Vacuum degree detection structure and detection method of external compound packaged five-layer coextrusion infusion bag

A co-extrusion infusion bag and detection structure technology, which is applied in vacuum gauges, measuring devices, transportation and packaging, etc., can solve the problems of no accurate and simple method, double-layer infusion bag vacuum degree detection, etc., and achieve the goal of reducing the cost of random inspection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A double-layer infusion bag vacuum detection method, comprising the following steps:

[0034] (1) Place the double-layer infusion bag that has formed a vacuum state in the testing room, the vacuum index of the packaging of the infusion bag is 0.5Mpa, and keep the air pressure in the testing room at normal pressure;

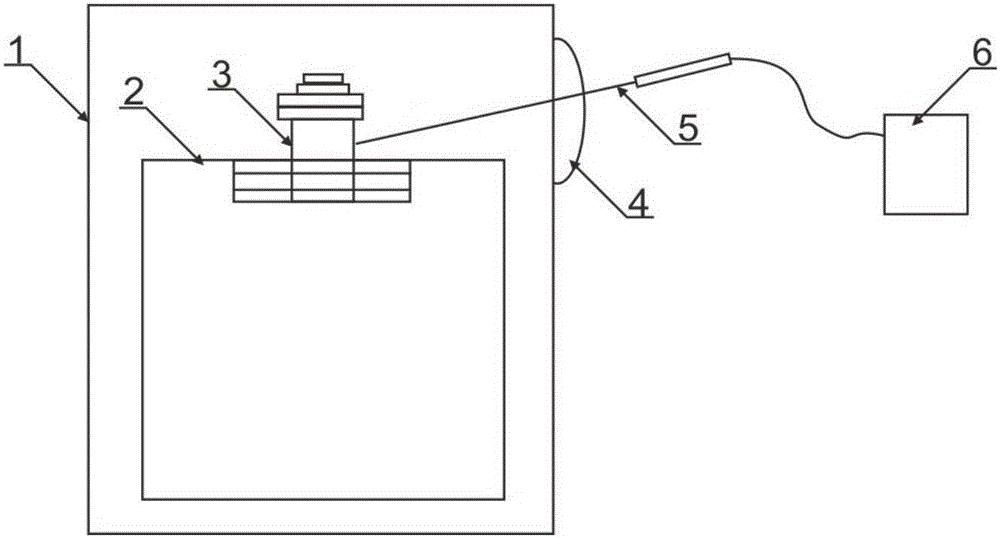

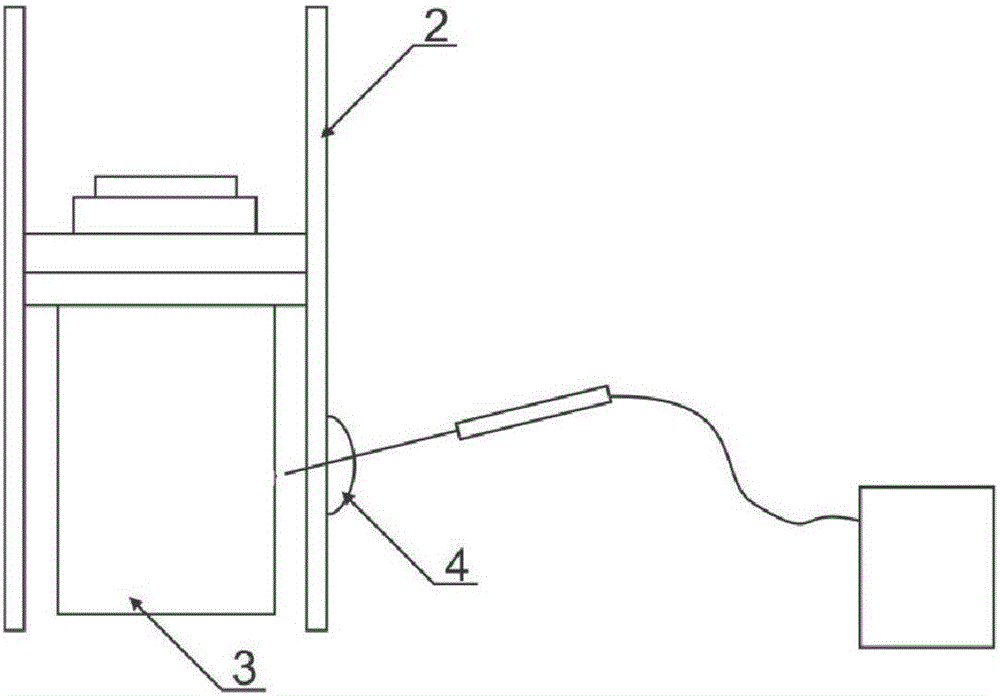

[0035] (2) If the double-layer infusion bag has a paper packaging box, remove the paper packaging box of the double-layer infusion bag, expose the outer layer 1 of the double-layer infusion bag, and glue the outer layer of the infusion bag near the infusion tube 3 Sealing tape 4, the sealing tape is made of viscous silica gel, which can be closely bonded to the outer layer of the infusion bag and has certain flexibility.

[0036] (3) After the sealant is bonded tightly, the sampling needle 5 of the vacuum detection device is sequentially pierced through the sealant and the outer layer of the infusion bag, so that the sampling needle enters the interlayer be...

Embodiment 2

[0041] A double-layer infusion bag vacuum detection method, comprising the following steps:

[0042] (1) Place the double-layer infusion bag that has formed a vacuum state in the testing room, the vacuum index of the packaging of the infusion bag is 0.5Mpa, and keep the air pressure in the testing room at normal pressure;

[0043] (2) Remove other packaging of the double-layer infusion bag, such as boxes and boxes, to expose the outer layer of the double-layer infusion bag, and stick a sealant on the outer layer of the infusion bag near the infusion tube. Choose viscous silica gel for the sealant. The viscous silica gel contains 0.5% sodium alginate and 0.5% sodium chloride. You can add the formula amount of sodium alginate and sodium chloride during the preparation of the silica gel.

[0044] (3) After the sealant is bonded tightly, the sampling needle of the vacuum detection device is sequentially pierced through the sealant and the outer layer of the infusion bag, so that t...

Embodiment 3

[0049] A double-layer infusion bag vacuum detection method, comprising the following steps:

[0050] (1) Place the double-layer infusion bag that has formed a vacuum state in the testing room. The vacuum index of the packaging of the infusion bag is 1Mpa, and the air pressure in the testing room is kept at normal pressure; the temperature in the testing room is controlled at 20 ° C, and the humidity is controlled at 60 %.

[0051] (2) Remove other packaging of the double-layer infusion bag, such as boxes and boxes, to expose the outer layer of the double-layer infusion bag, and stick a sealant on the outer layer of the infusion bag close to the infusion tube. The interlayers of the bags are connected. Choose viscous silica gel for the sealing tape, which can be tightly bonded to the outer layer of the infusion bag and has certain flexibility.

[0052] (3) After the sealant is bonded tightly, the sampling needle of the vacuum detection device is sequentially pierced through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com