Silicone emulsion, preparation method thereof, and fabric finishing agent

A technology of silicone emulsion and end-capping agent, used in fiber treatment, textile and papermaking, abrasion-resistant fibers, etc., can solve the problem that silicone oil cannot self-emulsify, achieve stable emulsion, small particle size, and improve the degree of yellowing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

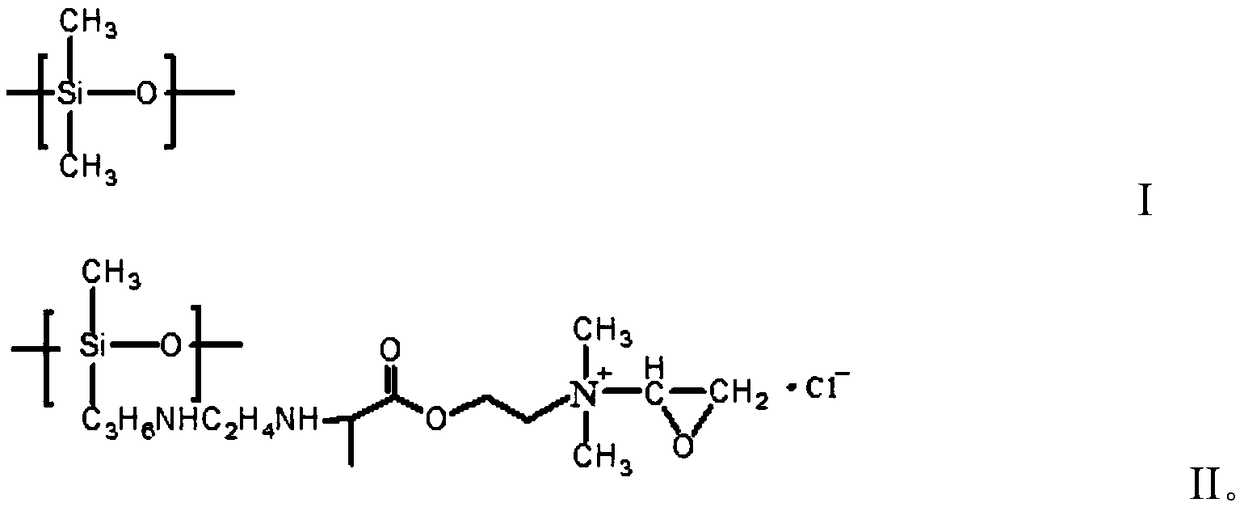

[0026] A preparation method of silicone emulsion, comprising the steps of:

[0027] Mix the aqueous solution of strong basic catalyst, octamethylcyclotetrasiloxane linear body, ammonia type coupling agent, and end-capping agent uniformly, and react at 100-110°C for 4-8 hours to obtain amino silicone oil; Wherein, the mass ratio of the octamethylcyclotetrasiloxane linear body, the ammonia type coupling agent, the end-capping agent and the strong basic catalyst is 30~50:2~10:0.1~06 :0.1~1;

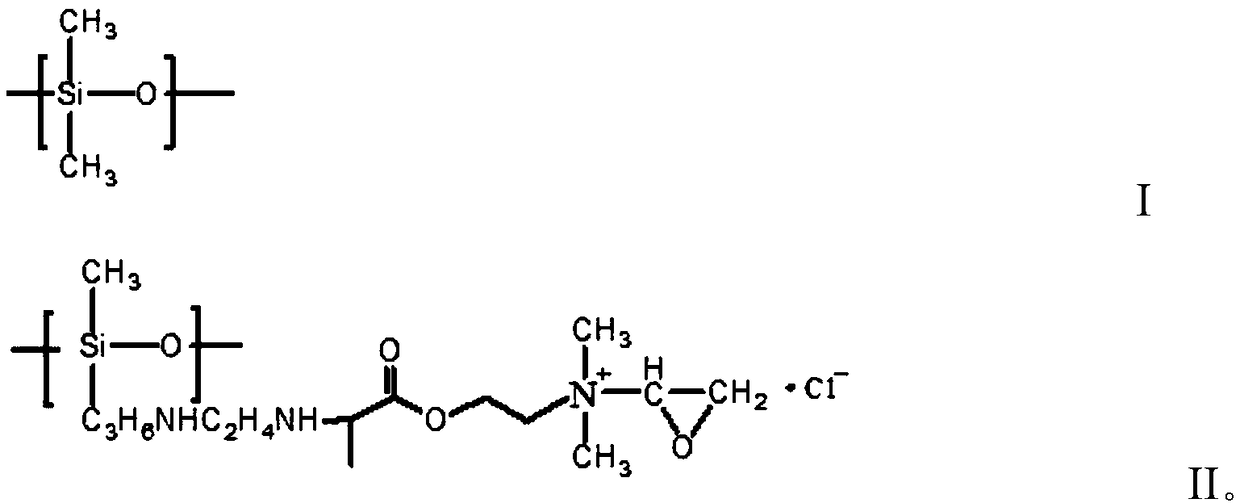

[0028] Mix the amino silicone oil with the dimethylaminoethyl methacrylate solution evenly, and react for 12-20 hours at a temperature of 20-30°C to obtain a modified amino silicone oil, wherein the primary amino group in the amino silicone oil and the The mol ratio of dimethylaminoethyl methacrylate is 1:1-1:1.15;

[0029] Add the modified amino silicone oil dropwise to the epichlorohydrin solution at 55-75°C, react for 3-6 hours, then raise the temperature to 80-90°C, and continue the re...

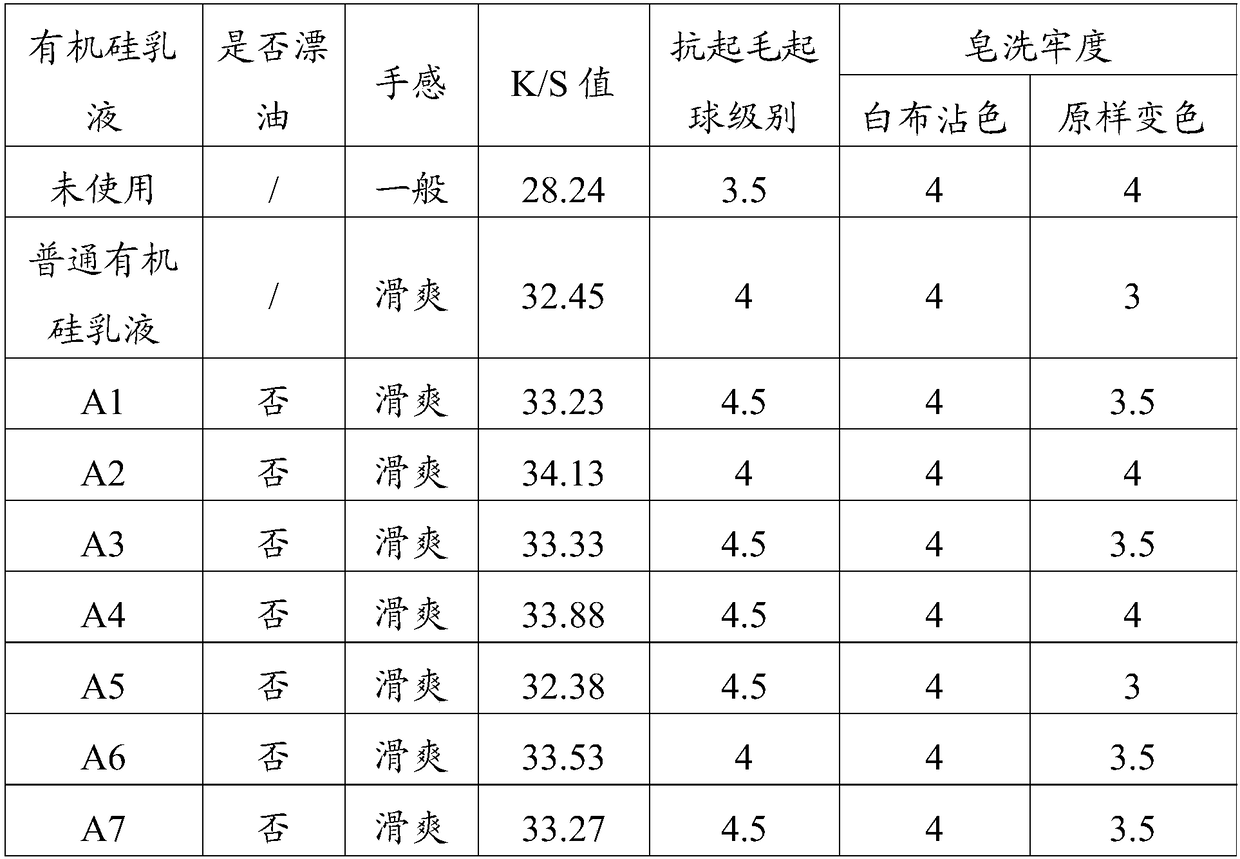

Embodiment 1

[0052] (1) Preparation of amino silicone oil: Dissolve 0.5g potassium hydroxide in 49g deionized water, then mix with 45g octamethylcyclotetrasiloxane linear body, 5.1g N-β-(aminoethyl)-γ-ammonia Add propylmethyldimethoxysilane and 0.4g hexamethyldisiloxane into a four-necked flask equipped with a stirrer, a reflux condenser and a thermometer, stir and mix evenly, then raise the temperature to 100°C, and react for 6 hours , to obtain amino silicone oil.

[0053] (2) Modification of amino silicone oil: the amino silicone oil obtained in step (1) is added to the ethanol solution of dimethylaminoethyl methacrylate (wherein the primary amino group of amino silicone oil and that of dimethylaminoethyl methacrylate The molar ratio is 1:1), after stirring and mixing evenly, the temperature was raised to 25°C, and the reaction was carried out for 15 hours to obtain the modified amino silicone oil.

[0054] (3) Quaternization treatment: Add the modified amino silicone oil obtained in s...

Embodiment 2

[0058] Embodiment two is basically the same as embodiment one, and the difference with embodiment one is: the consumption of octamethylcyclotetrasiloxane linear body is 35g, N-beta-(aminoethyl)-gamma-aminopropyl methyl The consumption of dimethoxysilane is 8g, and other parts are identical with embodiment one.

[0059] The obtained silicone emulsion is denoted as A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com