Efficient dust falling agent and preparation method thereof

A dust suppressant and high-efficiency technology, applied in the field of air purification, can solve the problems of clogging the spray device of sprinklers, low efficiency of water mist capturing particulate matter, and air quality purification can not meet the demand, etc., and achieve outstanding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

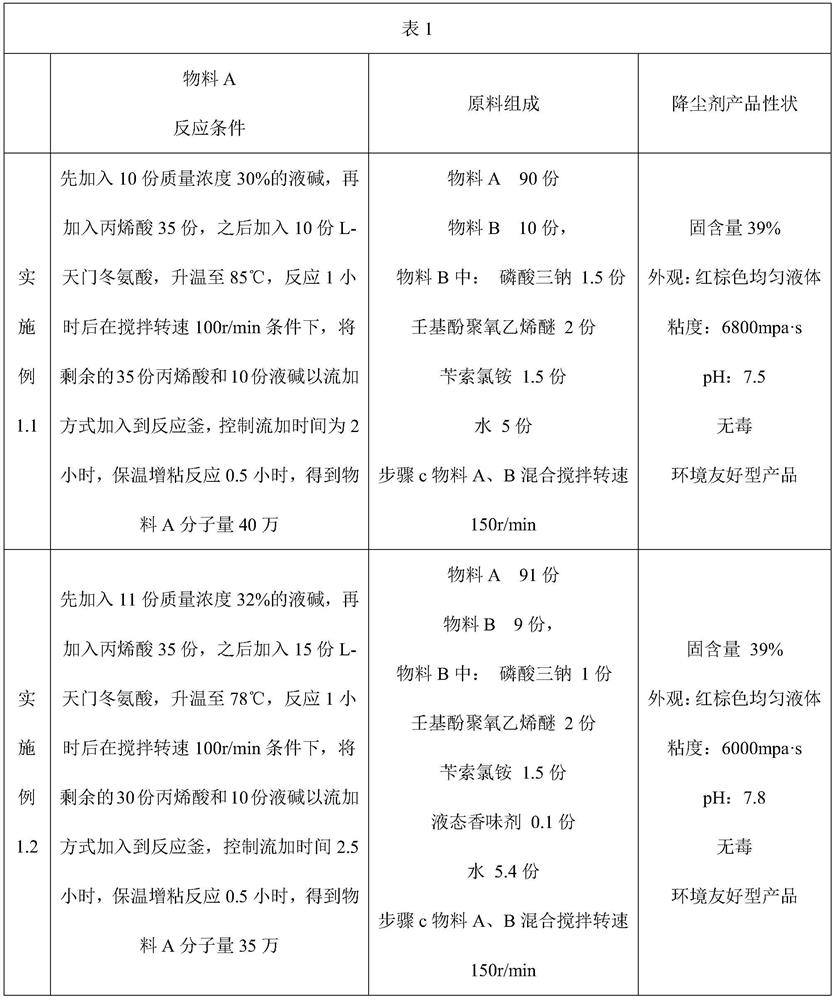

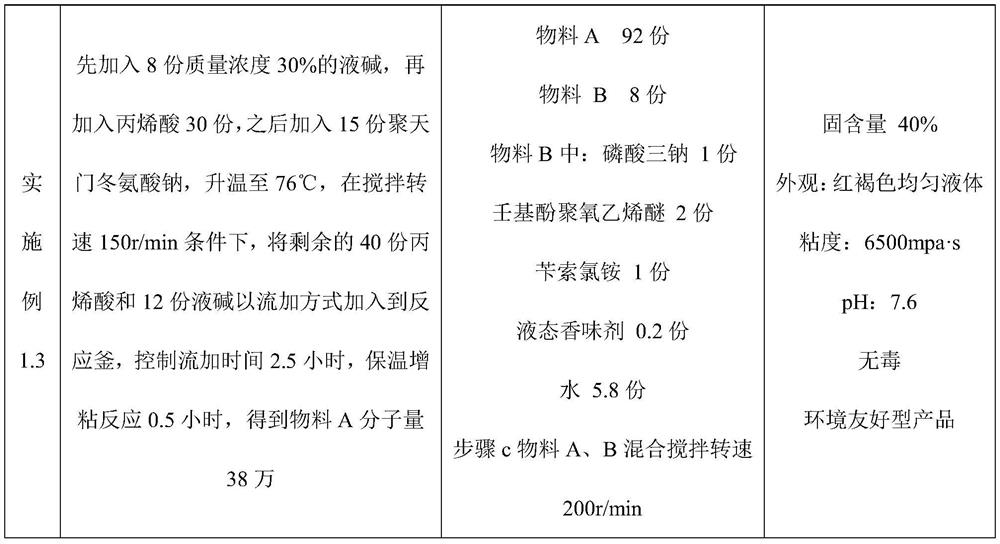

[0032] This example relates to the preparation and application effect of the high-efficiency dust suppressant of the present invention.

[0033] The raw materials involved are acrylic acid, aspartic acid or polycondensate of aspartic acid, liquid caustic soda or sodium hydroxide, trisodium phosphate, nonylphenol polyoxyethylene ether, benzethonium chloride and liquid flavoring agent, all of which are typical products purchased in the market , considering the friendliness to the environment, it is recommended to use L-aspartic acid as the raw material aspartic acid, polyaspartic acid polyaspartic acid, polyaspartic acid sodium salt, polyaspartic acid polycondensate Potassium salt, etc., the molecular weight is 3000-5000.

[0034] Prepare dust suppressant:

[0035] a. Preparation of material A: First add part of the lye and acrylic acid in sequence to the polymerization reactor, then add the entire amount of aspartic acid or aspartic acid polycondensate, then heat up to 75-85°C...

Embodiment 2

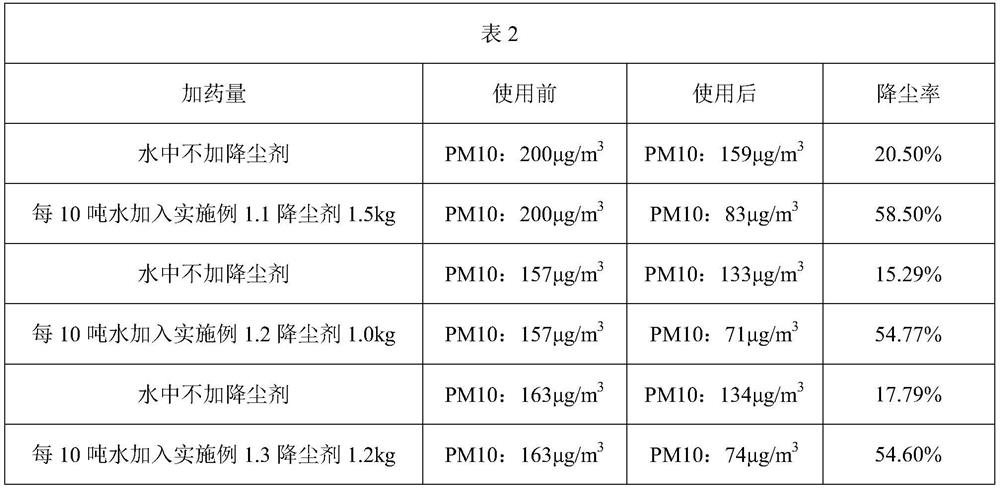

[0045] This example relates to the influence of the preparation conditions of material A on the dust reduction effect. Table 3 below shows the dust reduction effect data of materials A with different molecular weights obtained in different ratios of raw materials acrylic acid and aspartic acid or aspartic acid polycondensate, in different reaction temperatures and times.

[0046]

[0047]

[0048] From the results in the table above, it can be seen that material A with a molecular weight between 300,000 and 1,000,000 has the highest dust reduction effect. The reason for the analysis is: the polymerization reaction under low temperature conditions is not complete, and the molecular weight of the obtained polymer is too low, and the low molecular weight polyacrylic acid cannot achieve the purpose of adsorption bridging, net catch coagulation and sedimentation, but acts as a dispersant to absorb air The small dust particles in the air are wrapped to form independent individ...

Embodiment 3

[0050] This embodiment relates to the impact of the change of surfactant and bactericide in material B on the effect of dust suppression. The following table 4 provides the material A and different material B (formulated by other conventional surfactants and bactericides) in the following table 4. Obtain) dust-suppressing agent dust-suppressing effect data.

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com