Box type tunnel-bottom composite arched tunnel lining structure with water drain function

A functional, box-type technology, applied in tunnel lining, tunnel, wellbore lining, etc., can solve problems such as the inability of drainage system to lead in time, the rise of groundwater level, and the inability of effective drainage of accumulated water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

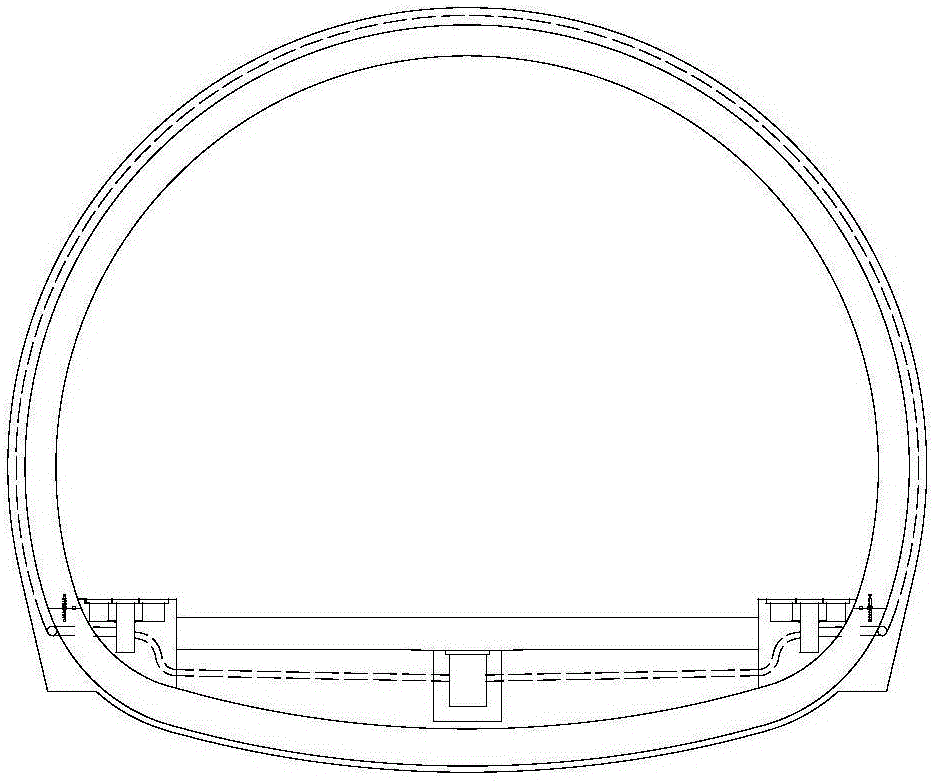

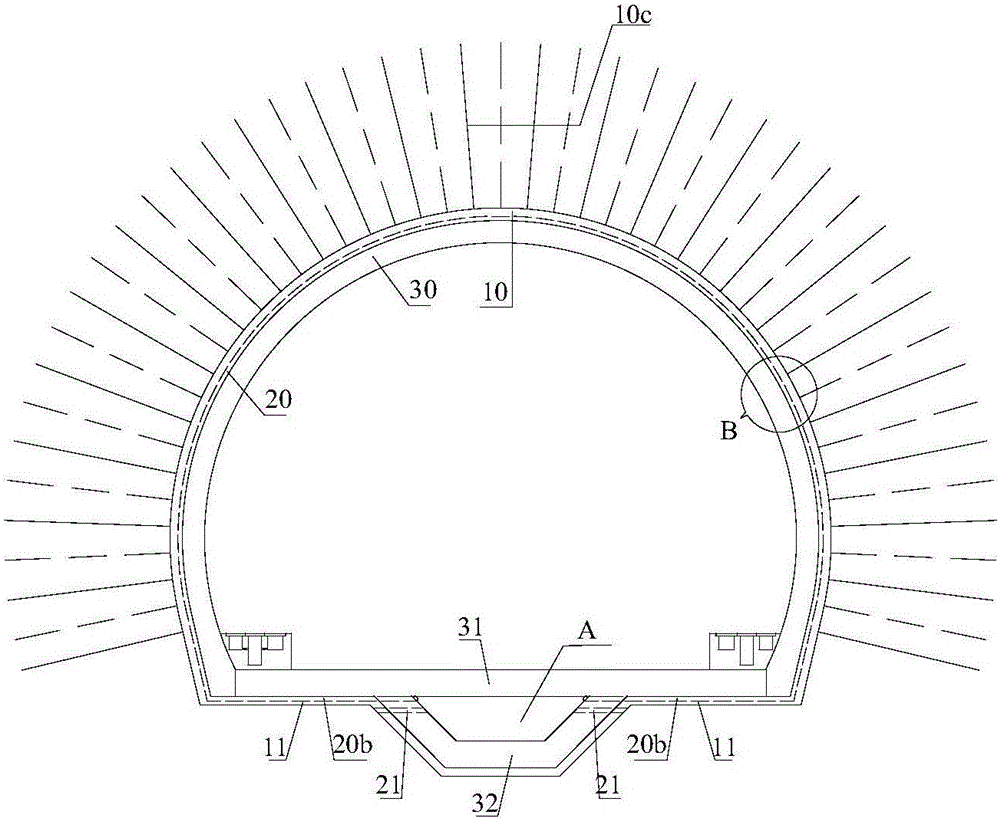

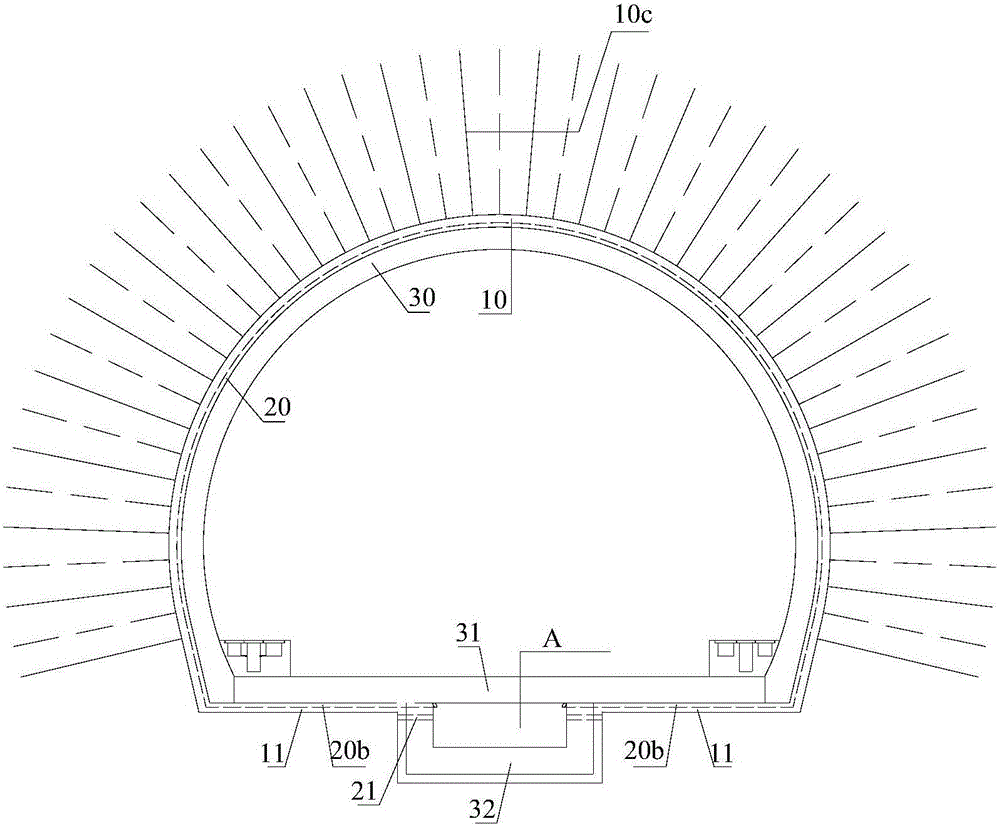

[0016] refer to figure 2 with image 3 , the box-type tunnel bottom composite arched tunnel lining structure with water-repelling function of the present invention includes an arch wall initial support structure 10, a secondary lining structure and a base leveling layer 11 arranged from the outside to the inside, and is arranged on the arch wall initial support structure. The waterproof and drainage system 20 between the structure 10 and the secondary lining structure communicates with the central drainage groove A. The secondary lining structure includes the secondary lining 30 of the arch wall and a box-shaped bottom structure composed of a bottom plate 31 and a groove plate 22. The two ends of the bottom plate 31 are consolidated with the bottom end of the secondary lining 30 of the arch wall, and the groove plate 22 is opposite A central drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com