Three-way clamping device

A clamping device and cylinder technology, applied in the field of machining, can solve the problems of large cylinder diameter, low pressure, increased cost, etc., and achieve the effects of improving output pressure, compact structure and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

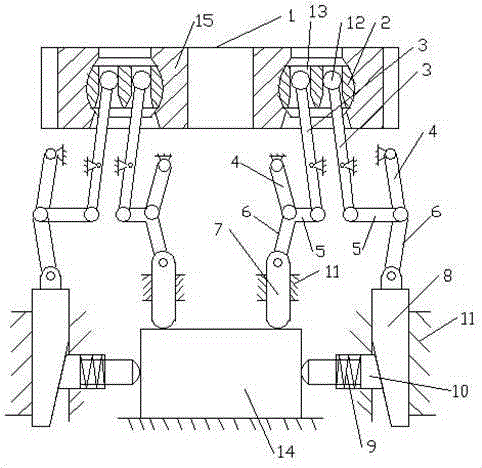

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] refer to figure 1 , is a three-way clamping device, including a cylinder 1, the cylinder 1 is a double-piston cylinder, the cylinder piston 15 is provided with a floating block 2, and the floating block 2 is provided with two sliding holes 13, so The two sliding holes 13 are respectively connected with lever mechanisms, wherein one lever mechanism is connected with a compression rod 7, and the other lever mechanism is connected with a wedge block 8, and the inclined surface of the wedge block 8 is connected with a compression guide rod 10. , the compression rod 7 and the compression guide rod 10 move along the guide sleeve 11 respectively, and the compression guide rod 10 is provided with a return spring 9 .

[0011] Described lever mechanism is made up of movable ball head 6, fixed rod 3, fixed hinge rod 4, pull bar 5, movable hinge rod 6, and described movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com