Multi-station automatic assembly machine for valve rod sealing rings

An automatic assembly machine and sealing ring technology, which is applied to assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as high product failure rate, inconvenient installation work, and limited assembly efficiency, so as to reduce labor intensity and production efficiency. cost, improve production efficiency and processing quality, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

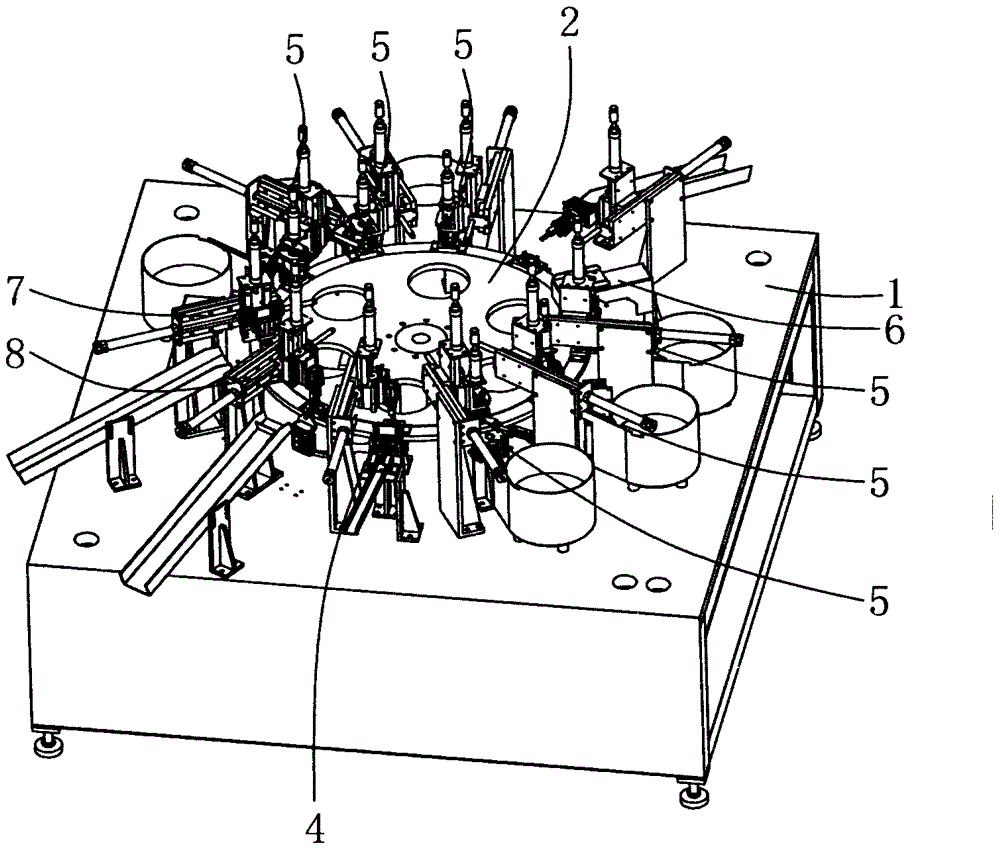

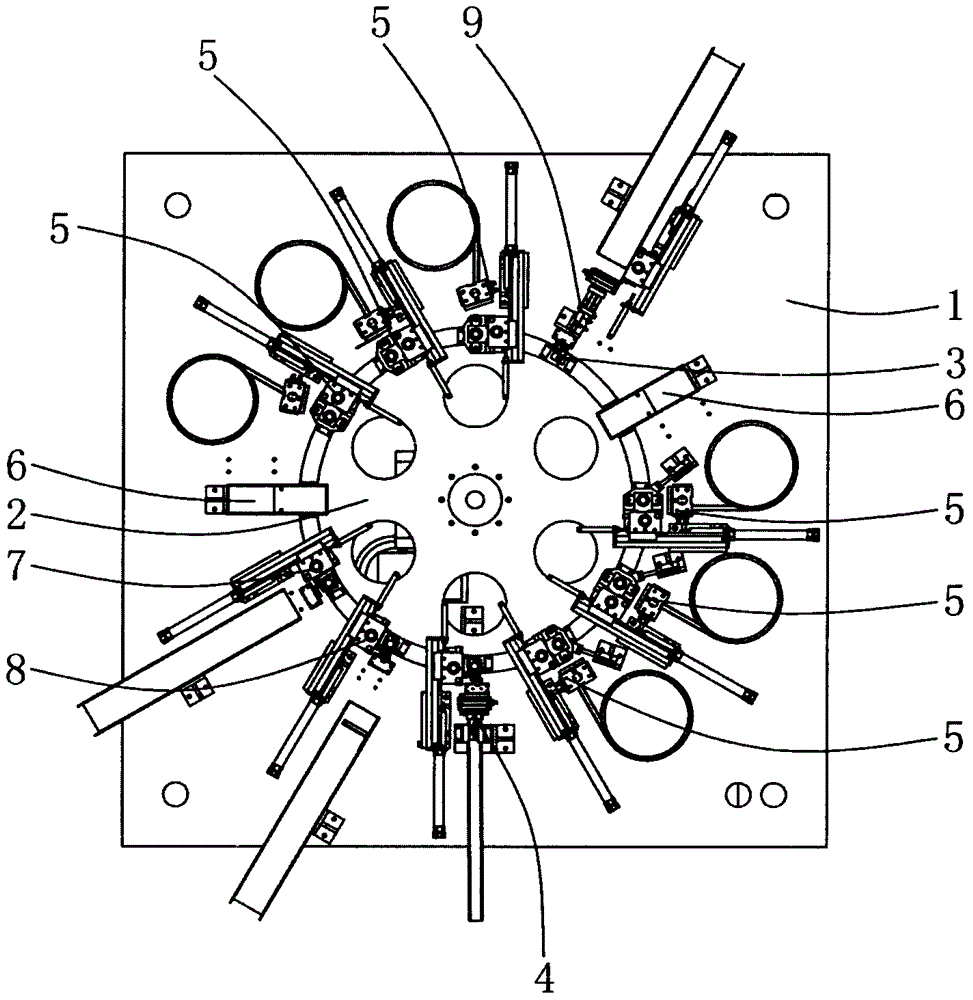

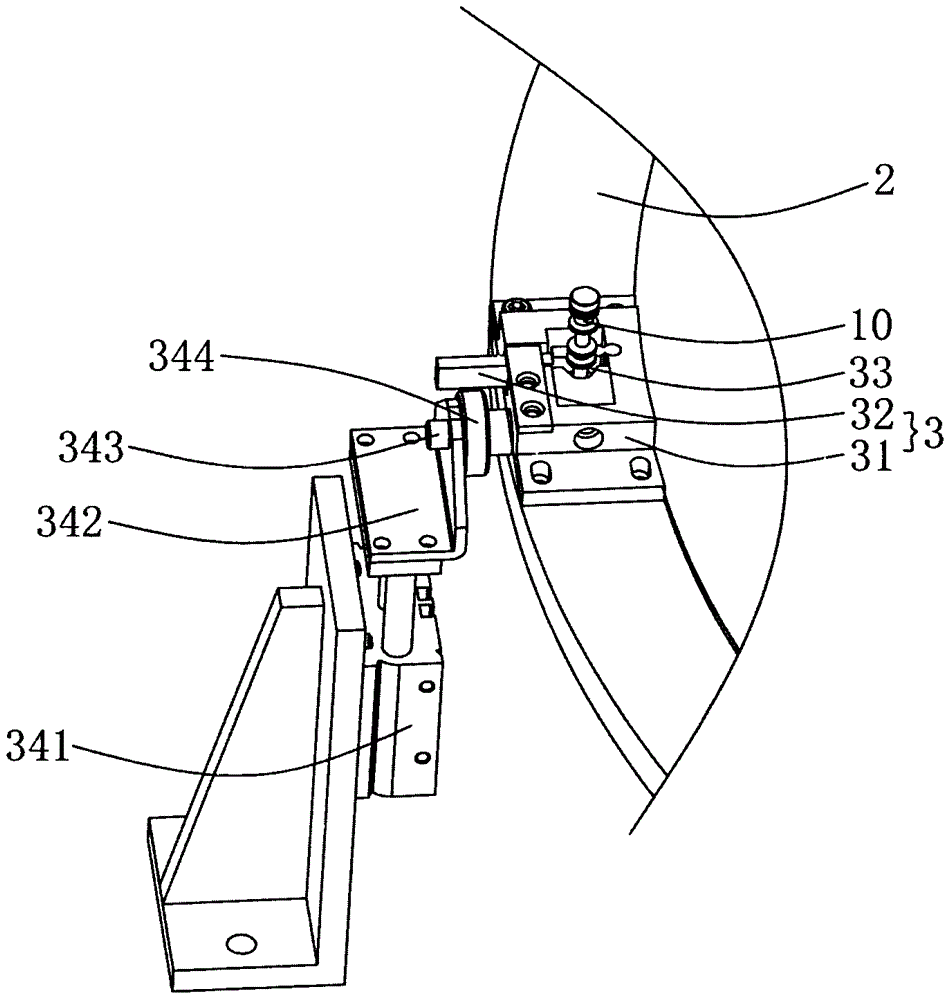

[0044] Such as Figure 1 to Figure 11 A multi-station valve stem sealing ring automatic assembly machine shown includes a base 1, an indexing plate 2 rotatably arranged on the base 1, and a number of clamps 3 are evenly arranged on the indexing plate 2 along the circumferential direction. 3 is used to clamp the valve stem workpiece 10, and the base 1 is provided with a valve stem feeding station, at least one sealing ring feeding assembly station, at least one testing station, a finished product collecting station and A reject collection station.

[0045] Specifically, in this embodiment, the number of sealing ring loading and assembling stations is six, and the number of testing stations is two. Among them, there are three sealing ring feeding assembly stations in sequence between the valve stem feeding station and the first testing station, and a Screening and U-t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap