Residual stress dynamic distribution ultrasonic array chromatography detecting and monitoring method

A technology of residual stress and ultrasonic array, which is applied in the analysis of solids by using sound waves/ultrasonic waves/infrasonic waves, material analysis by using sound waves/ultrasonic waves/infrasonic waves, and material analysis, etc., to achieve improved corrosion resistance, more lattices, and tighter lattices and solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

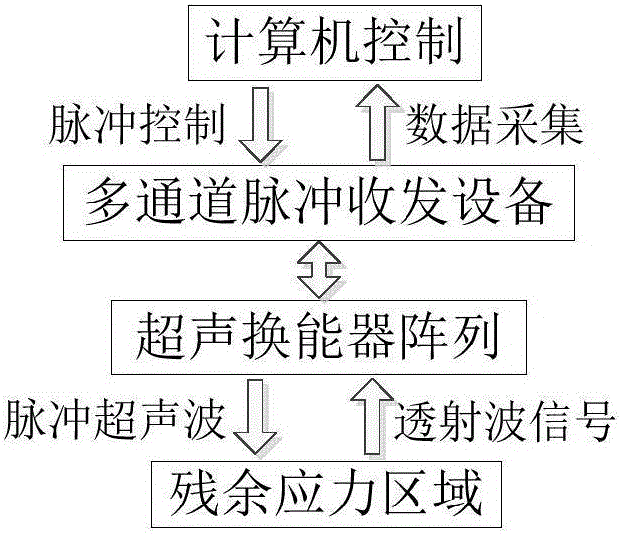

[0035] Concrete implementation steps of the present invention are described as follows:

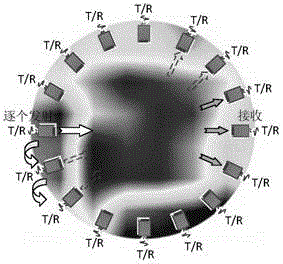

[0036] 1) Make one channel of the multi-channel pulse transceiver device emit pulses, excite an array element in the transducer array to emit ultrasonic waves, and then all array elements receive ultrasonic waves.

[0037] 2) The data acquisition device automatically stores the transmitted ultrasonic signal on the opposite side of the transmitting transducer, thereby completing a transceiving process.

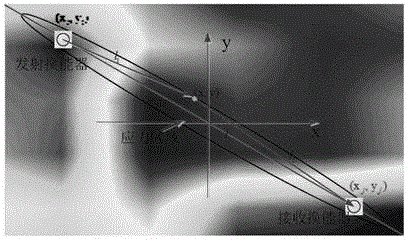

[0038] 3) To excite the critical refraction longitudinal wave in the component under test, each transducer in the array adopts oblique incidence mode, and the ultrasonic longitudinal wave is incident on the surface of the component, and the waveform conversion occurs on the surface of the component. The ultrasonic signal is excited by the piezoelectric transducer. On the interface between the plexiglass and the component under test, waveform conversion occurs, according to Snell's law,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com