Lid for a trash can and a trash can including the lid for the trash can

A trash can and garbage technology, applied in the direction of trash can, garbage collection, tobacco, etc., can solve the problems of clamshell obstruction, secondary pollution, less consideration, etc., and achieve the effects of convenient use, weight reduction, and expansion of opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

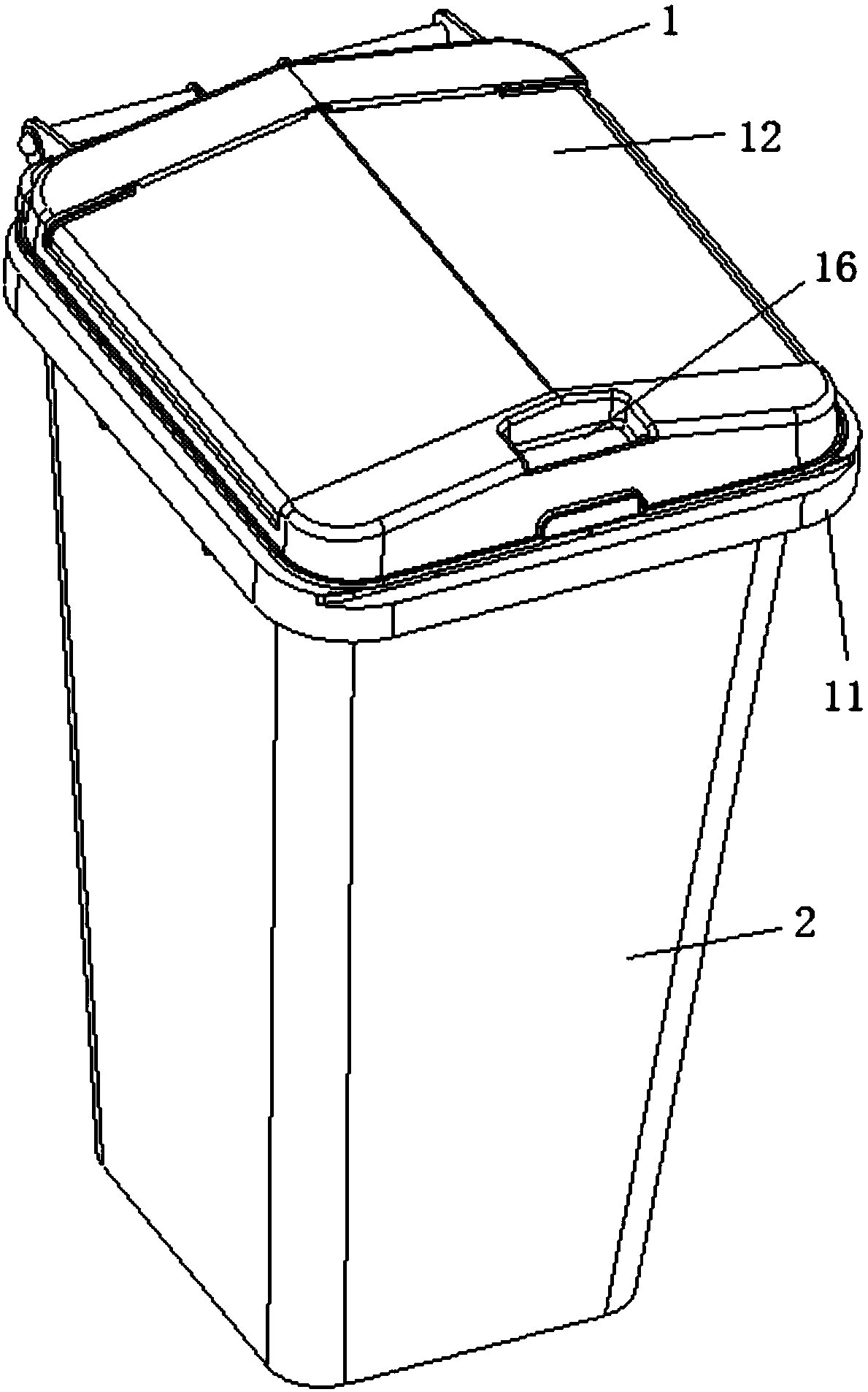

[0045] A trash can, see figure 1 , including a barrel body 2 with an opening and a trash can cover 1 matching the opening, the barrel body 2 is provided with a position (not shown) for installing a voice prompt device and for installing a trash can capacity measuring device location (not shown).

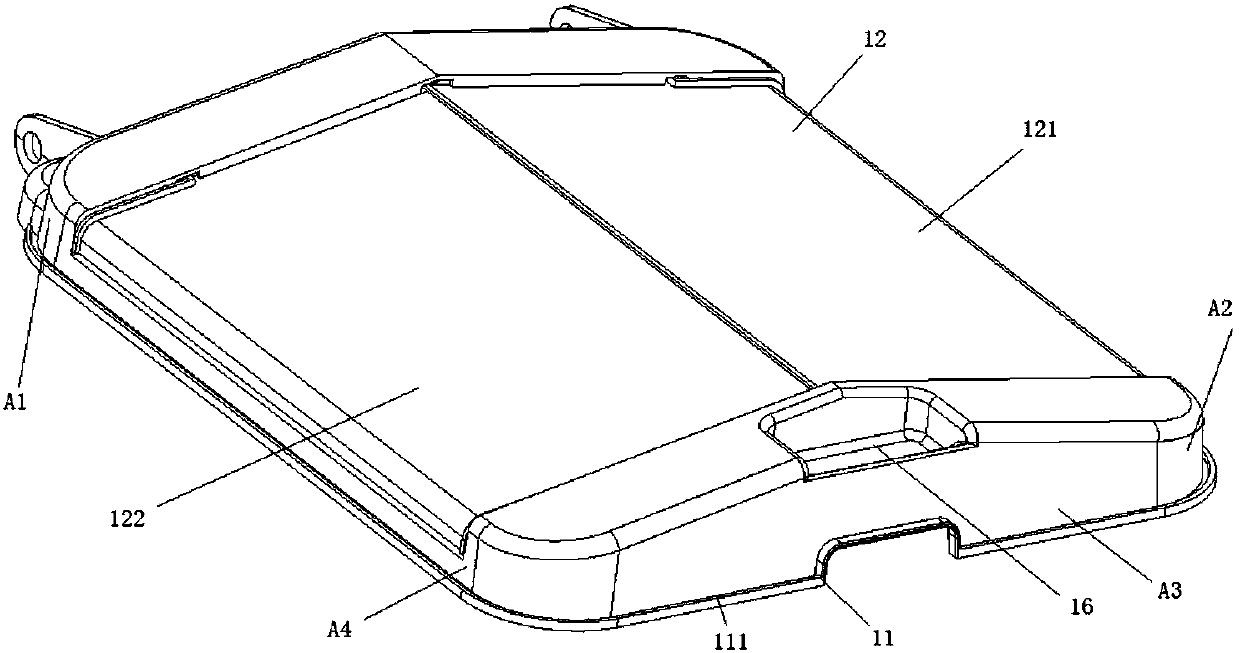

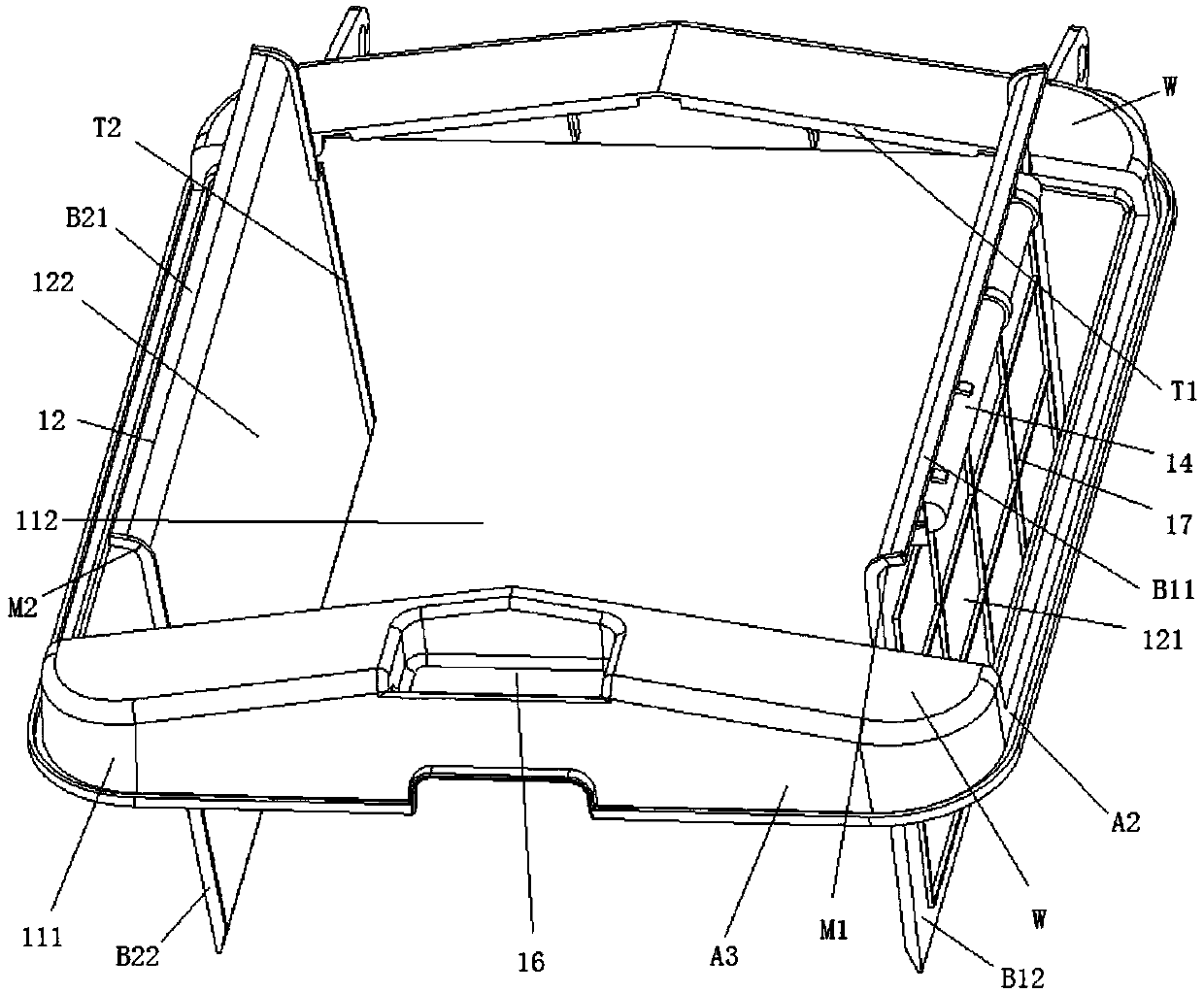

[0046] The structure of the trash can lid 1 is detailed in Figure 1-Figure 5 , specifically: include a large cover 11 matching the opening on the barrel body 2 of the trash can and a herringbone cover group 12 that is movably arranged on the large cover 11 .

[0047] The large cover 11 includes a large cover body 111 and a garbage inlet 112 which is arranged on the big lid body 111 and communicates with the interior of the trash can, and the herringbone cover group 12 is located at the garbage inlet. 112 place, when opening, it is used to throw in garbage, and when it is in a free state, it is used to completely seal the garbage inlet 112; the big cover body 111 is composed of fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com