A method for improving the hydrolysis and acidification of petrochemical wastewater

A technology for hydrolysis, acidification, and petrochemical wastewater, applied in the field of water treatment, can solve the problems of poor hydrolysis and acidification effect of petrochemical wastewater, and achieve the effects of increasing the mixing of mud and water, improving the mixing ratio of mud and water, and preventing sludge deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

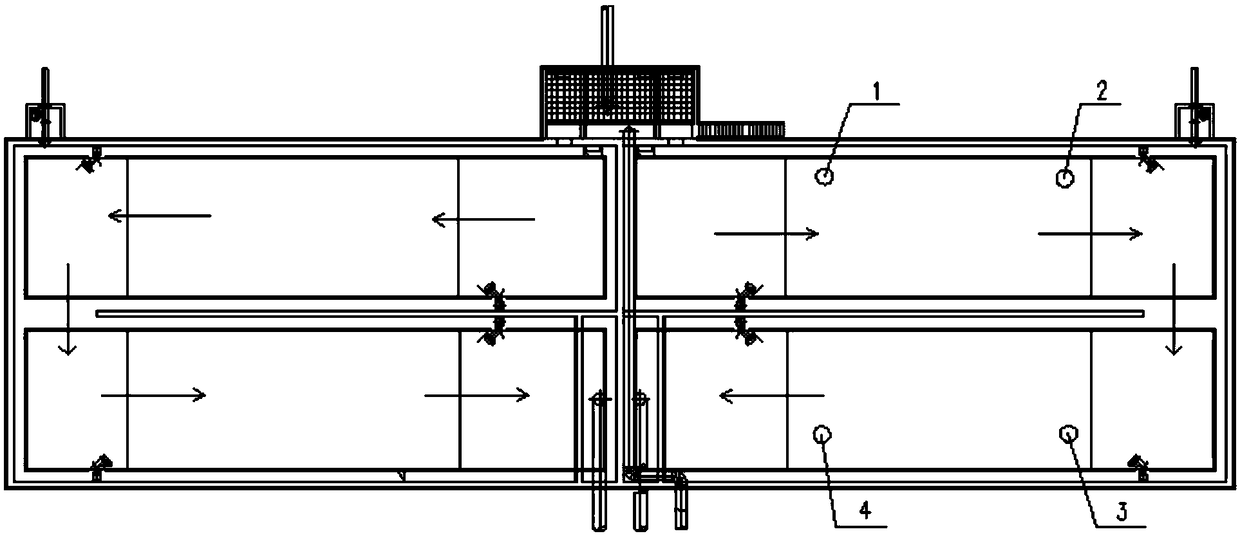

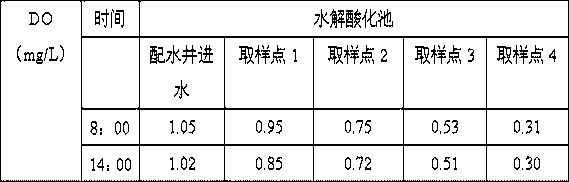

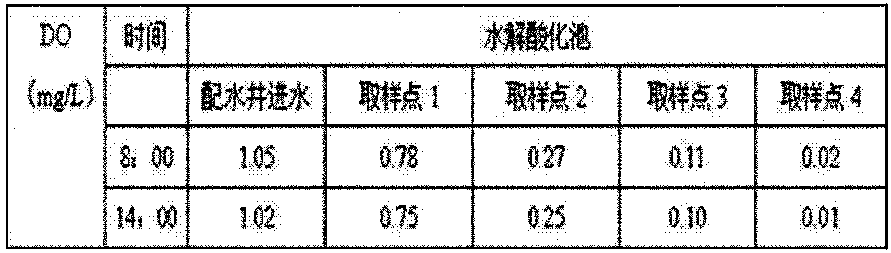

[0035] First, a partition wall is set up in the hydrolytic acidification tank, a filler bracket is arranged in the hydrolytic acidification tank, and a film filler is hung on the bracket; glucose is put in it, and the microorganisms obtain nutrients; No. 1 is placed at the front water inlet of the hydrolytic acidification tank Sampling point 1, No. 4 sampling point 4 is set at the water outlet at the rear end, and then No. 3 sampling point 3 and No. 4 sampling point 4 are evenly set in the middle, and then the dissolved oxygen DO parameters are counted. According to the dissolved oxygen DO parameters, at the same time , to observe the mud-water mixing effect and the film formation of the filler, firstly reduce the DO parameter through sludge reflux. There are four ways for sludge reflux:

[0036] First: Through the surge tank and the sludge pump, the sludge in the back section of the hydrolysis acidification tank is pumped to the front section agitator to make it mix with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com