LS-DYNA based method for optimally designing layout of storage tank area of chemical industry park

A chemical industry park, layout optimization technology, applied in the direction of multi-objective optimization, calculation, special data processing applications, etc., can solve problems such as expired, poorly designed, failed basic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

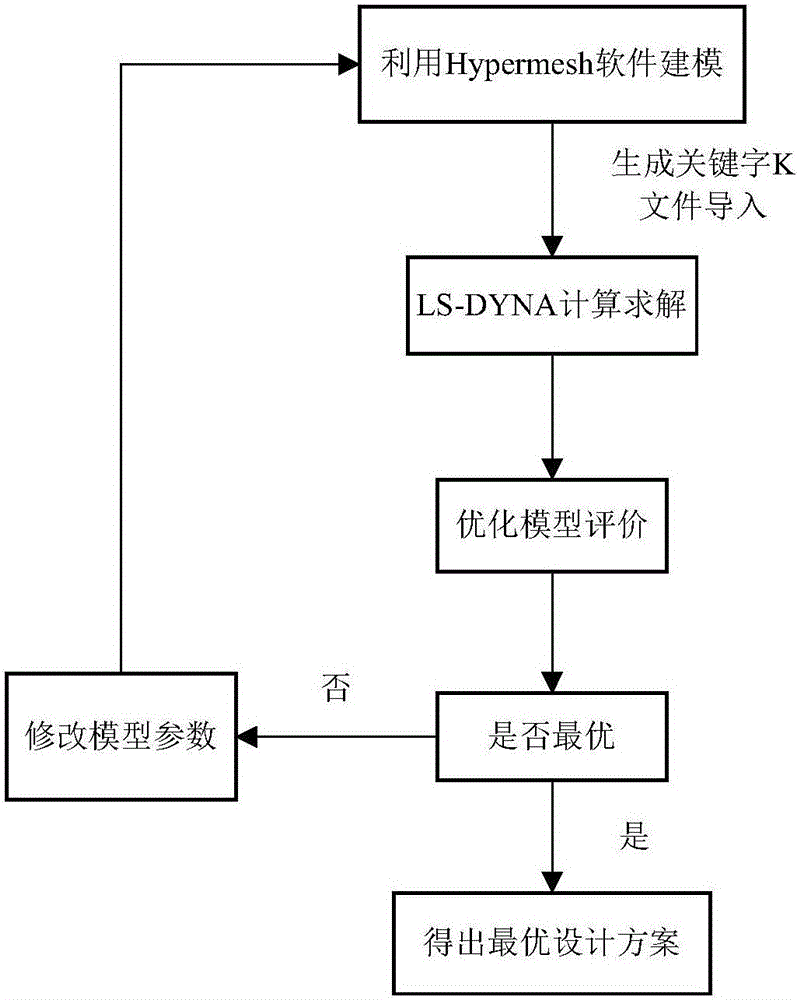

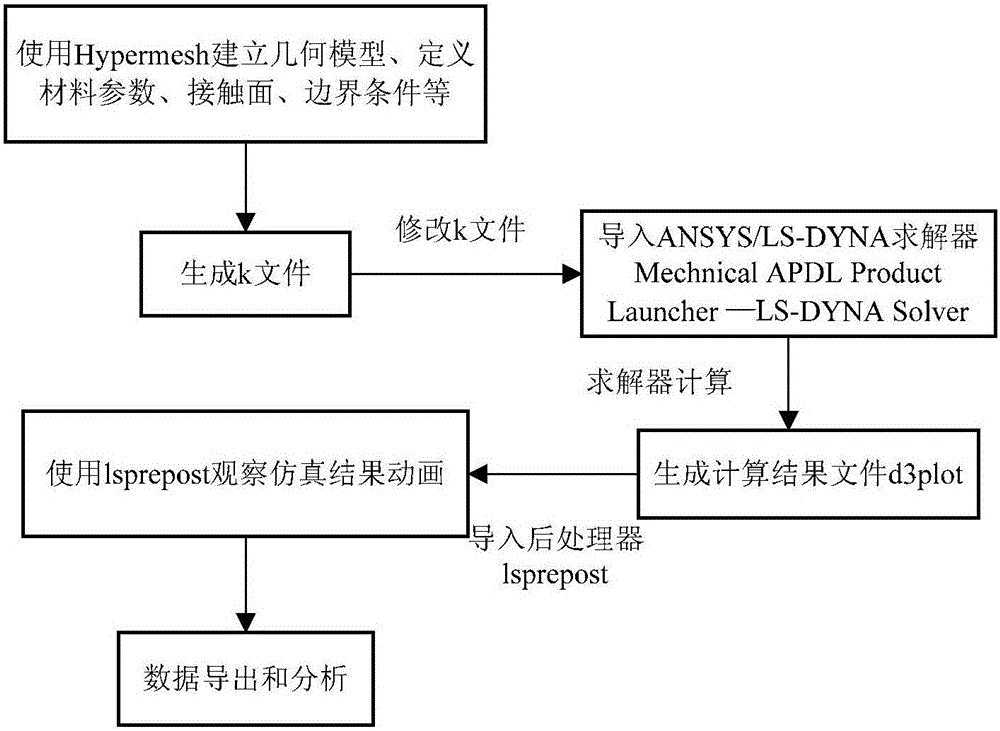

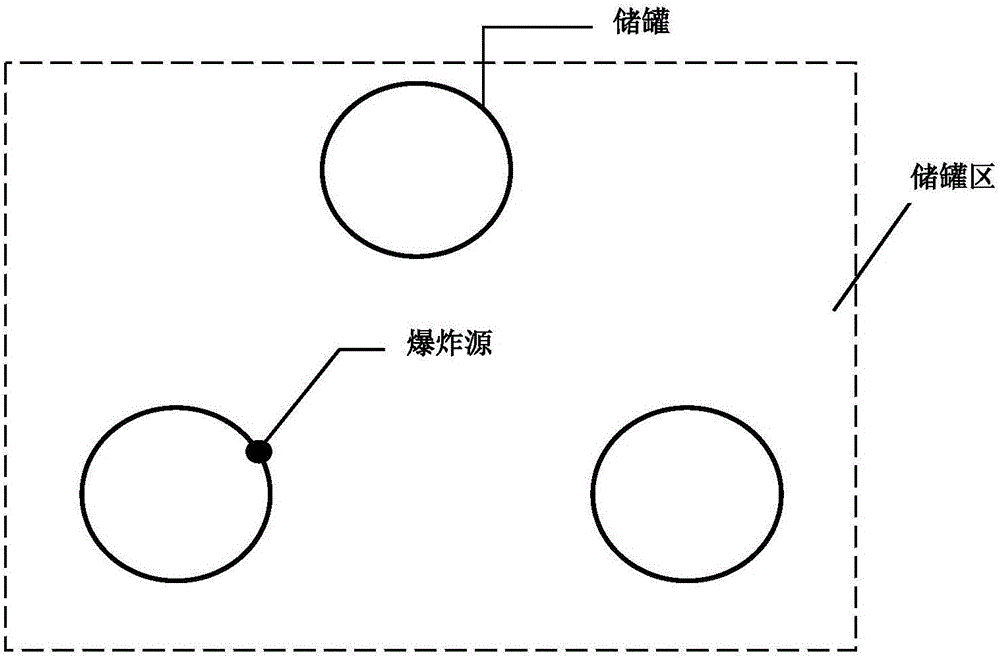

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 Describe this embodiment, a kind of method of this embodiment based on LS-DYNA to the layout optimization design of chemical industrial park storage tank area, specifically prepare according to the following steps:

[0018] Step 1. Select the storage tank area of the chemical industry park as the prototype of the numerical simulation, define the constraints of the selected storage tank area of the chemical industry park as the model parameters of the numerical simulation, and then the Hypermesh software generates a keyword k file, which contains the parameters of the storage tank area the modeling command;

[0019] Step 2: Input the parametric modeling command of the storage tank area contained in the keyword k file into the LS-DYNA software for solution, and obtain the d3plot result file through numerical simulation calculation;

[0020] Step 3. Use the LS-DYNA post-processor to post-proce...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the constraint conditions of the storage tank area in the chemical industry park in step 1 are the size of the storage tank area, the size of the storage tank, the material of the storage tank, the medium of the storage tank, the energy of the explosion source, The distance and relative position between storage tanks.

[0023] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the damage effect value of the storage tank area in the chemical industrial park described in step 3 in the whole explosion process includes the damage effect value when the storage tank area of the chemical industrial park exploded for the first time and the damage effect value that triggers the domino chain effect caused by the secondary explosion.

[0025] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com