Variable stator vane mechanism

A static vane, variable technology, applied in mechanical equipment, non-variable pumps, engine manufacturing, etc., can solve problems such as engine starting block and inability to start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

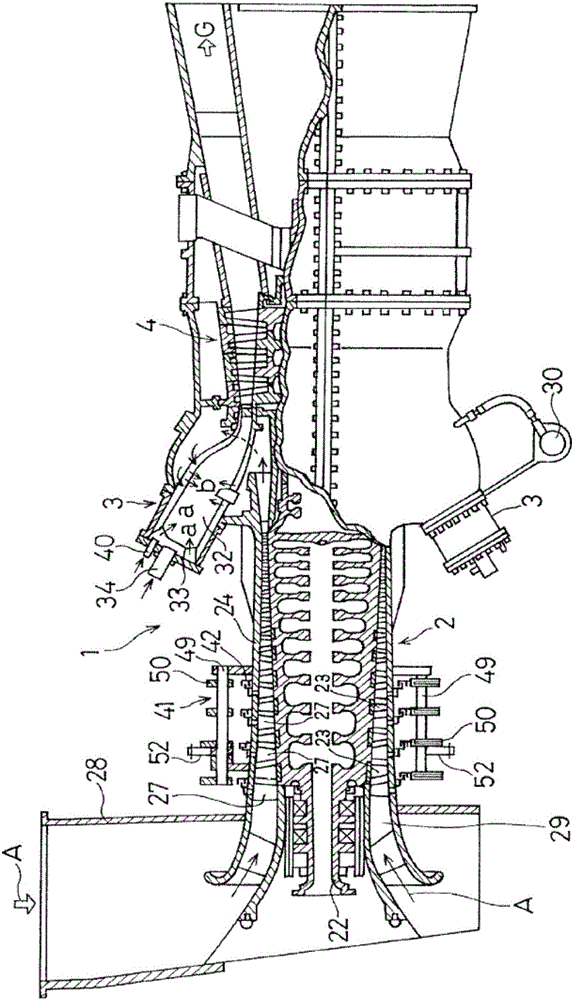

[0034] Next, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 A partially cutaway schematic side view showing a gas turbine engine employing a variable vane mechanism is shown. exist figure 1 Among them, the gas turbine engine 1 has a structure in which air is compressed by an axial flow compressor 2 and introduced into a combustor 3, and a gaseous fuel such as city gas is injected into the combustor 3 for combustion. The high temperature and high pressure combustion gas can drive the turbine 4 . The turbine 4 drives an unillustrated generator while driving the axial compressor 2 .

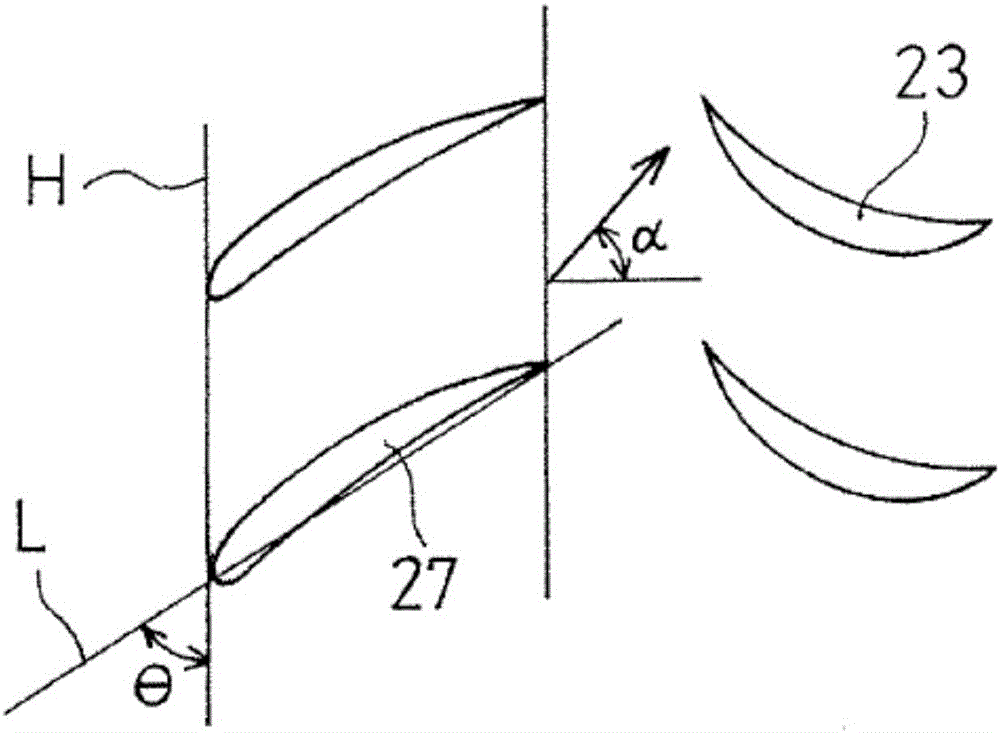

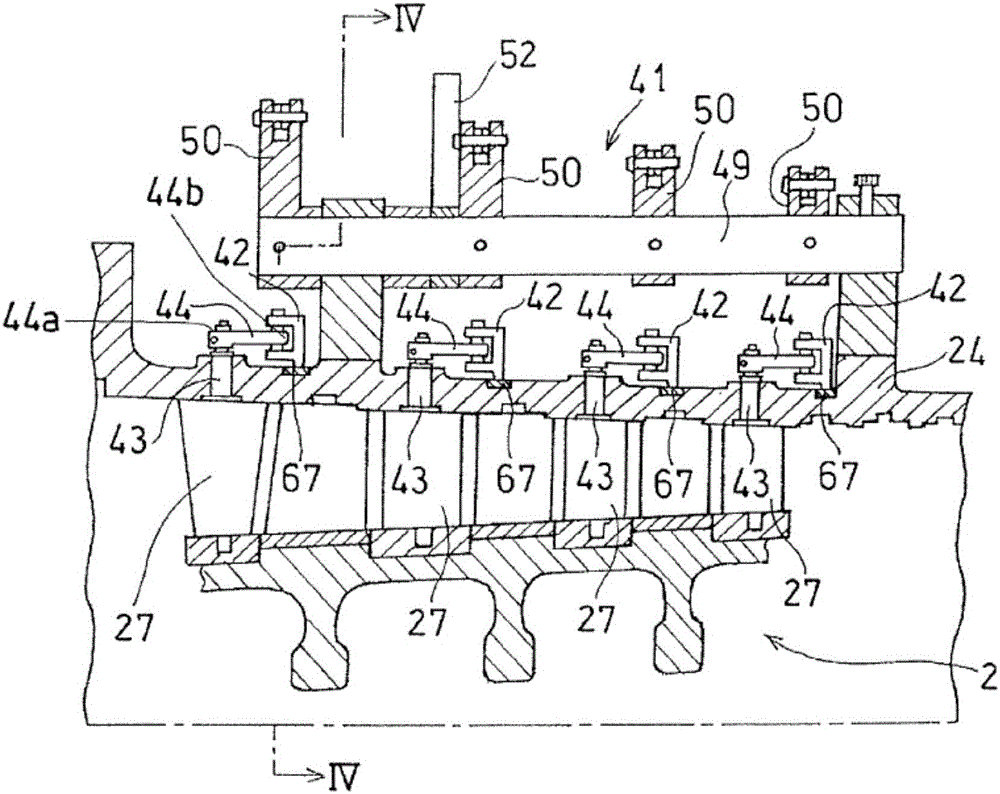

[0035] The axial flow compressor 2 compresses the air A sucked in from the suction cylinder 28 by a combination of a plurality of moving blades 23 arranged on the outer peripheral surface of the rotating shaft 22 and stationary blades 27 arranged in multiple stages on the inner peripheral surface of the casing 24, and the The compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com