Drying device for paint

A technology for drying equipment and coatings, applied in coatings, devices for coating liquid on surfaces, spray devices, etc., can solve problems such as shortages, and achieve the effect of high product yield and good drying and spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

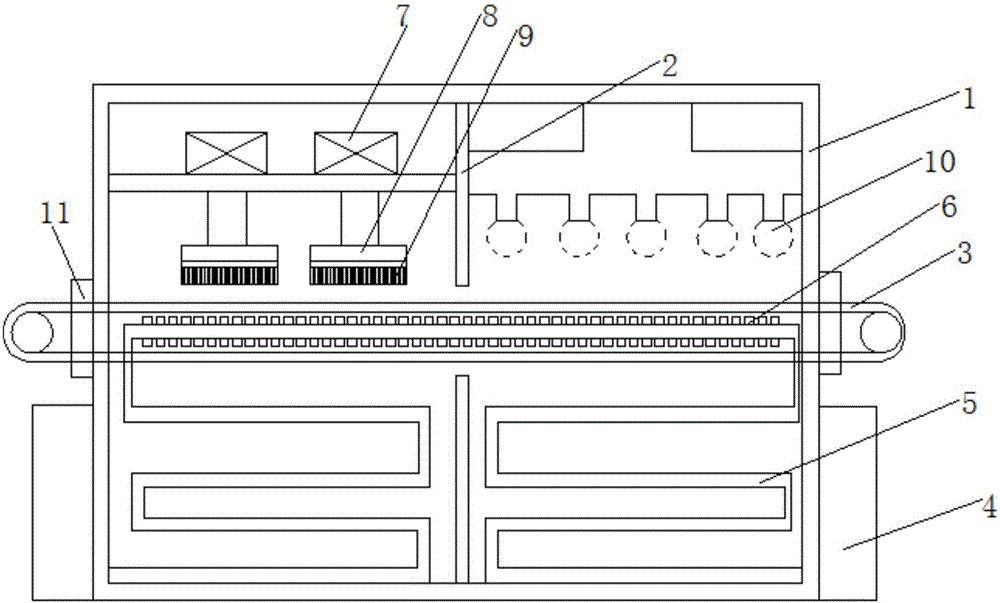

[0015] Such as figure 1 As shown, a paint drying equipment of the present invention includes a working room 1 and a horizontal conveyor belt 3 passing through the working room 1, and a partition board is arranged longitudinally above the horizontal conveyor belt 3 inside the working room 1 2. Partition board 2 divides the working room above the horizontal conveyor belt into two upper working areas on the left and right; among them, a number of electrostatic precipitators are installed in the upper working area near the material inlet, and spraying equipment is installed in the upper working area near the material outlet. Device 10; in the lower working area below the horizontal conveyor belt 3 (wherein the lower working area can also be separated by partitions according to actual needs, to ensure the drying effect), a thermal coil 5 is provided, and the thermal coil 5 passes through The horizontal conveyor belt 3 and the heating coil 5 communicate with the heating box 4 locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com