Method for preventing cool roller bed of hot rolling layer from steel rear-end collision

A technology for cold rolls and strips, applied in the field of preventing the hot-rolled layer from chasing steel on the cold-roller table, can solve the problems of production line shutdown, difficulty in precise control, scrapping of strips, etc., to avoid tailgating scrap and reduce waste of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

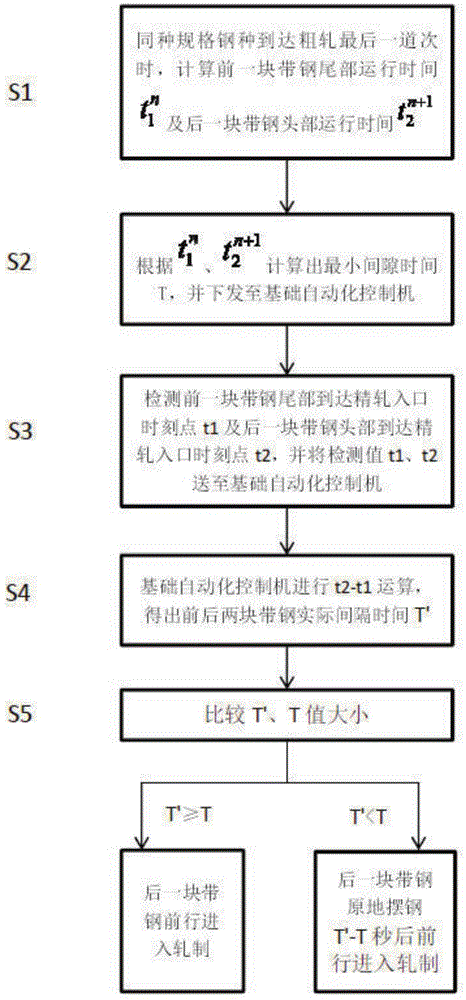

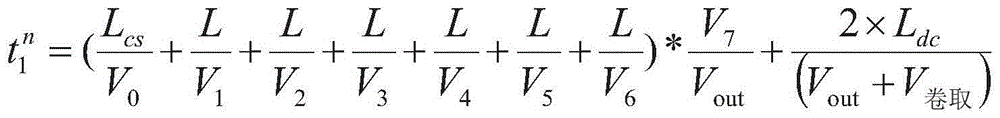

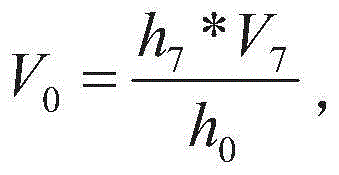

[0083] Since the main control is that the front and rear strips do not collide in the layer cooling roller table area, the main control is the minimum running time of the front and rear strips from the finish rolling entrance to the coiling area: that is, the front After the tail of a piece of steel strip leaves the finish rolling F7 stand, it meets the conditions for the latter piece of steel strip to enter the finish rolling stand for rolling, but it must be ensured that the tail of the previous piece of strip steel can be coiled smoothly before the latter piece of steel strip can reach the coiling The position of the machine, and at this time the function of the coiler has met the coiling conditions.

[0084] 1. Selection of the judgment point of the finish rolling entrance

[0085] In order to control the front and rear strips from colliding in the interlayer cooling area, if the head of the latter strip enters the finish rolling stand for rolling, it is difficult to recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com