An energy-saving seeding device suitable for growing seedlings in plug trays

A sowing device and plug seedling raising technology, which is applied in the field of energy-saving sowing devices, can solve the problems of high equipment cost and high energy consumption, and achieve the effects of low cost, reduced energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

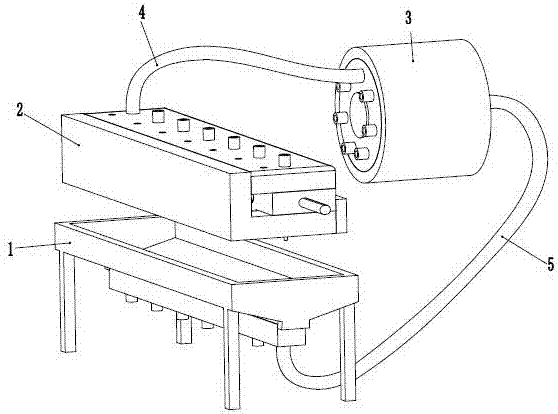

[0027] Embodiment 1: as Figure 1-10 As shown, when the 128-hole standard tray (16×8) of the present invention is used for sowing, it includes the seed box assembly 1, the seeding assembly 2, the fan assembly 3, the silicone tube I4, and the silicone tube II5;

[0028] One end of the silicone tube I4 is connected to the air hole II25 on the upper surface of the air guide 13 in the sorting assembly 2, and the other end is connected to the air inlet air hole 30 in the fan assembly 3; one end of the silicone tube II5 is connected to the air outlet air hole 33 in the fan assembly 3, and the other end Connected to the air hole I10 in the seed box assembly 1.

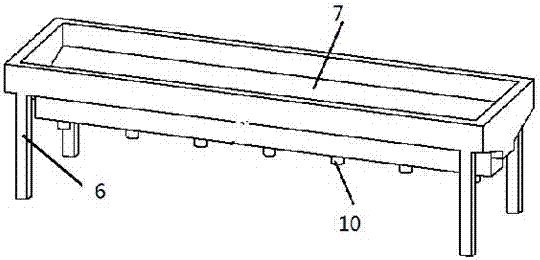

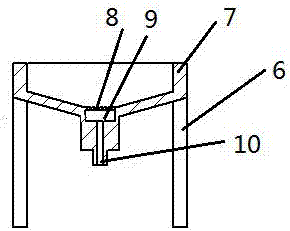

[0029] The seed box assembly 1 is composed of a frame 6, a box body 7, a gauze 8, an air chamber 9, and an air hole I10; wherein the box body 7 is installed on the frame 6; the lower part of the box body 7 forms an angle with the horizontal direction; the air chamber 9 is a hollow cuboid, the length is the same as the length...

Embodiment 2

[0034] Embodiment 2: as Figure 1-10 As shown, it is basically the same as in Example 1, the difference is that the present invention is used to sow the 72-hole standard hole tray (12×6), the distance between the two holes of the standard 72-hole hole tray is 3.9cm, and a row of hole tray holes The number is 12.

Embodiment 3

[0035] Embodiment 3: as Figure 1-10 As shown, it is basically the same as in Example 1, the difference is that the present invention is used as a 50-hole standard plug (10×5) for sowing, the distance between the two holes of the standard 50-hole plug is 4.6cm, and a row of plug holes The number is 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com