Flexible substrate manufacturing method, OLED (organic light-emitting diode) device manufacturing method and the applications thereof

A technology of a flexible substrate and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of difficulty in ensuring the flexibility and waterproofness of OLED devices, loss of waterproof effect, and failure of water-blocking layer, etc. Achieving the effect of good waterproof rate, better waterproofness and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

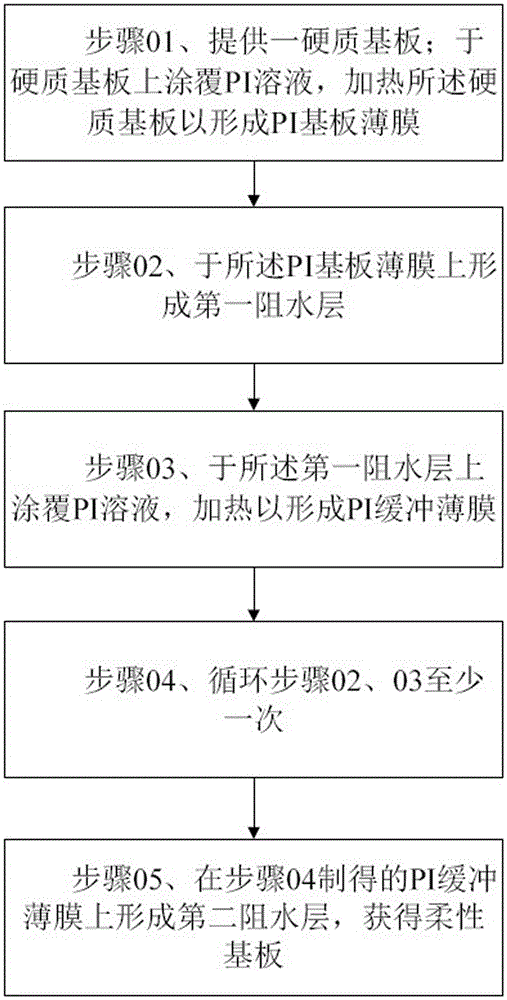

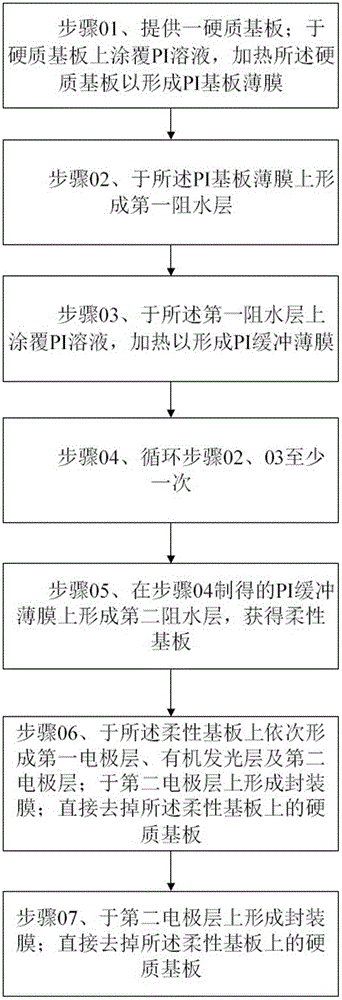

[0049] This embodiment provides a method for manufacturing a flexible OLED device, including the following steps:

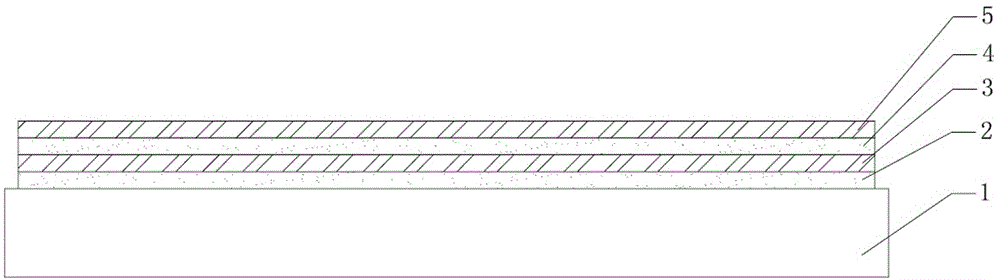

[0050] Step 11. Provide a rigid substrate; apply PI solution on the rigid substrate, and heat the rigid substrate to form a PI substrate film with a thickness of about 0.5 μm;

[0051] Step 12. A first water blocking layer with a thickness of about 1000 nm is formed on the PI substrate film, the first water blocking layer is SiNx, SiO 2 And Al 2 O 3 Any layer or any combination of two or more layers in the inorganic film;

[0052] Step 13. Coat a PI solution on the first water blocking layer and heat to form a PI buffer film with a thickness of about 10 μm;

[0053] Step 14. A second water blocking layer with a thickness of about 200 nm is formed on the PI buffer film; the second water blocking layer is made of SiNx, SiO 2 And Al 2 O 3 Any layer or any combination of two or more layers in the inorganic film;

[0054] Step 15. A first electrode layer (ITO or IZO layer), a...

Embodiment 2

[0057] This embodiment provides a method for manufacturing a flexible OLED device, including the following steps:

[0058] Step 21, providing a rigid substrate; coating PI solution on the rigid substrate, and heating the rigid substrate to form a PI substrate film with a thickness of about 5 μm;

[0059] Step 22: Form a first water blocking layer with a thickness of about 600 nm on the PI substrate film, the first water blocking layer being SiNx, SiO 2 And Al 2 O 3 Any layer or any combination of two or more layers in the inorganic film;

[0060] Step 23: Coating PI solution on the first water blocking layer and heating to form a PI buffer film with a thickness of about 0.5 μm;

[0061] Step 24: Loop the process of steps 22 and 23 5 times;

[0062] Step 25, forming a second water blocking layer with a thickness of about 1000 nm on the PI buffer film obtained in step 24; the second water blocking layer is SiNx, SiO 2 And Al 2 O 3 Any layer or any combination of two or more layers in th...

Embodiment 3

[0066] This embodiment provides a method for manufacturing a flexible OLED device, including the following steps:

[0067] Step 31, providing a rigid substrate; coating PI solution on the rigid substrate, and heating the rigid substrate to form a PI substrate film with a thickness of about 10 μm;

[0068] Step 32: Form a first water blocking layer with a thickness of about 200 nm on the PI substrate film, the first water blocking layer being SiNx, SiO 2 And Al 2 O 3 Any layer or any combination of two or more layers in the inorganic film;

[0069] Step 33: Coating PI solution on the first water blocking layer and heating to form a PI buffer film with a thickness of about 4 μm;

[0070] Step 34: Loop the process of steps 32 and 33 three times;

[0071] Step 35, forming a second water blocking layer with a thickness of about 600 nm on the PI buffer film prepared in step 34; the second water blocking layer is SiNx, SiO 2 And Al 2 O 3 Any layer or any combination of two or more layers in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com