Mounting structure for transformer and use method of mounting structure

An installation structure and technology for transformers, applied in the field of transformers, can solve the problems of difficulty in artificially adjusting their positions, unfavorable positions, collisions between personnel and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

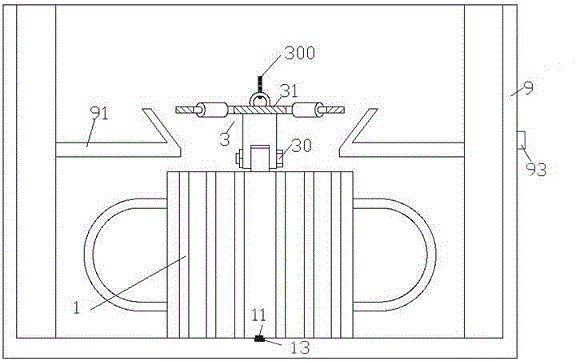

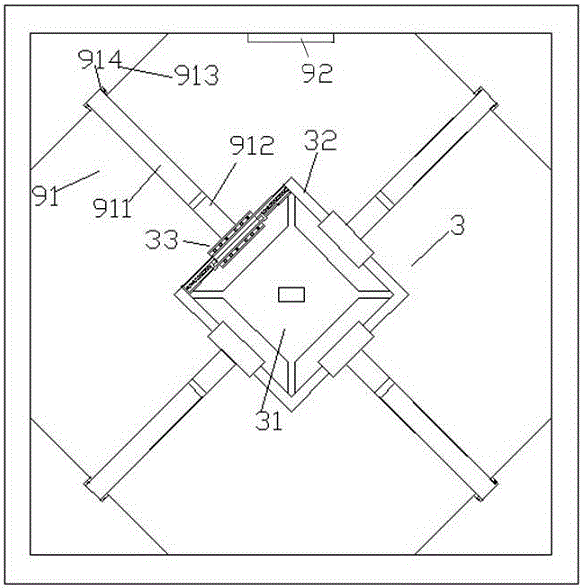

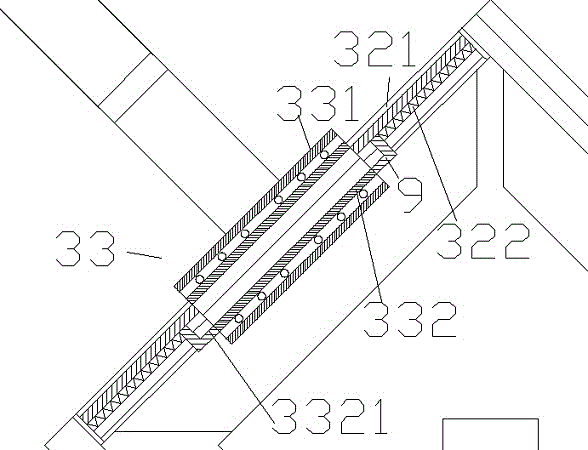

[0011] Combine below Figure 1-4 Embodiments of the present invention will be described.

[0012] refer to Figure 1-3 , according to an embodiment of an installation structure for a transformer, used to guide and position the transformer 1 during the process of installing the transformer 1 on a compartment device 9 with a square cross section, including installing the transformer 1 on the compartment device 9 The inclined plane guide frame assembly 91 and the positioning joint device 3 used to be fixedly connected with the transformer 1 through the fastener 30, the inclined plane guide frame assembly 91 includes four hingedly mounted on the compartment device 9 respectively. The four inclined-plane guide frames on the fixed corner plate 913 at the corner position, each inclined-plane guide frame all includes the rotating arm part 911 hinged with the described corner plate 913 through the hinge part 914 and the rotating arm part 911 hinged with the described rotating arm. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com