Method of testing hairiness on double surfaces of fabric cloth sample with yarn hairiness instrument

A double-sided hair and yarn technology, applied in textile testing, instruments, measuring devices, etc., can solve the problems of unable to detect double-sided hairiness of cloth samples, and achieve the effects of easy large-scale promotion and use, simple operation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

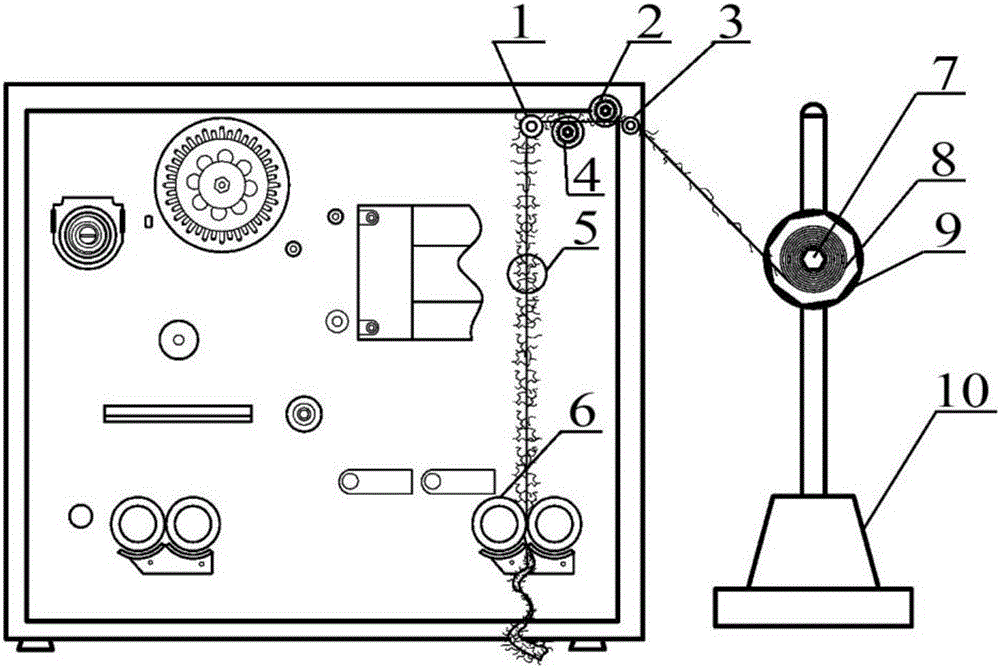

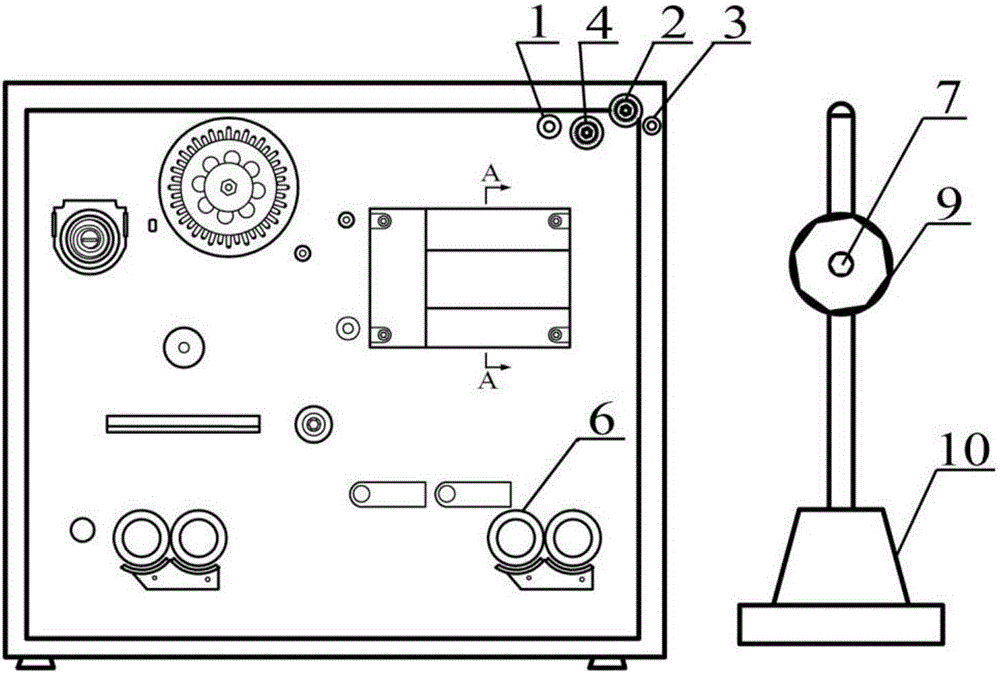

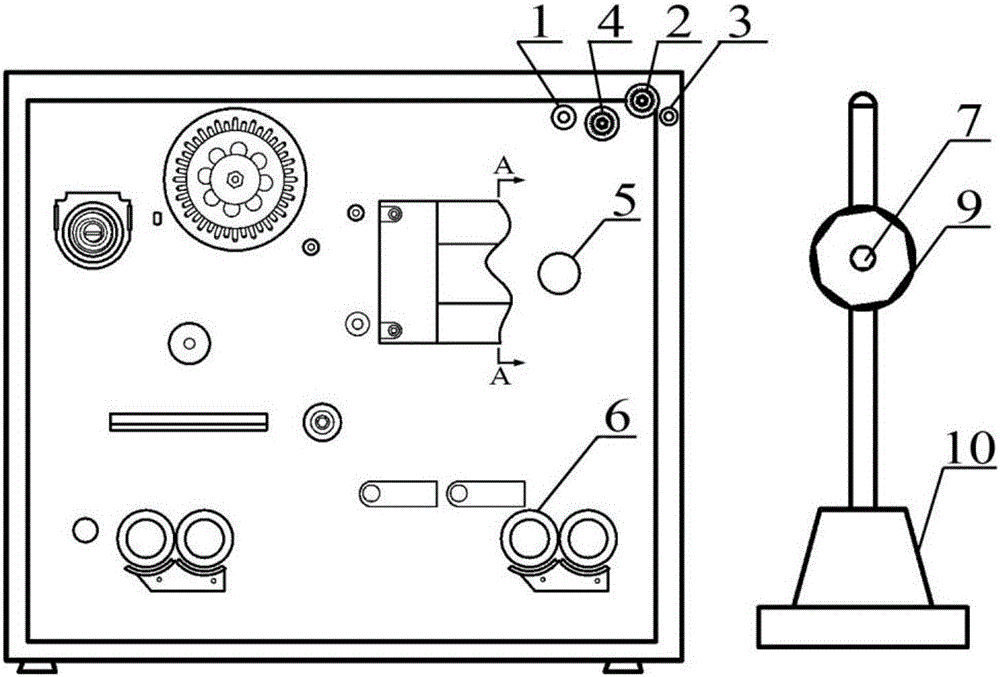

[0011] A method for testing hairiness on both sides of a fabric sample with a yarn hairiness meter of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] see Attachment.

[0013] A method for testing hairiness on both sides of a fabric sample with a yarn hairiness meter, in which a passive roller and an active roller 6 are arranged in front of the hairiness detection area formed by a yarn hairiness meter detection head and a circular emitting surface 5 of a laser emitter, and the passive roller and the active roller 6 are vertically installed on the working surface of the yarn hairiness meter along the axis of the roller, the passive roller and the active roller 6 mesh with each other to form a roller nip, and the roller nip line is located on the vertical plane of the circular emitting surface 5 of the laser transmitter Above, the first cloth guide roller 1 is installed behind the hairiness detection area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com