A movable stacking brick rack and a flipping stacking machine

A movable, brick racking technology, used in transportation and packaging, destacking of objects, stacking of objects, etc., can solve the problem of bricks being easily crushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

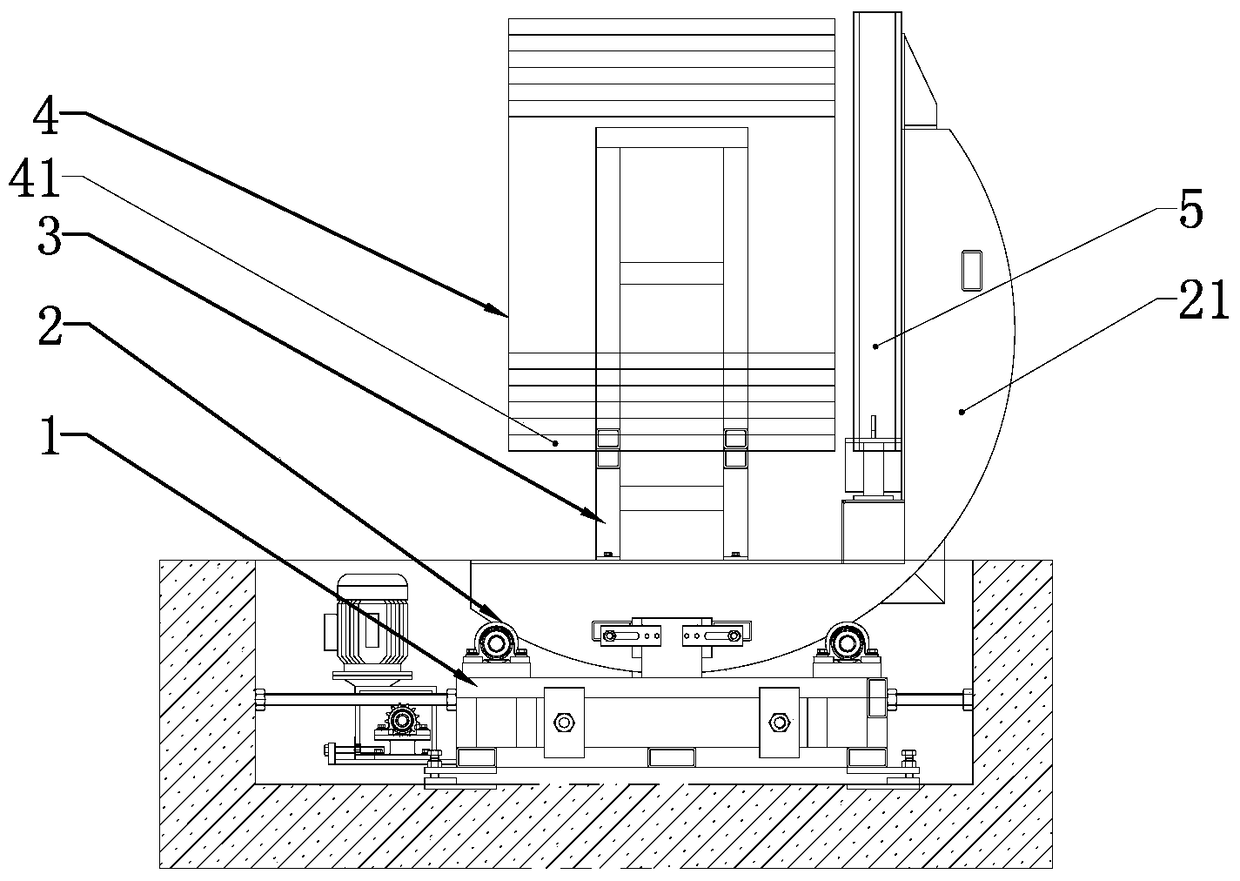

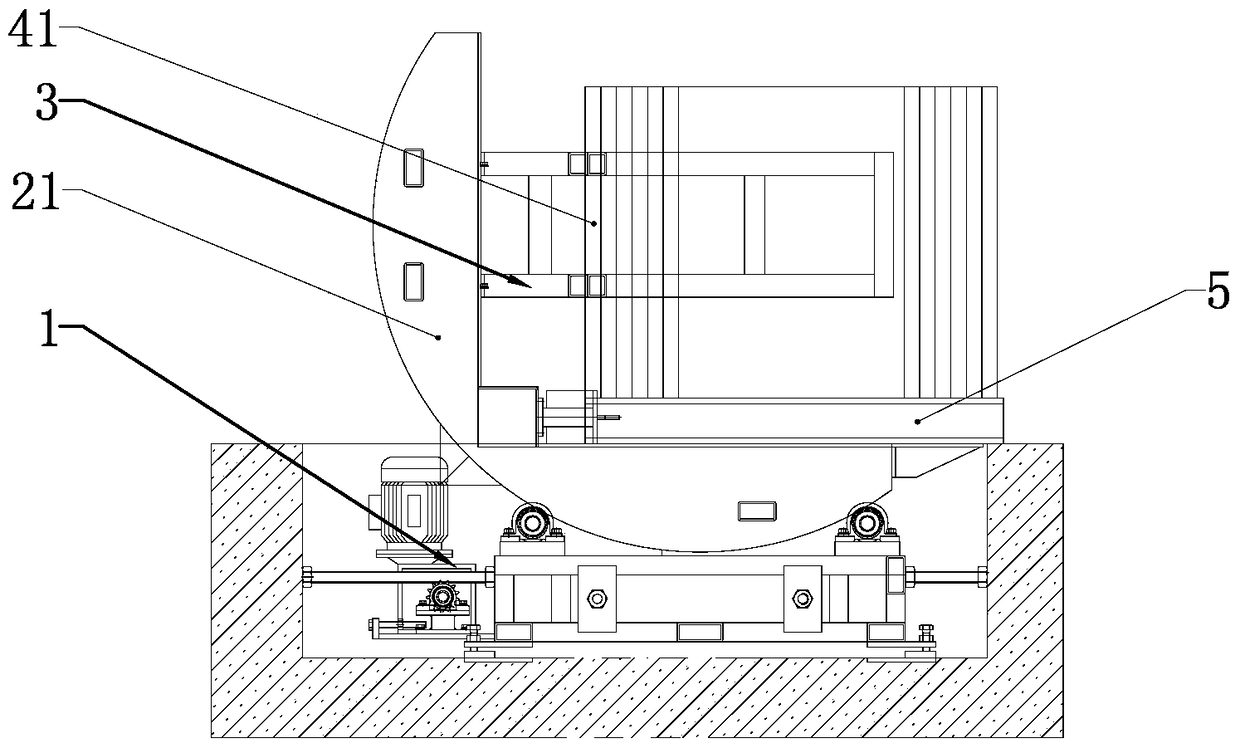

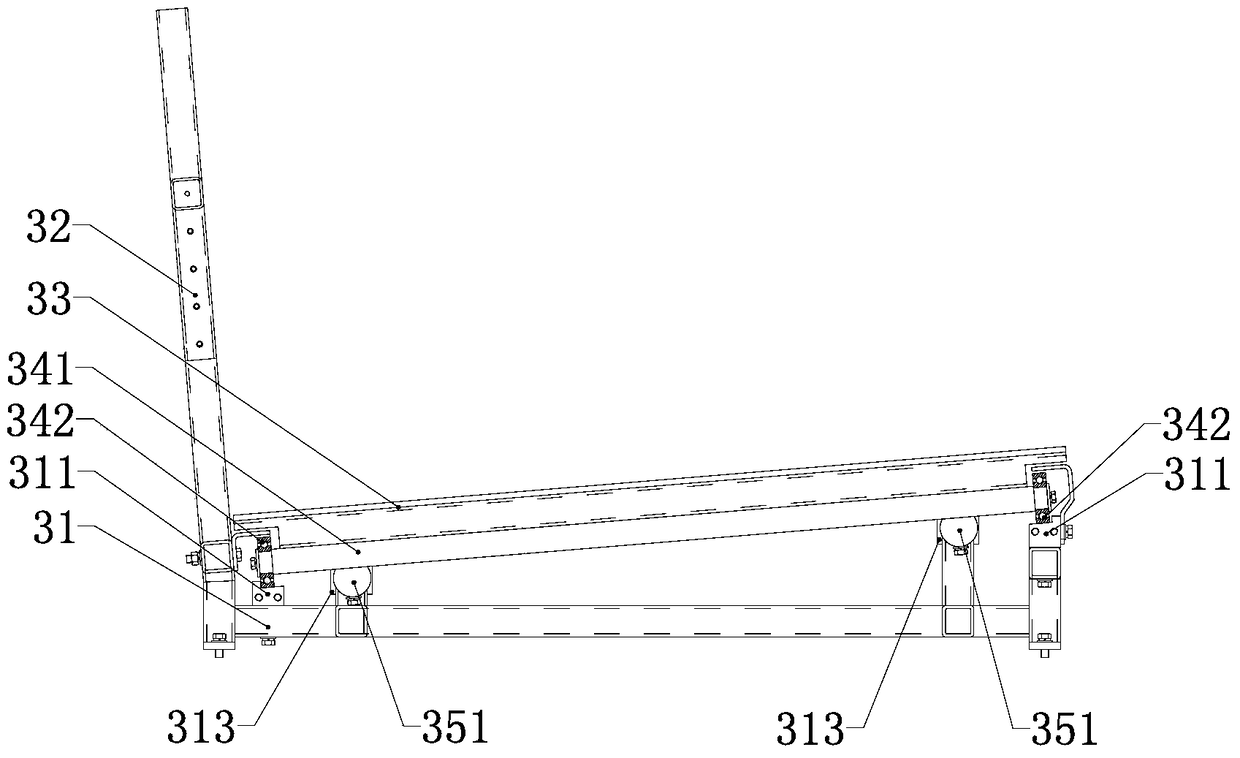

[0026] like Figure 3 to Figure 5 As shown, a movable pallet rack according to the present invention is mainly composed of a bottom frame 31, a support frame 32, a support frame 33, a rolling assembly and an elastic return assembly of the support frame.

[0027] The support frame 32 is fixed vertically on one side of the bottom frame 31 and forms an obtuse angle with the bottom frame.

[0028] The support frame 33 is arranged on the base frame 31 through a rolling assembly, and can move back and forth along the length direction of the frame, and an acute angle is formed between the support frame and the base frame. The rolling assembly is mainly composed of two guide rails 311 , two supporting rollers 341 and four rolling bearings 342 . Two guide rails 311 are installed in parallel on both sides of the underframe along the length direction of the frame, the installation position of the guide rail closer to the frame is lower, and the installation position of the guide rail fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com