Floor spring test system

A test system and frame technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of long time consumption, low precision, and large labor, saving time and labor, Improved accuracy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

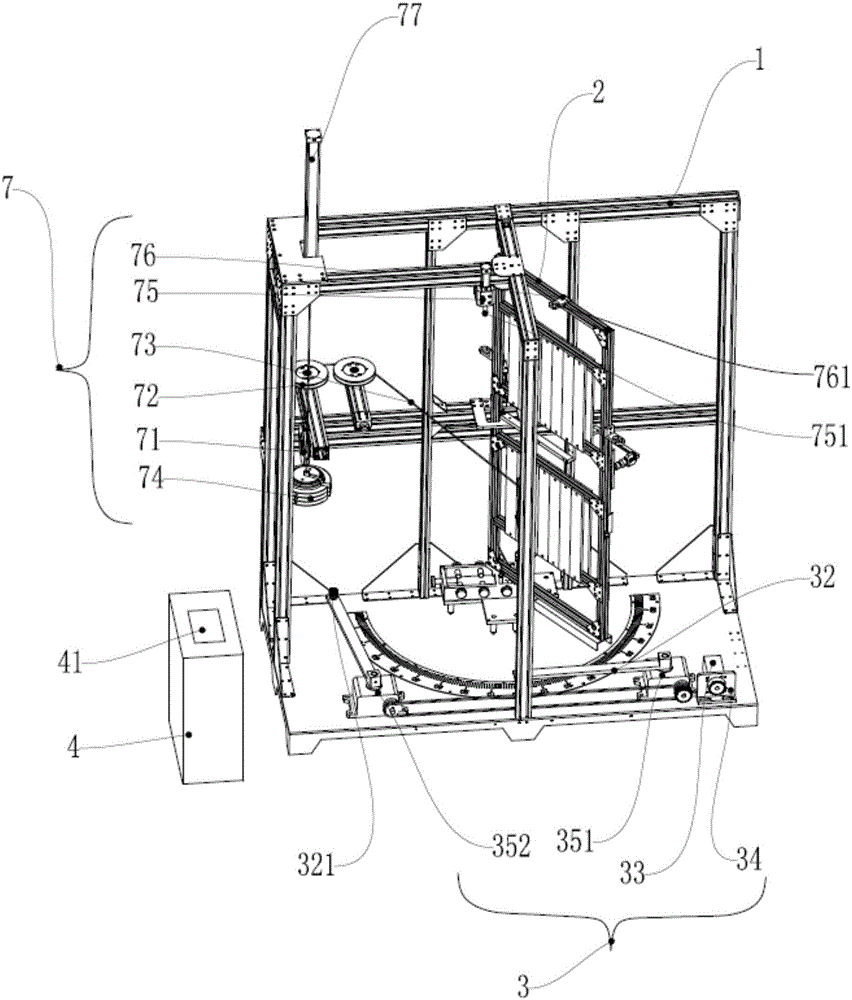

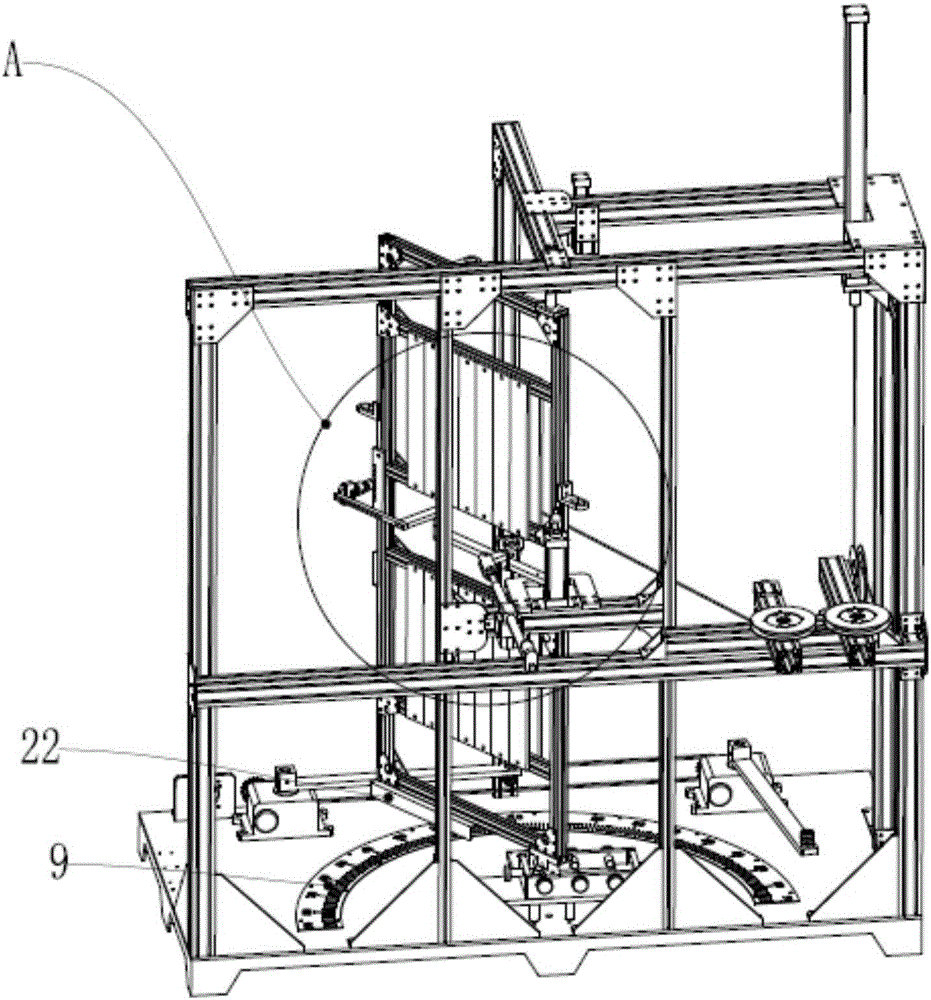

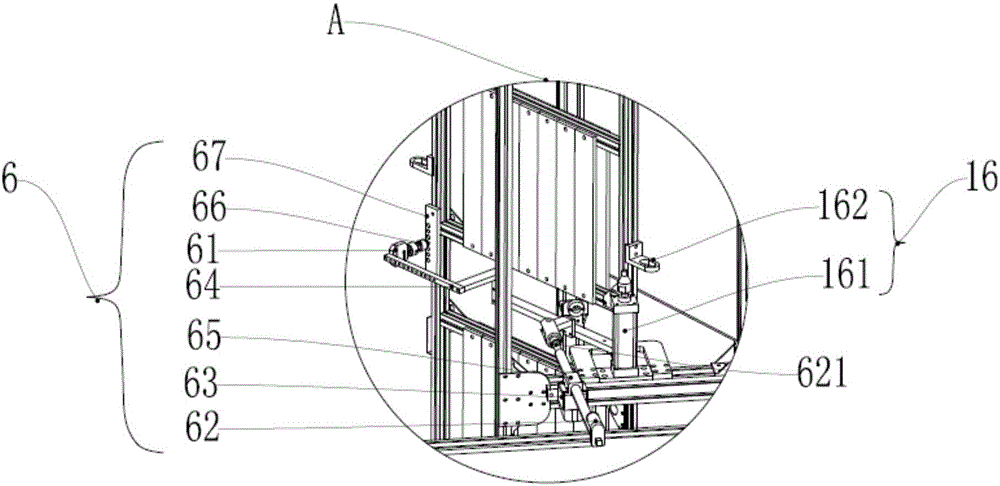

[0043] Such as figure 1 and figure 2 As shown, a floor spring test system includes a frame body 1, a test door 2, an actuator 3 and an electric control box 4;

[0044] The test door 2 is hinged in the frame 1 so that it can swing in the frame 1;

[0045] A swing groove 22 is installed at the bottom of the test door 2;

[0046] The actuator 3 is mounted on the bottom of the frame 1;

[0047] It also includes a swing rod 32, which is installed on the actuator 3, and the actuator 3 drives the swing rod 32 to rotate so as to cooperate with the swing groove 22 and pull the test door 2 to open and close;

[0048] It also includes a counting sensor installed on the frame body 1 .

[0049] The electric control box 4 is arranged on one side of the frame body 1 .

[0050] When using said a kind of groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com