Patents

Literature

37results about How to "No cracking problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing fast-growing poplar technical wood sawn timber at low temperature

InactiveCN102179851AQuality assuranceQuality improvementWood working apparatusPolyvinyl acetateMass ratio

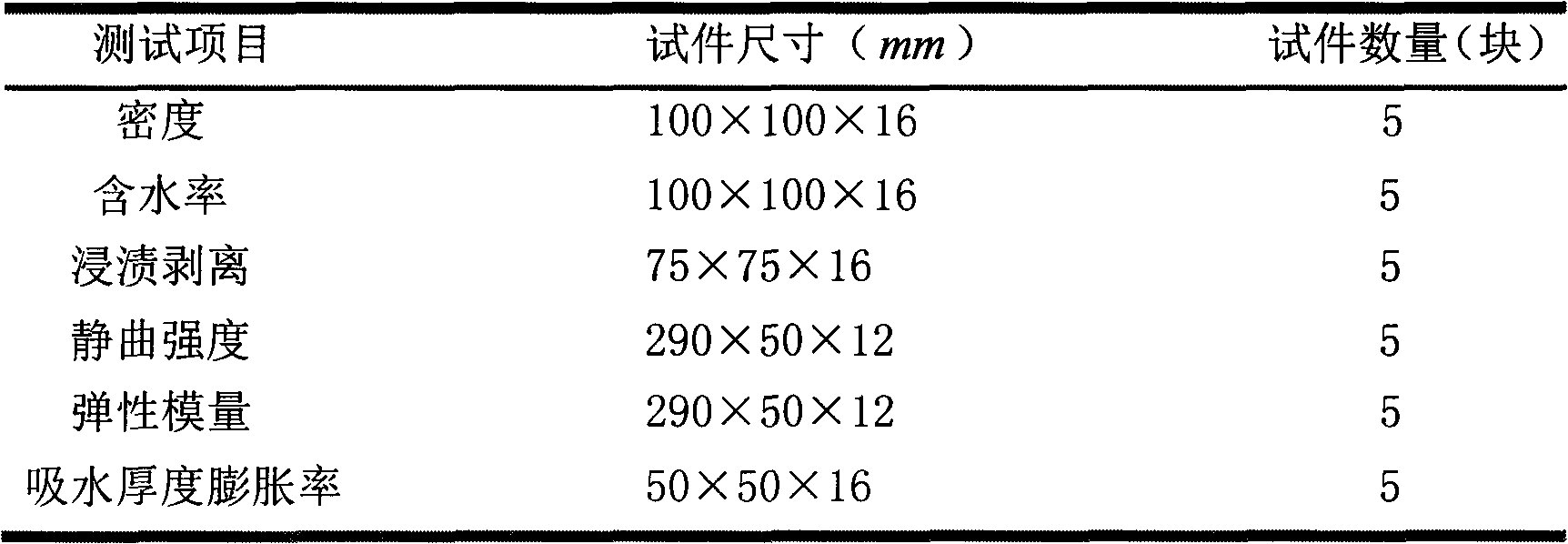

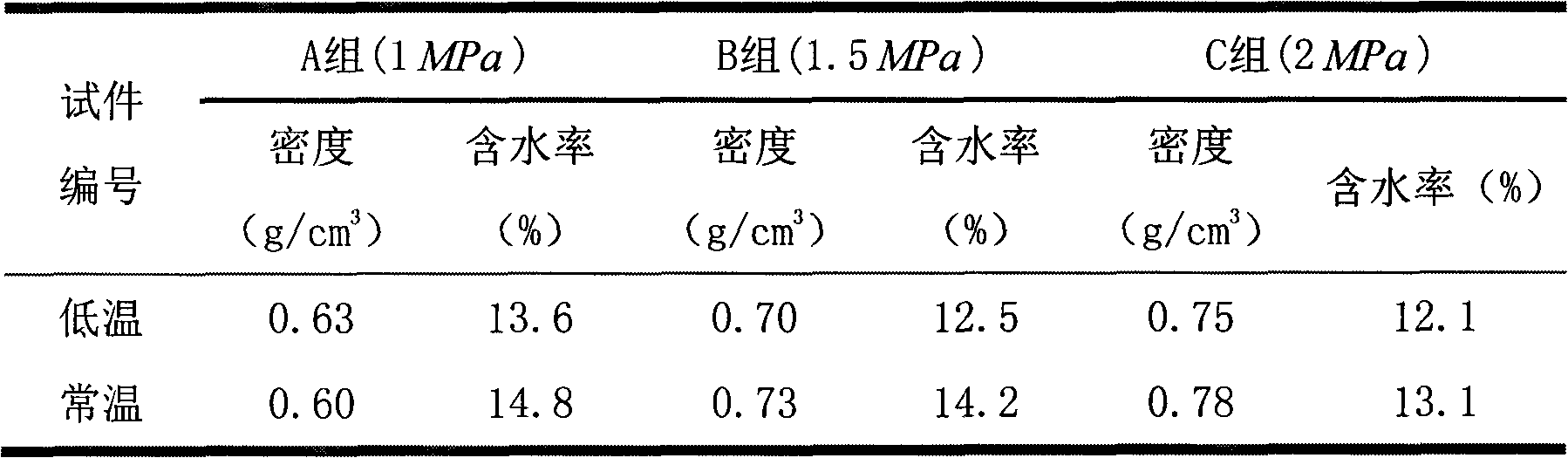

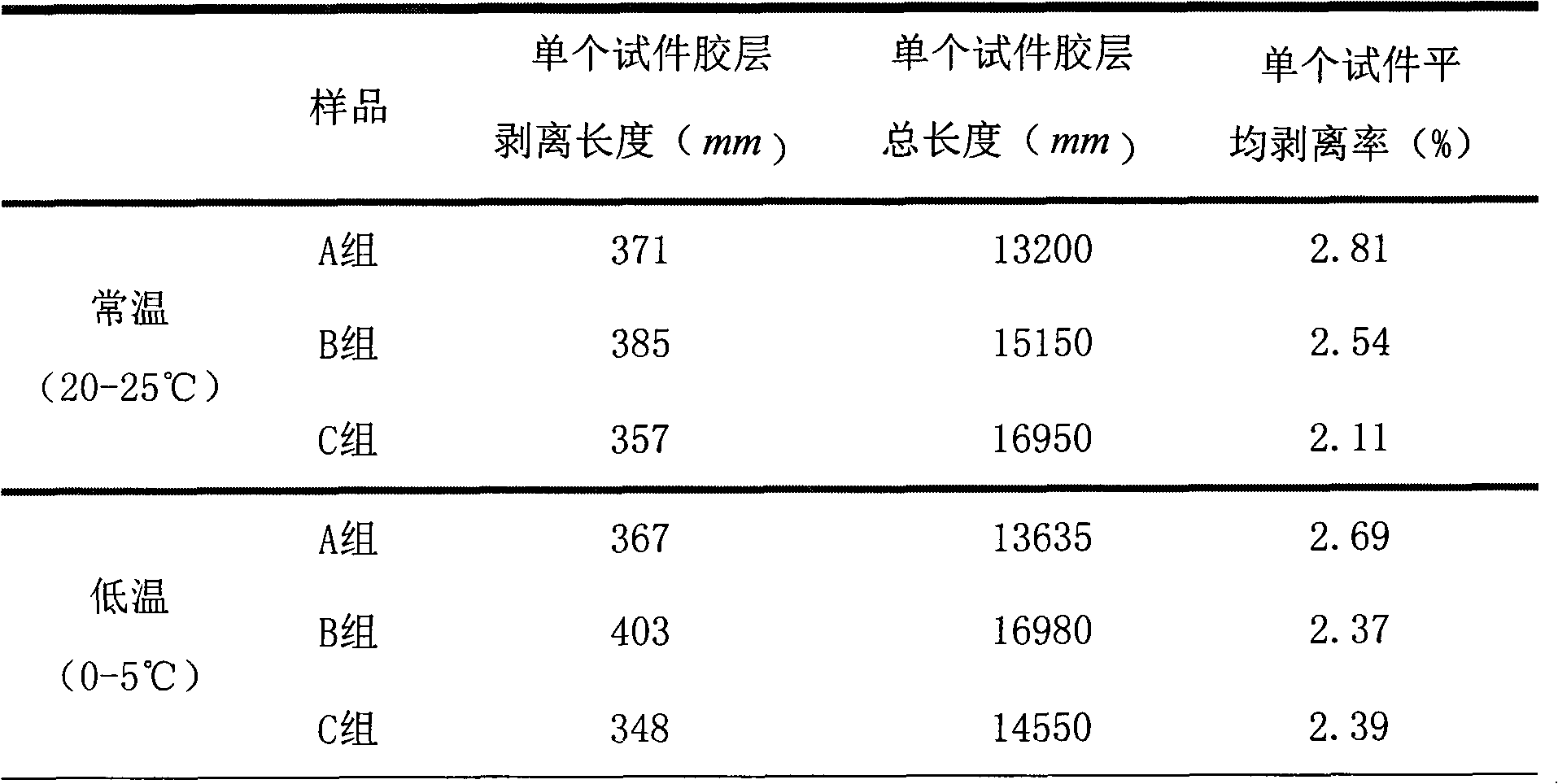

The invention provides a method for manufacturing a fast-growing poplar technical wood sawn timber at low temperature or normal temperature and aims to solve the problem of cracking of fast-growing poplar technical wood which is produced at low temperature (the ambient temperature is below 5 DEG C). The indexes of the dipping delaminating ratio, water-absorbing thickness expansion ratio, static bending strength and modulus of elasticity of the fast-growing poplar technical wood sawn timber which is produced by the method meet or exceed requirements of standard LY / T1655-2006 Reconstituted Decorative Lumber. The method comprises the steps of preparing a poplar single board, dyeing the single board, drying the single board, gluing the single board, assembling and cold-pressing, and fixing laminated battens of the single board obtained by cold-pressing into the die, maintaining, removing the die and lumbering. The formula of an adhesive which is used for gluing the single board is that: the mass ratio of urea-formaldehyde glue to polyvinyl acetate is (7-9):1; a curing agent which is 1 to 4 mass percent of the adhesive is added; during the cold-pressing, pressure is 1 to 2 MPa, and cold-pressing time is 0.5 to 1.5 hours; and during the maintenance, the temperature of a maintenance room is 35 to 45 DEG C, relative humidity is 65 to 75 percent, and maintenance time is 90 to 100 hours.

Owner:NANJING FORESTRY UNIV

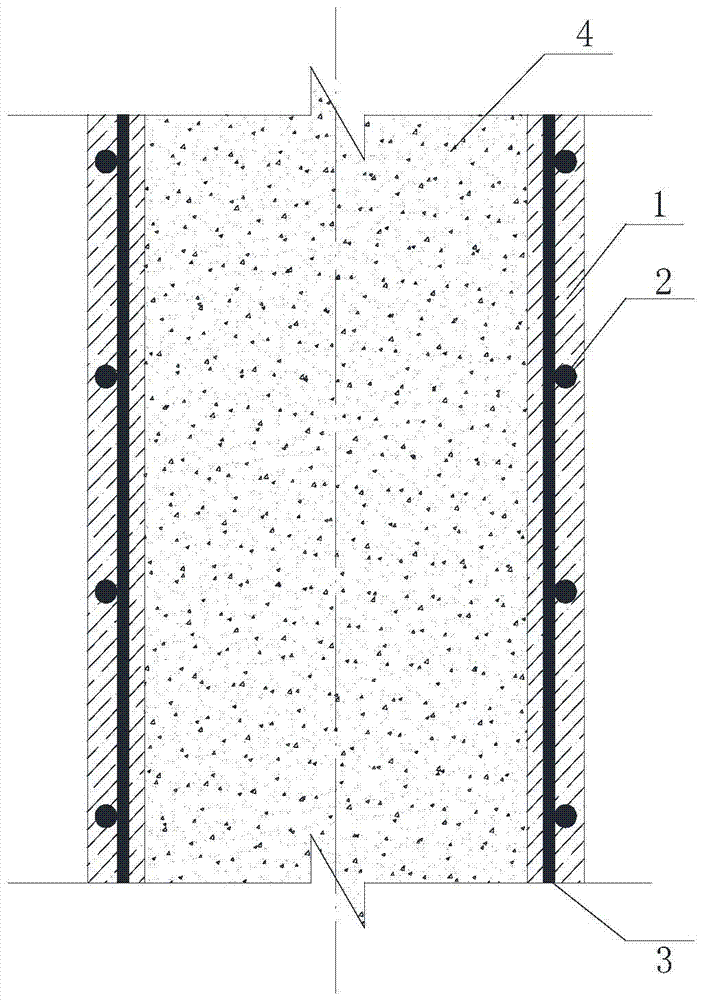

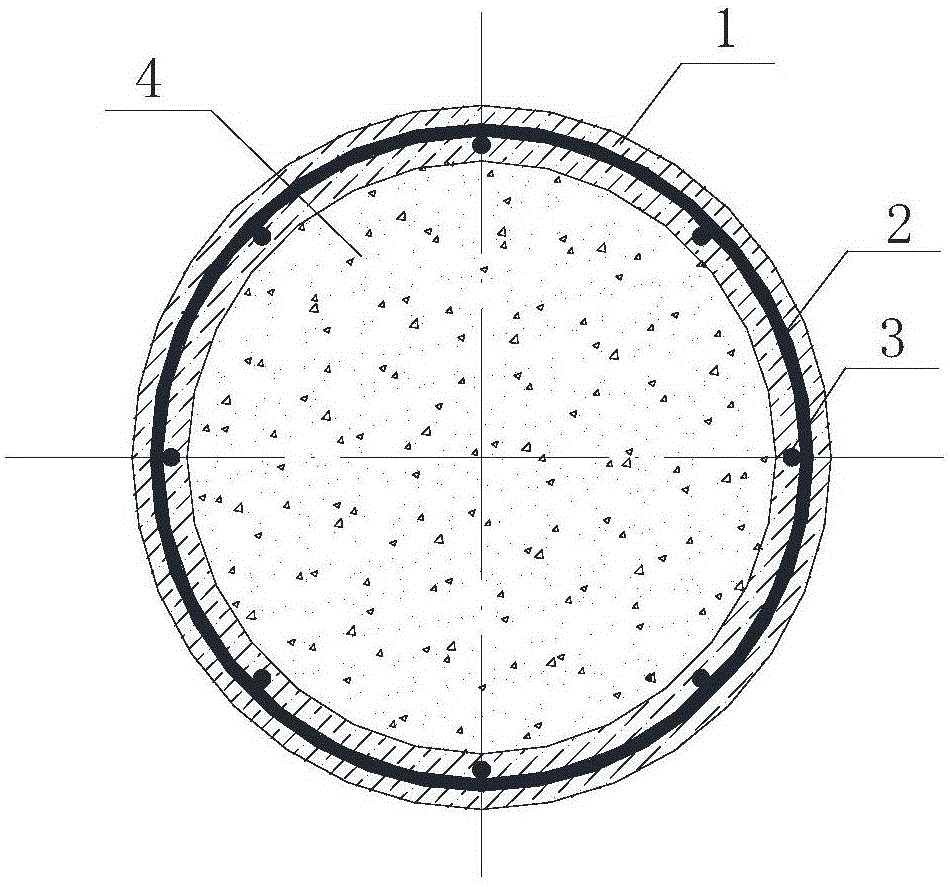

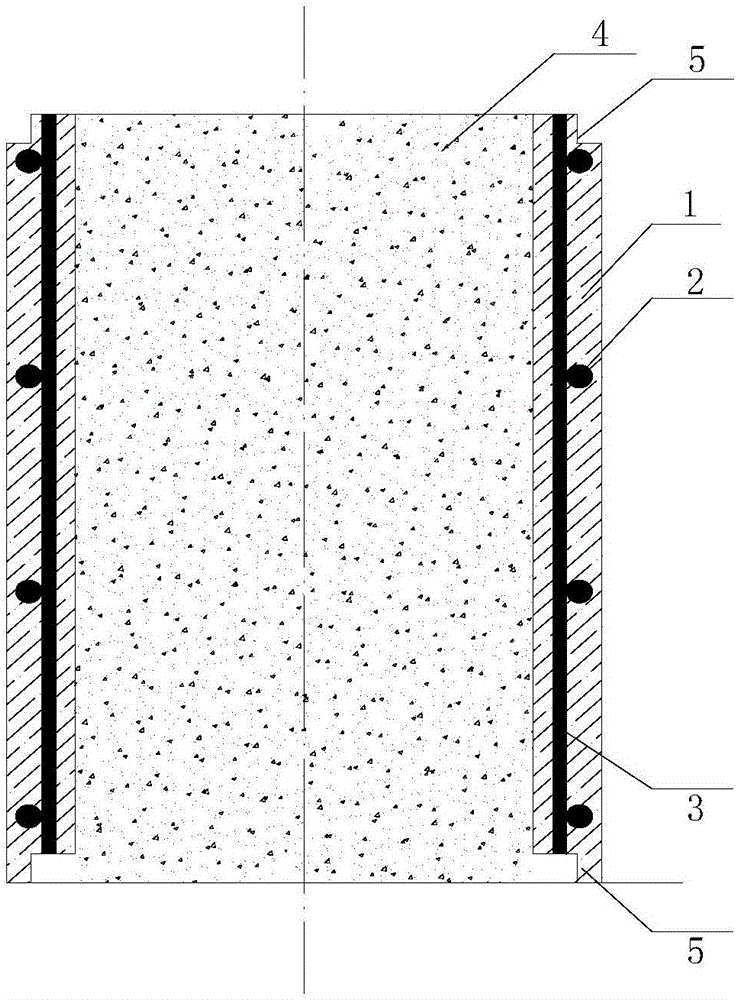

Reactive powder concrete pipe column for ocean engineering

InactiveCN105442590AImprove corrosion resistanceAvoid corrosionBulkheads/pilesSeawaterCorrosion resistant

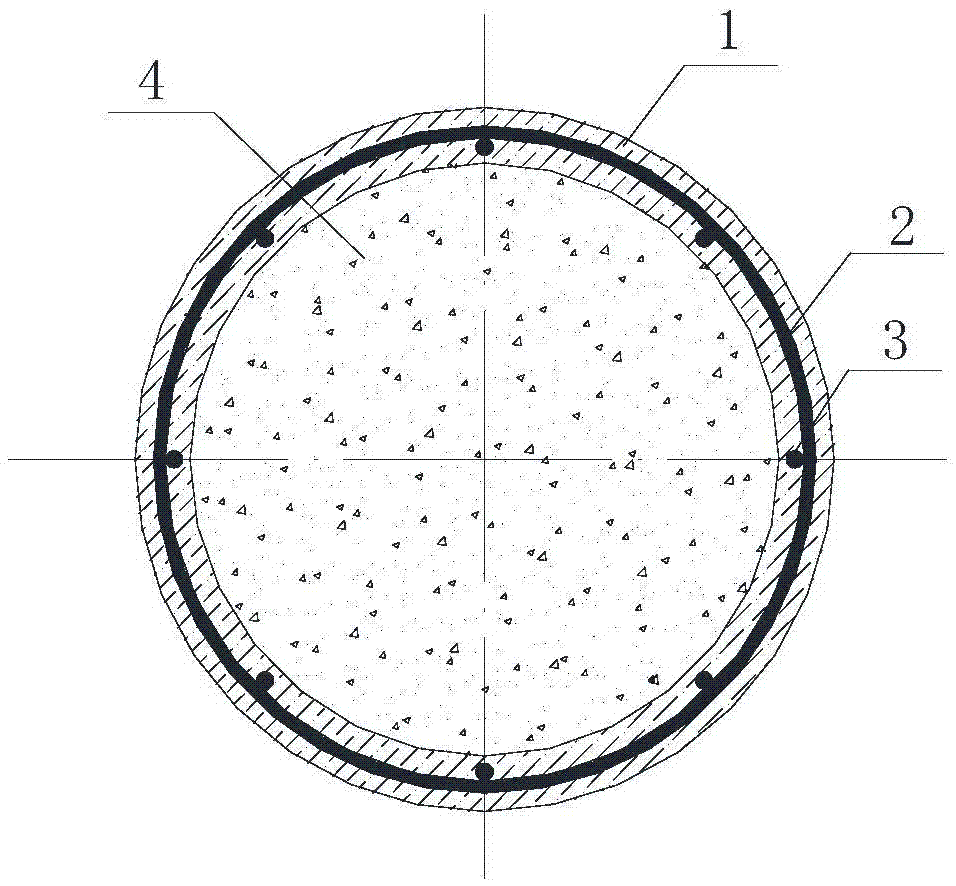

The invention discloses a reactive powder concrete pipe column for ocean engineering. The reactive powder concrete pipe column comprises a reactive powder concrete casing pipe (1), a stirrup (2), a longitudinal bar (3) and a concrete column (4), wherein the stirrup (2) and the longitudinal bar (3) are arranged in the reactive powder concrete casing pipe (1). The reactive powder concrete pipe column is characterized in that the stirrup (2) is a closed fiber-reinforced plastic stirrup (2), the longitudinal bar (3) is a longitudinal fiber-reinforced plastic bar (3), and corrosion-resistant short fibers are mixed into the reactive powder concrete of the casing pipe (1); and the concrete column (4) is cast in the casing pipe (1) in situ and is made of concrete prepared by mixing seawater and sea sand. The reactive powder concrete pipe column has the characteristics of excellent ocean environment corrosion resistance, prefabrication construction, high axial bearing capacity, utilization of on-site materials such as seawater and sea sand, good economical efficiency and the like, is a novel structural column capable of meeting the construction requirements of ocean engineering and particularly ocean island engineering and can also replace a steel pipe pile in ocean engineering.

Owner:HUNAN UNIV

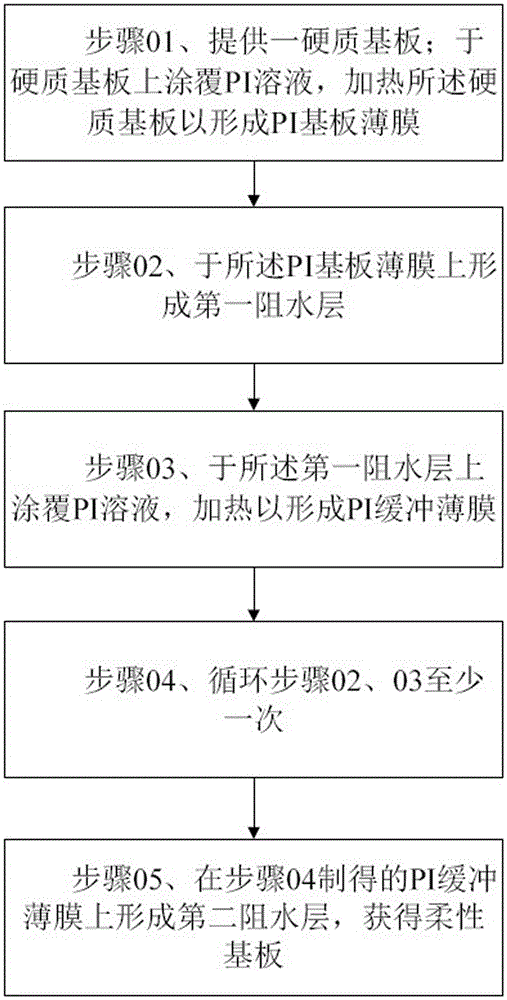

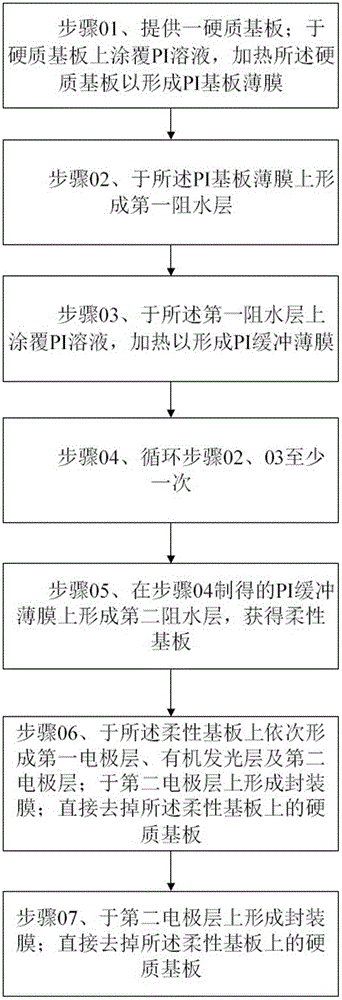

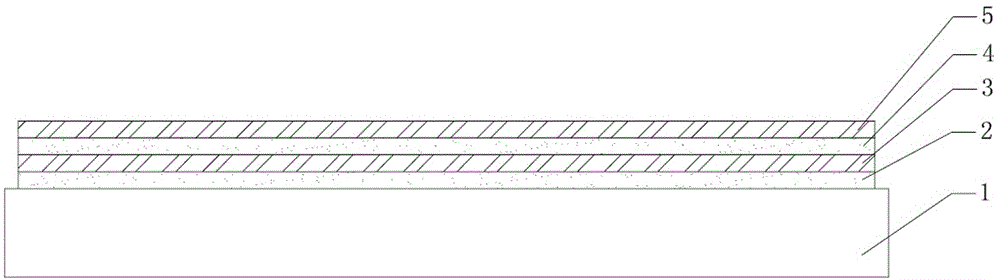

Flexible substrate manufacturing method, OLED (organic light-emitting diode) device manufacturing method and the applications thereof

InactiveCN105845844AThere will be no failure problemsImprove flexibilityFinal product manufactureSolid-state devicesLight-emitting diodeWater layer

The invention discloses a flexible substrate manufacturing method which comprises the following steps: 1) providing a hard substrate; coating the hard substrate with PI solution, and heating the hard substrate for a PI substrate film; 2) forming a first water resisting layer on the PI substrate film; 3) coating the first water resisting layer with PI solution and heating the first water resisting layer for a PI buffer film; 4) repeatedly conducting the step 2 and step 3 for at least one more time; and 5) forming a second water resisting layer on the PI buffer film for a flexible substrate. The invention further discloses an OLED device manufacturing method and the applications thereof. According to the invention, PI films and inorganic waterproof layers are alternately designed to form a water resisting layer and then further to form a bendable flexible substrate wherein the PI films serve as both base material films and buffer layer films. With a good winding performance, a good waterproof ability and easy to make, the flexible substrate can be produced in batches.

Owner:TRULY SEMICON

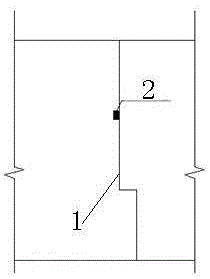

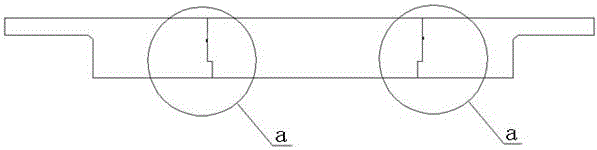

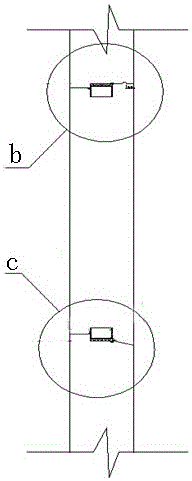

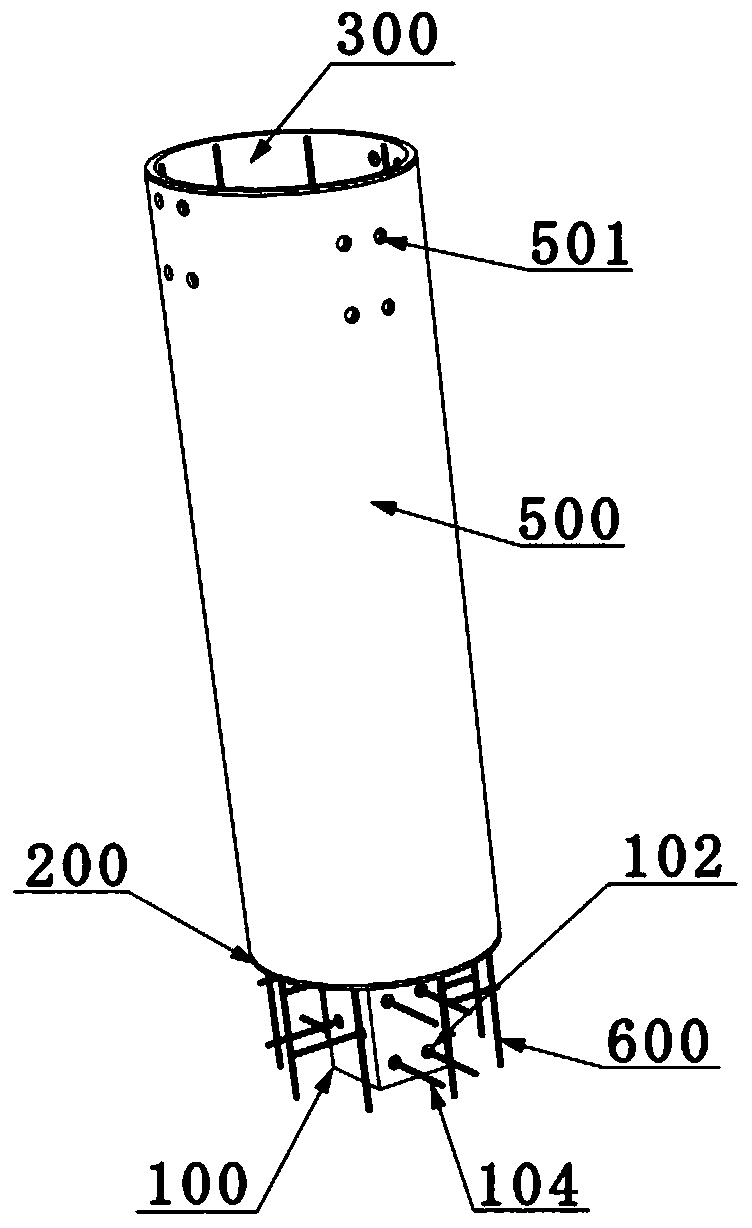

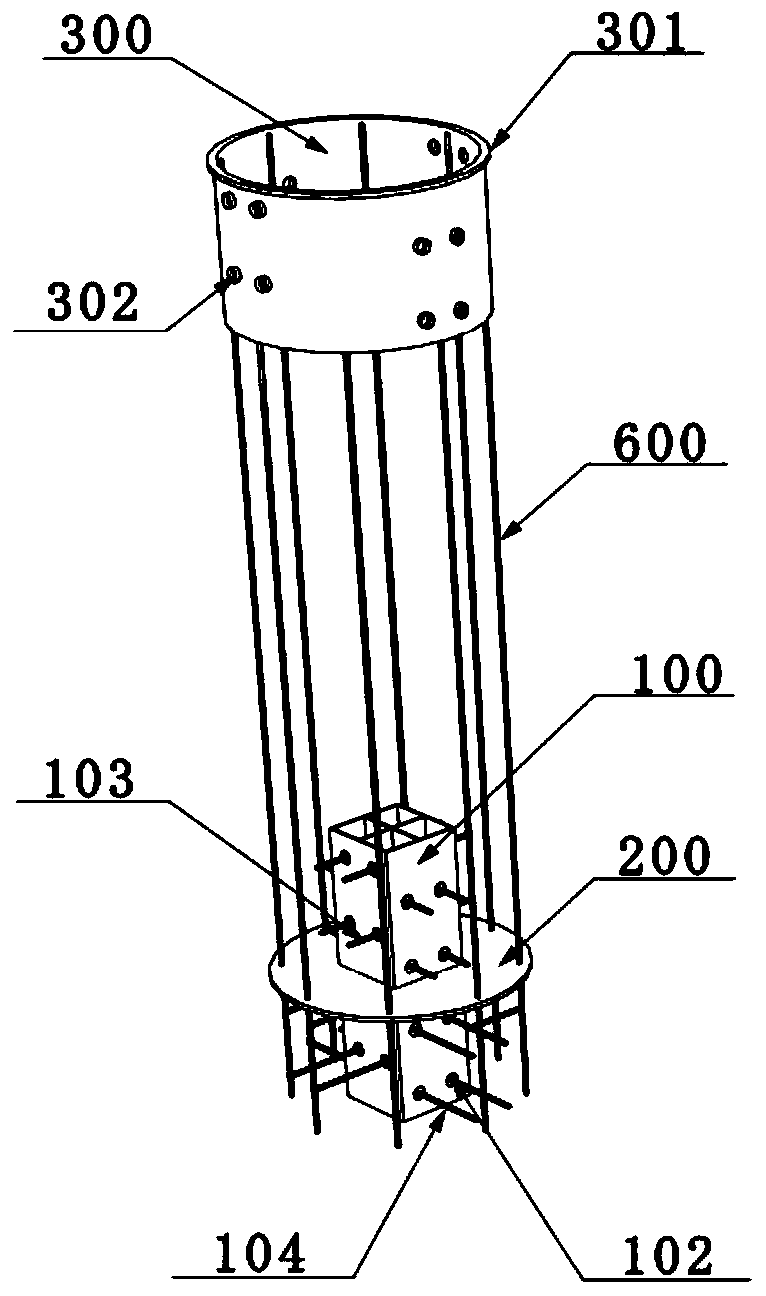

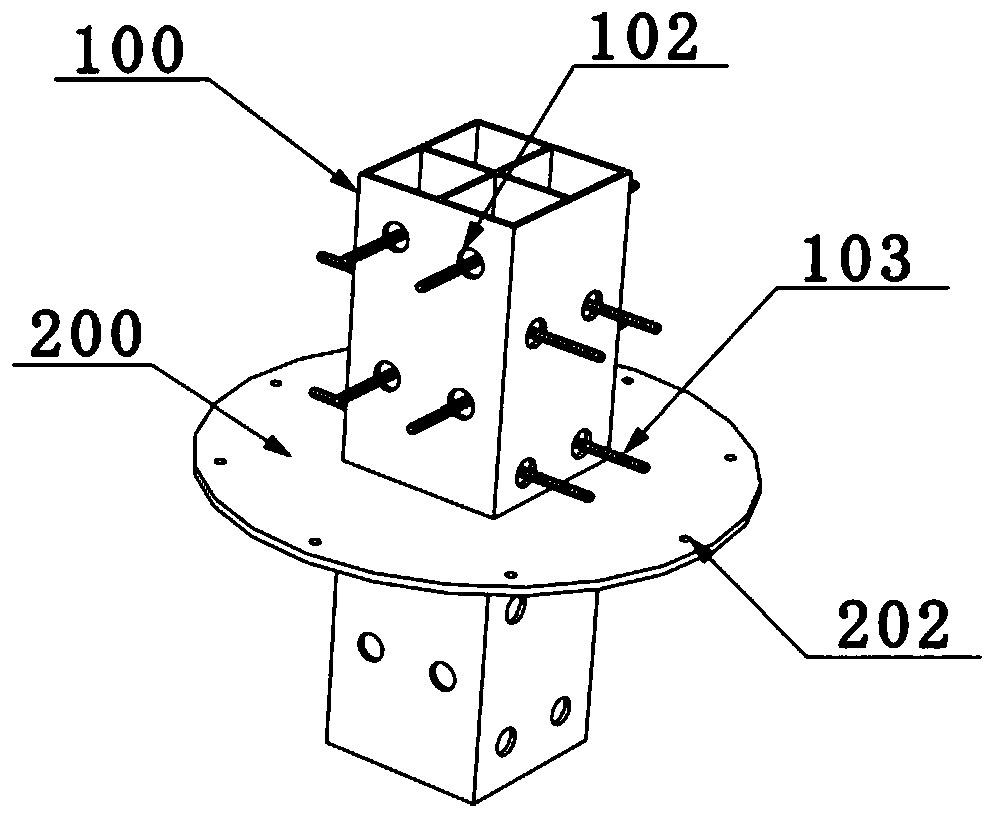

Ocean engineering composite column

PendingCN106013611AImprove corrosion resistanceAvoid corrosionStrutsPillarsMarine engineeringSeawater

The invention discloses an ocean engineering composite column which comprises an active powder concrete sleeve (1), stirrups (2), longitudinal bars (3) and a concrete column (4), wherein the stirrups (2) and the longitudinal bars (3) are arranged in the active powder concrete sleeve (1). The ocean engineering composite column is characterized in that the stirrups (2) and the longitudinal bars (3) are separately sealed fiber-enhanced plastic stirrups (2) and fiber-enhanced plastic longitudinal bars (3); corrosion-resistant staple fibers are mixed into active powder concrete of the sleeve (1); and the two ends of the active powder concrete sleeve (1) are separately provided with connectors (5) which are used for connecting the sleeves. The ocean engineering composite column is excellent in marine environment corrosion resistance, can adopt prefabricated construction, is high in axial carrying capacity, can utilize field materials such as seawater, sea sand and the like, is convenient to connect, is good in economical efficiency, can meet a novel structural column needed by construction of ocean engineering, especially ocean island-reef engineering, and can replace a steel tube column in the ocean engineering.

Owner:HUNAN UNIV

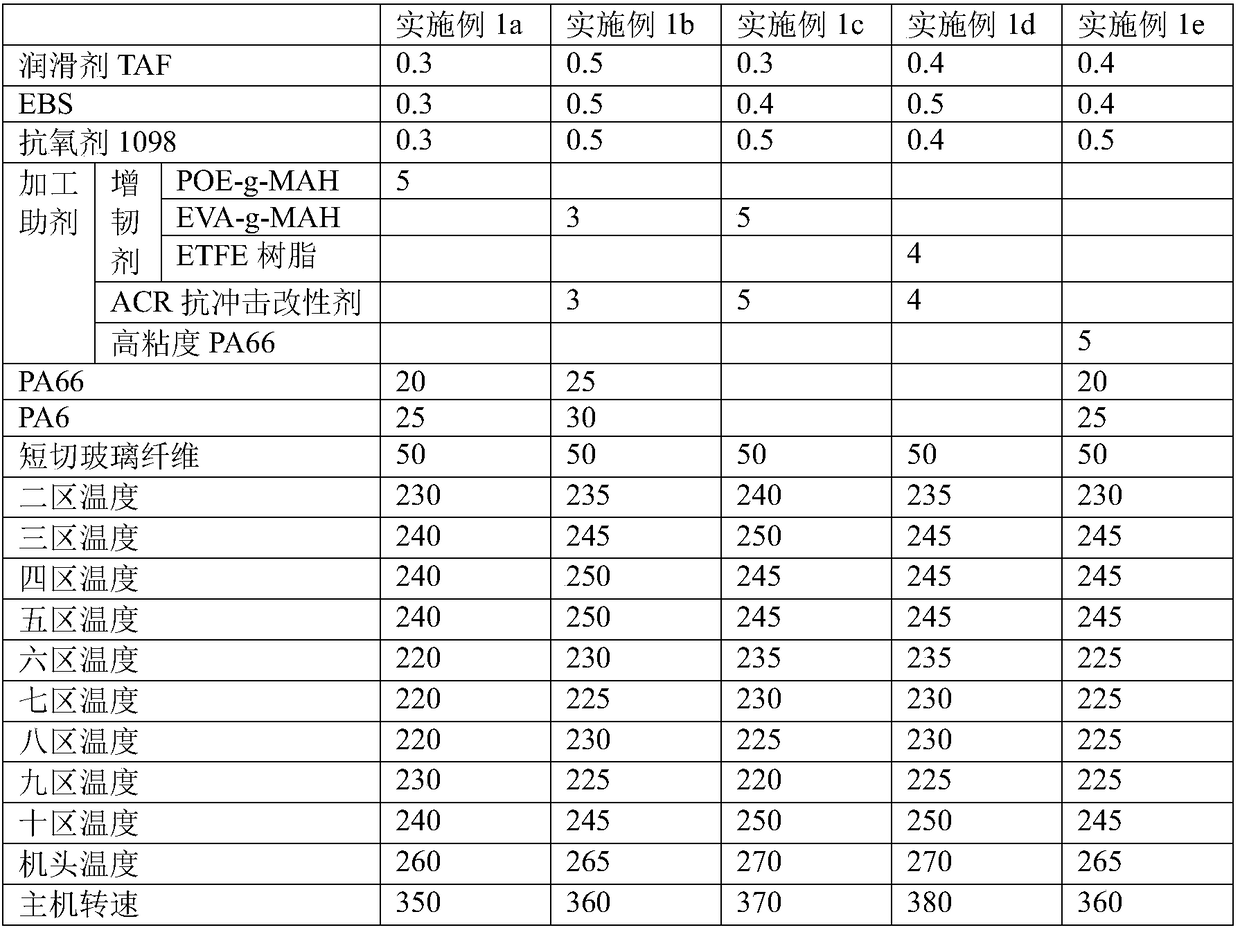

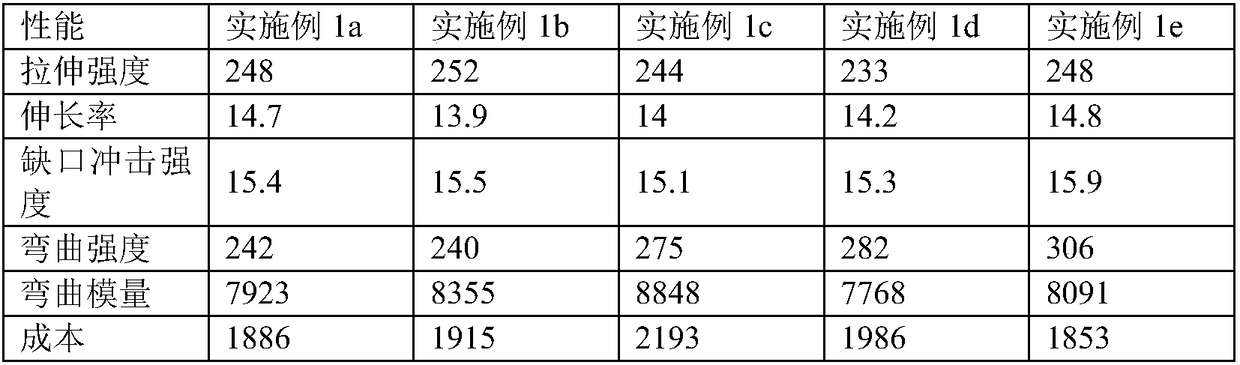

Nylon composite material and preparation method thereof

The invention discloses a nylon composite material and a preparation method thereof. The problems of poor strength and poor toughness of existing pure nylon are solved. The nylon composite material comprises, by mass, 20-30 parts of PA66, 25-30 parts of PA6, 50 parts of chopped glass fibers, 0.3-0.5 part of a lubricant TAF, 0.3-0.5 part of EBS, 0.3-0.5 part of an antioxidant 1098 and 5-10 parts ofa processing assistant; and the processing assistant is one or two or more of high-viscosity PA66, a flexibilizer and an impact modifier. The preparation method comprises the following steps: 1, uniformly stirring the lubricant TAF, EBS, the antioxidant 1098 and the processing assistant to obtain a mixed assistant; 2, uniformly mixing the PA66 with the PA6, adding the mixed assistant A, and performing uniform stirring to obtain a mixed raw material; 3, feeding the mixed raw material and the chopped glass fibers into a double screw extruder; and 4, performing melt extrusion, and pelletizing the obtained material to obtain nylon composite particles. The toughness and the strength of the nylon are improved.

Owner:厦门倍斯通塑胶科技有限公司

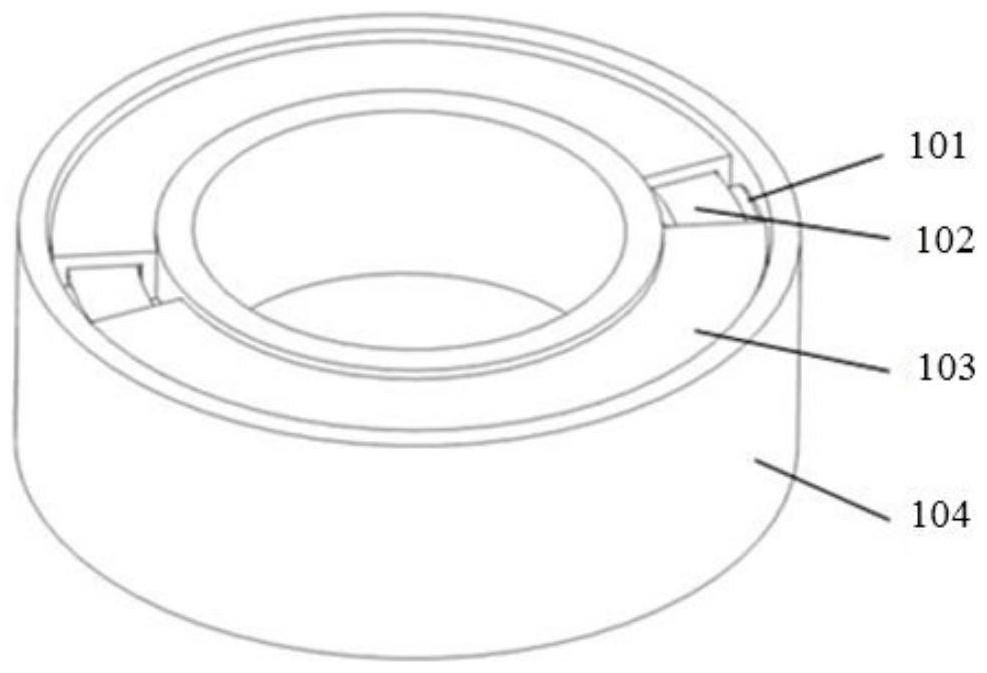

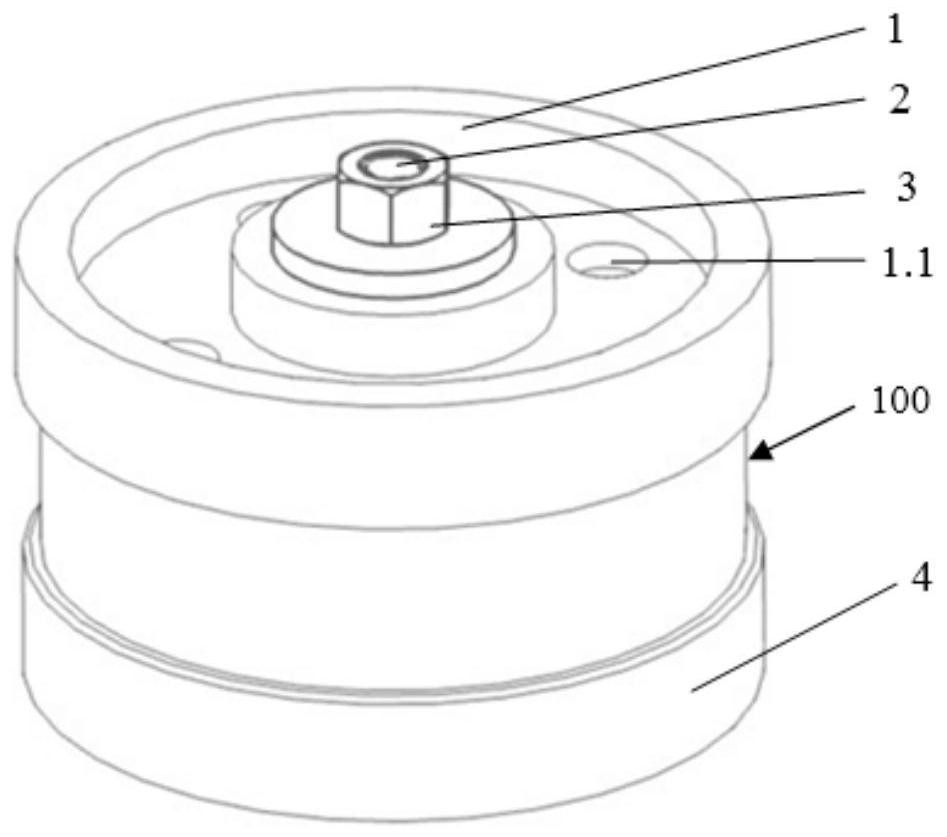

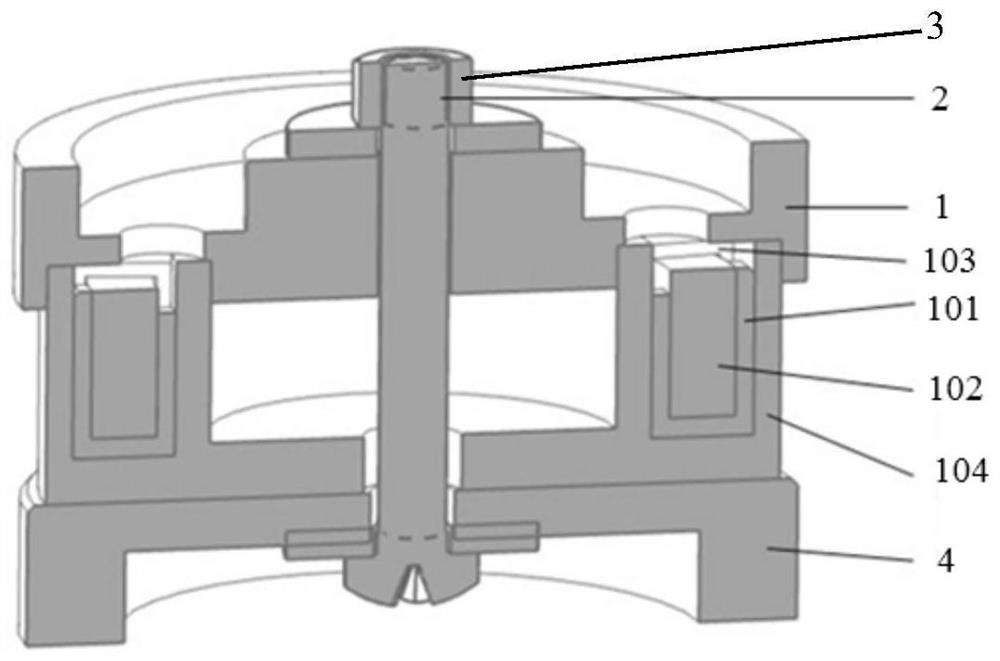

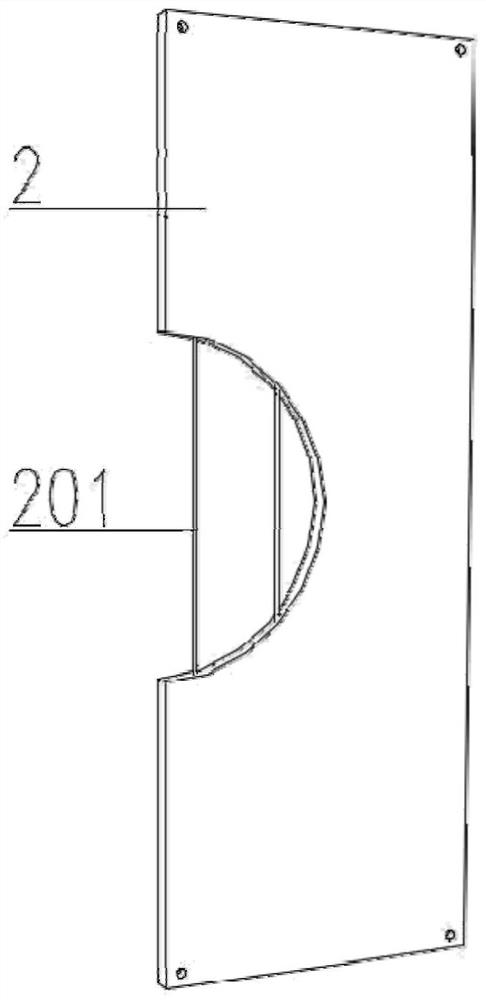

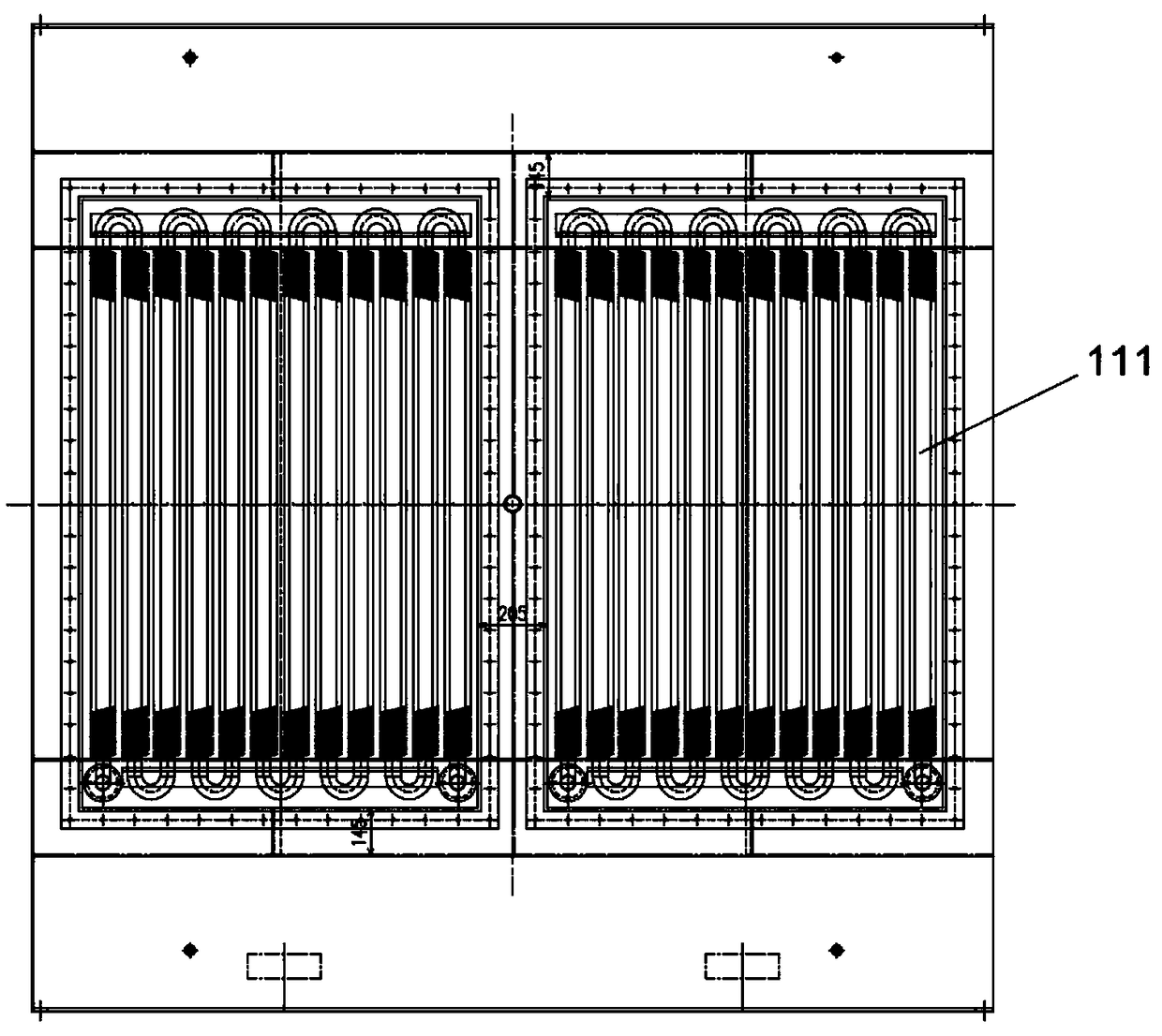

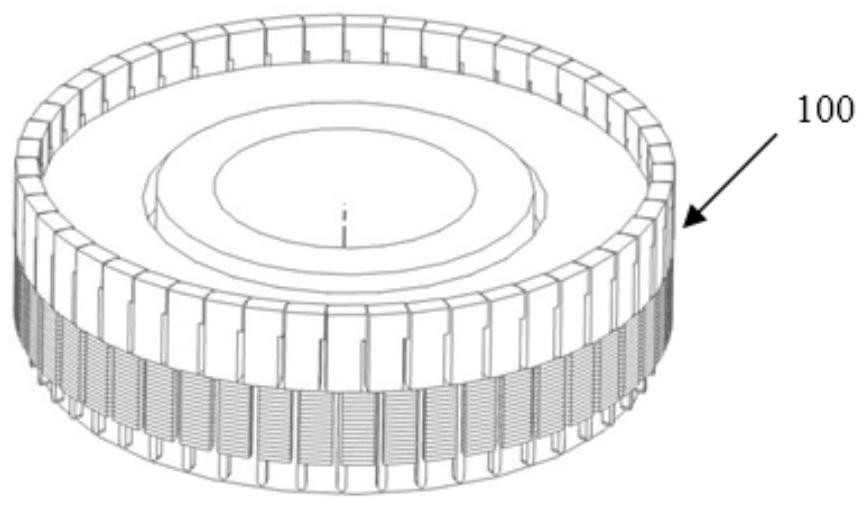

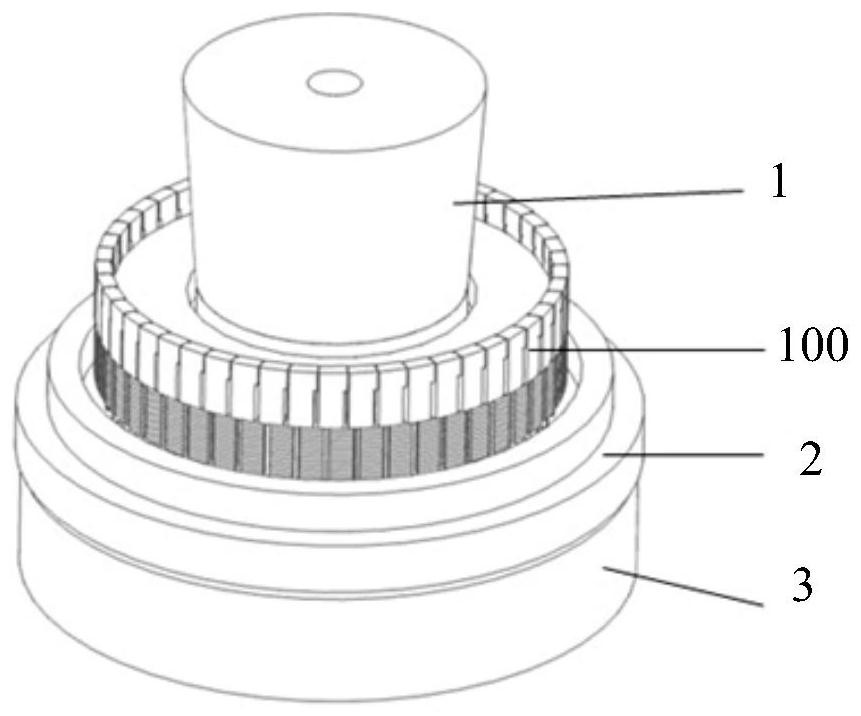

Pouring sealant for pouring limited-angle motor stator and pouring method

InactiveCN112391139AHigh strengthNo cracking problemsNon-macromolecular adhesive additivesManufacturing dynamo-electric machinesEpoxyCrazing

The invention relates to a pouring sealant for pouring a limited-angle motor stator and a pouring method. The pouring sealant comprises the components: 10 parts of epoxy resin, 1.2-1.6 parts of a component with curing and promoting effects, 5-15 parts of a filler component, and 1.5 to 5 parts of an epoxy toughening agent. The pouring method comprises the steps: 1, mounting and fixing a limited-angle motor stator into a potting mold; 2, putting the limited-angle motor stator after mold mounting into a drying oven for preheating; 3, preparing the pouring sealant according to the proportion of the components; 4, putting the pouring sealant into vacuum equipment to remove internal bubbles; 5, injecting the pouring sealant into the upper end face of the limited-angle motor stator through a sealant injection through hole of an upper mold, and achieving pouring; 6, removing bubbles in the mold in a vacuum environment; 7, putting the mold into an oven, carrying out thermocuring treatment, andcooling along with the oven after curing; and 8, disassembling the pouring mold, taking out the limited-angle motor stator, and processing to remove redundant colloid. According to the invention, theproblems of cracking of the pouring sealant and cracks among the pouring sealant, the punching sheet and the shaft sleeve are solved.

Owner:TIANJIN NAVIGATION INSTR RES INST

Polyurethane injection molding process for rubber film

InactiveCN102267239AReduce shoe-making processThe process is firmly bondedDomestic footwearPolymer scienceAdhesive

The invention relates to a process for forming a rubber base film by pouring polyurethane. The raw materials required for the process include RS-801 water-based washing agent, RS-601 rubber bottom treatment agent, RS-305PU perfusion glue and polyurethane stock solution. First, the RS-801 water-based After mixing the washing agent and water at a ratio of 1:13, heat it to 55-65°C; then take out the rubber film and put it in clean water; take out the rubber film and dry it; brush evenly on the dried rubber film Apply RS-601 rubber bottom treatment agent and then dry, then brush RS-305PU perfusion glue again, and dry; finally, after 3 hours, put the brushed bottom film into the oven, heat to 40-50 degrees, and then inject Polyurethane stock solution, the process described so that the rubber sole does not need to be thickened, and after the adhesive is applied, it can be placed for a long time. Bonding with this process makes the rubber and PU glue bonded without opening, and has the characteristics of strong aging resistance.

Owner:青岛瑞晟鞋业有限公司

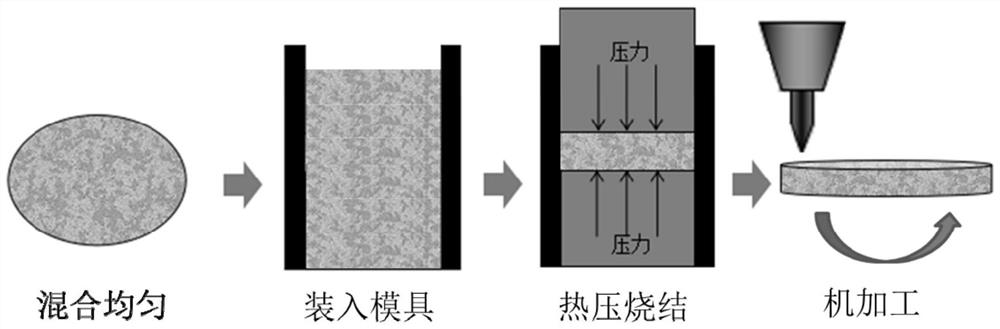

Preparation method of tantalum-silicon alloy sputtering target material

InactiveCN112030120AHigh densityUniform structureVacuum evaporation coatingSputtering coatingSilicon alloyTantalum

The invention relates to a preparation method of a tantalum-silicon alloy sputtering target material. The preparation method comprises the following steps of (1) uniformly mixing tantalum powder and silicon powder; (2) loading into a mold and sealing; (3) carrying out hot pressed sintering treatment on the sealed mold at 1130-1170 DEG C so as to obtain a tantalum-silicon alloy sputtering target crude product; and (4) machining to obtain the tantalum-silicon alloy sputtering target material. According to the preparation method, the tantalum-silicon alloy sputtering target material with the purity and density meeting the requirements can be prepared, the density reaches 99 percent or above, energy consumption and cost can be reduced, and the preparation method is suitable for large-scale popularization.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Economical longitudinal submerged arc welding X80 pipeline steel plate and production method

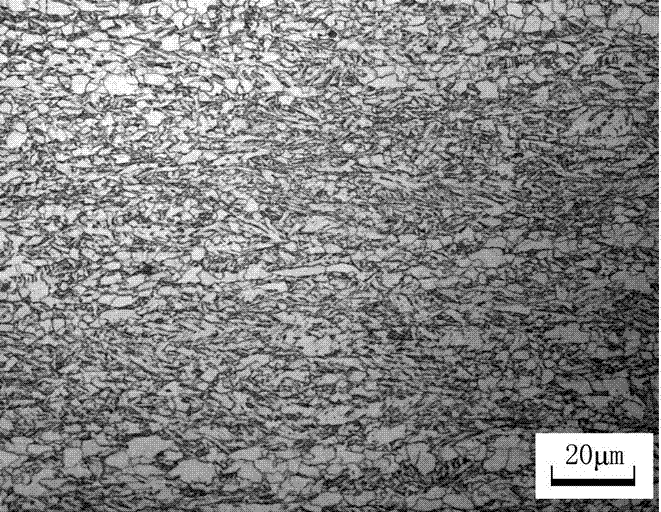

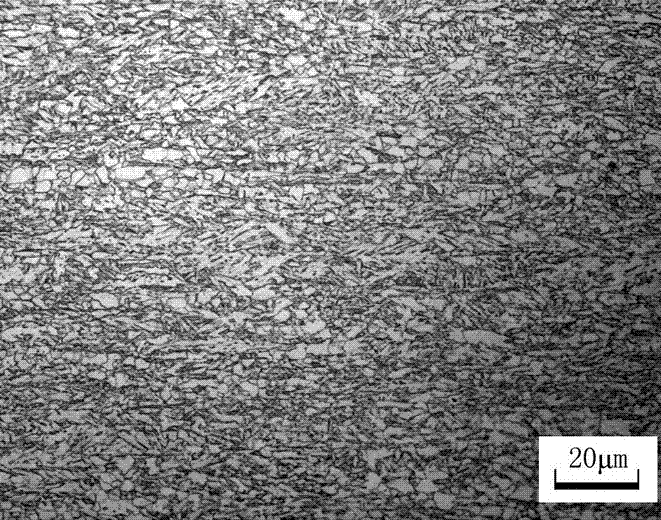

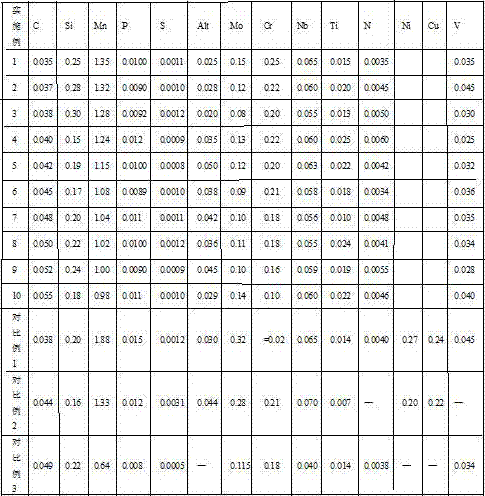

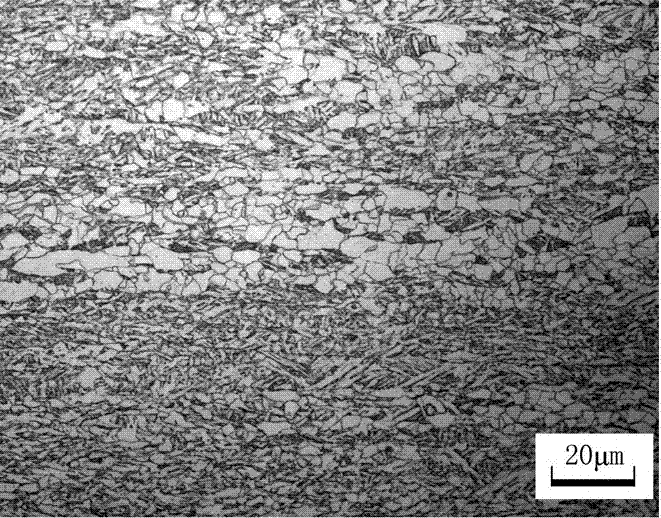

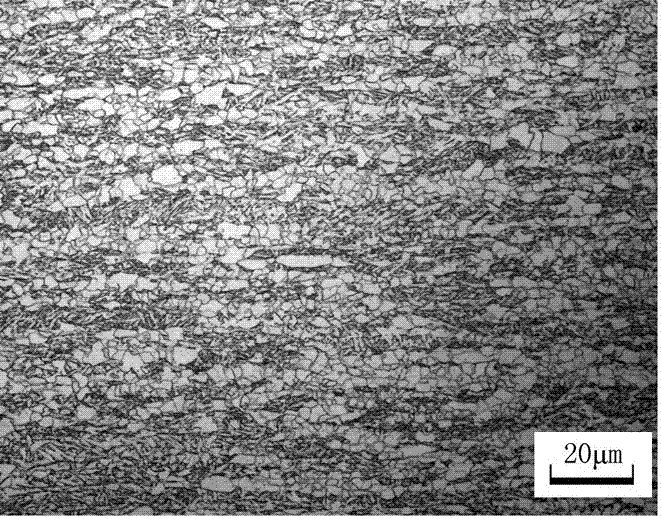

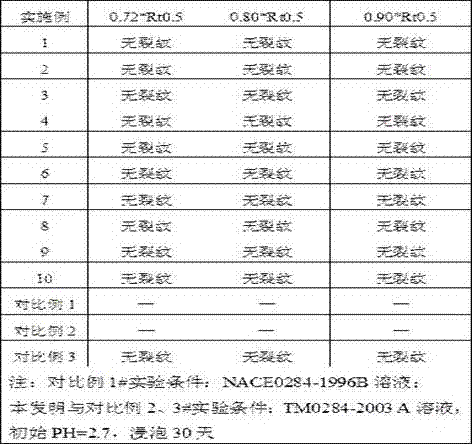

ActiveCN107974621AImprove acid resistanceReduce the susceptibility to hydrogen-induced crackingRoom temperatureSlow cooling

The invention discloses an economical longitudinal submerged arc welding X80 pipeline steel plate. The economical longitudinal submerged arc welding X80 pipeline steel plate comprises, by weight percent, 0.035 to 0.055% of C, 0.15 to 0.30% of Si, 0.98 to 1.355 of Mn, not large than 0.012% of P, not larger than 0.0012% of S, not larger than 0.006% of N, 0.055 to 0.065% of Nb, 0.025 to 0.045% of V,0.01 to 0.025% of Ti, 0.10 to 0.25% of Cr, 0.02 to 0.05% of Alt and 0.08 to 0.15% of Mo. The production method comprises the steps of slowing cooling of a casting blank stack not less than 24h; casting blank heating; rough rolling; fine rolling; cooling, tempering; re-straightening, and treating on a cold bed for air cooling to the room temperature. The grade of ant-acid pipeline steel is improved, Rt0.5 is larger than or equal to 580 MPa, Rm is larger than or equal to 650 MPa, A50.8 is larger than or equal to 25%, Rt0.5 / Rm is smaller than or equal to 0.92, at the temperature of -20 DEG C, theV gap KV2 is larger than or equal to 250J, at the temperature of -15 DEG C, DWTT:SA is larger than or equal to 85%, the Vickers hardness HV10 is smaller than or equal to 250, the anti-acid performance and the SSCC resistance performance are excellent, and cracking is avoided.

Owner:武汉钢铁有限公司

X80 pipeline steel plate with thickness larger than or equal to 26.4 mm used in longitudinal submerged arc welding pipe and production method thereof

The invention discloses an X80 pipeline steel plate with thickness larger than or equal to 26.4 mm used in a longitudinal submerged arc welding pipe and a production method thereof. The X80 pipeline steel plate comprises the following components in percentage by weight: 0.035-0.055% of C, 0.15-0.30% of Si, 0.25-0.55% of Mn, less than or equal to 0.012% of P, less than or equal to 0.0012% of S, less than or equal to 0.006% of N, 0.065-0.085% of Nb, 0.010-0.025% of Ti, 0.15-0.30% of Cr, 0.02-0.05% of Al, 0.08-0.15% of Mo, 0.1-0.2% of Cu and 0.30-0.50% of Ni. The production method comprises the steps that casting blanks are stacked and slowly cooled for more than 24 h; and the casting blanks are heated, rough rolled, fine rolled, cooled, straightened, tempered, straightened again and then isair cooled to room temperature on a cooling bed. By adopting the production method, the anti-acid performance is good; the yield strength (horizontal) : Rt 0.5 is greater than or equal to 555 MPa; Rmis greater than or equal to 630 MPa; A50.8 is greater than or equal to 25%; a pipe wall is not cracked with increasing conveying pressure; the thickness is greater than or equal to 26.4 mm; structureuniformity is good; Rt0.5 / Rm is less than or equal to 0.91; V-notch impact work KV2 is greater than or equal to 250 J at minus 20 DEG C; the drop weight tear tenacity DWTT:SA is greater than or equalto 85% at minus 15 DEG C; and the Vickers hardness HV10 is less than or equal to 250.

Owner:武汉钢铁有限公司

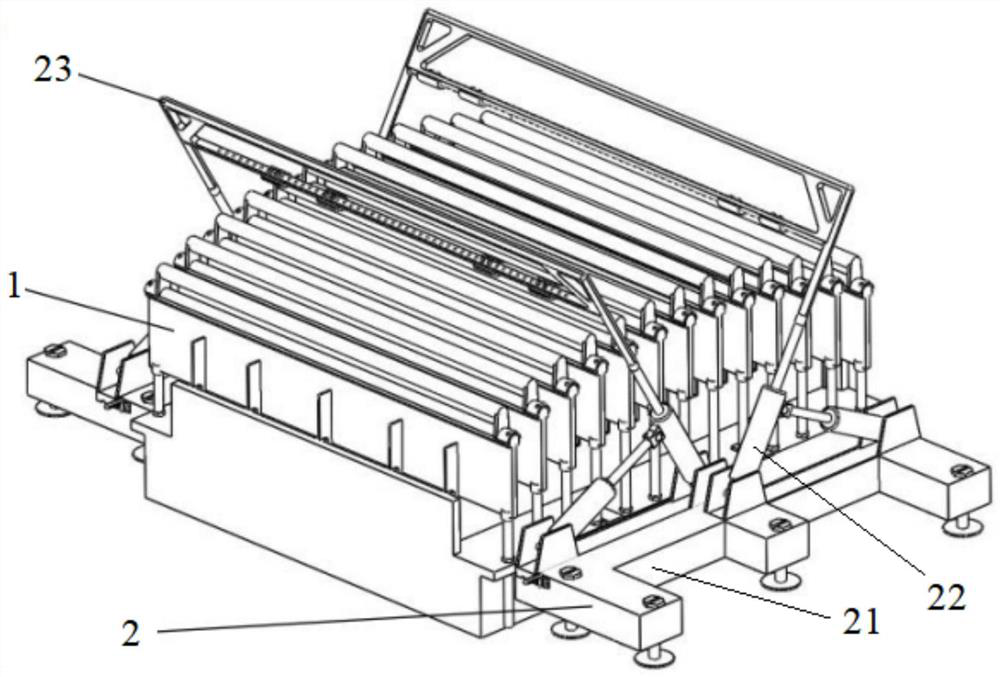

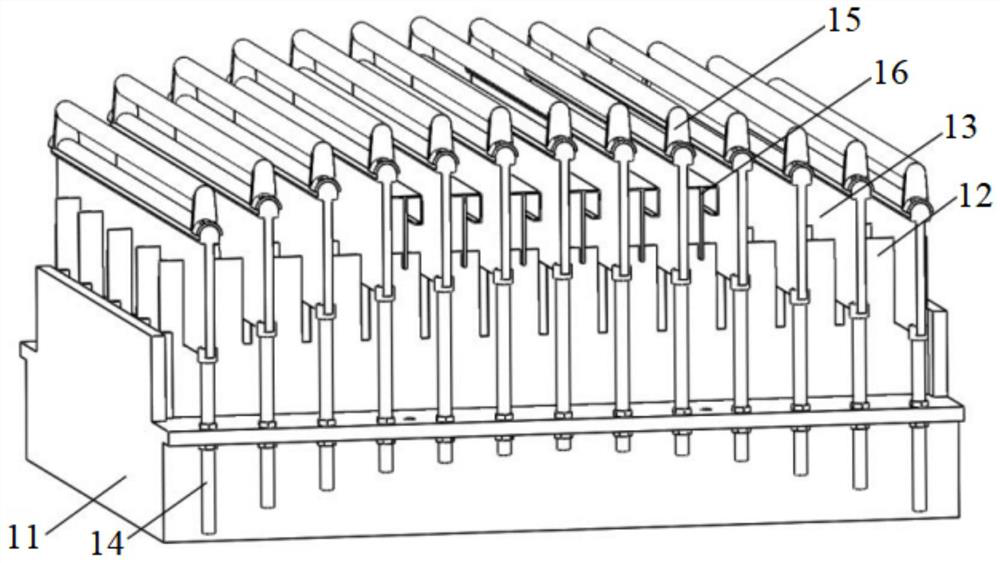

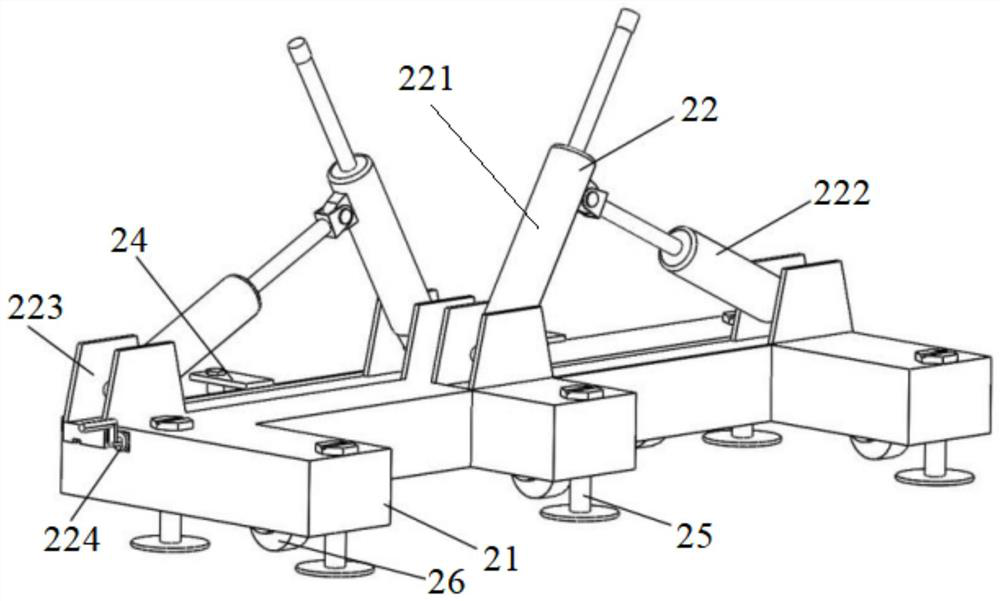

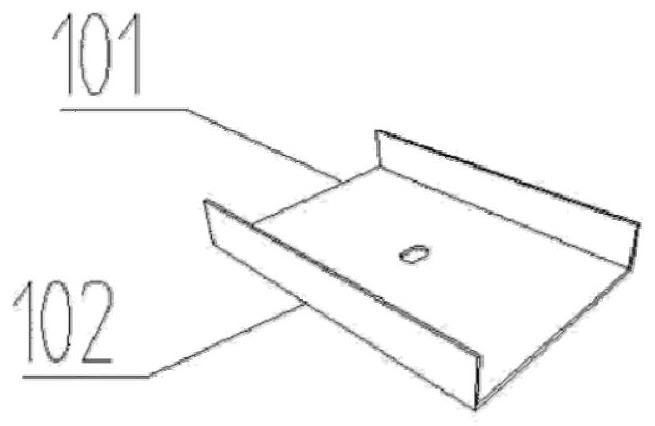

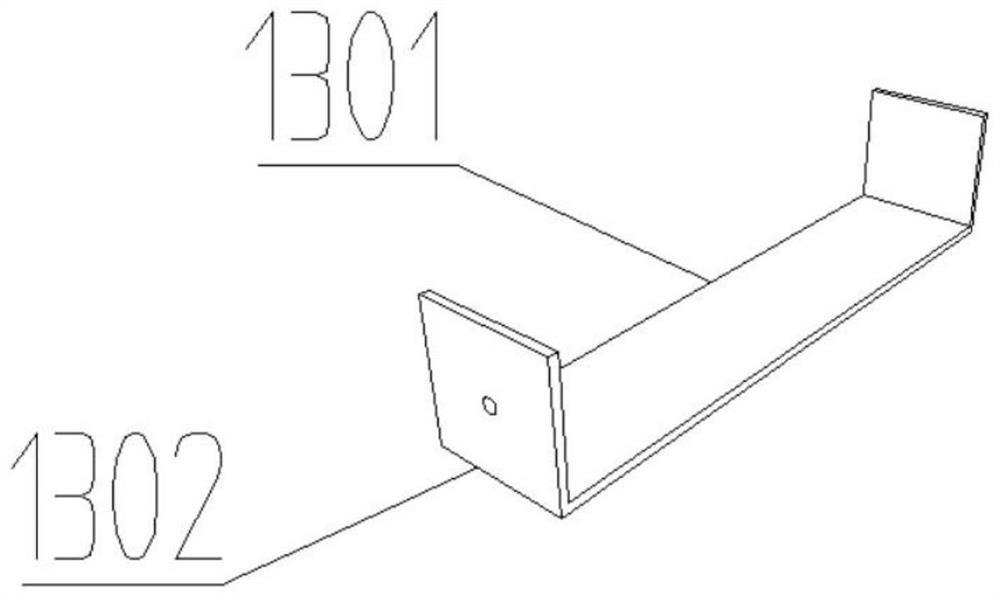

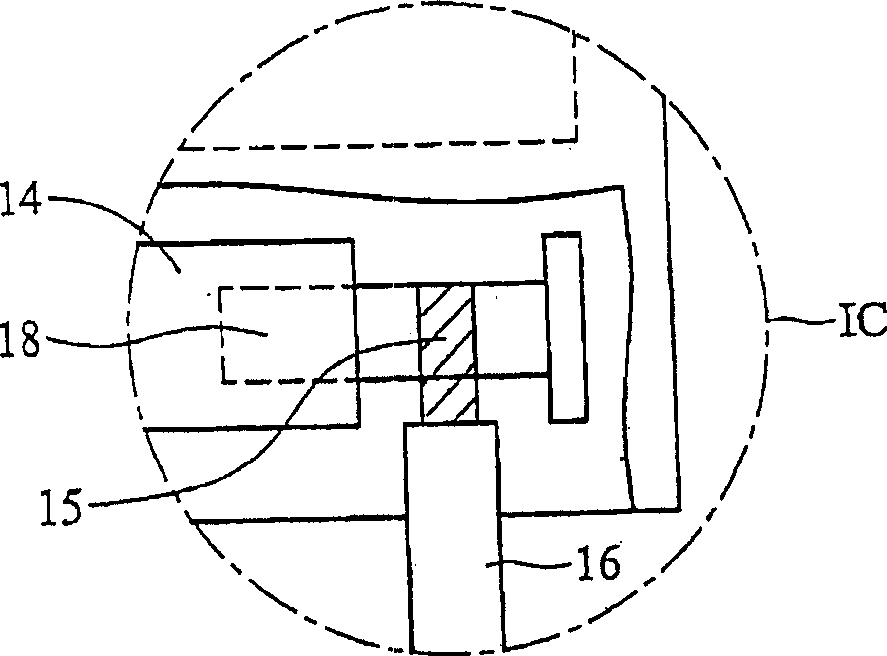

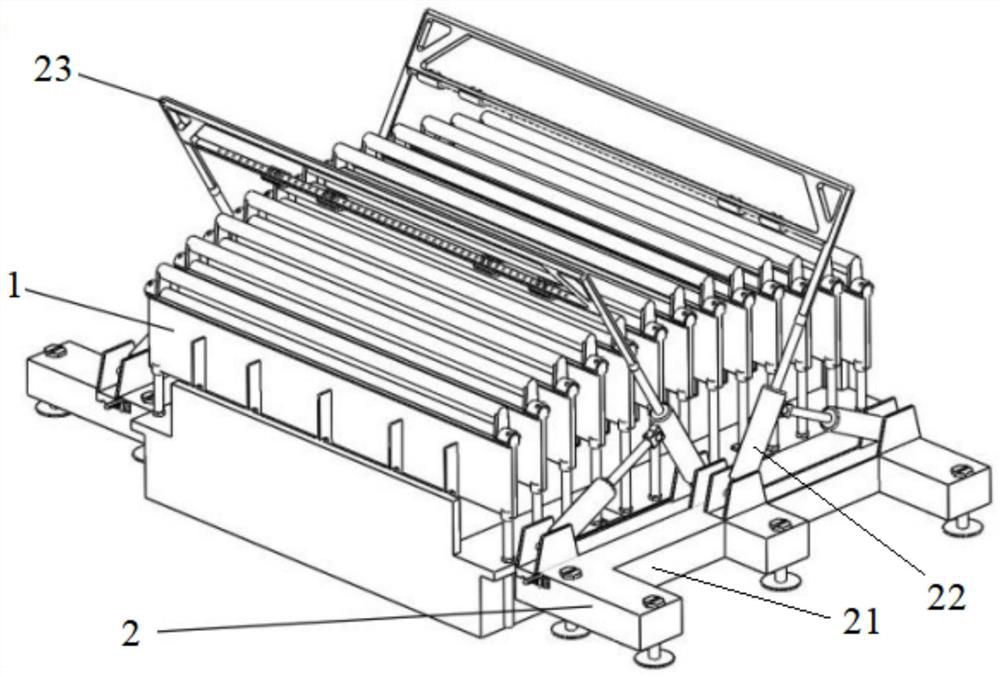

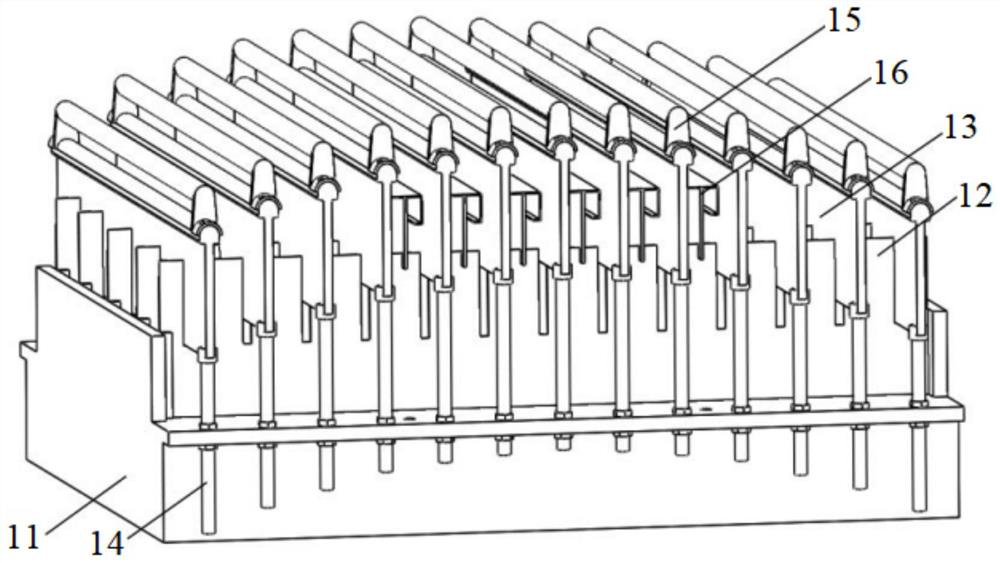

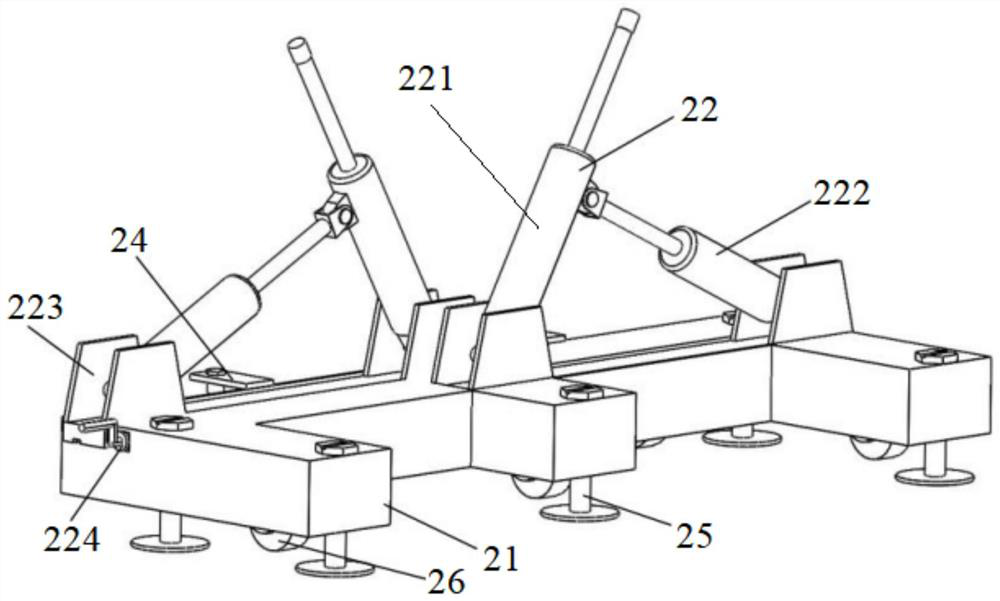

Mechanical loading tool and method for outer grid wallboard

The invention provides a mechanical loading tool for an outer grid wallboard. The mechanical loading tool comprises a clamping plate type mold and a movable loading system, wherein the clamping plate type mold comprises a mold base, a transverse clamping plate and a pressing plate; the movable loading system comprises loading system bases, pressurizing movable components, loading rod components and positioning connection structures; the loading system bases are arranged at the left side and the right side of the clamping plate type mold, and the positioning connection structure is arranged at one side of each loading system base; two groups of pressurizing movable components are arranged on each loading system base; the pressurizing movable components at the left side and the right side are connected through the loading rod components; and each pressurizing movable component comprises a first hydraulic cylinder. The invention further provides a mechanical loading method for the outer grid wallboard, and the method adopts the mechanical loading tool for the outer grid wallboard. According to the tool and the method, some defects of loading of a traditional mechanical method are avoided, the cost is greatly reduced, and a movable loading system is matched with an adjustable molded surface to meet the production requirements of wallboards of multiple specifications.

Owner:CENT SOUTH UNIV

Construction method of soft soil anti-collapse concrete road surface

The invention discloses a construction method of a soft soil anti-collapse concrete road surface. The construction method is characterized by comprising the following steps of: (1) treating a soft soil matrix: excavating sludge, filling slags, and performing layered rolling for levelling; (2) preparing a semi-rigid base course material: wherein the semi-rigid base course material is cement-stabilized macadam with a cement content of 5%, and is obtained by uniformly mixing cement, water, macadam and stone powder in a mass ratio of the cement to the water, to the macadam and to the stone powder being 102 to 120 to (1390-1400) to (650-660); and (3) performing construction of a semi-rigid base course: laying the cement-stabilized macadam obtained in the step (2) on the soft soil matrix treated in the step (1), performing paving, performing rolling and performing curing. The construction method disclosed by the invention aims to solve the technical problem of providing the construction method of the soft soil anti-collapse concrete road surface, which is good in firmness, few in cracks and high in construction speed, and besides, road materials can be saved, so that the paving cost is further reduced.

Owner:青建集团股份公司

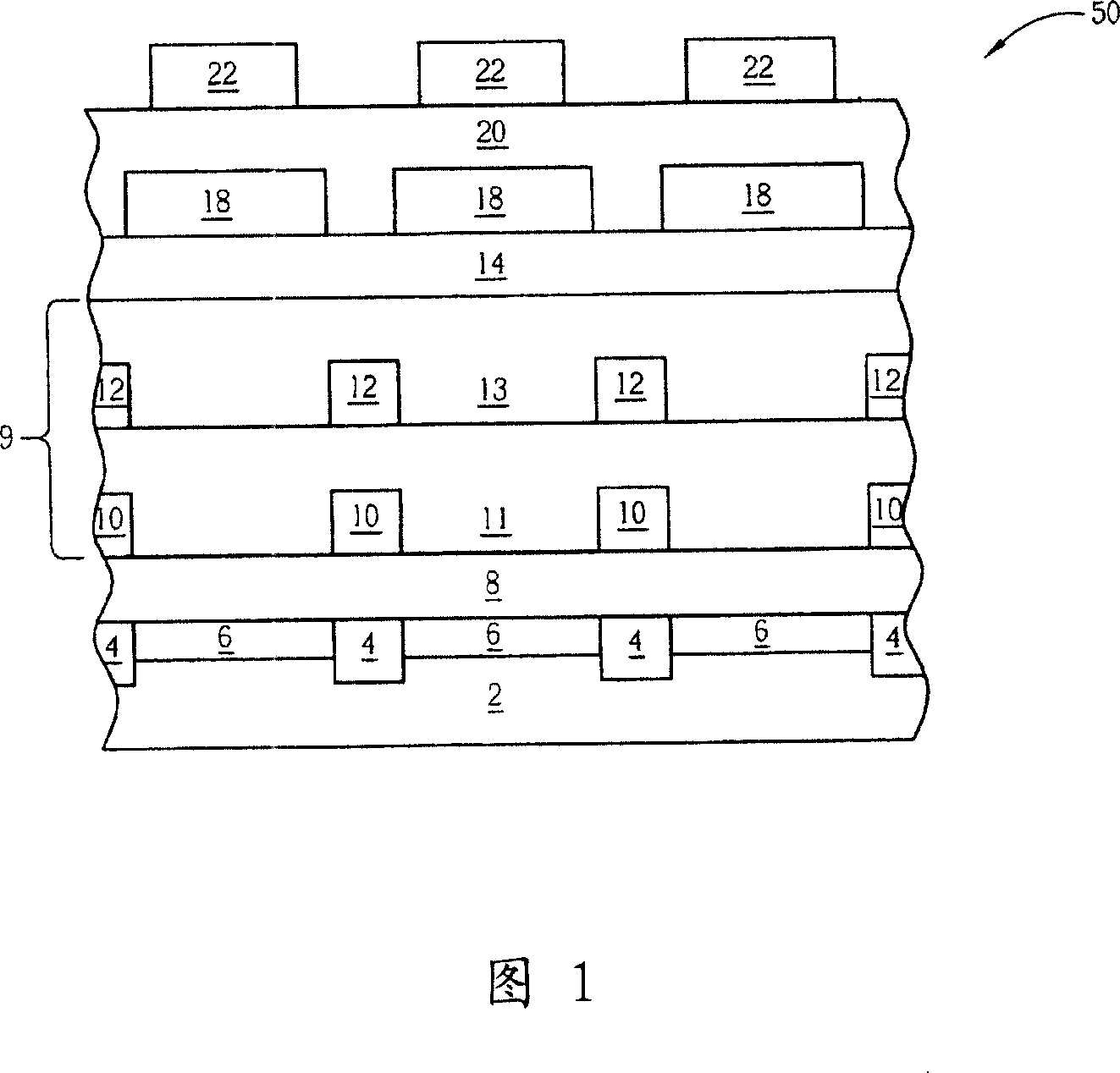

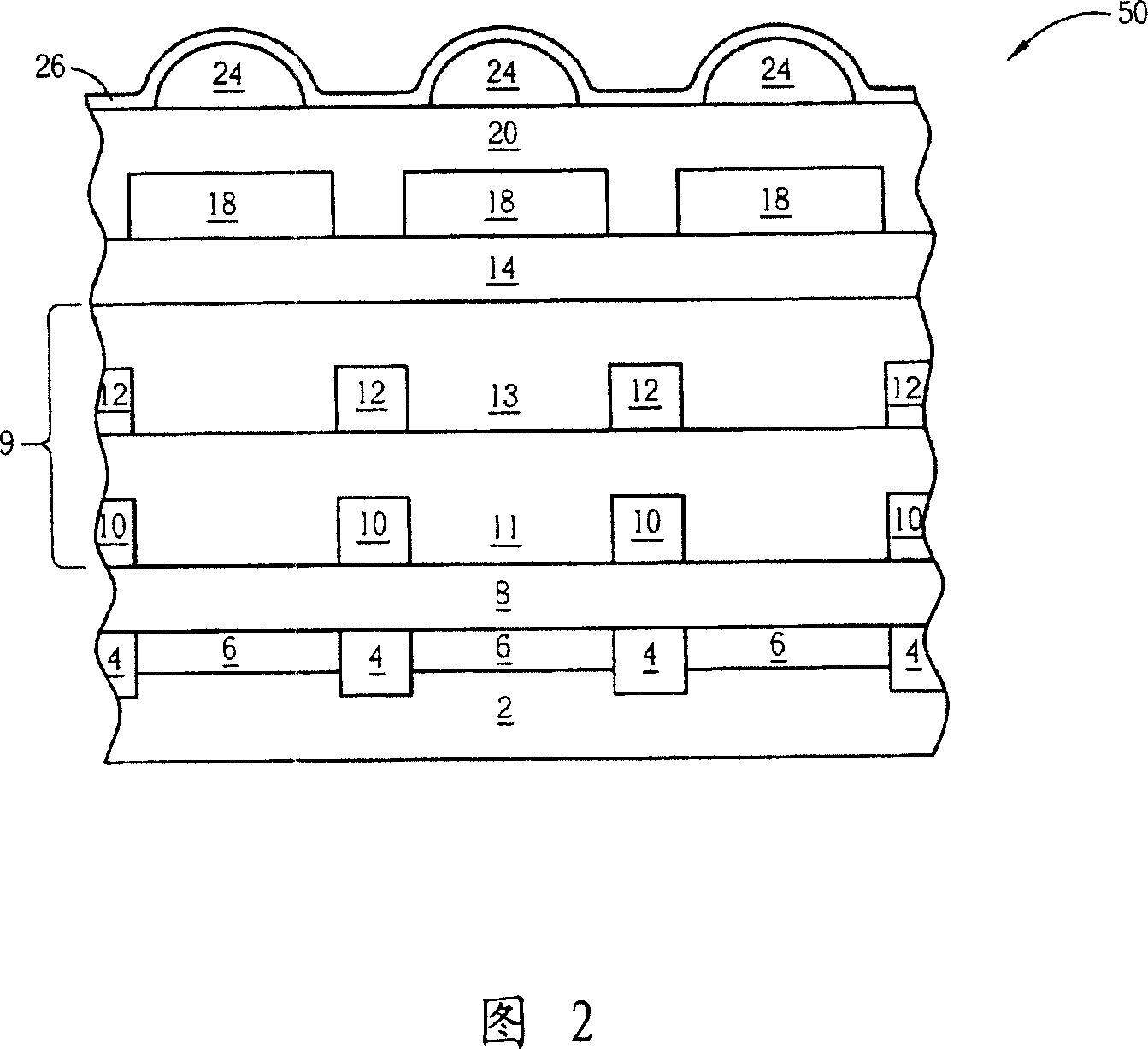

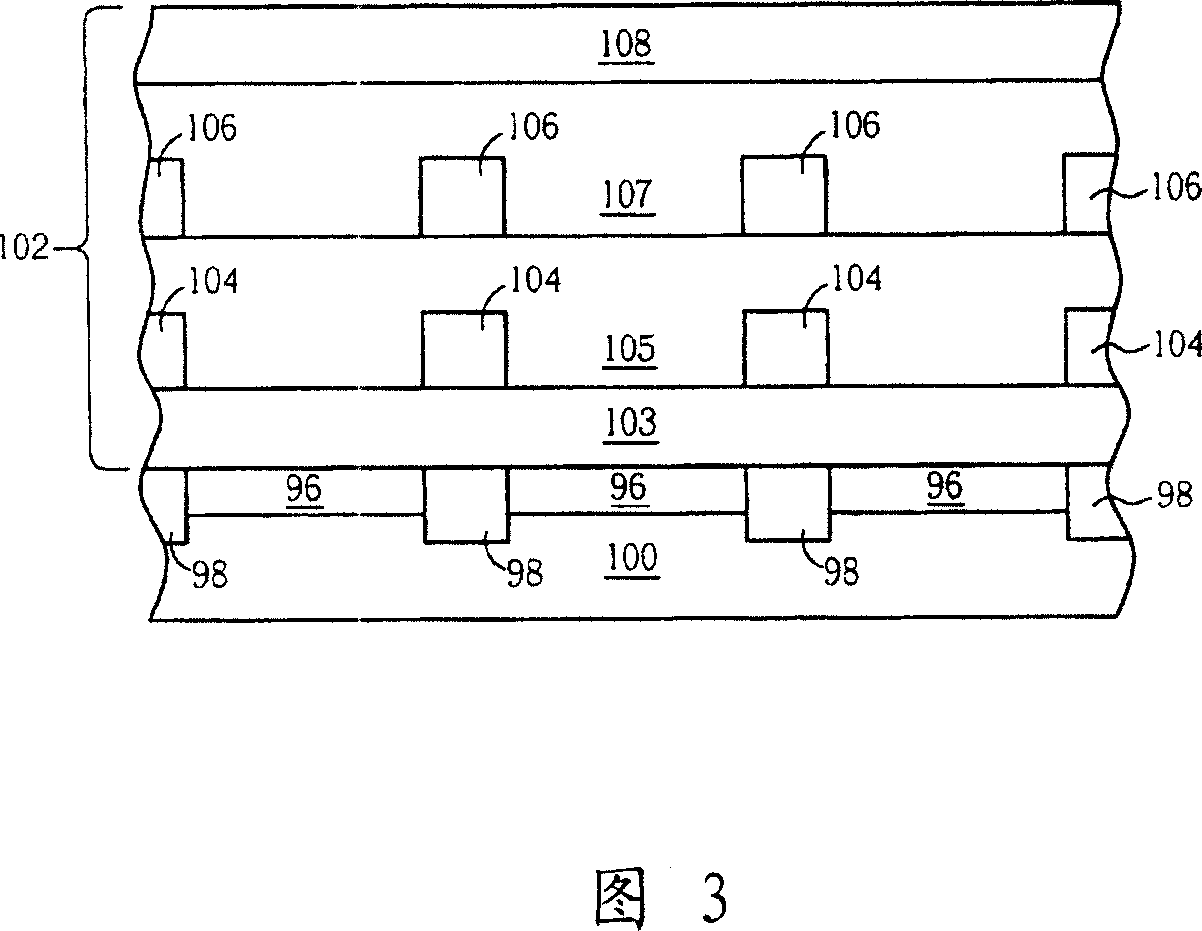

Micro-optical collector structure and manufacturing method thereof

InactiveCN101136363AImprove anti-blocking performanceReduce distanceSemiconductor/solid-state device manufacturingRadiation controlled devicesOptoelectronicsDielectric layer

This invention provides a method for manufacturing micro-condensers including: providing a base with at least one dielectric layer, forming a first film on the dielectric layer, etching said film to form at least one micro-convex block, forming a second film on the surfaces of the micro-convex block and the dielectric layer to form the micro-condenser with the convex block to be used in high temperature without processing an extra protecting layer.

Owner:UNITED MICROELECTRONICS CORP

Fabricated wall and mounting process thereof

PendingCN114508188ASolve self-importanceSolve space problemsWallsHeat proofingConstruction engineeringMechanical engineering

The invention discloses a fabricated wall and a mounting process thereof, and relates to the technical field of civil engineering construction. According to the fabricated wall and the mounting process thereof, the problems that a prefabricated wall panel is large in dead weight and difficult to place due to space limitation are solved; the template does not need to be brushed with a release agent; the problem of cracking at each interface of the wall body formed by pouring is solved, and the service life is long; the potential safety hazard of the externally hung insulation board is effectively solved; the water heating and electricity pre-embedding device has the advantages of being easy to operate, high in work efficiency and reliable in quality.

Owner:成都魔筑科技有限公司

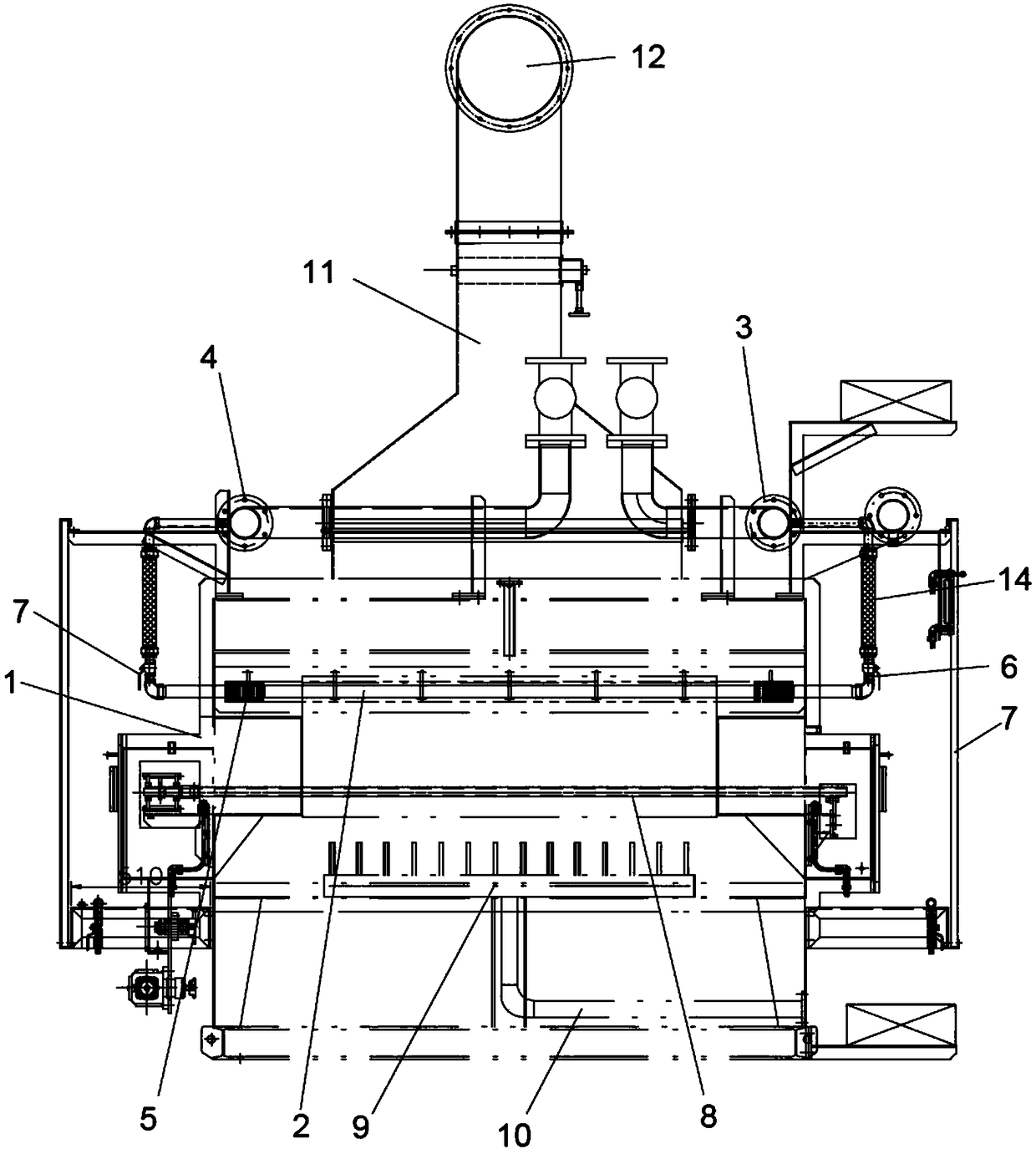

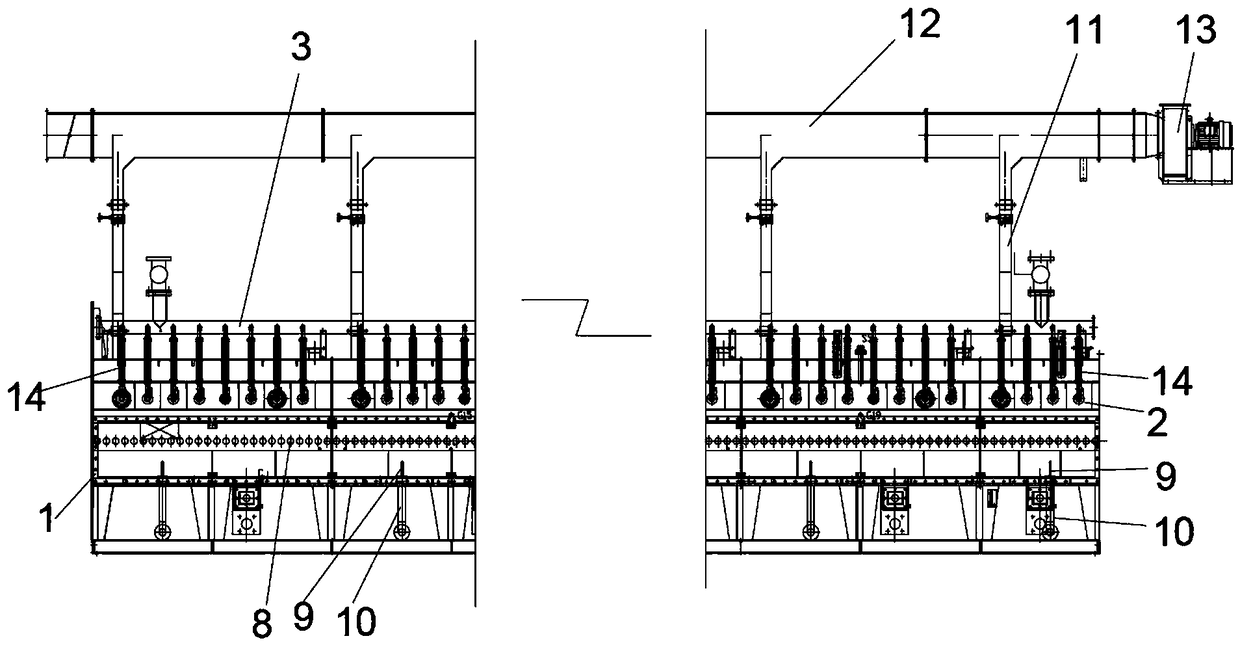

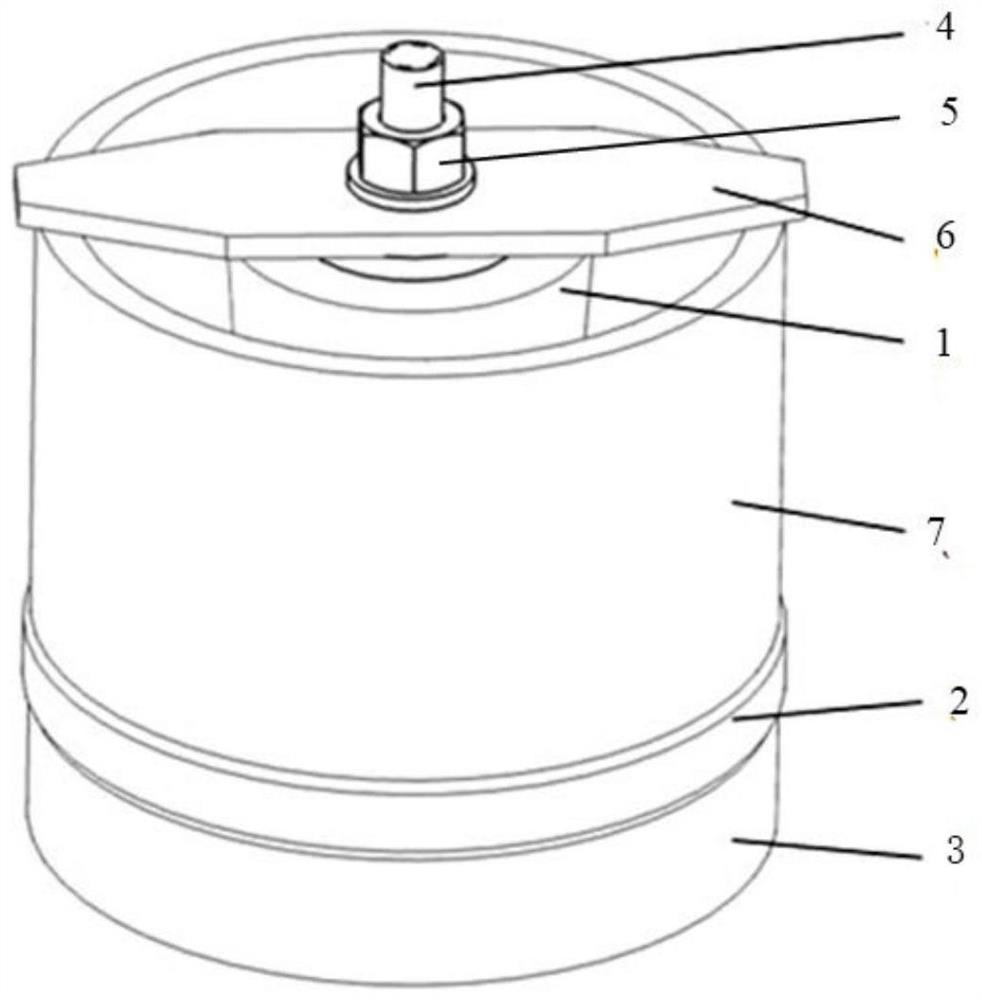

Sintering cooling device

PendingCN109186268ALess prone to fatigueWon't crackCharge treatment typeIncreasing energy efficiencyMetallurgyCooling pipe

The invention discloses a sintering cooling device. The sintering cooling device comprises a cooling furnace body, multiple cooling pipes are arranged in the cooling furnace body, and are seamless pipes, two ends of the cooling pipes penetrate through the corresponding inner wall of the cooling furnace body to the outer portion, one ends of the cooling pipes are connected with a water inlet main pipe, and the other ends of the cooling pipes are connected with a water outlet main pipe. The sintering cooling device has the higher service life, no leakage point exist in the device, and maintaining is facilitated.

Owner:SUZHOU HUIKE EQUIP CO LTD

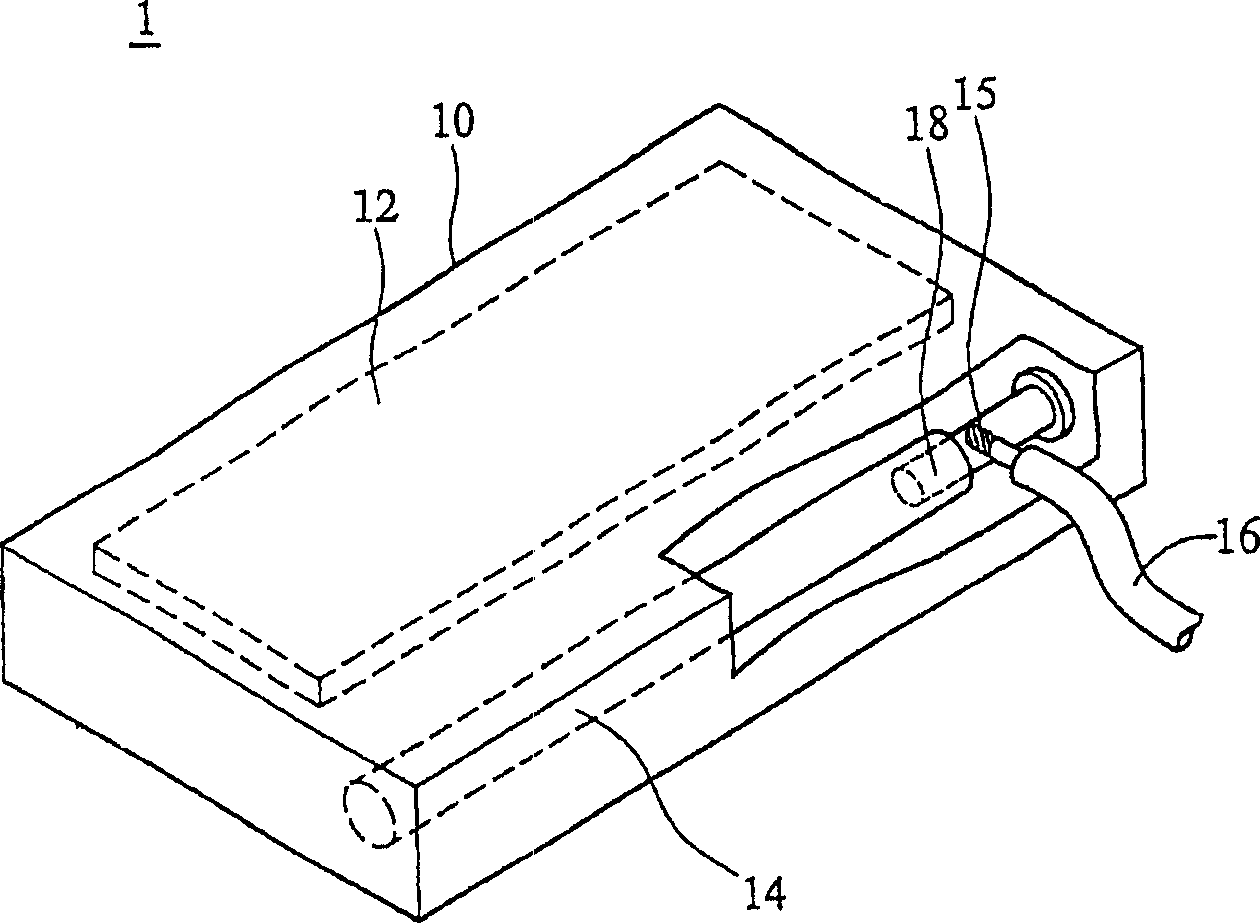

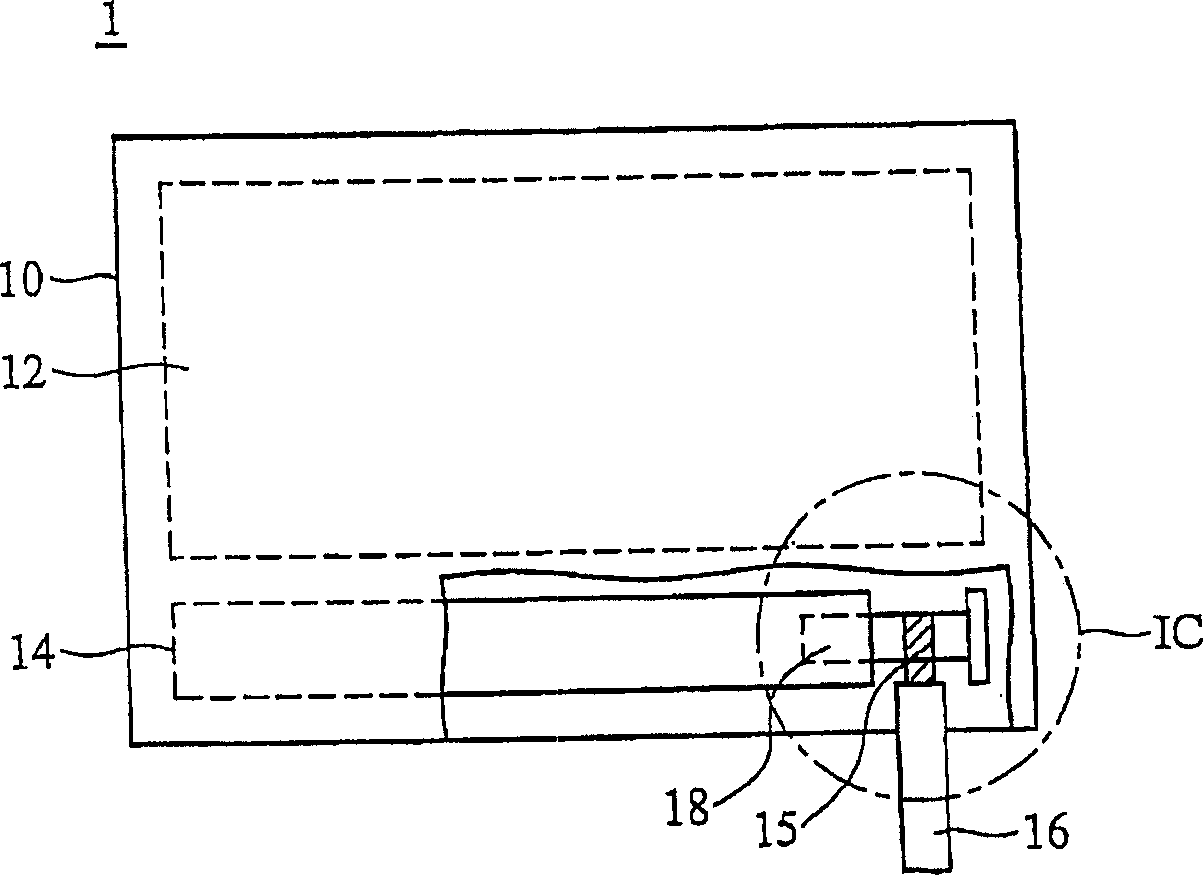

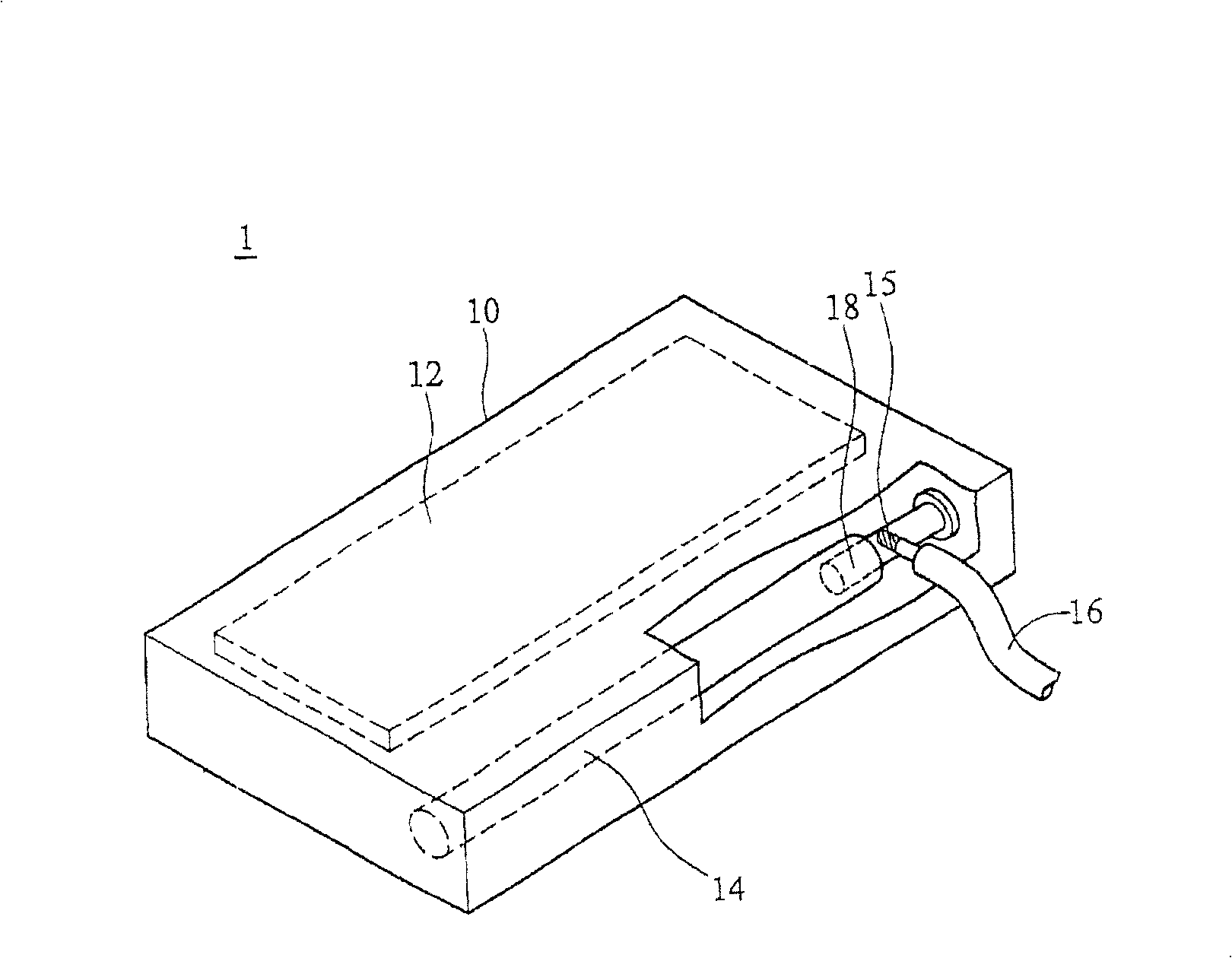

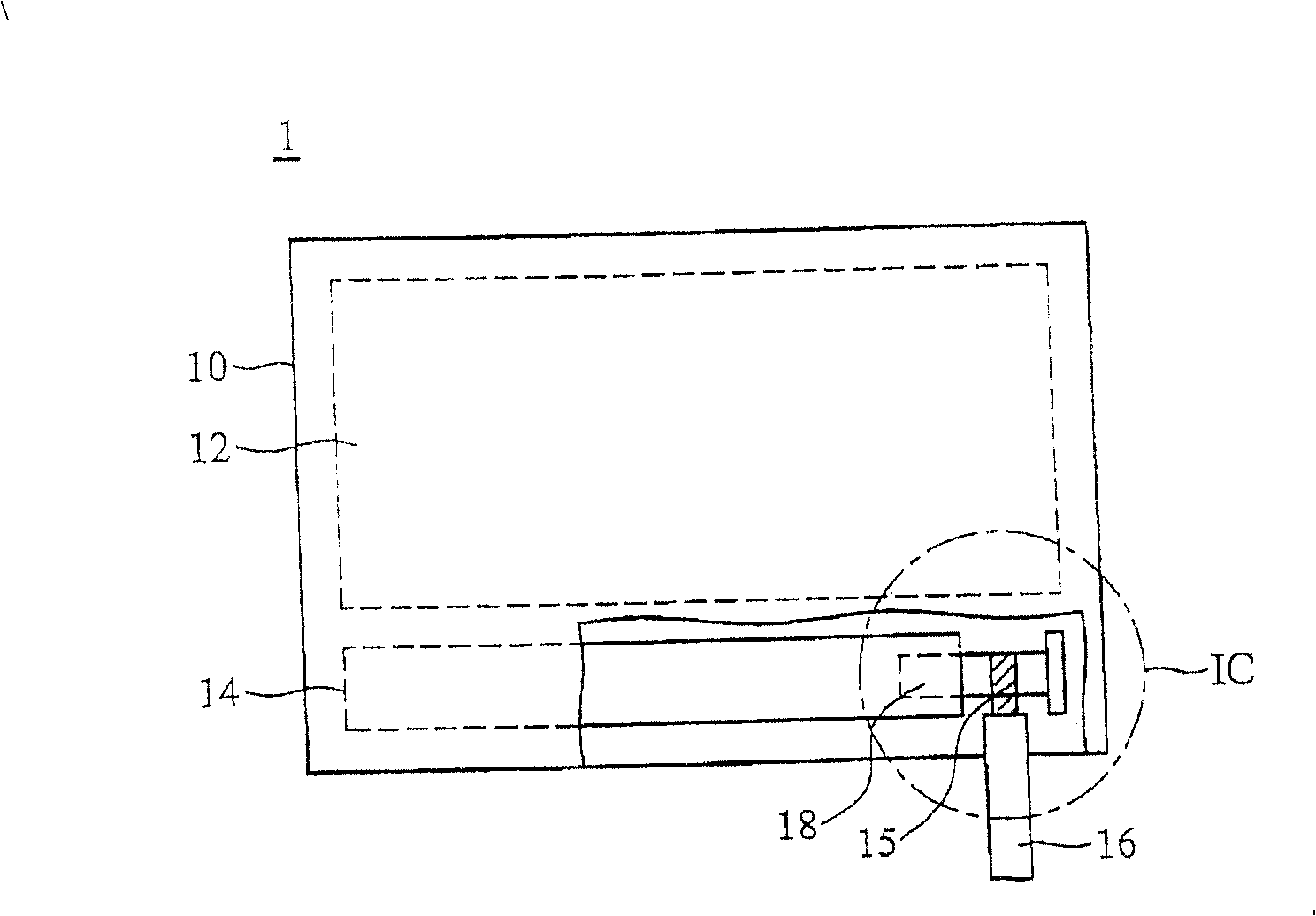

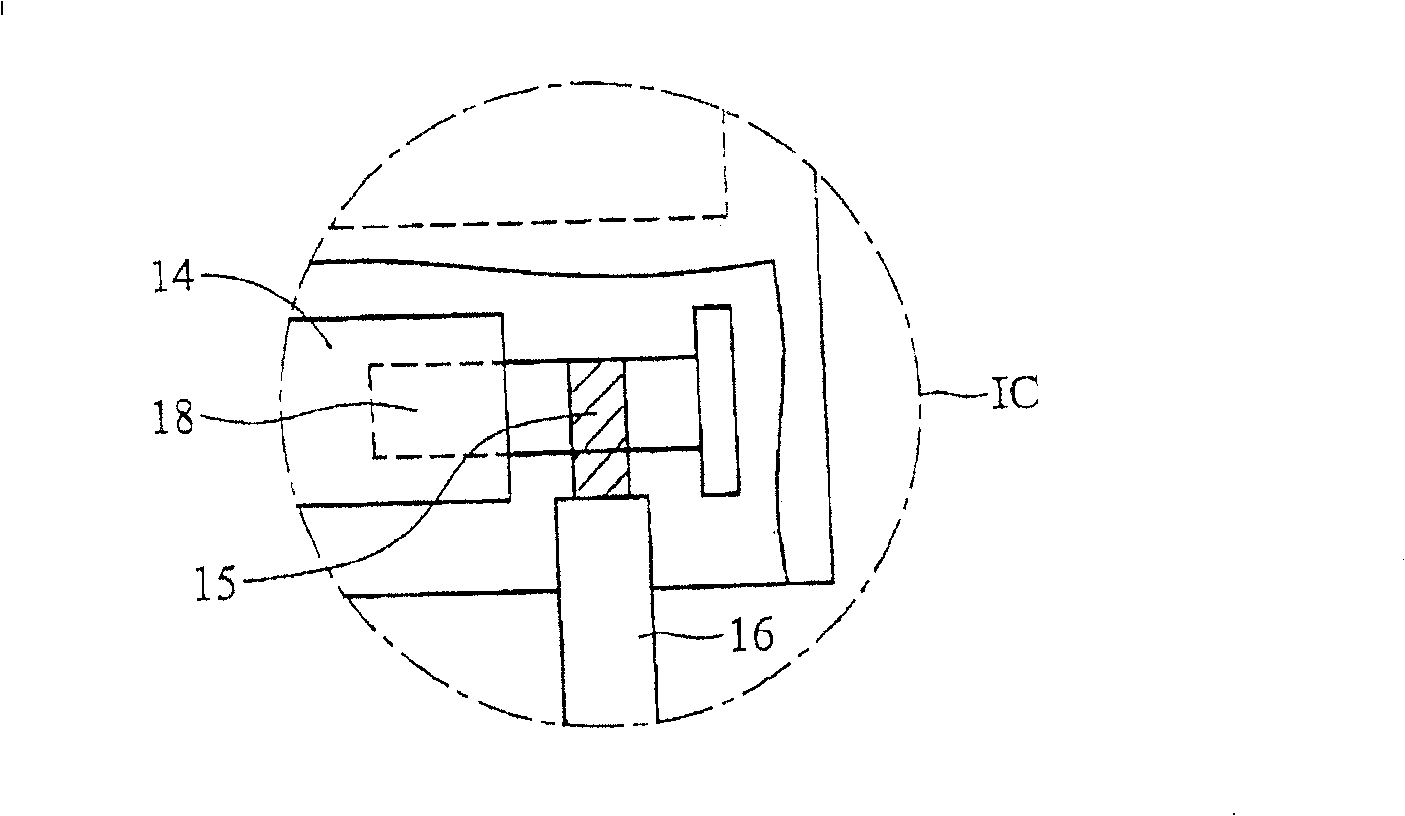

Display and dismountable light source structure thereof

It is a display and its detachable light source structure that comprises one light tube, one electrode, one first conjunction, one wire and second conjunction, wherein, the electrode is connected with light tube and the first conjunction comprises a first surface. The second conjunction comprises one-second surface and makes the wire electrically connected with the light tube through the second surface and first surface contacting.

Owner:AU OPTRONICS CORP

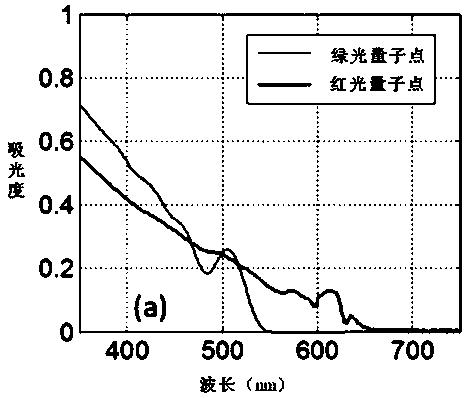

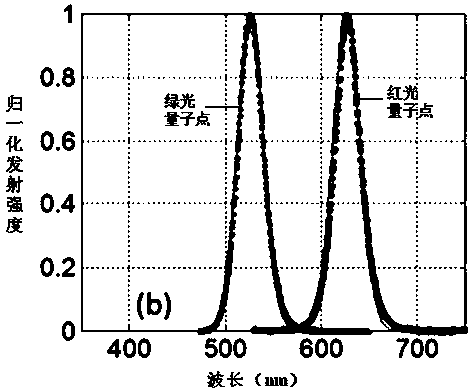

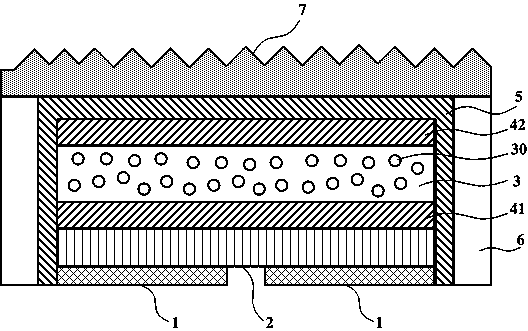

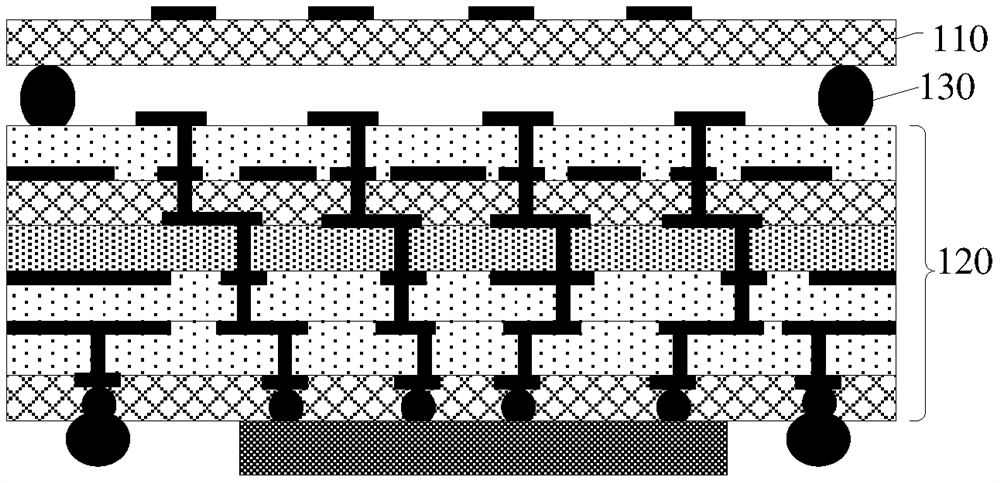

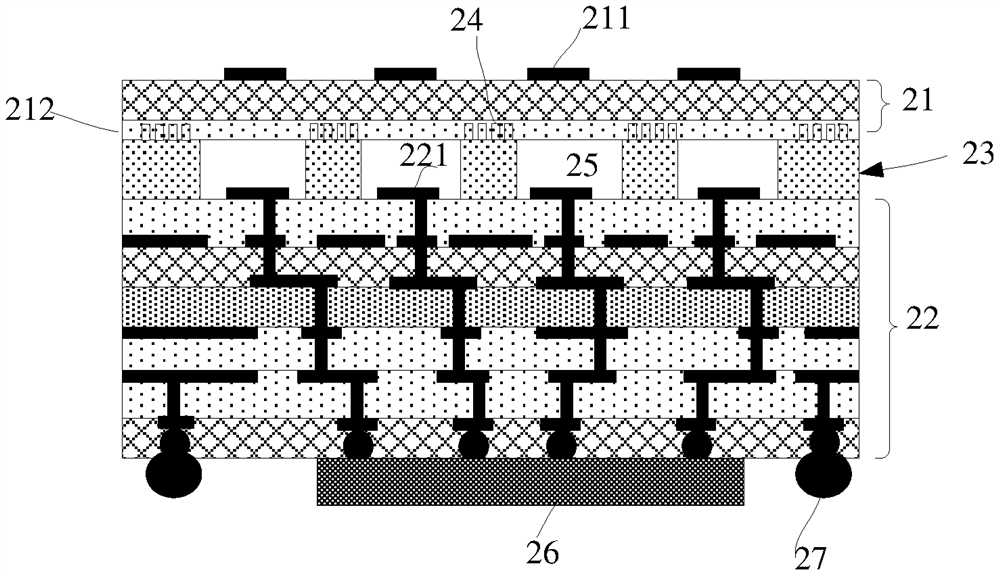

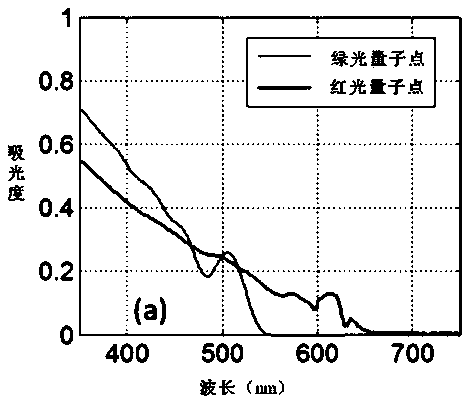

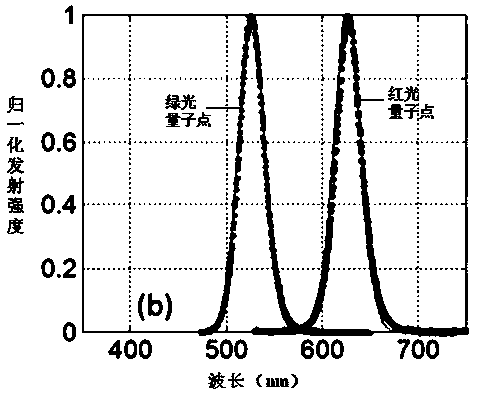

Quantum dot LED and preparation method

ActiveCN108461610AImprove luminous efficiencyExtended service lifeSemiconductor devicesOrganic layerQuantum dot

The invention provides a quantum dot LED and a preparation method, and the quantum dot LED comprises a pair of electrodes arranged side by side at intervals; a flip-chip LED chip which is disposed onthe electrode and electrically connected with the electrodes; a quantum dot interlayer disposed on the flip-chip LED chip; a packaging layer which covers the electrodes, the flip-chip LED chip and thequantum dot interlayer; and a white glue layer surrounding the packaging layer. Through the setting of the quantum dot interlayer, the LED can prevent the invasion of the quantum dot layer and the LED chip by the external water and oxygen, provides an environment for isolating water and oxygen for the quantum dots, and facilitates the improvement of the luminous efficiency and the prolonging of the service life of the quantum dots. The LED is provided with the organic layer of the structure, and improves the light-emitting efficiency. The inorganic packaging layer is formed by atomic layer deposition, and the LED can be flat in surface and uniform in thickness. A film cannot crack.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

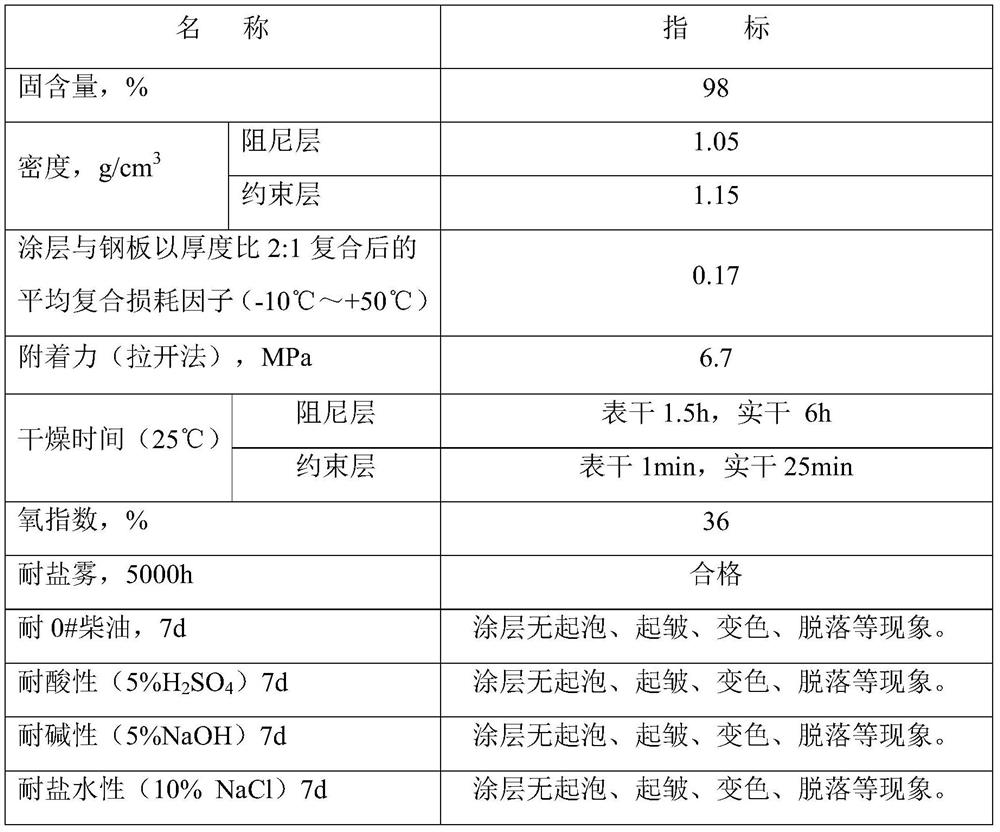

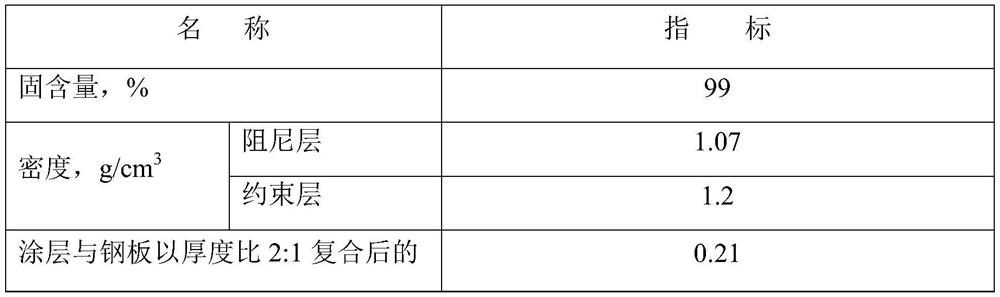

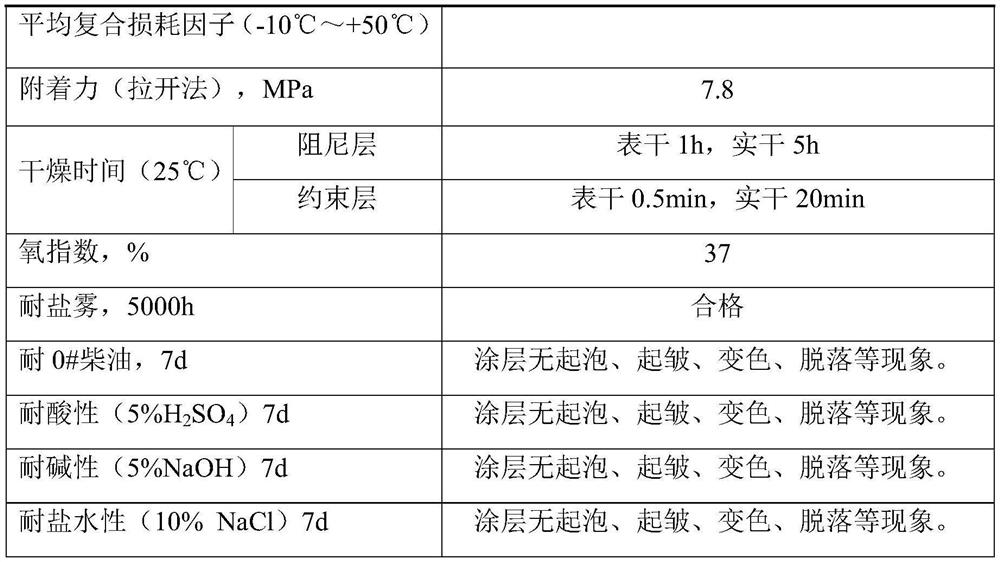

A fast-curing constrained structural damping coating and its preparation method

ActiveCN111635695BLittle influence of temperature and humidityImprove construction qualityFireproof paintsAnti-corrosive paintsPolymer sciencePtru catalyst

The invention proposes a fast-curing constrained structure damping coating and a preparation method thereof, which belong to the technical field of special functional materials. Chain agent, glycol, dispersant, defoamer, substrate wetting agent, adhesion promoter, first catalyst, damping pigment and filler; constraining layer is two-component solvent-free polyurethane coating, including component A: isocyanate , polyol, liquid flame retardant; B component: amino-terminated polyether, polyether polyol, flame retardant pigments and fillers, hollow microspheres, chain extender, second catalyst, antioxidant, dispersant, water remover , Color paste. The damping paint of the present invention, the curing speed of the damping layer and the constraining layer can be adjusted, and can be quickly cured in winter construction without sagging. The material can not only be applied to the vibration and noise protection in the field of ships, but also can be widely used in rail transit, automobiles, etc. , construction machinery and other fields.

Owner:QINGDAO AIR NEW MATERIALS

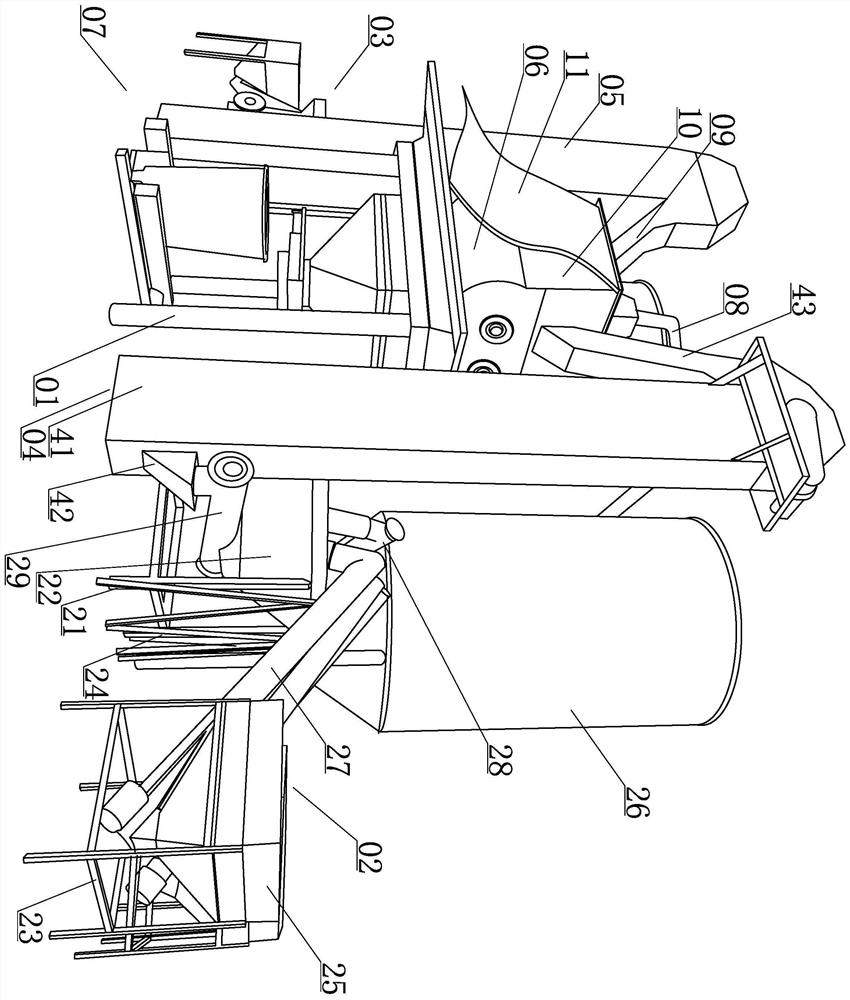

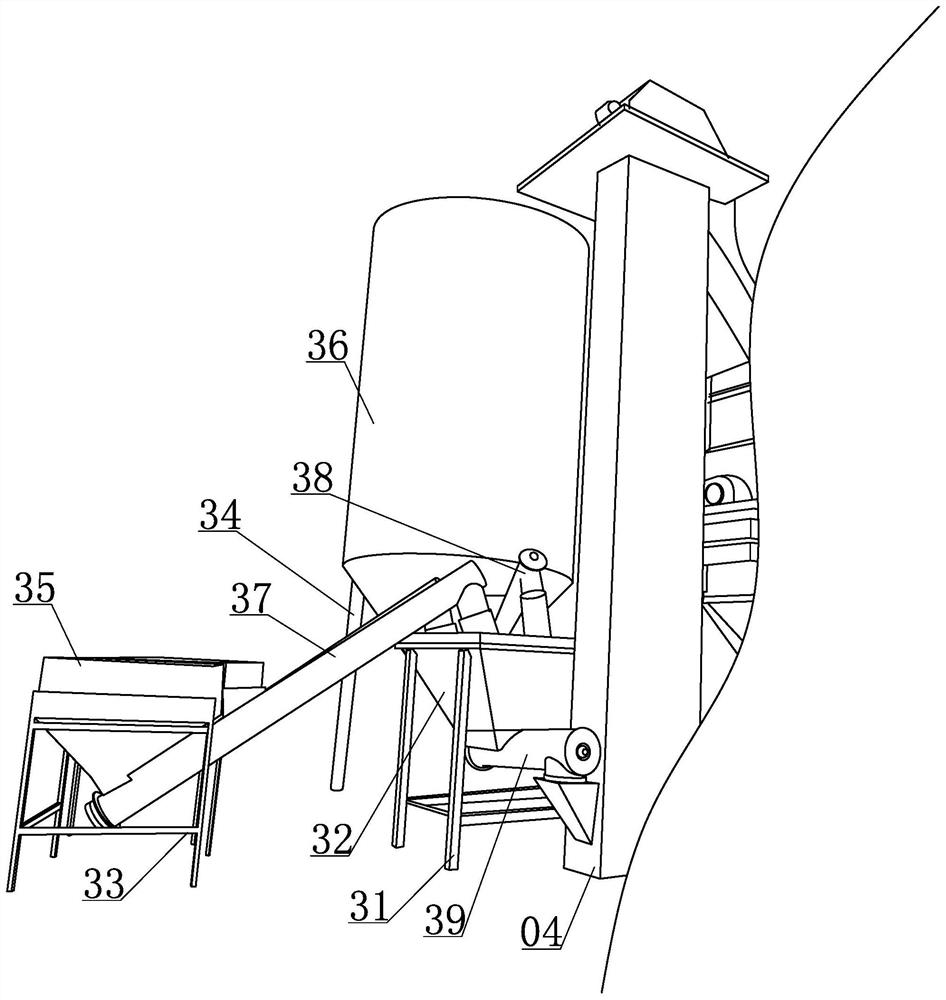

UHPC batching and mixing equipment

PendingCN111873187AAchieve the purpose of shipmentAvoid harmMixing operation control apparatusPretreatment controlMechanical engineeringIndustrial engineering

The invention discloses UHPC batching and mixing equipment. The UHPC batching and mixing equipment comprises a rack workbench, a first batching device and a second batching device are arranged on thetwo sides of the rack workbench, a first elevator is arranged on the first batching device, and a second elevator is arranged on the second batching device; and a mixing and stirring device which is communicated with the first elevator and the second elevator, a steel fiber vibration dispersing device arranged above the mixing and stirring device and a finished product loading and conveying devicearranged below the mixing and stirring device are arranged on the rack workbench. A steel fiber conveying belt is arranged on the steel fiber vibration dispersing device. The UHPC batching and mixingequipment has the effects that the UHPC material mixing production process is automatic, the machining efficiency is improved, and the construction environment is improved.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

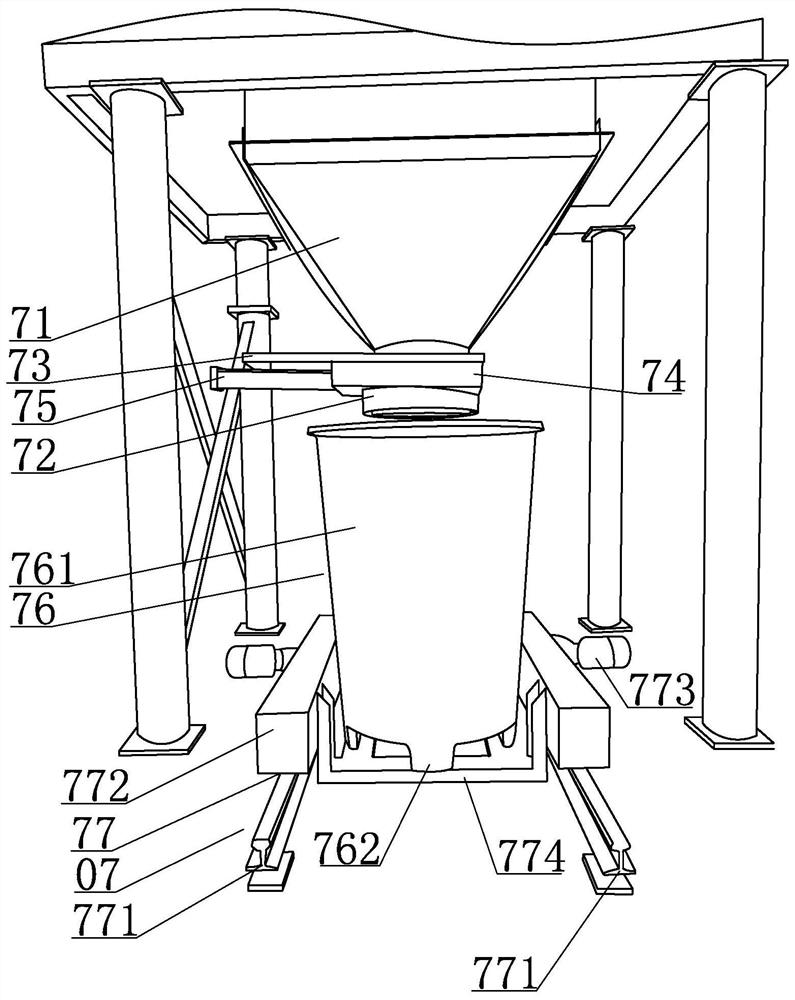

Pouring sealant for potting of torque motor rotor and pouring method

PendingCN112409969AHigh strengthRemove air bubblesNon-macromolecular adhesive additivesMacromolecular adhesive additivesTorque motorSealant

The invention relates to a pouring sealant for the potting of a torque motor rotor and a pouring method. The pouring sealant is prepared from the following raw materials in parts by weight: 10 parts of epoxy resin; 7-10 parts of a curing agent of epoxy resin; 5-15 parts of a filler of the epoxy resin adhesive; 1.5-3 parts of an epoxy toughening agent; and 0.02-0.08 part of an accelerant. The method comprises the following steps of: 1, mounting and fixing a motor rotor into a potting mold; 2, putting the rotor arranged in the mold into a drying oven for preheating the rotor; 3, preparing the pouring sealant according to the proportion of each component; 4, carrying out vacuum defoaming treatment on the pouring sealant; 5, potting the torque motor rotor; 6, removing bubbles in the mold in avacuum environment; 7, putting the mold into an oven, carrying out thermocuring treatment, and cooling the mold along with the oven after curing; and 8, disassembling the potting mold, taking out thetorque motor rotor, and machining to remove redundant sealant outside the rotor. With the pouring sealant and method of the invention adopted, the problems of cracking of the pouring sealant and cracks between the pouring sealant, a punching sheet and a shaft sleeve are solved.

Owner:TIANJIN NAVIGATION INSTR RES INST

Assembly type installing structure for prefabricated outer wall doors and windows

InactiveCN106285308ANo cracking problemsImprove integrityCondensed water drain-offJoints tightening/coveringFoaming agentWater flow

The invention relates to an assembly type installing structure for prefabricated outer wall doors and windows. Groove-and-tongues and glue tanks are sequentially arranged in the periphery of a window frame from inside to outside; a water drip is arranged outside the portion, located at the top of the window frame, of the glue tank; and sloping and flashing are conducted at the portion, located at the bottom of the window frame, of the glue tank. The bottom of the window frame is sealed and fixed through polyurethane foaming agents; and the four edges of the window frame are fixed through sealant. According to the assembly type prefabricated installing structure for the outer wall doors and windows, a concrete interface can be provided between a window and interior through the groove-and-tongues; the sealing materials make no direct contact with the interior, and even though the sealant is damaged, the foaming agents leak, water can be blocked when flowing to the groove-and-tongues; and sloping is conducted at the bottom of the window, the water can be drained to exterior through an action of the gravity.

Owner:SHANGHAI BAOYE GRP CORP

A kind of water-based environmental protection texture wood coating and preparation method thereof

ActiveCN110157253BReduce resistanceStrong three-dimensional senseEmulsion paintsEmulsionEconomic benefits

Owner:CARPOLY CHEM GRP

A Prefabricated Segmental Pier and Its Application in Bridge Construction

ActiveCN109989339BImprove bearing capacityIncrease stiffnessBridge structural detailsArchitectural engineeringPier

Owner:SOUTHWEST JIAOTONG UNIV

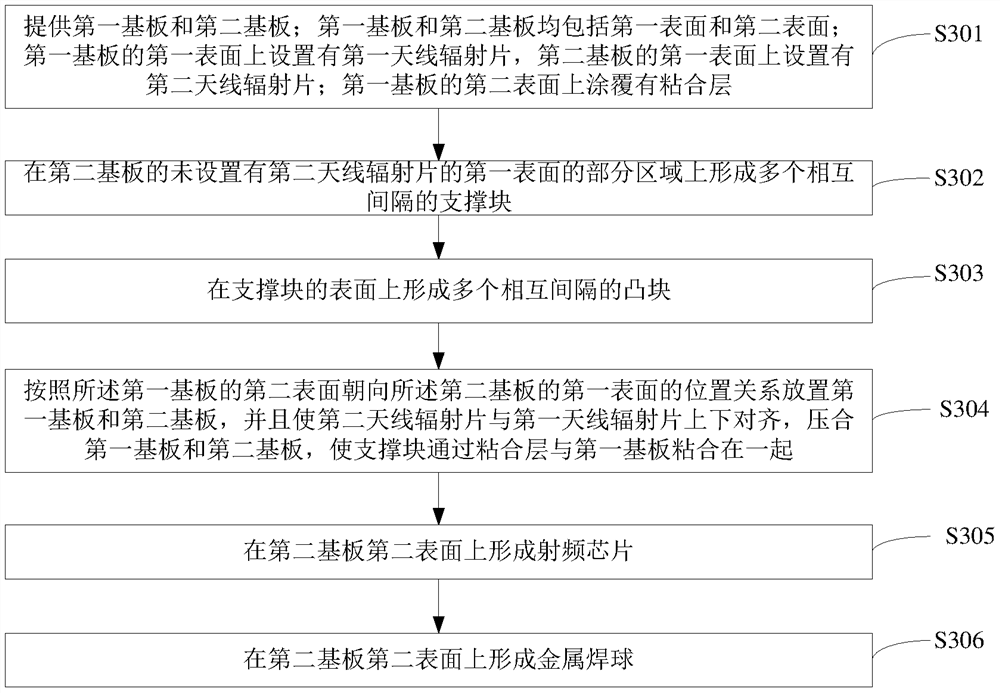

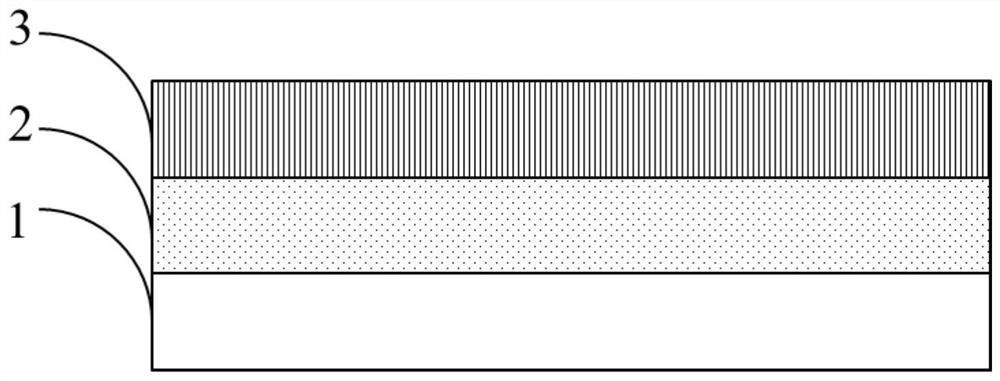

Antenna packaging structure and manufacturing method thereof

ActiveCN112074989BImprove adhesionAdhesivelyAntenna arraysSemiconductor/solid-state device detailsMechanical engineeringThermal cycle

The application discloses an antenna packaging structure and a manufacturing method thereof. In the antenna packaging structure, a plurality of support blocks spaced apart from each other are arranged between the first substrate and the second substrate, and an antenna cavity is formed between every two adjacent support blocks. Thus, the height of the support block determines the height of the antenna cavity. Because the plurality of support blocks spaced apart from each other are located between the first substrate and the second substrate, and at least one of the first substrate and the second substrate is bonded to the plurality of support blocks spaced apart from each other through an adhesive layer together. Moreover, the plurality of support blocks spaced apart from each other will not experience high-temperature metal melting, and they can maintain high stability even after multiple high-temperature thermal cycles. Therefore, the antenna packaging structure has a relatively stable antenna cavity height, Thus, it has better antenna performance.

Owner:HUAWEI TECH CO LTD

Lithium negative electrode, preparation method and application thereof

InactiveCN112151761AImprove cycle performanceGood cycle performanceNegative electrodesMetallic lithiumLithium electrode

The invention provides a lithium negative electrode, a preparation method and application thereof. According to the invention, a lithium negative electrode is provided and comprises a metal lithium layer and N protective layers sequentially stacked on the surface of the metal lithium layer, wherein the number set of the protective layers is marked as S = {1,..., N-1, N}, N is greater than or equalto 1, the direction from the first protective layer to the Nth protective layer is the direction gradually away from the metal lithium layer, and at least the Nth protective layer comprises a leveling agent; according to the lithium negative electrode provided by the invention, the leveling agent is added into the protective layer far away from the outermost layer of the metal lithium layer, so that the thickness of the protective layer is uniformly distributed, the problem of cracking is avoided, the metal lithium layer can be effectively protected, and the cycle performance of the lithium ion battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

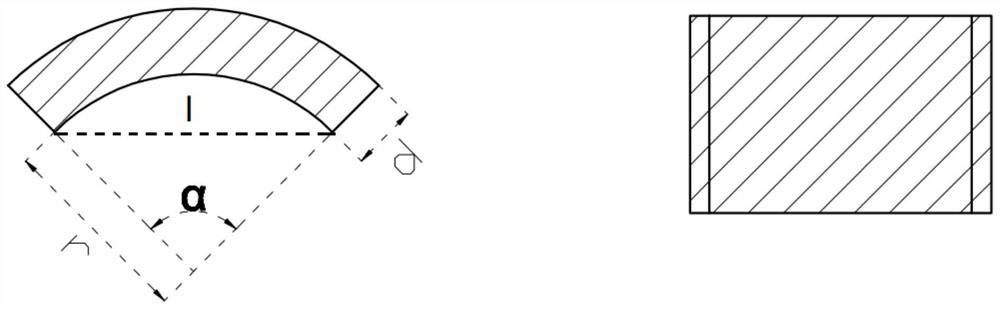

High-density ceramic fiber board with curved surface structure and preparation method thereof

The invention provides a high-density ceramic fiber board with a curved surface structure. The curvature radius of the high-density ceramic fiber board with a curved surface structure is larger than or equal to 500 mm. The thickness is 5-15 mm; and the central angle of the circular arc is 20-80 degrees. Due to the fact that the resilience of a high-density board wet blank is poor, when the curvature radius is smaller than 500 mm and the product thickness is larger than 15 mm, cracks are prone to occurring at the two ends of the curved surface; after the curvature radius is increased, the tensile stress of the high-density board wet blank is correspondingly reduced, so that the thickness of the product can be increased without cracking. The invention further provides a preparation method of the high-density ceramic fiber board with a curved surface structure.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

A kind of quantum dot LED and preparation method

ActiveCN108461610BImprove luminous efficiencyExtended service lifeSemiconductor devicesQuantum dotEngineering

Provided in the present invention is a quantum dot LED and a manufacturing method, the quantum dot LED comprising: a pair of electrodes provided side by side and spaced apart; a flip-chip LED chip provided on the electrodes and electrically connected to the electrodes; a quantum dot interlayer provided on the flip-chip LED chip; a packaging layer encapsulating the electrodes, the flip-chip LED chip, and the quantum dot interlayer; and a white glue layer surrounding the packaging layer. In the present invention, a quantum dot interlayer is provided, preventing external moisture and oxygen from corroding a quantum dot layer and an LED chip, providing an environment for insulating moisture and oxygen for quantum dots, and aiding the improvement of the luminous efficiency and service life of quantum dots; an organic layer of a micro-nano structure is provided, improving the light extraction efficiency; and an inorganic packaging layer is formed by means of atomic layer deposition, so that the inorganic packaging layer can have a flat surface and a uniform thickness, and the problem of film layer cracking does not occur.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Molding process for embedding large-piece special-shaped object in transparent resin

The invention discloses a molding process for embedding a large-piece special-shaped object in a transparent resin. The molding process comprises the following steps that (1), the transparent resin of47.286%-52.264% in proportion, transparent barras of 47.286%-52.264% in proportion, an accelerator of 0.1425%-0.1575% in proportion and a hardening agent of 0.285%-0.315% in proportion of raw materials are prepared; (2), the raw materials are mixed and uniformly stirred, and the raw materials are putted into a vacuum machine for vacuumizing; (3), the large-piece special-shaped object is fixed ina mold; (4), the embedding resin obtained in the step (2) is poured into the mold of the step (3) and is placed in the vacuum machine for vacuumizing; (5), standing is carried out for a period of time; (6), the steps (1)-(2) and (4)-(5) are carried out circularly for a plurality of times to enable the embedding resin to completely immerse the large-piece special-shaped object; and (7), demolding.According to the molding process, a large number of tests are carried out to obtain a scientific ratio of the embedding transparent resin and an accurate embedding and molding process, so that the embedding technology of the large-piece special-shaped object is realized, the success rate is high, and cracks are not exists; According to the technical scheme, the shape color of the special-shaped object embedded in the transparent resin is vivid, the resin transparency is high, and various details of the special-shaped object can be clearly observed.

Owner:深圳集美殿堂实业有限公司

Display and dismountable light source structure thereof

It is a display and its detachable light source structure that comprises one light tube, one electrode, one first conjunction, one wire and second conjunction, wherein, the electrode is connected with light tube and the first conjunction comprises a first surface. The second conjunction comprises one-second surface and makes the wire electrically connected with the light tube through the second surface and first surface contacting.

Owner:AU OPTRONICS CORP

Mechanical loading tooling and loading method for outer grid wall panels

ActiveCN113000682BAvoid the problem of taking up a lot of spaceNo cracking problemsFurnace typesHeat treatment furnacesHydraulic cylinderIndustrial engineering

The present invention provides an outer grid wall board mechanical loading worker, including cardboard molds and mobile loading systems; cardboard molds include mold bases, horizontal card boards and pressure plates;Pressing activity components, loading rod components and positioning connection structures; the stuck plate mold has a loading system base on the left and right sides, and the positioning connection structure on one side of the loading system base; two sets of pressure activity components on the loading system base; left and right; left and rightThe pressure activity components on both sides are connected through the loading rod component; the pressurized activity component includes the first liquid pressure cylinder.The present invention also provides a method of loading the outer grid wall board mechanical loading, which uses the aforementioned external mesh wall board mechanical loading.The present invention avoids part of the defects loaded by traditional mechanical methods, the cost is greatly reduced, and the mobile loading system with the adjustable surface can meet the production needs of multi -specification wall boards.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com