Nanofiber floating ball for reservoir

A nanofiber, reservoir technology, which is applied in the oil/oily substance/float removal device, polluted waterway/lake/pond/river treatment, liquid separation, etc., can solve the problem of easily polluted water resources, high production cost, use Short life and other problems, to achieve the effect of obvious social benefits, low production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

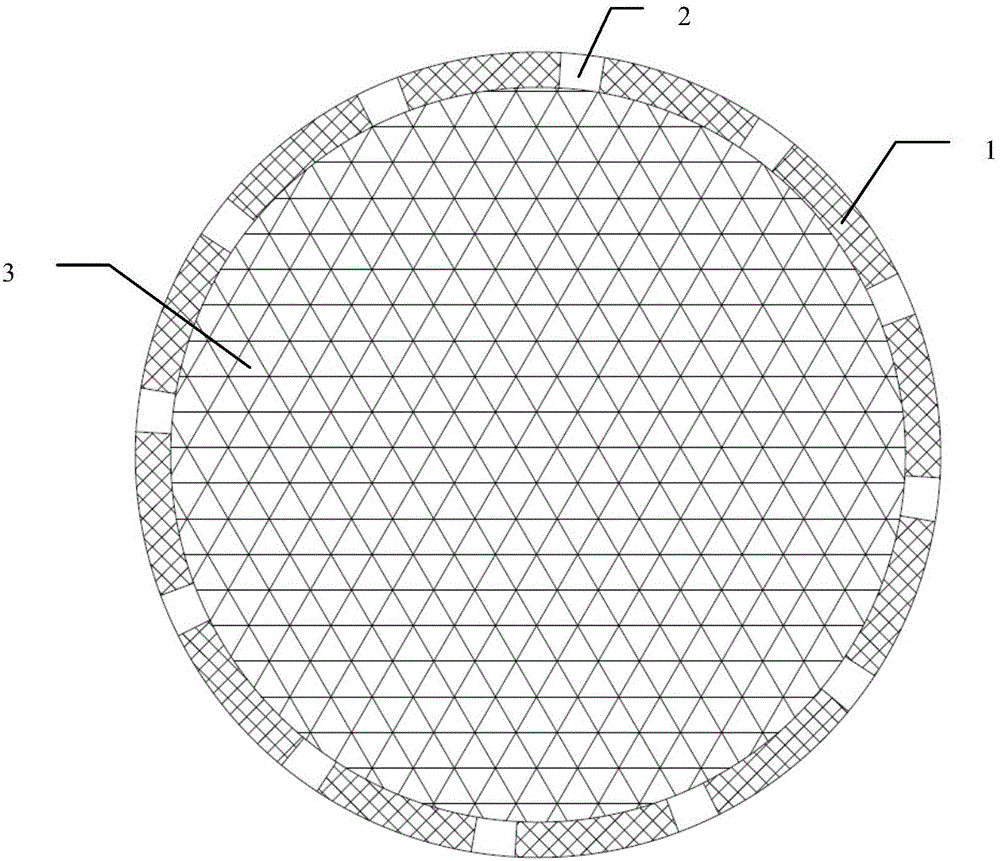

[0024] refer to figure 1 , the preferred embodiment 1 of the present invention provides a nanofiber floating ball for reservoirs, including an upper shell and a lower shell fixedly installed together to form a hollow spherical shell 1, the hollow spherical shell 1 is filled with nanofibers, the A number of circular through holes 2 are evenly provided on the upper shell and the lower shell, and the outer surfaces of the upper shell and the lower shell are white.

[0025] The outer diameter of the spherical shell 1 is 10 cm, the diameter of the through hole 2 is 2 to 5% of the outer diameter of the spherical shell 1, and the spherical distance between the through holes 2 is 10 cm of the outer diameter of the spherical shell 1. ~15%.

[0026] The nanofibers 3 are oil-absorbing nanofibers with a fiber diameter of 400 nm.

[0027] Both the upper casing and the lower casing are plastic casings.

[0028] The filling of nanofibers in the spherical shell of this embodiment can effec...

Embodiment 2

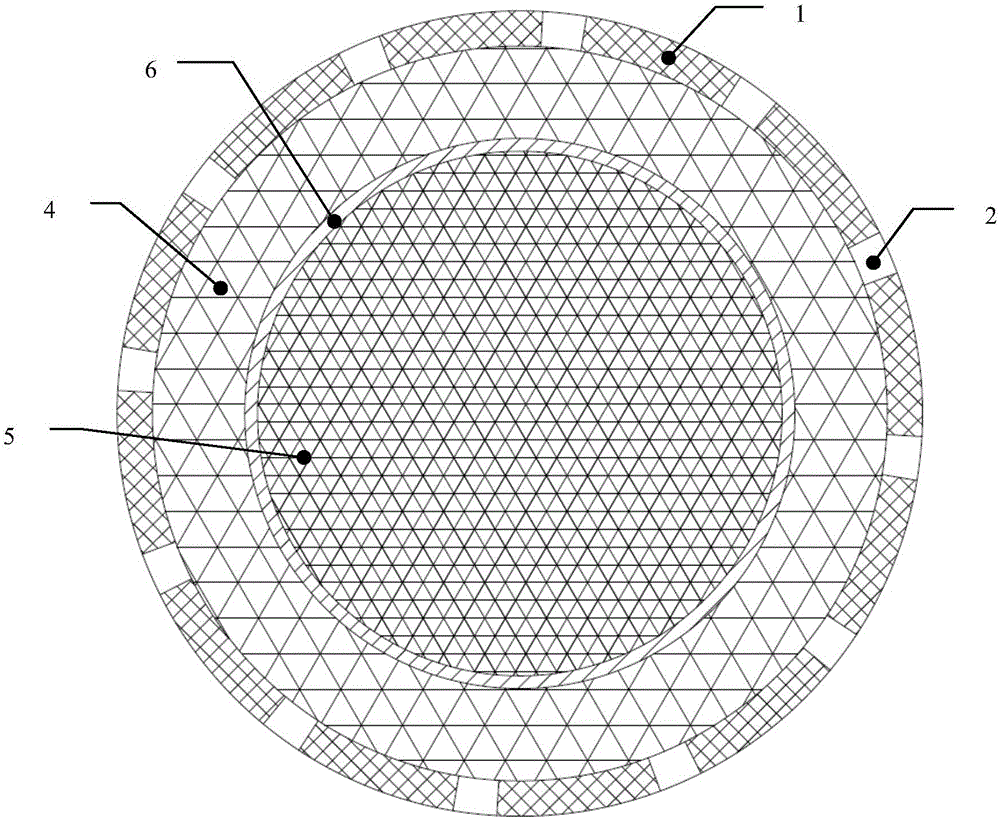

[0030] refer to figure 2 , the preferred embodiment 2 of the present invention provides a nanofiber floating ball for reservoirs, including an upper shell and a lower shell fixedly installed together to form a hollow spherical shell 1, and the upper shell and the lower shell are evenly provided with Several circular through-holes 2, the outer surfaces of the upper shell and the lower shell are white. The spherical housing 1 is also provided with a stainless steel spherical net 6, the stainless steel spherical net 6 is filled with oil-absorbing nanofibers A5, the middle of the spherical housing 1 and the stainless steel spherical net 6 is filled with oil-absorbing nanofibers B4, oil-absorbing nanofibers A5 The diameter of the fiber is 200-400nm, the fiber diameter of the oil-absorbing nanofiber B4 is 400-800nm, and the packing density of the oil-absorbing nanofiber A5 is greater than that of the oil-absorbing nanofiber B4.

[0031] The distance between the stainless steel sph...

Embodiment 3

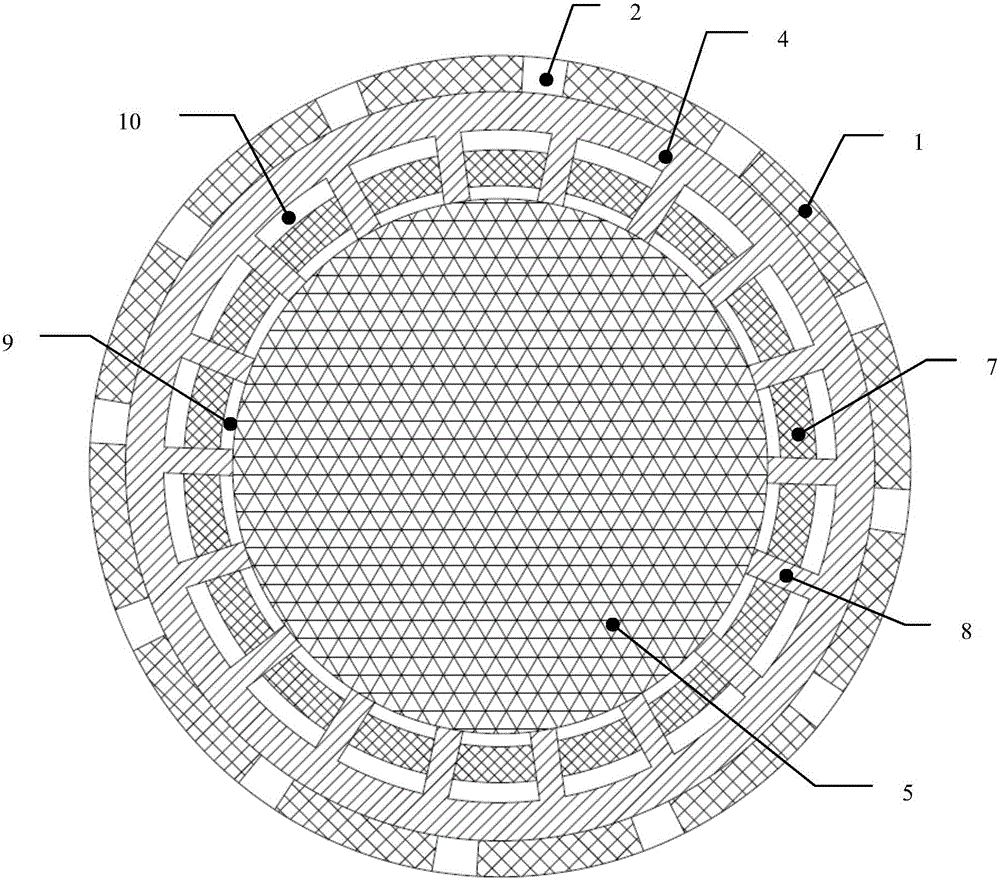

[0035] refer to image 3 , the preferred embodiment 3 of the present invention provides a nanofiber floating ball for reservoirs, including an upper shell and a lower shell fixedly installed together to form a hollow spherical shell 1, and the upper shell and the lower shell are evenly provided with A plurality of circular through-holes 2, the spherical shell 1 is provided with a spherical glass shell 10 and a glass inner shell 9, the inside of the glass inner shell 9 passes through a number of through holes 8 arranged between the glass shell 10 and the inner shell and the glass shell 10 is connected to the outside, the space between the glass inner shell 9 and the glass shell 10 is filled with heat-absorbing heat storage fluid 7, the space between the spherical shell 1 and the glass shell 10 and the through hole 8 are filled with oil-absorbing nanofibers B4, The inside of the glass inner shell is filled with oil-absorbing nanofibers A5, the fiber diameter of oil-absorbing nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com