Hoisting conveying device for sieling bottle appearance and size detecting equipment

A size detection and conveying device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems affecting productivity, low detection efficiency, affecting product quality, etc., and achieve the effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

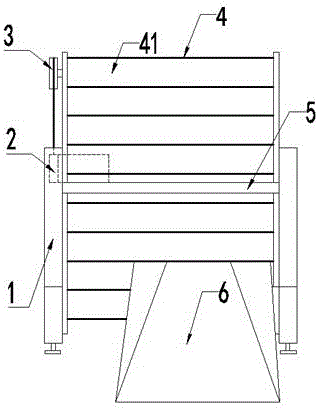

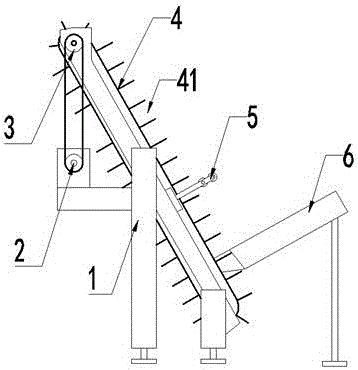

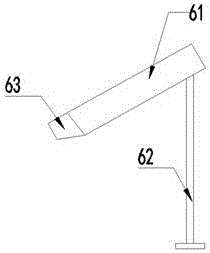

[0012] Depend on figure 1 , figure 2 , image 3 It is a structural schematic diagram of the present invention, a lifting conveying device for a vial appearance and size detection equipment, including a frame 1, a drive device 2, a transmission device 3, and a conveyor belt 4 are installed on the frame 1, and the machine The conveyor belt 4 installed on the frame 1 is placed at an inclined angle; the frame 1 is also provided with a filter plate 5 and a hopper 6, the filter plate 5 is located above the hopper 6, and the filter plate 5 is installed on two sides of the conveyor belt 4 On the frame 1 on the side, one side of the hopper 6 is fixedly connected to one side of the frame 1, so that the lower part of the conveyor belt 4 is located at the lower mouth of the hopper 6 . The feeding hopper 6 is composed of a hopper 61, a supporting foot 62, and a connecting plate 63. The supporting foot 62 is fixedly connected to the bottom of the hopper 61. The hopper 61 is placed on an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com