Fruit-fly-optimization-algorithm-based multi-station assembling sequence planning method

A technology for assembly sequence planning and fruit fly optimization algorithm, applied in computing, computing model, manufacturing computing system, etc., can solve the problems that affect the quality of the algorithm, the parameter has a great influence, etc., and achieve the effect of avoiding premature phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

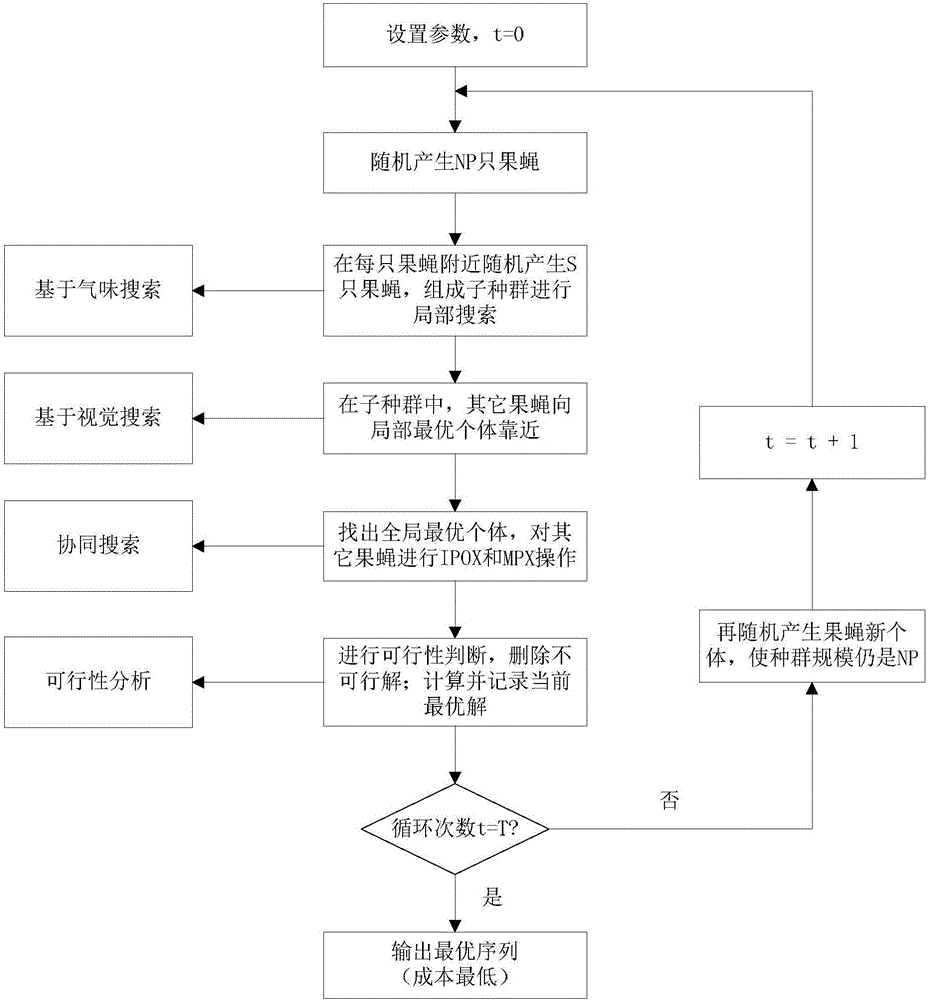

[0055] The multi-station assembly sequence planning method based on the fruit fly optimization algorithm of the present invention can be divided into four parts:

[0056] Part I - Coding Design

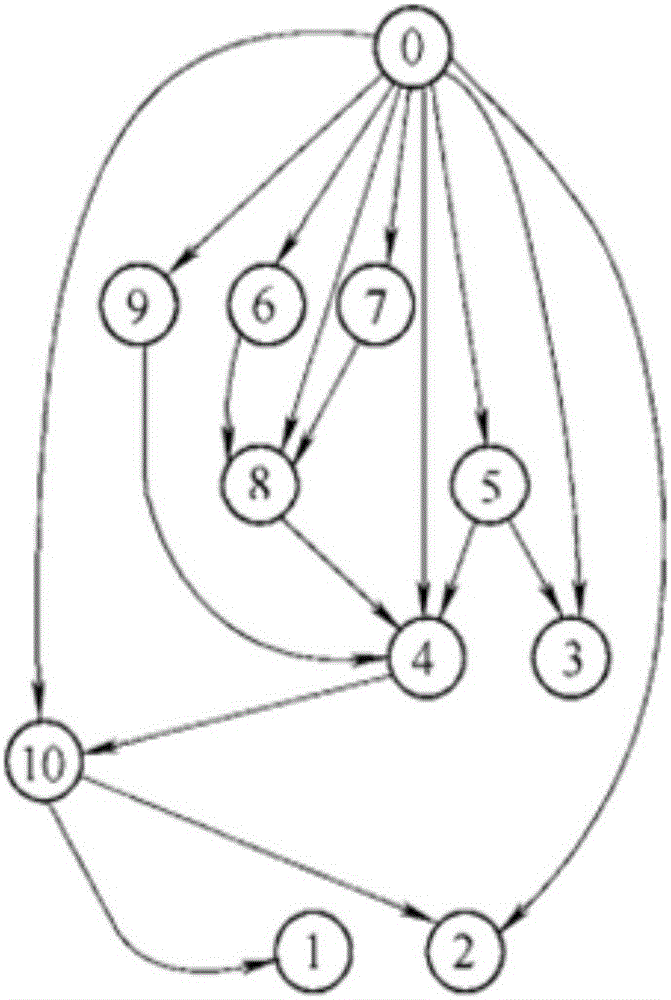

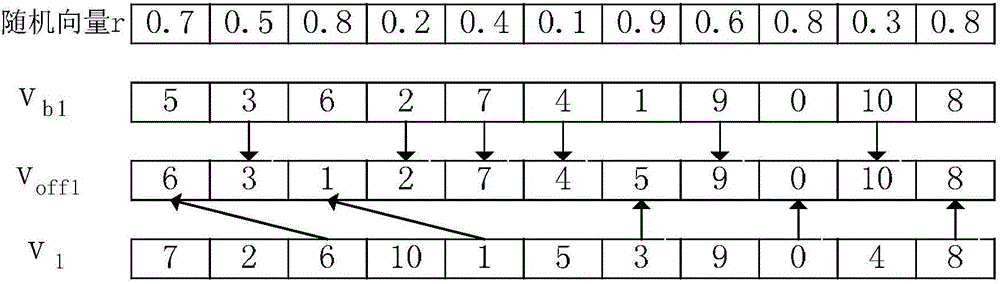

[0057] In the present invention, let each fruit fly represent a solution, that is, the assembly sequence and the station allocation sequence, and these two sequences are respectively represented by the vector v 1 and v 2 Indicates that the two-vector encoding method is used. Assembly sequence vector (v 1 ) represents the assembly order of the parts, its length is equal to the number of parts in value, and the position number on the vector where the part number is located represents the assembly order of the corresponding parts. The station allocation vector (v 2 ) indicates the corresponding assembly station in the part assembly process, and its length is also equal to the number of parts in value.

[0058] Part II - Fitness Function Construction

[0059] The invention takes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com