Limited stroke ball screw

A ball screw and ball technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission, etc., can solve problems such as mechanism failure, inapplicability, elastic fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable the examiner to have a further understanding and understanding of the purpose, features and functions of the present invention, please cooperate with [simplified description of drawings] to describe in detail below.

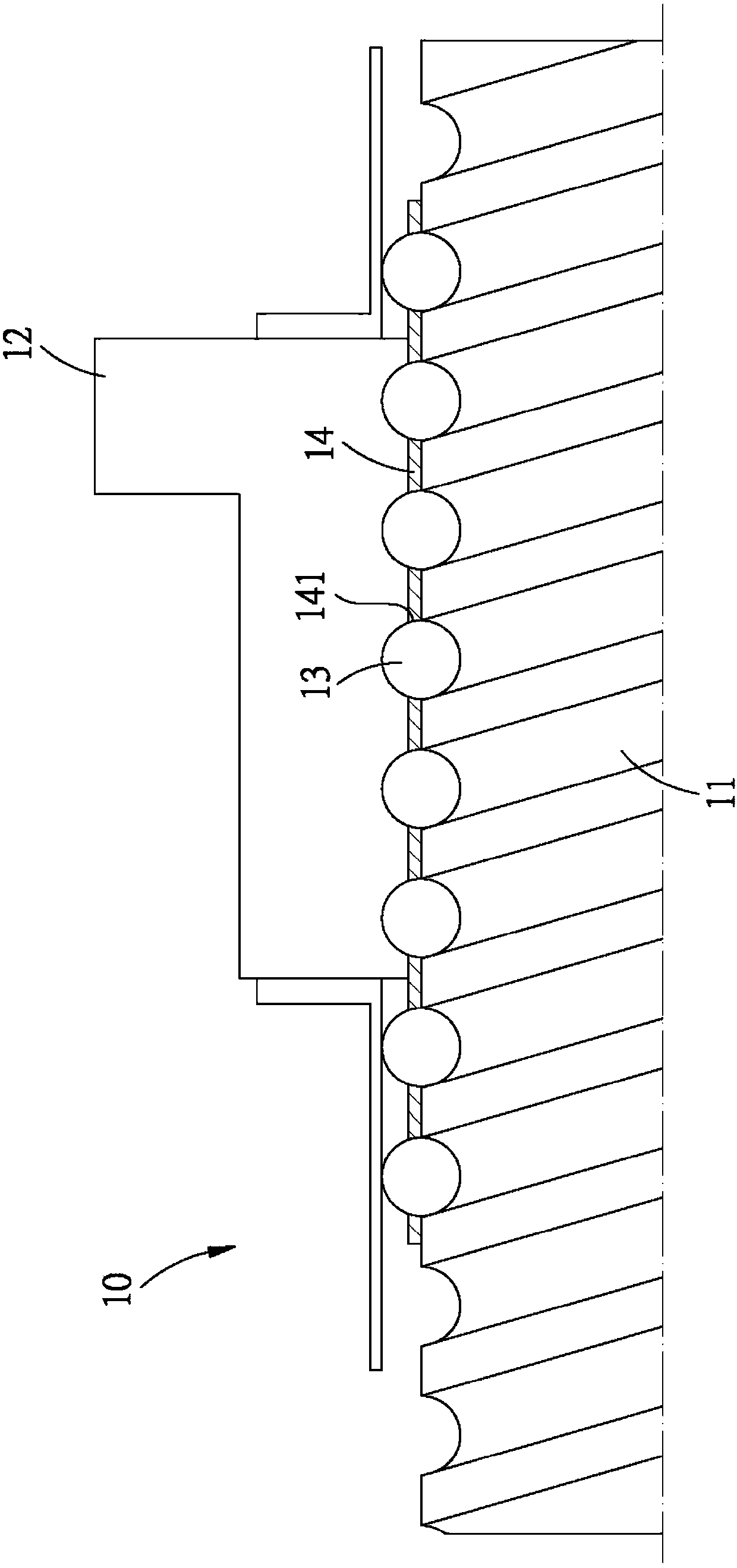

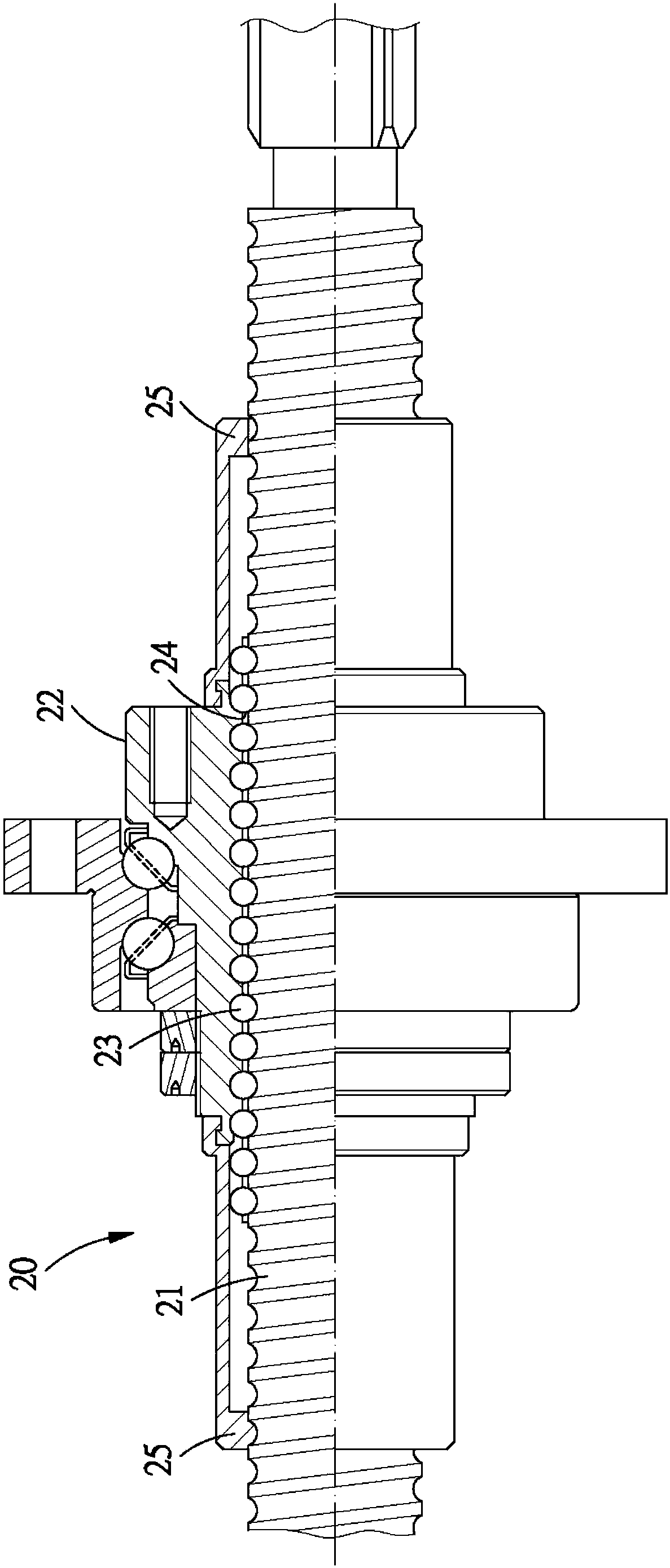

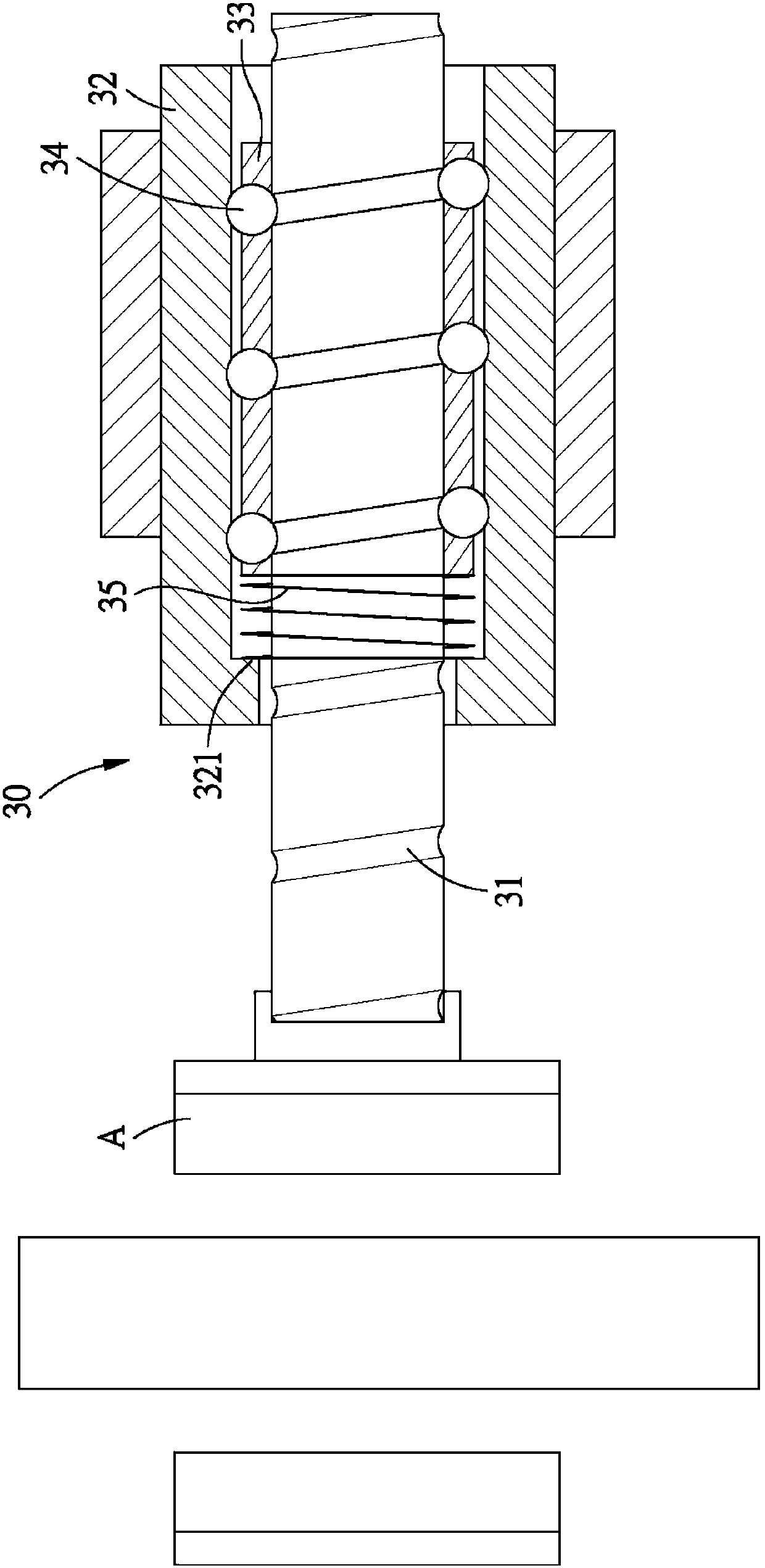

[0053] The preferred embodiment of the limited stroke ball screw of the present invention is as follows: Figures 4 to 12 shown, including:

[0054] A screw 40 extends along an axial direction X, and the outer surface of the screw 40 has an external helical groove 41; and the vertical axis X is defined as a radial direction Y;

[0055] A nut 50 is provided with a set of holes 51 along the axial direction X, and an inner helical groove 511 is provided on the inner surface of the set hole 51, the nut 50 can be slipped on the outside of the screw rod 40 along the axial direction X, and the outer helical A plurality of balls 60 can be accommodated between the groove 41 and the inner helical groove 511; one end of the nut 50 extends inwardly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com