Dynamic calibration system, and combined optimization method and combined optimization device in dynamic calibration system

A joint optimization and dynamic calibration technology, applied in image data processing, instrumentation, computing, etc., can solve problems such as limited scalability, poor calibration accuracy, and affecting the overall performance of the panoramic view system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

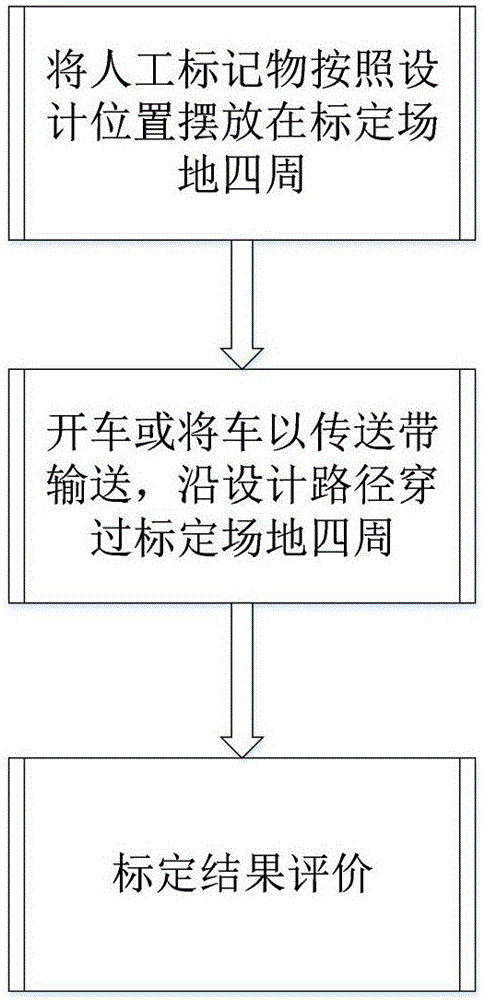

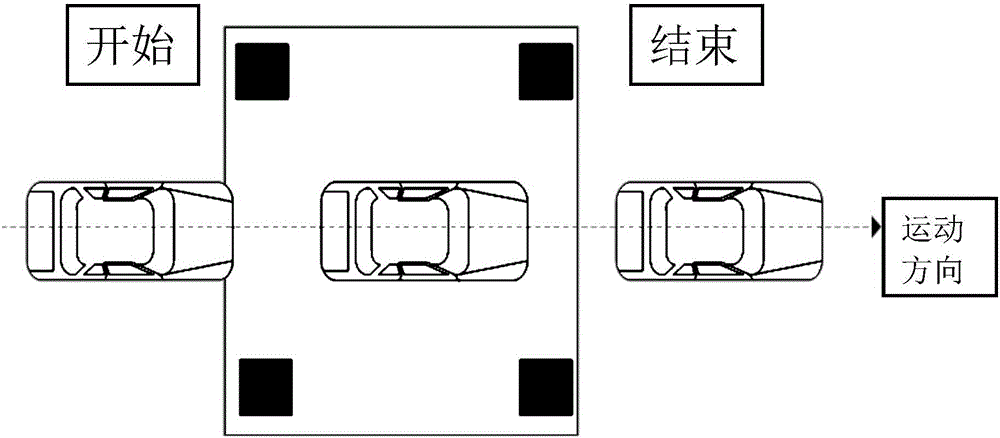

[0114] When a new car is assembled on the assembly line, based on the principles of the present invention, it includes: a feature picking module, a feature parameter extraction module, a calibration parameter optimization module, and a calibration result inspection module; specifically includes the following execution steps:

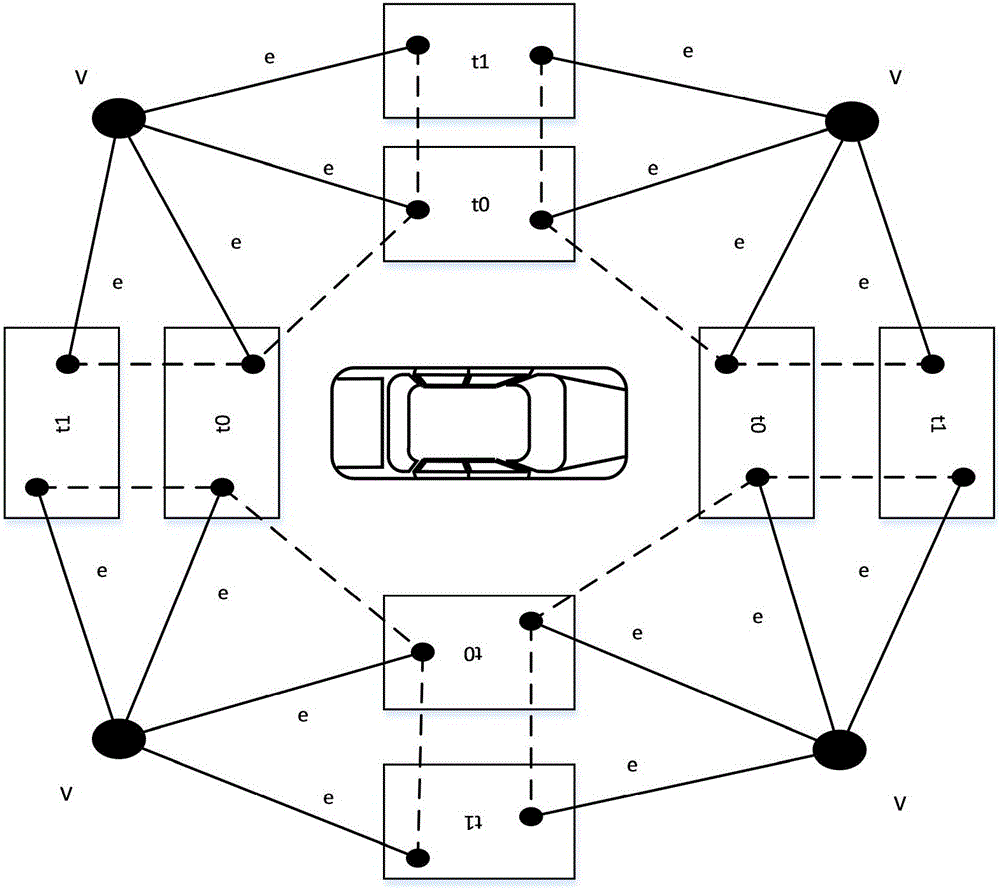

[0115] 1) The feature picking module can contain several pre-designed artificial markers and a designated global coordinate system. Markers are placed around the calibration field, and their positions in the set global coordinate system are known. The position of the car in the global coordinate system is known. Images are automatically detected and localized to this artificial marker.

[0116] 2) The feature parameter extraction module automatically extracts the position of the artificial marker in the image.

[0117] 3) The calibration parameter optimization module combines the obtained position of the artificial marker in the image with the position...

Embodiment 2

[0120] In the 4S shop of vehicle maintenance, for the calibration of the panoramic system, based on the principle of the present invention, including: a feature picking module, a feature parameter extraction module, and a calibration parameter optimization module, the following steps can be adopted:

[0121] 1) The feature picking module contains a specially designed artificial marker. Markers are placed around the vehicle. The position of the marker in the image can be located manually or by image recognition.

[0122] 2) The feature parameter extraction module extracts the position of each feature parameter of the artificial marker in the image.

[0123] 3) The calibration parameter optimization module combines the obtained position of the artificial marker in the image with the position of the global coordinate system known in advance to calculate and optimize the calibration parameters.

[0124] 4) The calibration result inspection module stitches the panoramic images ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com