling 3, and the power part adopts a motor 2 or a diesel engine; a suction-assisted mechanism is provided on the inlet channel 1.3 of the pump body 1.1, and the suction-assisted mechanism is controlled by a vacuum Water diverter 7, vacuum pump 6, condenser 8 are composed; the rotating shaft of vacuum pump 6 is connected by belt 5 and pulley 4 fixed on the pump shaft 1.2, and when the pump shaft 1.2 rotates, it drives the vacuum pump 6 to rotate at the same time, and the first inlet 6.1 of the vacuum pump 6 passes through The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com